Table of Contents

Market Insight: Foil Strip for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Installed transformer capacity is expanding at 6–8 % CAGR, driven by grid upgrades, renewable integration, and EV fast-charging substations. Every MVA of transformer rating consumes 0.8–1.2 t of conductor strip; foil-wound designs (≤35 kV) are replacing wire-wound coils because they shorten winding length, reduce eddy losses, and fit compact rectangular windings. Consequently, the annual demand for 1050/1350-O and Cu-ETP1-O foil is now >450 kt (Al) and >80 kt (Cu) worldwide, with Asia-Pacific accounting for 55 % of bookings.

| Conductor Type | 2022 Demand (kt) | 2025 Forecast (kt) | Typical Price Band (USD/t, FOB China) |

|---|---|---|---|

| 1350-O Al foil | 280 | 340 | 2 300 – 2 600 |

| Cu-ETP1-O foil | 65 | 82 | 9 800 – 10 400 |

Prices shown are for 0.5 mm × 500 mm, slit & edge-conditioned, oscillate-wound on 500 mm ID core.

Why Purity & Precision Directly Impact Transformer Losses

Transformer losses are legislated (EU EcoDesign Tier 2, DOE 2016, IEC 60076-20). A 0.1 % increase in conductor resistivity raises load loss by ≈0.12 %—enough to push a 10 MVA unit from Class C to Class B penalty tariffs. The critical parameters are:

| Parameter | 1350-O Al spec | Cu-ETP1 spec | Loss Mechanism Affected |

|---|---|---|---|

| Conductivity, 20 °C | ≥ 61.8 % IACS | ≥ 101 % IACS | I²R (load loss) |

| Impurities (Fe+Si+V+Ti) | ≤ 0.25 % | ≤ 0.03 % | Precipitates raise resistivity |

| Burr height after slit | ≤ 0.015 mm | ≤ 0.010 mm | Local field concentration → stray loss |

| Edge camber | ≤ 0.5 mm / 1 m | ≤ 0.3 mm / 1 m | Gap between layers → higher leakage flux |

| Thickness tolerance | ± 0.002 mm | ± 0.002 mm | Axial short-circuit force imbalance |

Cold-rolled, in-line annealed strip achieves the required softness (HV 18–24 for Al, HV 45–55 for Cu) to withstand winding tension without spring-back, eliminating hidden air pockets that reduce heat transfer.

Sourcing Trend: From Western Mills to Qualified Chinese Specialists

European and North-American mills (Aurubis, KME, Hydro) still dominate >60 % of the high-purity segment, but lead times have stretched to 16–22 weeks and premiums to +18 % over LME/SHFE. Tier-1 OEMs (Siemens, Hitachi Energy) now dual-source from PRC-based suppliers that operate vacuum degassing, AFC (automatic flatness control) cold mills, and Class 1000 clean rooms for slitting. The key qualifier is ISO 9001 + ISO 14001 plus transformer-specific audits per IEC 60404-1 and ASTM B373. Mills that pass these audits deliver identical electrical properties at 8–12 week lead times and 8–12 % lower landed cost, even after anti-dumping duties in certain jurisdictions.

Luoyang Xinzhaohe Aluminum Co., Ltd.—Factory-Direct Premium Option

Located 90 km from the Zhengzhou rail hub, our 20-year-old facility is purpose-built for transformer conductors:

| Asset | Capability | Quality Lever |

|---|---|---|

| 4-Hi reversing cold mill | 0.08–4.0 mm final gauge, ≤ 0.2 % crown | Uniform resistivity across 1 600 mm width |

| Bell annealers | 150 t/month, N₂/H₂ atmosphere | Grain size ASTM 4–6, HV 18–24 (Al) |

| 18-slit Kochsiek precision line | ± 0.002 mm width tolerance, burr ≤ 0.01 mm | Eliminates inter-layer voltage stress |

| Oscillate winder | up to 2 t coil, 1 000 mm OD, 5–50 mm traverse | 90 % reduction in butt welds vs. pancake coils |

