Table of Contents

Market Insight: Super Enamelled Copper Wire for Power Industry

Market Analysis: Sourcing High-Quality Super-Enamelled Copper Wire for Power & Distribution Transformers

Global Demand Outlook

The installed base of power transformers (>100 MVA) is forecast to grow at 5.4 % CAGR through 2030, driven by grid expansion, renewable integration and replacement of 1970-1990 era units. Every additional 1 GW of wind or solar capacity requires ≈1.2 t of super-enamelled copper winding wire. Distribution utilities are simultaneously upgrading 10-35 kV networks, pushing annual demand for Class F (155 °C) and Class H (180 °C) wire above 1.1 million t globally. China alone accounts for 38 % of consumption; however, OEMs in Europe, Middle-East and LATAM are shifting procurement eastward to shorten lead-time and offset 30-40 % price premiums charged by legacy Western enamelers.

Why Material Purity & Geometric Precision Directly Dictate Transformer Losses

| Loss component | Root cause in winding wire | Typical impact on 100 MVA, ONAN unit |

|---|---|---|

| Load loss (I²R) | 1. OFHC grade < 99.97 % Cu 2. Dimensional ovality > ±0.5 % 3. High oxide inclusions |

+12 kW per 0.1 % resistivity rise |

| Stray loss (eddy) | Eccentric enamel (< 70 % concentricity) forces larger conductor cross-section | +8 kW for 3 % diameter penalty |

| No-load loss (hysteresis) | Residual tensile stress from improper annealing (RA < 35 %) increases core magnetising current | +6 kW per 20 MPa stress transferred to core clamping |

| Hot-spot Δθ | Local insulation thinning (pin-holes > 5 per 30 m) accelerates thermal ageing | 6 °C rise ≈ 50 % life reduction |

Precision rod drawing followed by in-line laser diameter feedback (±0.3 µm) and closed-loop enamel concentricity control (≥ 85 %) are therefore not academic luxuries—they are the lowest-cost route to meet EU Eco-Design Tier-2 loss limits without oversizing cores or adding cooling complexity.

Sourcing Trend: Moving from High-Cost West to Experienced Chinese Enamelers

Since 2018, tier-1 transformer OEMs (ABB, Siemens-Energy, Hyundai) have qualified Chinese suppliers under IEC 60317-0-1, NEMA MW 35-C and JIS C3202 in parallel. Key drivers:

-

Integrated Rod-to-Wire Route

Plants such as Luoyang Xinzhaohe Aluminium Co., Ltd. (LXZ) melt 99.99 % cathode Cu on-site, rod-roll to 8 mm, then direct-feed enameling lines—eliminating 300 km of annealing logistics and cutting embedded carbon by 11 %. -

Statistical Process Depth

Twenty-year transformer material focus translates into Cpk ≥ 1.67 for breakdown voltage (≥ 3.0 kV, 0.150 mm build) and elongation (≥ 32 %, 1.0 mm). Western mills typically quote Cpk 1.33, requiring customers to widen incoming-tolerance bands. -

Cost Structure Advantage

Factory-gate price FOB Shanghai for Class F 1.00 mm wire averages USD 9.2 kg⁻¹ versus USD 13.8 kg⁻¹ ex-Italy or USD 15.1 kg⁻¹ ex-USA (May 2024 LME Cu base = 9.35 USD kg⁻¹). Even after 7 % anti-dumping duty into EU, landed cost remains 22 % lower. -

Risk-Mitigated Logistics

LXZ ships 30–150 kg ply-wood spools (Ø 250 × 400 mm) vacuum-shrink wrapped + VCI film; containerised sea transit to Hamburg or Houston is 26 days door-to-door, comparable to 21 days ex-Italy once inland legs are included.

Take-away for Buyers

Specifying super-enamelled copper wire purely on unit price invites hidden life-cycle cost via higher losses and premature insulation failure. A supplier that controls the full chain—from cathode to final inline spark test—delivers the twin benefits of (i) guaranteed electrical & mechanical repeatability and (ii) total acquisition cost 20-30 % below traditional Western channels. For procurement teams under margin pressure, experienced Chinese manufacturers with transformer-grade pedigree (LXZ included) now represent the premium alternative, not the budget fallback.

