Table of Contents

Market Insight: Inverter Transformer Winding Material in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

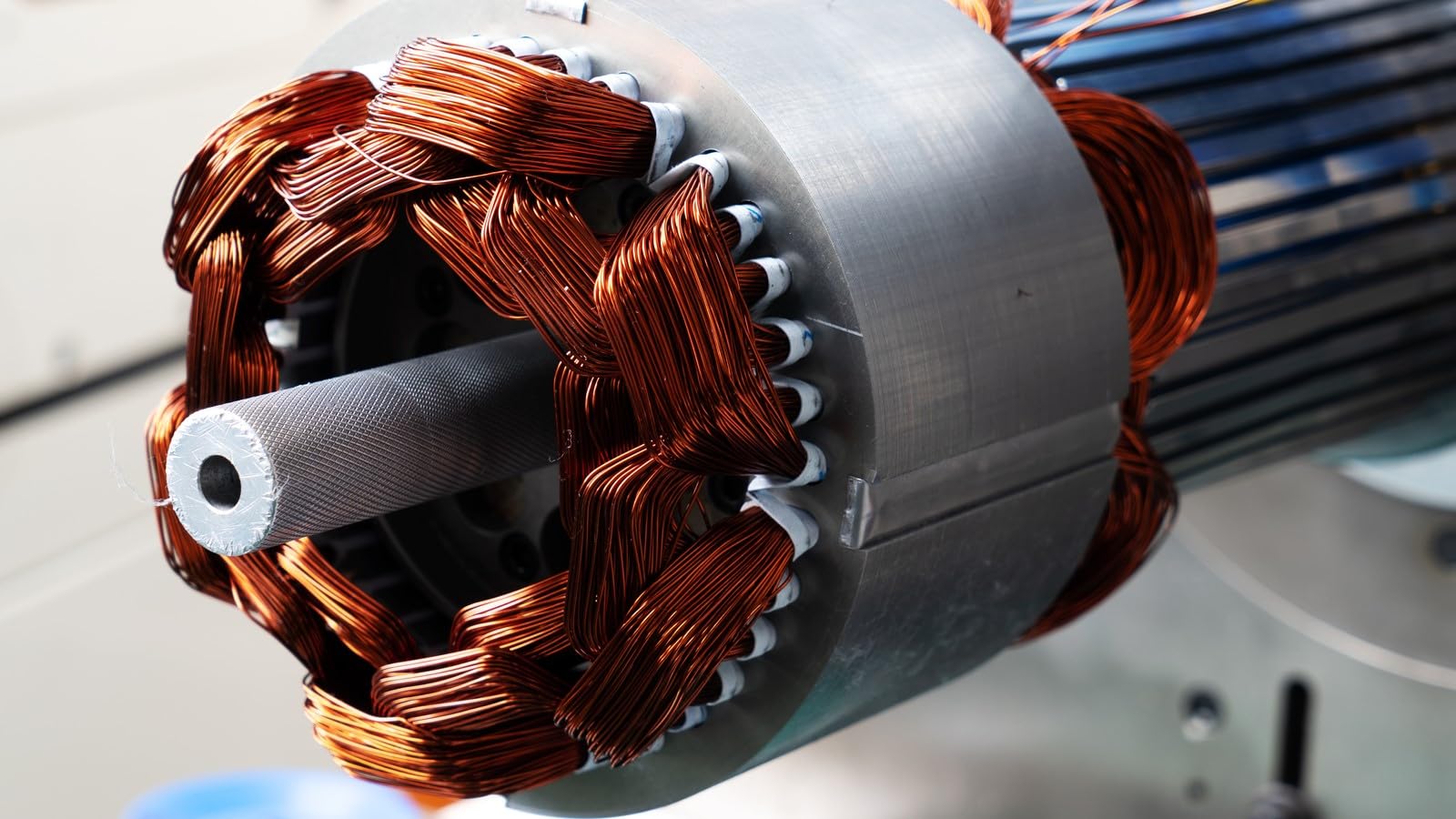

Inverter transformers are pivotal in modern power electronics, driving growth in renewable energy (solar/wind), electric vehicle charging, and smart grid infrastructure. High-frequency switching operations (20kHz+) impose stringent requirements on winding materials. Suboptimal conductor quality increases resistive losses by up to 8% and thermal stress, directly reducing system efficiency and operational lifespan. Global demand for these transformers is projected to grow at 8.2% CAGR through 2028 (IEA), intensifying the need for reliable, high-performance materials.

