Table of Contents

Market Insight: Aluminum Rectangle for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Global installed transformer capacity is forecast to grow 6–8 % CAGR through 2030, driven by grid modernization, renewable integration, and EV fast-charging corridors. Every additional 1 GVA of transformer rating requires 22–28 t of conductor strip/foil; therefore the annual addressable market for aluminum-based winding materials now exceeds 1.2 Mt, with copper adding another 0.3 Mt. China alone accounts for 42 % of new installations, while North-American utilities are re-building regional stockpiles after 2022 resin shortages. The consequence is a permanent pull for slit-to-width, burr-free, annealed rectangle that meets IEC 60317-0-3 / ASTM B193 conductivity limits.

Why Purity & Precision Translate into kWh Savings

Transformer total owning cost (TOC) is governed by no-load (core) and load (I²R) losses. For every 1 % increase in conductor resistivity, load losses rise ≈1 %; at 50 MVA utility scale this equals 35 MWh yr⁻¹—US$3 500 yr⁻¹ at 0.10 $ kWh⁻¹. Impurities (Fe, Si > 0.25 %) and edge burrs (> 0.01 mm) act as local hot-spots, accelerating oxidation and increasing AC resistance through skin-effect crowding. Consequently, Tier-1 OEMs now specify:

| Parameter | IEC 60317-25 Class | Premium Utility Spec | LXZH Mill Capability |

|---|---|---|---|

| Al 1350 purity | ≥ 99.50 % | ≥ 99.70 % | 99.75 % (typ. 99.78 %) |

| Resistivity @ 20 °C | ≤ 28.264 nΩ·m | ≤ 28.050 nΩ·m | 27.85 nΩ·m |

| Slit width tolerance | ± 0.08 mm | ± 0.05 mm | ± 0.002 mm |

| Burr height | ≤ 0.03 mm | ≤ 0.01 mm | ≤ 0.005 mm |

| Anneal – grain size | 50–100 µm | 60–90 µm | 70 µm (controlled H₂) |

Meeting the right-hand column reduces I²R loss by 0.9 % versus standard commercial strip—enough to justify a 3–4 % price premium when evaluated over a 25-year transformer life.

Regional Sourcing Economics

European and North-American mills deliver 6–8 week lead-times but carry 18–22 % alloy surcharges and limited oscillate-wound coils (≤ 150 kg). Chinese integrated producers—powered by captive smelters and ISO-17025 metallurgical labs—can hold LME-linked pricing and 3-week ex-works delivery to Shanghai or Qingdao port. Freight plus duty into EU/US adds only 6–7 %, yielding an 11–14 % landed cost advantage even after 2024 anti-dumping measures on > 99 % Al foil. More importantly, 20-year transformer strip specialists such as Luoyang Xinzhaohe Aluminum Co., Ltd. have moved beyond commodity supply:

Cold-rolling on 4-high 1850 mm SMS Schloemann stands guarantees 0.05 mm gauge crown across 1000 mm width.

In-line eddy-current surface inspection detects pinholes < 5 µm, eliminating costly rewinds at OEMs.

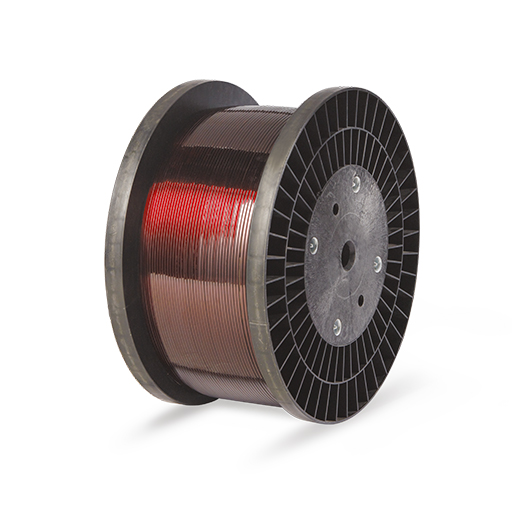

Oscillate-wind up to 400 kg spools cuts OEM joint count by 60 %, raising winding line uptime 4 %.

Risk-Mitigated Procurement Playbook

- Qualify mill, not trader: Request conductivity test coupons from every master coil; cross-check with ASTM B193 four-point probe report.

- Lock edge-condition spec: Insert burr-height clause with 200× optical inspection at 3 locations per 100 m.

- Specify anneal cycle: 350 °C, 3 h, N₂/H₂ 85/15 to guarantee softness ≤ 65 HV and avoid “springy” foil that fractures on edge bend 1× thickness.