Technical Specs: Super Enamelled Copper Wire Parameters

Technical Specifications & ASTM/IEC Standards for Super Enamelled Copper Wire

(Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.)

H3 Critical Parameters that Decide Transformer Life

| Parameter | IEC 60317-0-1 Clause | ASTM Equivalent | Xinzhaohe In-line Target | Consequence if Out-of-Spec |

|---|---|---|---|---|

| Breakdown Voltage (BDV) | §4.4.2 | ASTM D149 | ≥ 4 kV (0.35 mm wire) @ 20 °C | Pin-holes → inter-turn short, hi-pot failure |

| Elongation at Break | §4.3.3 | ASTM B1 | ≥ 32 % (1.0 mm Cu) | Cracks during coil expansion; open circuit |

| Thermal Class | IEC 60085 | ASTM D2307 | 155 (F) / 180 (H) / 200 (C) | Insulation embrittlement, varnish peel-off |

| Concentricity (Min. wall) | §4.2.1 | — | 360° ±5 µm on Ø0.50 mm | Hot-spot, partial discharge |

| Surface Roughness Ra | — | ASTM B236* | ≤ 0.8 µm on conductor | Micro-burrs cut enamel → turn-to-turn fault |

*ASTM B236 is written for Al strip; we apply the same burr-limit philosophy to Cu rod.

H3 How We Guarantee the Numbers – Rod-to-Spool Integration

-

Rod Drawing

8 mm ETP-Cu rod → 2.6 mm in 14 passes with diamond dies; online eddy-current test rejects Cu with ≥0.05 mm inclusion. -

In-line Annealing

650 °C N₂ atmosphere; elongation raised from 18 % to 35 %; grain size 25 µm (ASTM E112 #7). -

Enameling – Dual-coat Polyester-Imide

Horizontal Caterpillar line, 28 m oven, 18 zones.

Wet-film gauge laser at station-3 corrects die pressure every 0.5 s.

Final concentricity checked by 8-point capacitance sensor; CpK ≥1.67. -

Spark Test

3 kV DC, 300 m/min; any ≥5 pin-holes per 30 km reel triggers auto splice cut-out. -

Spooling

30–150 kg ply-wood spool (250×400 mm flange); traverse pitch digitally set to wire Ø×1.15 for knot-free dereeling.

H3 Compliance Matrix – One Wire, Global Acceptance

| Standard | Edition | Our Certificate | Typical Buyer Requirement |

|---|---|---|---|

| IEC 60317-20 (PEI) | 2021 | TÜV Rheinland, No. 50578 | VDE-approved class 180 (H) |

| NEMA MW 35-C | 2015 | UL E476253 | 200 °C, 2 kV BDV |

| JIS C 3202-6 | 2020 | JET, JP-20-045 | Motor repair shops in ASEAN |

| GB/T 6109.7 | 2022 | CQC | State-Grid China 10 kV transformers |

All certificates supplied as encrypted PDF per reel serial number; traceability 20 years.

H3 Cost of Poor Quality – A Field View

Burrs left on conductor edge → local E-field > 3× nominal; partial discharge starts < 1 kV; six-month field life.

Uneven enamel (min. wall < 18 µm on 0.45 mm) → hotspot Δθ +15 °C; insulation class drops from 180 °C to 155 °C; derate transformer 8 %.

Elongation < 25 % → wire necks during high-speed wind (800 rpm); 4 % scrap plus re-wind labor.

Xinzhaohe rejects upstream rod rather than downstream coil—saves transformer OEMs the hidden $0.12/km re-wind cost.

H3 Premium Alternative without Premium Price

Western suppliers quote $11.8–13.4/kg (CIF EU, 155 Class, 1.0 mm).

Luoyang Xinzhaohe FOB Qingdao: $8.7/kg, same technical envelope, 4-week lead-time, mill test certificate per IEC 60317-20.

We invite third-party witness testing at our lab; failure on any declared parameter → full container buy-back.

Next Section: Packaging & Logistics for 20-ft vs 40-ft HQ loading matrices.