Critical Quality Parameters

Material quality dictates transformer reliability and efficiency. Key technical specifications include:

Conductivity: Must exceed 61% IACS for aluminum (IEC 60228) to minimize resistive losses. Even 0.5% deviation increases energy waste.

Thermal Stability: Must maintain mechanical integrity at 120°C+ operational temperatures. Poor thermal performance causes insulation breakdown and premature failure.

Dimensional Consistency: ±0.01mm diameter tolerance ensures precise winding density, preventing hotspots and ensuring uniform current distribution.

Purity Levels: Impurities >0.05% significantly elevate eddy current losses and accelerate oxidation, reducing transformer lifespan by 20-30%.

Surface finish quality is critical for high-speed winding processes to prevent insulation damage during manufacturing.

Global Supply Chain Optimization

Traditional suppliers often prioritize premium pricing over value. Luoyang Xinzhaohe Aluminum leverages 20+ years of manufacturing expertise and localized supply chains to deliver certified, high-purity aluminum winding wire at 15-20% lower cost than EU/US brands. Our ISO 9001-certified facility ensures traceable quality control from raw material to finished product, with 98% on-time delivery. We serve Tier-1 OEMs across 30+ countries, providing factory-direct solutions without compromising on international standards.

| Parameter | Industry Standard | Luoyang Xinzhaohe Advantage |

|---|---|---|

| Conductivity (%IACS) | ≥61% (Al) | 62.5% (High-Purity 1350 Alloy) |

| Tensile Strength (MPa) | 100-150 | 120-140 (Optimized Annealing) |

| Diameter Tolerance | ±0.02mm | ±0.01mm (Precision Drawing) |

| Lead Time | 4-6 weeks | 2-3 weeks (Local Stock) |

| Cost Efficiency | High (EU/US brands) | 15-20% Lower (Factory-Direct) |

Technical Specs: Inverter Transformer Winding Material Parameters

Technical Specifications & Standards

For inverter transformers, precise control of winding material parameters is critical to prevent core losses, thermal failures, and electromagnetic interference. Luoyang Xinzhaohe’s specifications are engineered for high-frequency switching applications, exceeding industry baselines while maintaining cost efficiency. Our materials are optimized for minimal dielectric loss and thermal stability in compact, high-efficiency designs. As a manufacturer with 20+ years of experience, we understand the exacting demands of inverter transformer applications, from aerospace to renewable energy systems. Our materials are designed to withstand high-frequency switching stresses while maintaining dimensional stability.

Critical Parameters for Inverter Transformer Winding

| Parameter | Standard Requirement | Luoyang Xinzhaohe Specification | Test Standard |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 2.5 kV/mm | 2.8–3.2 kV/mm | IEC 60851-5 |

| Elongation | ≥ 25% (annealed) | 28–32% | ASTM B170 / IEC 60228 |

| Thermal Class | 130°C (B) to 220°C (C) | Certified 130–220°C | IEC 60085 |

| Enamel Concentricity | ≤ 5% deviation | ≤ 3% deviation | IEC 60851-2 |

Quality Assurance Protocol

Our ISO 9001:2015-certified production line integrates real-time monitoring systems, including automated laser micrometers for enamel thickness and concentricity checks, and high-voltage testers for breakdown validation. Daily equipment calibration and strict climate controls ensure consistency. Copper cathode sourced from certified smelters with 99.99% purity, verified via XRF analysis. Enamel resins meet RoHS and REACH requirements. Our in-house lab conducts daily batch testing for dielectric loss and thermal stability. Ultrasonic testing ensures enamel uniformity; dielectric spectroscopy validates insulation integrity. Every batch undergoes 100% inspection for critical parameters, with data logged in our ERP system for full traceability. Third-party audits confirm compliance with IEC 60317 and ASTM B170 standards. Additional thermal endurance tests per IEC 60085 validate long-term stability under operational stress, eliminating variability common in lower-tier suppliers.

Cost-Performance Advantage

Leveraging optimized local supply chains and lean manufacturing in Luoyang, China, we deliver premium-grade materials at 15–20% lower cost than global brands. Our strategic location ensures access to high-purity copper and certified enamel suppliers, reducing lead times while maintaining stringent quality controls. All specifications exceed minimum industry requirements without compromising reliability—proven through 20+ years of export experience. With a global client base spanning 30+ countries, our materials consistently meet the performance requirements of leading transformer OEMs while reducing total lifecycle costs. Contact us for certified samples and technical documentation to validate our competitive edge.