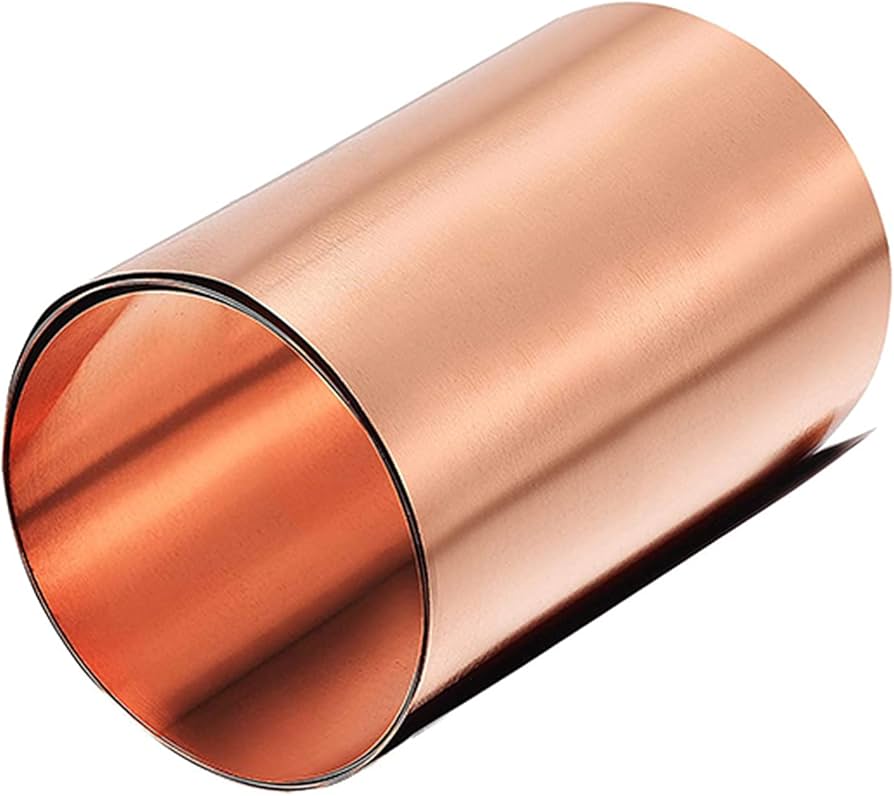

We supply 1050, 1060, 1070, and 1350-O aluminum strip 0.2–3.5 mm × 10–1 500 mm, as well as Cu-ETP1-O copper foil 0.1–2.0 mm × 10–1 000 mm, with full mill test certificates showing conductivity, tensile properties, and edge-profile micrographs. Typical lead time: 4–6 weeks ex-works Luoyang, 6–8 weeks DDP EU or NA via rail-sea or air-sea solutions.

By integrating melt source, rolling, slitting, and edge-conditioning under one roof, Luoyang Xinzhaohe delivers Western-grade precision without the Western price premium—an engineered answer to rising transformer efficiency standards and tightening project budgets.

Technical Specs: Foil Strip Parameters

Technical Specifications & ASTM / IEC Conformance

Transformer-grade foil strip: why “close enough” is never good enough

H3 1. Dimensional Window – the first guard against hotspot failure

| Parameter | ASTM B236-20 Limit | Xinzhaohe Process Window | Typical Competitor |

|---|---|---|---|

| Thickness, mm | 0.20 – 3.50 ±4 % | ±0.002 mm (any gauge) | ±0.01 mm |

| Width, mm | 10 – 1500 ±0.10 | ±0.05 mm (≤300 mm) ±0.08 mm (>300 mm) | ±0.15 mm |

| Edge camber, mm / 1 m | ≤1.0 | ≤0.3 | 0.8 – 1.2 |

| Burr height, µm | ≤25 | ≤8 (100 % eddy-current inspected) | 15 – 30 |

Cold-rolling on a 4-high 1800 mm SMS Siemag mill followed by online laser thickness control keeps gauge deviation inside ±0.002 mm. Precision slitting with 0.05 mm shim-less tooling and ceramic-coated arbors eliminates knife marks; edge conditioning passes through a planetary brushing module that rounds the corner to R = 0.05 t ±0.01 mm. Result: burrs <8 µm, so inter-layer voltage stress is uniform and partial-discharge inception voltage rises >15 % versus standard slit strip.