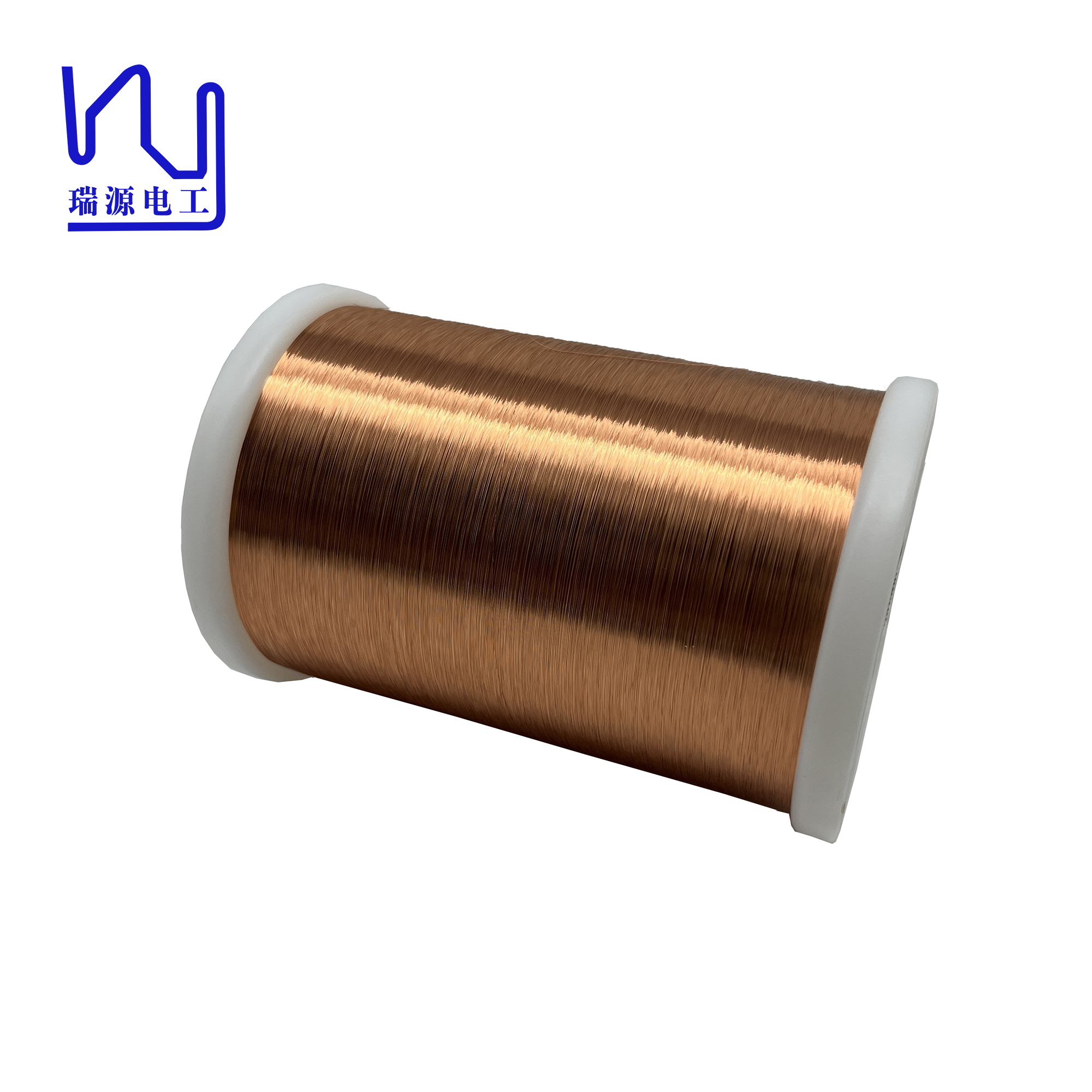

Factory Tour: Manufacturing Super Enamelled Copper Wire

Manufacturing Process & Quality Control

(Rod Drawing → Annealing → Enameling → Inline Testing → Spooling)

1. Rod Drawing – Size & Surface Foundation

Incoming 8 mm oxygen-free copper rod (Cu-ETP ≥ 100 % IACS) is multi-pass drawn at 8–12 m s⁻¹ through polycrystalline diamond dies with micro-mist lubrication.