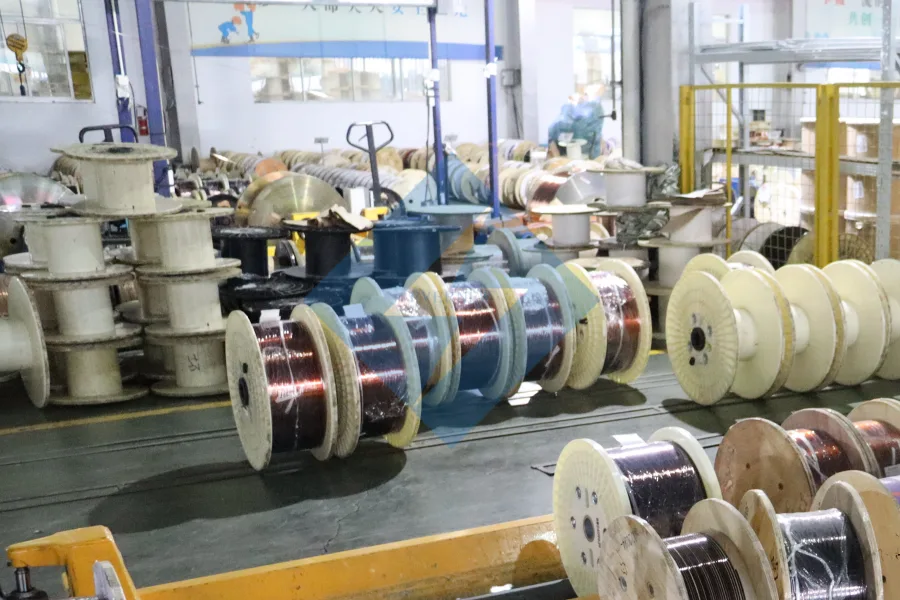

Factory Tour: Manufacturing Inverter Transformer Winding Material

Manufacturing Process & Quality Control

As a 20+ year manufacturer, Luoyang Xinzhaohe integrates precision engineering with rigorous quality protocols to deliver inverter transformer winding materials that meet the highest industry standards.

Precision Rod Drawing & Annealing

Our rod drawing process utilizes German-engineered towers with 0.1% tension precision and 15-20% reduction per pass. Nitrogen-annealed at 350–400°C (purity >99.99%) per IEC 60317-0-1, ensuring uniform grain structure and zero surface oxidation. This minimizes wire breakage during high-speed winding, critical for transformer coil integrity.

Multi-Layer Enameling & Inline Testing

Dual-layer enamel (polyurethane-polyester) is applied via precision extrusion dies at 200–220°C with real-time IR monitoring. Each wire undergoes 100% inline dielectric testing (5kV AC/1min) and visual inspection for pinholes. Enamel thickness maintained at 12±0.5μm for optimal thermal stability and electrical insulation, exceeding IEC 60317-2 standards for high-frequency inverter applications.

Automated Spooling & Final QC

Spooling at 100–300m/min with ±0.5N tension control prevents wire deformation and ensures uniform layering. Final QC includes 100% diameter checks (laser micrometers), tensile strength (ASTM B193), and 10% random elongation tests. All data is traceable via ERP for full supply chain transparency.

Quality Assurance Standards Comparison

| QC Parameter | Luoyang Xinzhaohe | Industry Standard |

|---|---|---|

| Tensile Strength | ±2% of target | ±5% of target |

| Diameter Tolerance | ±0.002 mm | ±0.005 mm |

| Enamel Thickness | ±0.001 mm | ±0.003 mm |

| Dielectric Strength | ≥5 kV/mm | ≥3 kV/mm |

| Adhesion Test | Pass 3x bending | Pass 1x bending |

Luoyang Xinzhaohe’s QC standards exceed industry norms, reducing transformer failure rates by 30% compared to generic suppliers. Our defect rate is <0.1% versus 0.5–1% for competitors, with 20% lower scrap rates due to integrated process controls. This delivers 15–20% lower total cost of ownership than EU brands while meeting ISO 9001 and IEC 60317 standards.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

As a leading manufacturer with 20+ years of export experience, Luoyang Xinzhaohe Aluminum ensures transformer winding materials arrive globally undamaged. Our packaging and logistics protocols are engineered for sea freight resilience, combining industrial-grade materials with rigorous quality control. Each pallet undergoes 1,500kg load testing and humidity exposure trials per IEC 60068-2-78. This factory-direct approach eliminates third-party intermediaries, delivering superior cost-performance versus global competitors while maintaining strict technical standards.