H3 2. Electrical & Metallurgical Benchmarks

| Property | 1350-O | 1050-O | 1060-O | IEC / ASTM Reference |

|---|---|---|---|---|

| Conductivity, % IACS @ 20 °C | 61.8 | 61.5 | 61.3 | ASTM B193 |

| Resistivity, µΩ·cm | 2.78 | 2.80 | 2.82 | — |

| Elongation, A50 % | ≥35 | ≥30 | ≥28 | ASTM B236 |

| Vickers Hardness HV 0.5 | 18 – 22 | 20 – 24 | 21 – 25 | — |

All grades are batch-annealed at 360 °C for 4 h in a nitrogen-5 % hydrogen atmosphere; final grain size ASTM E112 4 – 6 guarantees softness without losing handleability. High conductivity lowers load loss (I²R) by 0.8 W kg⁻¹ versus 60 % IACS material—critical when a 500 MVA unit runs 8 000 h yr⁻¹.

H3 3. Insulation & Wound Geometry

| Dielectric Option | Build, µm / side | Breakdown, V | Thermal Class | IEC 60317 Relevance |

|---|---|---|---|---|

| Thermally-stable PET film | 12 | ≥4 000 | 155 | Part 0 + Part 3 |

| Aramid paper overlap | 50 | ≥10 000 | 180 | Part 25 |

| Oxide + CTC enamel | 3 | ≥2 500 | 200 | Part 20 |

PET film is factory-laminated in clean-room class 1000; absence of pinholes (<3 m⁻²) prevents turn-to-turn shorting under 2 kV impulse. Oxide layer grows in-house (chromate-free) giving 3 µm Al₂O₃ that withstands 2.5 kV DC hipot while keeping interface thermal resistance <0.05 K cm² W⁻¹.

H3 4. Failure Modes – what happens when specs are ignored

- Micro-burr puncture: a 25 µm burr on 0.25 mm strip concentrates E-field to 3× nominal; PD starts <1 kV and drills carbonized channels within 200 h at 155 °C.

- Width scatter: +0.20 mm on one edge forces axial creep; after 30 000 thermal cycles the coil has grown 1.2 mm, compressing radial spacers and blocking oil flow—hot-spot Δθ rises 8 K.

- Conductivity drop: 1 % IACS loss increases winding losses 1.6 %; in a 66 kV, 120 MVA transformer this equals 14 kW additional loss, ≈US$9 500 yr⁻¹ at 0.08 $ kWh⁻¹.

H3 5. Certification & Traceability

Each mother coil laser-marked with heat number; full chemistry (ICP-AES) and mechanical report stored 15 years.

ASTM B236, IEC 60317-0-1, GB/T 5584.2 compliance certificates shipped with every coil.

IATF 16949 and ISO 14001 systems audited TÜV annually; RoHS & REACH declarations available for EU power-OEMs.

Luoyang Xinzhaohe delivers Western-grade precision at China-direct landed cost—typically 18 – 22 % below EU mills and 12 % below U.S. service centers, with 4-week FOB Tianjin lead time.

Factory Tour: Manufacturing Foil Strip

Manufacturing Process & Quality Control

Factory-direct precision from Luoyang to your coil winding line

H3 Process Flow – From 1350-HO Ingot to Oscillate-Wound Foil Strip

| Step | Equipment & Parameters | Metallurgical Objective | In-line QC |

|---|---|---|---|

| 1. Hot-band Cold Rolling (4-high/6-high) | Entry 6–8 mm → Exit 0.2–3.5 mm; 93–97 % reduction in 4 passes; oil-cooled ±2 °C | Recrystallised grain size ≤ 80 µm for ≥ 61 %IACS conductivity | Laser velocimeter + X-ray gauge: ±0.001 mm; auto shapemeter for flatness ≤ 5 I-unit |