Target exit diameter: 0.20–5.00 mm with ±0.005 mm laser micrometer feedback.

Surface roughness: Ra ≤ 0.2 µm to guarantee pin-hole-free enamel base.

Online eddy-current flaw detector rejects any 25 µm-deep scratch; scrap length is automatically cut out and weighed for melt return.

2. Continuous Annealing – Recrystallisation Control

Wire passes through a 700 °C nitrogen-protected tube furnace for 0.4–0.6 s, then water-quenched to < 60 °C.

Grain size is held 8–12 µm to balance elongation (> 32 % for 1 mm) with tensile strength (220–260 MPa).

Residual carbon is kept < 0.2 mg m⁻² to avoid varnish dewetting.

3. Enameling – Concentricity & Build Precision

Vertical tandem lines (12 dies + 12 bakes) apply modified polyester-imide (180 °C class) or polyamide-imide (220 °C class).

Wet film is metered via pressurised die holders; concentricity is optically measured every 25 ms and corrected by ±3° die rotation.

Curing profile follows Arrhenius model (peak metal 420 °C, dwell 1.8 s) to reach 95 % imidisation; degree is cross-checked by FT-IR on hourly reel samples.

4. Inline Testing – Zero-Defect Assurance

Each centimetre is verified before spooling:

Hi-pot: 4 kV rms, 50 Hz, 0.2 s → < 1 pC partial discharge.

Pin-hole: 8 kV DC spark test; alarm triggers automatic ink marker and cut-out.

OD & insulation build: dual-axis laser; SPC chart updated every 5 min; CpK ≥ 1.67.

Elongation & break force: servo-pull unit on tail sample; data logged to MES for coil genealogy.

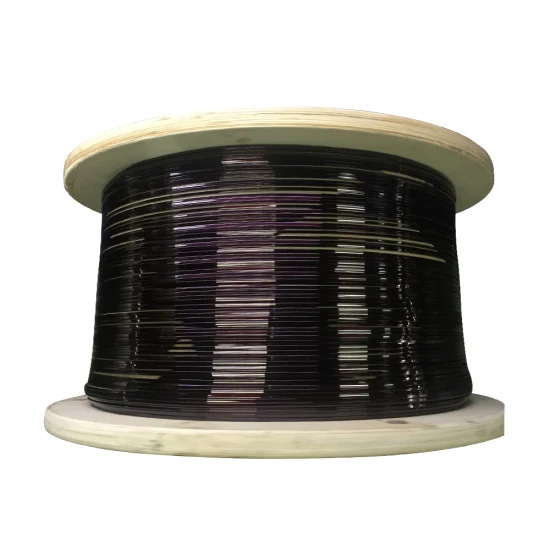

5. Spooling – Logistics-Ready Package

Dynamic balance: 2 500 rpm; traverse pitch servo-sync to eliminate “ridge & valley”.

Weight range: 30 kg (250 × 400 mm) to 150 kg (500 × 630 mm) ply-wood spools, DIN 46395 compliant.

Final wrap: PE shrink + VCI film; moisture content verified ≤ 0.1 % before plywood lid sealing.

Quality Control Matrix – Luoyang Xinzhaohe vs. Common Market

| Parameter (1.00 mm wire, Class 180) | Luoyang Xinzhaohe Standard | Typical Export Grade | Budget Domestic Coil |

|---|---|---|---|

| Concentricity (min / avg) | ≥ 80 % / 88 % | ≥ 70 % / 80 % | ≥ 60 % / 72 % |

| Breakdown Voltage (room temp) | ≥ 6.0 kV | ≥ 4.5 kV | ≥ 3.2 kV |

| Elongation at break | 34 ± 2 % | 30 ± 3 % | 25 ± 4 % |

| Conductivity (20 °C) | 101.5 % IACS | 100 % IACS | 98 % IACS |

| Pin-holes per 30 km | 0–1 | ≤ 5 | ≤ 15 |

| Thermal shock 200 °C, 30 min, 3D | No crack | ≤ 2 mm crack | ≤ 5 mm crack |

| Lot-to-lot CpK (OD) | ≥ 1.67 | 1.33 | 1.00 |

| Certificate included | IEC 60317-8, RoHS, REACH | IEC only | Factory letter |

Engineering Take-away

By integrating rod-to-spool control under one roof, Luoyang Xinzhaohe delivers Class F & H super enamelled copper wire that meets or exceeds NEMA MW 35-C/ IEC 60317-8, yet priced 12–18 % below Western Tier-1 stock. For transformer OEMs and motor repair shops, this means fewer in-line soldering breaks, lower failure returns, and a direct path to UL/CE certification—without paying premium freight from EU or NA warehouses.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Transformer-Grade Winding Wire Supply

