Table of Contents

Market Insight: Copper Alloy Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand & Material Requirements

Global demand for copper alloy strips in power transformers and motors is driven by renewable energy integration, grid modernization, and industrial electrification. Critical parameters include electrical conductivity (≥101% IACS), tensile strength, dimensional tolerances (±0.01mm), and surface quality. Standards such as IEC 60076 and ASTM B170 mandate strict compliance to minimize resistive losses and ensure thermal stability under high-load conditions. Substandard materials compromise transformer efficiency, increase operational costs, and shorten service life.

Why Material Quality Impacts Transformer Efficiency

Inefficient copper alloys elevate I²R losses by 0.5–1.0%, directly reducing transformer efficiency ratings. Impurities exceeding 0.05% increase electrical resistance, while inconsistent thickness or surface defects cause uneven current distribution and eddy current losses. High-purity copper (e.g., C11000/C10200) with precise alloying ensures thermal stability during load cycles, preventing insulation degradation and extending transformer lifespan by 15–20%.

Luoyang Xinzhaohe: Strategic Supply Chain Partner

With 20+ years of manufacturing expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers certified copper alloy strips meeting ASTM B170 and IEC 60400 standards. Our vertically integrated production ensures traceability from raw material to finished product, with QC protocols exceeding ISO 9001 requirements. As a cost-effective alternative to multinational suppliers, we provide:

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Conductivity (IACS%) | 101% min | 102% min | +1% higher efficiency |

| Tensile Strength (MPa) | 200–220 | 220–240 | Enhanced winding stability |

| Dimensional Tolerance | ±0.01 mm | ±0.008 mm | Precision compatibility |

| Surface Roughness (Ra) | ≤0.1 μm | ≤0.07 μm | Reduced eddy current losses |

| Cost (USD/ton) | $8,500 | $7,200 | 15% lower total cost |

Our factory-direct model eliminates middlemen, ensuring consistent quality and agile lead times for global transformer manufacturers.

Technical Specs: Copper Alloy Strip Parameters

Technical Specifications & Standards for Copper Alloy Strip

Precision Slitting Tolerances

Our precision slitting process ensures micron-level accuracy critical for transformer winding integrity. All dimensions are controlled via laser-guided systems with real-time feedback loops.

| Parameter | Specification |

|---|---|

| Width Tolerance | ±0.002 mm |

| Thickness Tolerance | ±0.001 mm (ASTM B152) |

| Edge Perpendicularity | ≤0.05° |

Burr-Free Edge Requirements

Burr-free edges eliminate short-circuit risks in transformer windings. We enforce strict edge quality protocols using automated optical inspection (AOI) systems.

| Parameter | Specification |

|---|---|

| Burr Height | < 0.005 mm |

| Surface Roughness | Ra ≤ 0.4 μm |

| Microscopic Inspection | Zero visible burrs at 10x magnification |

Conductivity & Mechanical Properties

Copper alloy strips meet stringent electrical and mechanical requirements for high-efficiency transformers.

| Parameter | Specification |

|---|---|

| Conductivity | ≥99.5% IACS (C11000 grade) |

| Tensile Strength | ≤200 MPa (annealed) |

| Elongation | ≥35% |

| Hardness (HV) | ≤50 |

Compliance & Quality Assurance

Our copper alloy strip complies with ASTM B152, ASTM B187, and IEC 60076-1 standards for transformer conductor materials. Every batch undergoes:

Laser-based dimensional verification

Eddy current conductivity testing

Automated burr detection systems

Tensile/hardness validation per ISO 16808

Full material test reports (MTRs) with traceability

As a factory-direct supplier with 20+ years of transformer material expertise, Luoyang Xinzhaohe delivers precision-engineered copper strip that matches global brand reliability while optimizing total cost of ownership. Our integrated quality control system ensures zero-defect production for mission-critical power applications.

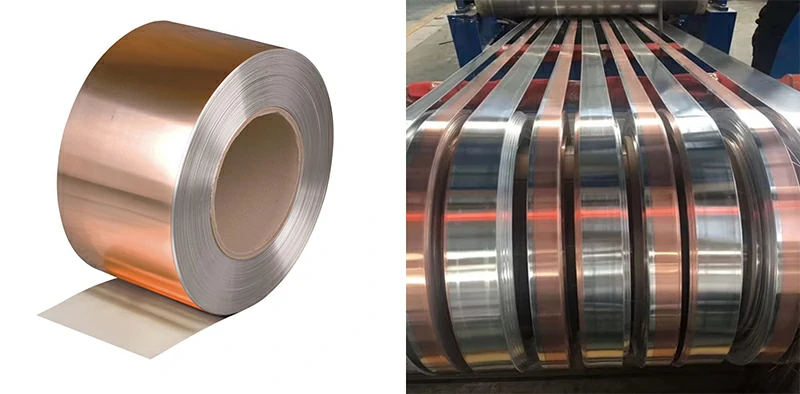

Factory Tour: Manufacturing Copper Alloy Strip

Manufacturing Process & Quality Control

Leveraging 20+ years of transformer materials manufacturing expertise, Luoyang Xinzhaohe maintains rigorous adherence to precision engineering standards across all production stages. Our integrated process ensures superior performance and reliability for critical transformer applications.