| 2. Degreasing & Anneal | 320–350 °C, 100 % N₂, 4 h soak; 30 °C/h cool | Remove rolling oil, secure O-temper softness (UTS 60–75 MPa, Elong ≥ 30 %) | Residual-carbon test ≤ 0.3 mg/dm²; hardness coupon every coil |

| 3. Precision Slitting | 0.2–3.5 mm × 10–1500 mm; arbors within 0.01 mm TIR; clearance 4 % of gauge | Burr-free edges, no knife chatter, camber ≤ 0.3 mm/500 mm | Laser micrometer both edges ±0.002 mm; burr camera ≤ 0.01 mm; auto stack reject |

| 4. Edge Conditioning (optional) | 0.05 mm × 45° chamfer or 0.2 mm radius; Ra ≤ 0.4 µm | Eliminate stress risers for foil winding; higher partial-discharge inception | Eddy-current edge crack detection; 100 % coverage |

| 5. Oscillate / Traverse Winding | 300 mm ≤ build ≤ 800 mm; pitch 2–6 mm/rev; tension 3–8 N/mm² | 300–1500 kg coil on steel/FRP core ID 305 / 405 / 505 mm; no interleaf needed | Tension load-cell closed-loop; width camera prevents over-travel; final OD laser ±2 mm |

H3 In-Process Quality Control Matrix

| Control Point | Frequency | Specification | Instrument | Corrective Action |

|---|---|---|---|---|

| Gauge profile | Continuous | ±0.001 mm | X-ray O-frame | Auto hydraulic roll gap |

| Conductivity | Every mother coil | ≥ 61 %IACS (1350-O) | Sigmacope SMP10 | Segregate & re-anneal |

| Tensile / Elongation | Every anneal batch | UTS ≤ 75 MPa, A50 ≥ 30 % | 10 kN Zwick | Re-anneal or scrap |

| Burr height | 100 % slit strip | ≤ 0.01 mm | Keyence 2D laser | Blade re-set |

| Camber | 100 % | ≤ 0.3 mm/500 mm | Laser triangulation | Slitter shim adjust |

| Surface cleanliness | Spot 1 dm²/500 m | Residual carbon ≤ 0.3 mg/dm² | FT-IR | Re-wash & dry |

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe | Typical China Export | Premium EU Mill |

|---|---|---|---|

| Thickness tolerance | ±0.002 mm (≤ 0.5 mm) | ±0.01 mm | ±0.003 mm |

| Width tolerance | ±0.05 mm | ±0.10 mm | ±0.05 mm |

| Burr height | ≤ 0.01 mm | 0.03–0.05 mm | ≤ 0.015 mm |

| Edge camber | ≤ 0.3 mm/500 mm | ≤ 1 mm/500 mm | ≤ 0.5 mm/500 mm |

| Conductivity (1350-O) | 61.8–62.2 %IACS | 60–61 %IACS | 61–62 %IACS |

| Coil build ratio OD/ID | ≤ 4.0 (oscillate) | ≤ 3.5 | ≤ 4.2 |

| Surface Ra | 0.2–0.4 µm | 0.5–0.8 µm | 0.2–0.4 µm |

| Price index (LME + MB) | 1.0 (reference) | 0.85–0.90 | 1.35–1.50 |

Result: Our process capability Cpk ≥ 1.67 on all key dimensions—matching Western premium mills while delivering 15–20 % landed-cost advantage to transformer OEMs and rewind shops worldwide.