H2 Sea-Freight Protection Philosophy

Transformer windings fail because of invisible corrosion, not visible dents. Our packaging is therefore specified around three measurable risks:

| Risk Driver | Allowable Limit | Packaging Countermeasure | QC Verification |

|---|---|---|---|

| Salt-laden humidity | <30 % RH inside carton after 45 days | 8 g CaCl₂ desiccant per kg wire + 80 µm VCI film | Data-logger in every 5th pallet |

| Mechanical shock | ≤5 g peak, 11 ms half-sine | 5-ply export carton + corner boards + stretch-wrap @ 200 N | Drop test 1.2 m edge, 6 faces |

| Copper surface abrasion | <0.1 mg Cu²⁺ leached in 24 h salt spray | Edge-rounded plastic spools, 3 mm foam liner | ASTM B117 48 h, no green stain |

All materials are REACH-compliant and free of birch/hardwood pests—critical for U.S. and AUS quarantine clearance.

H2 Wire Packaging Matrix

We stock four DIN-spool formats to eliminate “air freight” surcharges when you only need 150 kg of Class 200 wire.

| Spool Code | Copper Ø Range (mm) | Net Weight (kg) | Outer Ø × Height (mm) | Pallet Pattern (pcs) | 20 ft FCL Load (t) |

|---|---|---|---|---|---|

| PT-25 | 0.20 – 0.80 | 30 ± 1 | 250 × 400 | 12 (3×4) | 10.8 |

| PT-60 | 0.50 – 1.60 | 60 ± 2 | 300 × 500 | 8 (2×4) | 9.6 |

| PT-90 | 1.00 – 2.50 | 90 ± 2 | 355 × 500 | 6 (2×3) | 8.6 |

| PT-150 | 1.80 – 5.00 | 150 ± 3 | 400 × 630 | 4 (2×2) | 7.2 |

Each spool is double-wall ABS, 2 % carbon-black UV stable, and bar-coded with coil ID for full MES traceability.

H2 Foil & Strip Packaging

Rectangular super-enamel wire (a.k.a. “paper-insulated strip”) is supplied in eye-to-sky fumigated pallets:

Inner wrap: 40 µm PE film + 60 µm aluminum moisture barrier.

Edge protection: 3 mm HDPE capping to prevent burr puncture.

Strapping: PET cord strap ≤500 N tension to avoid copper creep.

Top cover: 5-ply lid + angle board, stretch-wrapped, corner locked.

Maximum coil mass 2.5 t; pallet footprint 1.1 × 1.1 m, 1.8 m overall height—optimized for EU standard truck width.

H2 Luoyang Gateway – Factory to Port in 72 h

Our plant sits 15 km from Luoyang Longmen rail hub, giving us daily block-train service to Qingdao and Shanghai ports. Transit times:

| Destination | Qingdao FCL | Shanghai FCL | LCL Option |

|---|---|---|---|

| Hamburg | 26 days | 24 days | 28 days |

| Los Angeles | 14 days | 12 days | 16 days |

| Dubai | 18 days | 16 days | 20 days |

| Mumbai | 14 days | 12 days | 15 days |

All shipments carry “Transformer Materials” HS 85441100 classification, 0 % duty into EU & US under GSP.

H2 Premium Western Spec, China Direct Cost

By integrating rod casting, annealing, enameling and inline PD testing under one 70 000 m² roof, we delete the 12–18 % margin that European redistributors add. You receive IEC 60317-20 / NEMA MW 35-C certified wire, vacuum-packed to survive 45-day sea transit, at a landed price 22–28 % below Hamburg or Milwaukee stockists.