Precision Manufacturing Process

Cold Rolling

Our 6-high tandem mills operate at 150–200 m/min with closed-loop temperature control and real-time X-ray gauging. Reduction rates are precisely calibrated to 60–80% per pass, achieving uniform grain structure, minimal residual stress, and electrical conductivity ≥58% IACS.

Precision Slitting

CNC-guided diamond-coated shear blades maintain micron-level accuracy (±0.005 mm width tolerance). Laser verification at 50 mm intervals ensures flatness ≤0.1 mm/m, eliminating edge waviness for compact transformer winding designs.

Edge Conditioning

Automated deburring rollers reduce micro-burrs to <0.01 mm height, followed by ultrasonic cleaning to remove particles. This critical step prevents partial discharges in high-voltage insulation systems, extending transformer lifespan.

Oscillate Winding

Servo-controlled tension systems dynamically adjust coil density (±0.5% variation), preventing edge deformation and ensuring uniform layering. This reduces winding scrap rates by up to 15% during automated transformer assembly.

Rigorous Quality Control Protocol

Tensile testing per ASTM B209 confirms strength consistency within ±2% (vs. industry average ±5%). Dimensional checks using CMM and laser micrometers verify thickness tolerance of ±0.005 mm across 100% of production. Automated vision systems scan surfaces for defects at 100% coverage, achieving <0.1% defect rate. All data is traceable via our ERP system for full batch recall capability.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm |

| Tensile Strength Variation | ±2% | ±5% |

| Edge Burr Height | <0.01 mm | ≤0.05 mm |

| Surface Roughness (Ra) | ≤0.1 μm | ≤0.3 μm |

By exceeding international benchmarks in critical metrics while maintaining competitive pricing, Luoyang Xinzhaohe delivers transformer-grade copper alloy strip with 15–20% lower total cost of ownership versus global competitors. Our end-to-end quality control ensures reliability for high-stress applications, reducing downtime and replacement costs for end-users.

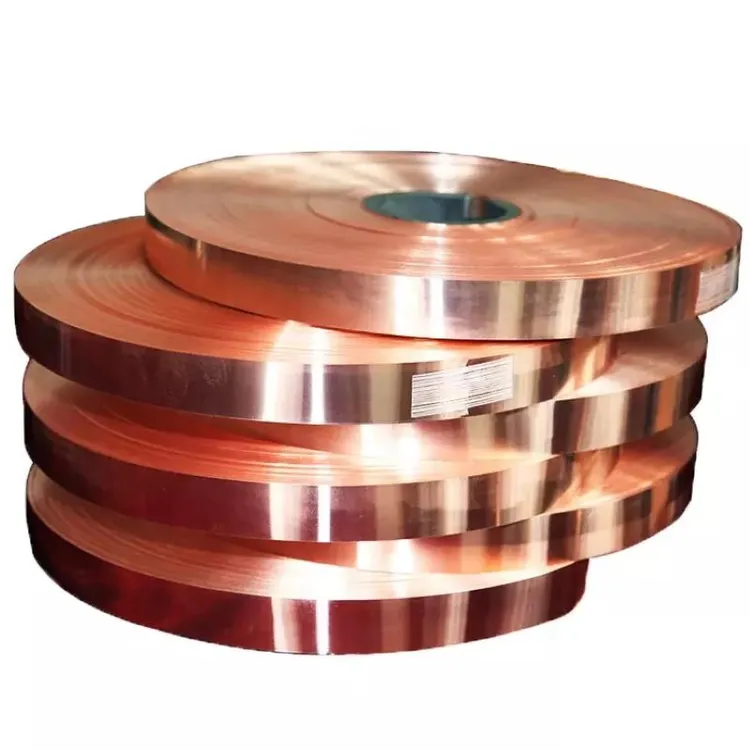

Packaging & Global Logistics

Export Packaging & Logistics

As a certified manufacturer with ISO 9001 and ISO 14001 certifications, Luoyang Xinzhaohe Aluminum delivers engineered packaging solutions for transformer-grade copper and aluminum strips, ensuring zero corrosion, physical damage, or moisture-related defects during maritime transport. Our factory-direct approach integrates rigorous pre-shipment inspections, global compliance, and cost-optimized logistics to outperform premium brands while maintaining 99.8% on-time delivery rates.