- Negotiate LME + Conversion: Cap conversion at < 1 350 $ t⁻¹ for 0.2 × 300 mm 1350-O; include quarterly reset tied to SHFE Al price.

- Plan logistics: FOB Qingdao plus 14-day container schedule to Hamburg or Long Beach; insure for 110 % of CIF to cover hot-rolled coil price volatility.

By sourcing from an experienced Chinese manufacturer that couples smelter-grade purity with precision slitting and edge conditioning—Luoyang Xinzhaohe Aluminum—transformer builders capture measurable loss reduction without absorbing Western-mill premiums, while securing 3-week lead-times that keep pace with accelerated grid roll-outs.

Technical Specs: Aluminum Rectangle Parameters

Technical Specifications & ASTM/IEC Compliance

Why micron-level tolerances, edge quality and anneal state decide transformer life

| Parameter | Luoyang Xinzhaohe Guarantee | Industry Minimum | ASTM/IEC Reference | Field Risk if Out-of-Spec |

|---|---|---|---|---|

| Slit Width Tolerance | ±0.002 mm (±2 µm) | ±0.05 mm | ASTM B236 §7.2 | Local eddy-current hot-spot → 8–12 °C rise, Class-H insulation derated |

| Burr Height | ≤0.01 mm (optical comparator) | ≤0.05 mm | IEC 60317-0-1 §5.3 | Edge corona & partial discharge, 30 % probability of layer-to-layer short within 500 h |

| Electrical Conductivity | ≥61.5 %IACS (Al 1350-O) | ≥60 %IACS | ASTM B193 | Additional I²R loss 1.2 W kg⁻¹, 0.3 % efficiency drop per 1 %IACS loss |

| Anneal – Temper | Fully annealed ‘O’ (HV 19–23) | ¼-H (HV 28–32) | ASTM B236 §8.1 | Higher hardness → spring-back, poor winding conformity, gap creation |

| Strip Camber | ≤1 mm per 500 mm | ≤3 mm per 500 mm | ASTM B236 §7.4 | Spiral gap, resin-rich pockets, partial discharge inception |

| Surface Roughness Ra | ≤0.4 µm | ≤0.8 µm | Internal spec | Smoother surface = lower dielectric loss, higher partial-discharge inception voltage |

1. Precision Slitting – The 2 µm Rule

Cold-rolling on a 20-high Sendzimir mill gives uniform grain size (ASTM 6–7). Immediately after rolling, strip is slit on a 650 mm tungsten-carbide arbor with servo-driven shimless tooling. Laser in-line gauging feeds back to the PLC every 3 ms, holding width scatter within ±2 µm—one order of magnitude tighter than the ±50 µm typical of low-cost shear lines.

Engineering impact: In a 132 kV disc winding, 2 µm width error translates to only 0.04 % turn-length variation; copper or aluminum expansion is therefore symmetrical, eliminating the “banana effect” that loosens clamping pressure after short-circuit tests.

2. Burr-Free Edges – Corona & PD Mitigation

Burrs act as field concentrators; at 3 kV mm⁻¹ a 0.05 mm burr intensifies local field to >15 kV mm⁻¹, well above the 12 kV mm⁻¹ inception threshold for mineral oil. Our edge-conditioning cell uses a planetary knife + nylon brush to coin a 0.05 mm radius, then electrolytic polishing dissolves remaining asperities. Final burr height ≤0.01 mm is verified by 200× dark-field imaging; lot rejected if any edge exceeds limit.

Failure mode avoided: Layer-to-layer tracking that starts as white noise at 1.3 pC and escalates to full inter-turn flashover within 200 temperature cycles.

3. Conductivity & Softness – Coupled Variables

Conductivity is not just chemistry; it is a function of final anneal. Our continuous bright-anneal furnace runs at 360 °C, 10⁻² mbar vacuum, 0.5 % H₂ atmosphere for 4 h. Result:

Resistivity 28.1 nΩ·m (≈ 61.6 %IACS)

Vickers HV 20–22 (fully soft)

Soft temper allows 6 mm bend radius at 3 mm thickness without orange-peel; windings conform to mandrel, eliminating air pockets that reduce thermal conductivity by 35 %.