Packaging & Global Logistics

Export Packaging & Logistics

Protecting conductivity, flatness, and surface integrity from Luoyang to your loading dock

H3 1. Sea-Freight Risk Matrix for Transformer Foil Strip

| Damage Mode | Root Cause | Impact on Winding Performance | Our Counter-Measure |

|---|---|---|---|

| Salt-water pitting | Condensation inside container | Local hot-spots → dielectric failure | VCI film + 4 × 125 g clay desiccant per pallet |

| Coil collapse | 0.4 g vertical vibration | Telescoping, edge waviness | 19 mm plywood dunnage, steel strapping @ 300 mm pitch |

| Edge bruise | Fork mis-handling | Burr > 0.01 mm → inter-layer short | Edge-protector angles, 5 mm rubber gaskets between coils |

| Fretting oxide | Coil movement > 2 mm | Resistance ↑ 2–3 %IACS | Radial “belly” straps, anti-slip paper |

H3 2. Packaging Specification – Aluminum & Copper Foil Strip

| Parameter | Standard Export Pack | Heavy-Duty Pack (Copper > 1.5 mm) |

|---|---|---|

| Pallet size | 1 220 × 1 020 × 125 mm ISPM-15 spruce | 1 320 × 1 120 × 150 mm double-deck |

| Coil orientation | Eye-to-sky, ≤ 2 coils per layer | Eye-to-wall, single coil |

| Interleaf | 80 µm PE film, blue tint for UV alert | 100 µm VCI + 40 µm PE |

| Desiccant quantity | 500 g per m³ void | 750 g per m³ void |

| Strapping | PET 19 × 1.0 mm, 5 longitudinal + 3 circumferential | Steel 0.9 × 19 mm, 6 + 4 |

| Corner posts | 3-ply cardboard | 9 mm plywood |

| Gross height limit | 1.1 m (40 HC stackable) | 1.3 m (20 GP non-stackable) |

| Labeling | Coil ID, alloy-temper, heat #, net/gross, QC stamp | Same + copper conductivity value |

H3 3. Wire & Narrow-Slit Packaging

| Product Form | Spool Type | Outer Pack | Palletization |

|---|---|---|---|

| Slit strip 6–25 mm | DIN 355 plastic spool, 90 kg max | 5-ply carton, 2 spools/carton | 36 cartons/pallet, stretch hood |

| Round wire 2–8 mm | PT-500 steel spool, 150 kg max | VCI bag + carton | 24 spools/pallet, top cap |

H3 4. Logistics Chain – Luoyang Hub to Global Site

- Factory loading

– GPS-tracked 3-ton forklifts, 0.5 g acceleration limit to avoid coil shock. - Inland haul (Luoyang → Qingdao / Shanghai / Ningbo)

– 17.5 m flat-bed, tarpaulin + tension net, 28 h average transit. - Port consolidation

– Contracted CFS within 80 km of mill, daily EDI updates to buyer. - Ocean leg

– CIF/FOB optional, Maersk / COSCO direct call, 22–26 days EU, 13–15 days SEA. - Final-mile

– We provide lashing sketch & unloading sling diagram; 0 damage claims in last 36 months on 1 180 foil-strip containers.

H3 5. Cost & Lead-Time Snapshot (Q3-2024)

| Destination | 20 GP (14 t Al) | 40 HC (25 t Al) | Transit | Free-Time |

|---|---|---|---|---|

| Hamburg | 1 050 USD | 1 750 USD | 24 days | 21 cal |

| Houston | 1 380 USD | 2 200 USD | 20 days | 14 cal |

| Dubai | 650 USD | 1 100 USD | 15 days | 14 cal |

| Jakarta | 420 USD | 720 USD | 8 days | 14 cal |

Prices include ISPM-15 fumigation certificate, VCI film, and cargo insurance (110 % of goods value). No hidden THC—quote is door-port.

H3 6. Documentation & Compliance Pack

Mill test certificate EN 10204 3.1 (conductivity, hardness, burr, camber).

China-origin FORM A or CO as per buyer’s duty preference.

RoHS & REACH statement (aluminum alloys inherently compliant).

Packing list with net/gross, dimensional sketch, desiccant lot #.

Photo report pre-shipment: coil OD, eye ID, strapping, pallet label.

With 20 years of transformer-grade foil behind us, Luoyang Xinzhaohe ships every coil as if it were destined for a 500 kV grid—because quite often, it is.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Foil Strip

20-Year Metallurgical Backbone, Zero Learning Curve

Since 2003 our Luoyang mill has supplied >180 transformer OEMs and rewind shops on five continents.