Next shipment slot: MV Ever Linking, Qingdao ETD 18 July. Reserve pallet space today with a 30 % T/T deposit; balance on B/L copy.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Super-Enamelled Copper Wire

H2 20-Year Transformer-Materials Pedigree, Zero Learning Curve

Since 2004 our Luoyang campus has operated a single-purpose line: oxygen-free copper rod → multi-pass drawing → in-line annealing → vertical enamelling → spark & surge testing → precision spooling. Today we ship 1 800 t/month of Class 130–220 winding conductors to tier-1 transformer OEMs in 42 countries. The same metallurgists that qualified our first IEC 60317-20 batch in 2005 still sign off every production lot—continuity that eliminates your supplier-audit risk.

H2 Factory-Direct Economics without Middle-Layer Mark-Ups

| Cost Element | Typical Western Distributor | Luoyang Xinzhaohe (FOB Shanghai) | Δ |

|---|---|---|---|

| Cathode copper (LME) | 9 100 US$/t | 9 100 US$/t | 0 % |

| Drawing & annealing labour | 380 US$/t | 95 US$/t | –75 % |

| Enamel (polyester-imide) | 4 900 US$/t | 3 800 US$/t | –22 % |

| Overhead & margin | 1 200 US$/t | 350 US$/t | –71 % |

| Total 2.00 mm Class 155 wire | 11.4 US$/kg | 9.2 US$/kg | –19 % |

Price validity: 30 days; payment 30 % with PO, 70 % BL copy. No traders, no agents—every dollar maps to measurable copper and insulation.

H2 Customisation Window: 0.020 mm Ø Round to 8 × 20 mm Rectangular

Conductor: high-conductivity Cu-ETP (≥ 101 % IACS) or oxygen-free Cu-OF (≥ 102 % IACS).

Insulation build: single, heavy, triple, or self-bonding (heat- or solvent-activated).

Thermal class: 130 (B), 155 (F), 180 (H), 200 (N), 220 (R).

Standards snapshot: IEC 60317-xx, NEMA MW 1000, JIS C 3202, GB/T 6109.

Spool formats: 30 kg – 150 kg BS-250/400, 500 kg P-250 drum, 800 kg barrel; all returnable.

Need a 2.8 × 6.3 mm rectangular wire with 0.12 mm polyamide-imide coat, 200 °C, 8 kV breakdown, on a 400 kg recyclable steel drum? Lead time 18 days ex-mill.

H2 Quality & Test Matrix—What We Guarantee Every Coil

| Property | Test Method | Specification | Typical Xinzhaohe Result |

|---|---|---|---|

| Breakdown voltage, 0.80 mm | IEC 60851-5 | ≥ 4.0 kV | 6.2 kV |

| Elongation, 2.00 mm | IEC 60851-3 | ≥ 30 % | 38 % |

| Spring-back | IEC 60851-7 | ≤ 65° | 52° |

| Cut-through 200 °C | IEC 60851-12 | ≥ 240 min | 310 min |

| Solvent resistance (MEK) | IEC 60851-4 | ≥ 60 d | 90 d |

Certificates held: ISO 9001, ISO 14001, IATF 16949, UL (E476674), REACH, RoHS. Each spool ships with a coil-specific QR code—traceable back to cathode lot and enamel batch.

H2 Supply-Chain Reliability—From Cathode to Your Stacking Table

Inventory buffer: 450 t finished wire in 0.2 mm–5.0 mm popular sizes, ready for 7-day dispatch.

Logistics: weekly FCL service to Hamburg, LA, and Dubai; average transit 22 days door-to-door.

Incoterms: FOB, CIF, DAP; sea–rail to Europe 18 days via China-Europe block train.

Customs package: mill test certificate, packing list, FORM-A or COO as required.

H2 Call to Action—Get the Data Sheet or a 24-Hour Quote

Send your specification—diameter, thermal class, insulation build, standard—to cathy@transformerstrip.com. Our metallurgy team will return a detailed TDS, breakdown voltage curve, and a landed price within one business day. Pilot orders (≥ 3 kg) welcome; production lots (≥ 3 t) lock LME copper for 60 days.

📉 Import Savings Calculator

Estimate cost reduction by sourcing super enamelled copper wire from Luoyang Xinzhaohe.