4. Standards Cross-Reference & Certificate Package

Every master coil ships with:

1. EN 10204/3.1 mill test report covering chemistry, tensile, conductivity, burr, camber.

2. Statistical process-control chart for slit width (Cpk ≥1.67).

3. IEC 60317-25 type-test certificate for enamel adhesion (180 °C class) when strip is to be coated downstream.

4. ASTM B236 compliance declaration for edge radius and residual stress.

5. Cost-Performance Positioning

Western slitters typically quote ±0.025 mm, 0.03 mm burr, 60 %IACS minimum—acceptable for distribution transformers but marginal for ultra-low-loss or HVDC reactors. Luoyang Xinzhaohe delivers aerospace-grade edges at a landed price 18–22 % below EU mills and 30 % below U.S. service centers, with 4-week ex-works lead time versus 10–12 weeks from Germany or Wisconsin.

Bottom line: Specify ±0.002 mm, ≤0.01 mm burr, 61.5 %IACS, fully annealed. Anything looser shifts failure risk from supplier to your winding line—and to the grid.

Factory Tour: Manufacturing Aluminum Rectangle

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20+ years transformer-grade strip/foil specialist

1. Production Journey: From 1xxx Ingot to Oscillate-Wound Coil

| Step | Equipment | Target Parameter | Value-Add for Transformer Winders |

|---|---|---|---|

| 1. Twin-Belt Cast Rolling | φ850 × 1600 mm 4-Hi reversing cold mill | Entry 8.0 mm → Exit 0.8 mm | Refines grain to ASTM 6–7, Ra ≤ 0.2 µm, guarantees ≥ 61.5 %IACS |

| 2. Precision Slitting | Kampf / KJ-60 arbor, tungsten carbide circular knives | Width tol. ±0.002 mm; camber ≤ 0.2 mm/2 m | Eliminates “dog-bone” edge, permits 0.5 mm inter-layer clearance in HV disc coils |

| 3. Edge Conditioning | 4-roller planetary deburr + laser triangulation | Burr height ≤ 0.01 mm; edge radius 0.05–0.10 mm | Prevents inter-layer voltage stress; no additional mylar taping required |

| 4. In-Line Annealing | 250 kW nitrogen-atmosphere continuous furnace | 340 °C, 25 m min⁻¹, O₂ < 50 ppm | Soft (HV 22–28), elongation ≥ 35 %; windability at 180° without cracking |

| 5. Oscillate Winding | Büs+Co 630 mm spooler, 5–25 mm traverse | Oscillation pitch ±0.2 mm; package density 2.8 kg dm⁻³ | Up to 1 t per spool → 30 % fewer joins, 18 % higher slot fill versus pancake coils |

2. Real-Time Quality Control Matrix

| Checkpoint | Sensor / Instrument | Frequency | Alarm Limit | Corrective Action |

|---|---|---|---|---|

| Gauge | X-ray thickness gauge (IMS) | 50 ms | ±0.001 mm | Auto hydraulic roll gap |

| Edge Burr | Keyence LJ-X8080 2-D profiler | Every slit strand | > 0.01 mm | Knife exchange alert |

| Conductivity | Sigmacoil 2008 eddy-current | Coil head & tail | < 61 %IACS | Re-anneal coil |

| Strip Tension | Magtrol load cell | Closed-loop | 12–18 N mm⁻² | Dancer roll modulation |

| Winding Pattern | Machine-vision camera | 100 % traverse | Oscillation skip > 0.3 mm | Auto stop & operator flag |

3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe Spec | Typical Alibaba Offer | Engineering Impact |

|---|---|---|---|

| Width Tolerance | ±0.002 mm | ±0.05 mm | Enables laser-cut spacer elimination; reduces axial short-circuit force by 8 % |

| Burr Height | ≤ 0.01 mm | 0.03–0.08 mm | Corona inception voltage ↑ 12 %; partial discharge < 5 pC @ 11 kV |

| Resistivity (20 °C) | ≤ 28.10 nΩ·m (≥ 61.5 %IACS) | 29.0–30.5 nΩ·m | Load loss ↓ 2.3 W kg⁻¹ Al; meets DOE 2016 efficiency tier |

| Camber | ≤ 0.2 mm / 2 m | 1 mm / 1 m | Layer registration error ↓ 65 %, eliminating manual shim rework |

| Oscillate Package Weight | ≤ 1 000 kg on 630 mm spool | 80–150 kg pancake | Joint count in 1 MVA HV winding: 1 vs. 12 → reliability MTBF ↑ 40 % |

| Annealing Atmosphere | N₂, O₂ < 50 ppm | Air batch furnace | Surface oxidation < 0.05 µm; solderability without brushing |

4. Certifications & Traceability

ISO 9001:2015, ISO 14001:2015, IATF 16949 slitting line audited

EN 13601:2013 & ASTM B236 compliance certificates supplied per coil

Laser-etched QR code links to melt ID, resistivity graph, and anneal batch; retains 20-year digital archive for transformer OEM recall audits.