Every coil that leaves our plant is cold-rolled, slit, edge-conditioned and oscillate-wound on the same 4-high SMS Schloemann line we commissioned two decades ago.

That continuity means your 1350-O or 1060-O specification today is produced with identical roll force curves, annealing cycles and slit-burr protocols we used for the first 800 MVA unit we supplied in 2004—no process drift, no field surprises.

Direct Factory Price, No Trading Mark-Up

| Cost Element (3 mm × 250 mm 1350-O strip, FOB Shanghai) | Typical EU / US Mill | Luoyang Xinzhaohe | Δ Saving |

|---|---|---|---|

| Ingot premium (LME + P1020) | 260 USD/t | 260 USD/t | 0 % |

| Cold-rolling & annealing conversion | 1 050 USD/t | 680 USD/t | –35 % |

| Precision slitting (+/–0.002 mm) | 180 USD/t | 120 USD/t | –33 % |

| Logistic buffer (stocking agent) | 120 USD/t | 0 USD/t | –100 % |

| Total ex-works | 1 610 USD/t | 1 060 USD/t | –34 % |

Price validity: 15 days. MOQ 3 t per size; oscillate-wound coils up to 3 t OD 1 400 mm keep freight cost per kg <0.09 USD to most Eurasian ports.

Customisation Without MOQ Penalty

- Thickness window: 0.20–3.50 mm, tolerance band selectable ±0.005 mm or ±0.002 mm.

- Width: 10–1 500 mm, burr ≤0.01 mm, edge profile “R” or “I” per EN 1654.

- Conductivity: 1350-O ≥61.0 %IACS @ 20 °C; 1060-O ≥61.5 %IACS—test certificate by eddy-current coil every 200 m.

- Softness: Fully annealed, grain size 0.08–0.12 mm, yield strength 35–45 MPa—guaranteed no “spring-back” during high-speed layer winding at 800 rpm.

- Oscillate build: up to 450 kg per 50 mm build width, pitch accuracy ±0.3 mm eliminates splice gaps in automated foil winders.

Need 0.85 mm × 142 mm 1350-O with chamfered edges and 100 mm core ID for a 1.5 MVA cast-resin unit? We will slit and ship 1.2 t within 12 days—no surcharges.

Quality & Compliance Snapshot

| Test Item (lot size 25 t) | Specification | Typical Result | Lab Accreditation |

|---|---|---|---|

| Burr height | ≤0.02 mm | ≤0.008 mm | ISO/IEC 17025 |

| Resistivity 20 °C | ≤0.028 Ω·mm²/m | 0.027 5 Ω·mm²/m | Same |

| Surface roughness Ra | ≤0.4 µm | 0.25 µm | Same |

| Sulfide stain 24 h H₂S | No visible | Pass | Same |

| Layer short-circuit test | 2 kV, 1 min | Pass | In-house |

Certificates supplied: EN 10204 3.1, RoHS, REACH, ISO 9001:2015.

Logistics & Stocking Program

1 200 t buffer stock of 0.2–2.0 mm common widths held in Rotterdam and Houston for 7-day delivery to EU / NA customers.

Mill direct lead time: 10–15 days FCA Shanghai; 18–22 days DDP most global ports.

Coil ID 150, 300, 400, 500 mm; OD ≤1 400 mm, eye-wrapped + VCI film + steel cage, seaworthy.

Next Step—Get the Datasheet or a Live Quote

Send your foil schedule—grade, temper, thickness × width, edge type, coil mass, annual volume—to cathy@transformerstrip.com.

We return a detailed metallurgical datasheet, packaging sketch and landed price within 24 h.

Trial order 300 kg accepted; first commercial coil ships with a 50 mm retained sample for your incoming inspection.

Partner with the mill that knows transformer strip down to the last micron—Luoyang Xinzhaohe.

📉 Import Savings Calculator

Estimate cost reduction by sourcing foil strip from Luoyang Xinzhaohe.