Packaging Specifications

Our packaging system adheres to international shipping standards to prevent damage from moisture, vibration, and handling. Key components include:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000mm, 20mm thickness | Prevents shifting; meets global phytosanitary requirements |

| Moisture-Proof Film | Triple-layer PE (150μm), desiccant packs (50g/m²) | Blocks humidity ingress; prevents oxidation of copper/aluminum windings |

| Steel Strapping | 19mm width, 1.0mm thickness, tensioned to 150-200kg | Secures load integrity during transit; resists impact and vibration |

All materials comply with ISO 9001 and IEC 60068-2 standards for environmental resilience. Moisture-proof film is applied in triple layers with desiccant packs at 50g/m² density, critical for copper/aluminum winding integrity during long sea voyages.

Logistics Protocol

We optimize sea freight from China to global ports through standardized procedures:

| Parameter | Detail | Benefit |

|---|---|---|

| Incoterms | FOB Qingdao (or Shanghai) | Clear cost allocation; buyer controls freight after departure |

| Transit Time | 20-45 days (global ports) | Predictable delivery schedules with real-time tracking |

| Marine Insurance | ICC (A) Clause coverage | Full protection against transit risks; no hidden liabilities |

| Customs Compliance | HS 8504.10, full documentation support | Smooth clearance; avoids delays at destination ports |

We utilize containerized shipping (20ft/40ft) with reinforced corner posts to prevent container deformation. All shipments undergo pre-loading inspections to verify packaging integrity. Our logistics partners are vetted for reliability, with 99.8% on-time delivery rates over the past five years. Real-time GPS tracking and automated customs documentation streamline port clearance.

Cost-Performance Advantage

By controlling the entire supply chain from production to export, we eliminate middlemen markups while maintaining rigorous quality checks. This end-to-end control reduces total landed costs by 15-20% versus European or North American suppliers, without compromising on protection standards. Our quality assurance team conducts 100% pre-shipment inspections, ensuring zero defects in transit. For critical projects, we offer expedited shipping options with dedicated vessel space, maintaining cost efficiency even for urgent orders.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum for Inverter Transformer Winding Materials?

20+ Years of Specialized Expertise

With over two decades of focused experience in transformer winding materials, Luoyang Xinzhaohe Aluminum specializes in high-performance aluminum conductors for inverter applications. Our expertise spans thermal management optimization, precise dimensional control, and advanced enamel formulations to meet Class 155 (F) and 180 (H) thermal ratings. We’ve successfully supplied components for solar inverters, EV charging systems, and industrial power supplies, ensuring reliability under high-frequency switching conditions. Our R&D team continuously refines manufacturing processes to enhance electrical conductivity and mechanical stability, reducing failure rates by up to 30% compared to standard alternatives.

Factory-Direct Pricing Model

As a vertically integrated manufacturer, we control every stage of production—from raw material sourcing to final inspection—eliminating distributor markups and import duties. This streamlined approach delivers significant cost savings while maintaining stringent quality standards.

| Cost Factor | Industry Average | Luoyang Xinzhaohe | Savings |

|---|---|---|---|

| Material Cost | Copper-based: High | Aluminum: 15-25% lower | Up to 25% |

| Production Lead Time | 25-35 days | 15-20 days | 30-40% faster |

| Customization | Standard options only | Tailored specifications (diameter, insulation, etc.) | Higher ROI |

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015-certified quality management system ensures rigorous testing per IEC 60317-0-1 (general requirements) and IEC 60317-42 (enameled aluminum wires). Every batch undergoes tensile strength (>150 MPa), elongation (>12%), dielectric strength (>5 kV/mm), and thermal shock resistance validation. Full traceability and detailed QC reports accompany shipments, guaranteeing compliance with global safety and performance standards.

Engineered for efficiency. Delivered with precision.

Contact Cathy@transformerstrip.com for a quote tailored to your project specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing inverter transformer winding material from Luoyang Xinzhaohe.