Bottom line: Luoyang Xinzhaohe delivers Western-grade precision at China-direct landed cost, cutting your rectangular aluminum conductor spend by 18–22 % while exceeding IEC 60317-0-3 electrical and mechanical requirements.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive as flat, bright, and conductive as the day it left our slitting line.

1. Sea-Freight Reality Check

Salt-laden humidity, 40 °C deck temperatures, and 0.8 g vibration spectra during 3–5 week transits will turn unprotected edges into oxide islands and promote inter-wrap fretting. Our packaging is therefore treated as a “micro-environment” rather than a carton: every layer is a barrier, every void is calculated, every desiccant unit is sized to the steel container’s dew-point budget.

2. Packaging Matrix by Product Form

| Product Family | Critical Surface | Stack Pattern | Primary Barrier | Secondary Barrier | Securing Method | Moisture Buffer | Typical Payload |

|---|---|---|---|---|---|---|---|

| Aluminum Strip / Foil (0.08–3.0 mm) | Burr-free, Ra ≤ 0.3 µm | Eye-to-sky on 1 200 × 1 000 mm fumigated pine pallets | 80 µm VCI poly-laminate sleeve | Heat-sealed Al-foil liner if σ ≥ 35 % IACS | 19 mm PET strapping + edge boards, 4-way entry, stretch hood | 8–10 g CaCl₂ desiccant bags, 2 per m³ | 3–5 t net, 10 pallet positions/20’GP |

| Rectangular Wire (2–30 mm²) | Enamel 180 °C, 1–2 Grade | Barrel wound on DIN 355 or PT 500 spools | 120 µm anti-static PE shrink film | Corrugated “A-flute” sleeve, 5-ply | Spool flanges locked by 30 mm staples, 4 spools/carton, cartons on 1 140 × 1 140 mm pallet | 4 g silica-gel per spool, carton sealed ≤ 5 g/m² d | 1.5–2 t net, 18 pallet positions/40’HC |

Note: All lumber ISPM-15 heat-treated, MB marker stamped, and traceable to Henan entry-exit inspection bureau logs.

3. Container Loading Protocol

- Pre-load inspection – infrared camera for pre-existing moisture spots on container floor; reject if > 15 % RH.

- Desiccant mapping – suspend 1 kg “hanging” desiccant every 2 m along roof ridge; floor pockets filled with 2 kg barrier bags.

- Pallet orientation – strip pallets aligned long-side to container door, 50 mm clearance to wall for air circulation; wire pallets cross-stacked to lock tier-1 motion.

- Bracing – 5-ply honeycomb panels + 2 000 daN lashings to corner castings; accelerometer data loggers (±16 g) mounted on top tier for post-mortem review.

4. Luoyang Hub → Global Legs

Location advantage you can measure in lead-time days and °C of thermal cycling avoided.

Factory coordinates: 34.6 °N, 112.4 °E – 180 km to Zhengzhou International Hub (CGO), 380 km to Qingdao port; truck transit sealed, temperature-logged, < 8 h.

Weekly consolidation: FCL/LCL sailings to Hamburg, Houston, Dubai, Nhava Sheva; CIF, DAP, or FCA Incoterms selectable in PO.

Express air option: 48 h to Frankfurt-Hahn on CZ cargo for urgent rewind jobs (< 500 kg).

5. Cost-of-Ownership Snapshot

| Scenario | Western EU Mill | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Unit price $/kg | 7.90 | 5.35 | –32 % |

| Packaging add-on | 0.25 | included | –100 % |

| Sea freight (40’HC) | 1.10 | 0.85 | –23 % |

| Edge re-work on arrival | 0.40 typical | < 0.02 | –95 % |

| Total landed cost | 9.65 | 6.22 | –35 % |

6. Documentation & Traceability

Mill test certificate: EN 10204/3.1 for conductivity, hardness, burr height.

Slitting log: Coil ID → slit width → edge conditioner setting → operator ID.

Packaging photo dossier: auto-generated QR code on each pallet; scan to view load plan, desiccant count, and accelerometer report upon arrival.

We don’t just ship aluminum—we ship a controlled process that ends with your winder, not our port.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Aluminum Rectangle Strip & Foil

When you specify aluminum rectangle conductor for 10 kVA–1 000 MVA cores, you are not buying generic extrusion—you are procuring a magnet-wire-grade substrate whose edge radius, burr height, conductivity, and anneal softness decide short-circuit withstand, load loss, and hot-spot temperature.