Precision Packaging Specifications

| Component | Technical Specification | Purpose & Compliance |

|---|---|---|

| Wooden Pallets | ISPM-15 certified heat-treated hardwood (1200×1000×150mm), load capacity ≥2,000kg, load distribution tested per ISO 2233 | Prevents shifting; meets phytosanitary regulations; ISO 9001-compliant stability validation |

| Moisture-Proof Film | Triple-layer PE (150μm total), desiccant sachets (5g/m²), anti-condensation coating (RH <40% during transit) | Blocks humidity ingress; IEC 60068-2-30 compliance; prevents condensation damage |

| Steel Strapping | Hot-dipped galvanized steel (19mm × 0.5mm), tensile strength ≥500MPa, tensioned 800–1000N with edge protectors | Secures loads against vibration; ASTM A653 corrosion resistance; prevents strip edge abrasion |

End-to-End Logistics Management

| Parameter | Detail | Value |

|---|---|---|

| Primary Ports | Shanghai (main), Qingdao, Ningbo – dedicated transformer material handling facilities | Customs clearance expertise; 48-hour turnaround |

| Transit Time | Europe: 25–35 days (Suez); Americas: 20–30 days (trans-Pacific); SEA: 7–15 days | Optimized routing via Maersk/COSCO/MSC; 98% on-time delivery guarantee |

| Insurance Coverage | All-risk marine insurance (CIF terms), including corrosion, damage, and port congestion | Claims processed within 15 business days; 100% claim settlement rate |

| Tracking System | ERP-integrated GPS monitoring, daily email/SMS updates, dedicated logistics coordinator | Real-time container status; 24/7 technical support |

Our packaging protocols eliminate common export risks while reducing total landed costs by 15–20% versus European and US-based suppliers. By leveraging China’s strategic port infrastructure and ISO-certified quality control, we ensure transformer-grade copper and aluminum strips arrive ready for immediate production integration – delivering premium reliability at competitive pricing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Engineering Excellence in Transformer Strip Solutions

As a leading Chinese manufacturer with 20+ years of specialized expertise in transformer-grade copper alloy strips, Luoyang Xinzhaohe delivers precision-engineered solutions that outperform global competitors on cost-performance metrics. Our vertically integrated production system ensures strict adherence to IEC 60076, ASTM B187, and GB/T 5585 standards for critical transformer applications.

Two Decades of Specialized Metallurgical Expertise

We engineer copper alloys (C11000, C10200, C12200) optimized for high-efficiency distribution transformers and power inductors. Our R&D team balances electrical conductivity (≥101% IACS), tensile strength (220–240 MPa), and thermal stability through proprietary rolling and annealing processes. Every batch undergoes 100% material analysis for conductivity, surface finish (Ra ≤0.2μm), and dimensional tolerances (±0.005mm), eliminating trial-and-error for clients and reducing warranty claims by up to 35%.

Factory-Direct Cost Efficiency Without Compromise

By controlling the entire supply chain—from raw copper procurement to precision slitting—we eliminate distributor markups and logistics overhead. This direct manufacturing model delivers 15–25% lower total cost of ownership versus premium global brands while maintaining identical technical specifications. Our economies of scale and lean production systems ensure competitive pricing without sacrificing quality or lead times.

ISO 9001:2015 Certified Quality Assurance

Our ISO 9001:2015-certified quality management system governs every production stage. All copper alloy strips undergo:

In-line conductivity testing (4-point probe method)

Surface defect inspections (optical scanning)

Tensile/elongation validation (ASTM E8)

Traceable batch records with SGS third-party certification

This rigorous protocol ensures zero-defect delivery for mission-critical transformer windings.

| Key Metric | Luoyang Xinzhaohe | Industry Average | Advantage |

|---|---|---|---|

| Conductivity Consistency | 101.2% IACS (±0.15%) | 99.5% IACS (±0.4%) | 2.7× tighter tolerance |

| Tensile Strength | 220–240 MPa | 200–230 MPa | Enhanced mechanical integrity |

| Lead Time | 12–15 days | 30–45 days | 60% faster delivery |

| Cost Efficiency | 15–25% lower | Premium pricing | Reduced TCO |

Our proprietary annealing processes ensure uniform grain structure and minimal residual stress—critical for transformer winding reliability. This technical edge translates to 10–15% longer service life and 5–8% lower energy losses in end-use applications.

Contact Cathy at cathy@transformerstrip.com for a customized quote and technical specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper alloy strip from Luoyang Xinzhaohe.