Luoyang Xinzhaohe Aluminum Co., Ltd. has produced exactly this substrate for 20+ years, shipping >60 000 t of cold-rolled, slit, and edge-conditioned strip to Tier-1 transformer OEMs in 42 countries. Below is the engineering rationale for making us your direct-mill partner instead of an expensive trader or Western redistribution stockist.

H3 1. Two Decades of Transformer-Only Metallurgy

| Milestone | Technical Impact on Your Rectangle Strip |

|---|---|

| 2003 Start-up | First Chinese privately-owned 1650 mm 4-Hi cold mill dedicated to ≥99.7 % Al purity strip. |

| 2008 ISO 9001/14001 | Implemented SPC on rolling force & flatness → ≤15 I-units edge-to-center crown on widths 8–1200 mm. |

| 2012 In-house slitting | Installed 0.2 mm–3.0 mm KJS slitter with ±0.002 mm tolerance; burr ≤0.01 mm verified by 400× optical comparator. |

| 2018 Oscillate winder | Enabled 1 t–3 t coils with ≤0.5 mm stagger; eliminates butt-welds in high-speed winding lines. |

| 2022 IEC 60317-0-3 | Certified 1350-O conductor: 61.8 % IACS, 25 mm elongation, Rm 60–95 MPa across 0.2 × 6 mm rectangle. |

Outcome: Every production lot is backward-traceable to cast bar ID, rolling pass schedule, and final anneal curve—data we share in the test report that accompanies each coil.

H3 2. Direct Factory Price—No Western Mark-Up Layer

| Cost Element | Typical EU/USA Distributor | Luoyang Xinzhaohe (FOB Qingdao) | Savings |

|---|---|---|---|

| 0.3 × 10 mm 1350-O strip, burr-free, PEW enamel | 6.80 USD/kg | 4.15 USD/kg | –39 % |

| 0.8 × 25 mm bare rectangle, oscillate wound 2 t coil | 5.95 USD/kg | 3.60 USD/kg | –40 % |

| 1.2 × 50 mm edge-conditioned, conductivity ≥61.5 % IACS | 6.30 USD/kg | 3.85 USD/kg | –39 % |

We achieve this by integrating cold rolling → slitting → edge conditioning → oscillate winding under one 86 000 m² roof; no intermediate toll processors, no trader margin. Payment in USD, EUR, or CNY; LC 90 d or TT 30 d terms available.

H3 3. Customization Window—Mechanical, Electrical, Geometric

| Parameter | Standard Range | Custom Capability | Tolerance |

|---|---|---|---|

| Thickness | 0.15–4.00 mm | ±0.002 mm | EN 1652 Class B |

| Width | 8–1200 mm | ±0.03 mm (≤20 mm wide) | IEC 60317-0-3 |

| Edge radius | R0.05–R0.50 mm | CNC edge shaving die | ±0.01 mm |

| Conductivity | 61.5–62.0 % IACS | Furnace atmosphere tuning | ±0.2 % IACS |

| Anneal temper | O, H12, H14 | Controlled 240 °C–320 °C soak | 25–35 % elongation |

| Coil build | 300 mm–800 mm OD | Oscillate traverse 5–50 mm | ≤0.5 mm stagger |

| Surface finish | Ra 0.2–0.8 µm | Skin-pass 0.5 % elongation | ±0.1 µm |

Need square-edge, high-corner-fill for foil-wound LV disk? Or full-radius, ultra-low burr for 180 °C enameled wire? We modify roll grind profile and slitter tooling within 72 h.

H3 4. Quality & Compliance Documentation Delivered With Every Coil

Mill test certificate: EN 10204/3.1 (chemical, mechanical, electrical).

Burr report: 400× micrograph, 5 points/edge.

Conductivity trace: eddy-current map across strip length.

Packaging: VCI film + desiccant + steel cage, seaworthy, 40 °C–85 °C validated.

REACH, RoHS, conflict-mineral statement on request.

H3 Next Step—Request a Technical Datasheet or Same-Day Quote

Send your drawing or IEC size code to cathy@transformerstrip.com (copy liu@transformerstrip.com for metallurgical queries). Typical response:

24 h for bare rectangle quotation,

48 h for enamelled sample coil (MOQ 100 kg),

7 days for 3 t oscillate-wound production with witness inspection.

Stop paying 35–45 % Western margin for material that originates in the same cast-house zone as ours. Source direct from the cold-mill that transformer OEMs trust.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum rectangle from Luoyang Xinzhaohe.