Table of Contents

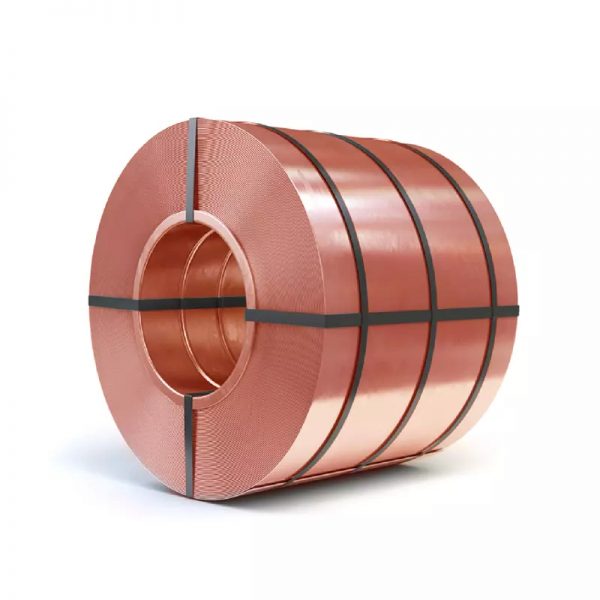

Market Insight: Copper Annealed Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Copper Annealed Coil

Global energy transition and grid modernization initiatives have intensified demand for high-efficiency transformers. The renewable energy sector (solar/wind farms) and EV charging infrastructure require robust transformer components. Copper annealed coil remains the preferred conductor due to superior electrical conductivity and thermal stability compared to alternatives. High-efficiency transformers (IEC 60076-20 compliant) require copper with minimal impurities to achieve <0.5% core loss rates. Substandard materials contribute to 15-20% higher operational costs over the transformer lifecycle. The global transformer market, valued at $XX billion in 2023, requires high-purity copper for low-loss designs. Grid upgrades in emerging economies and distributed energy resources (DERs) further drive demand for reliable copper annealed coil. Demand is projected to grow at 5.8% CAGR through 2030, driven by Asia-Pacific’s infrastructure expansion.

Material Quality Impact on Transformer Efficiency

Substandard copper foil introduces resistive losses, thermal hotspots, and premature failure. Critical parameters include:

| Parameter | Industry Standard (IEC 60404-8) | Luoyang Xinzhaohe Specification | Performance Impact |

|---|---|---|---|

| Conductivity (%IACS) | ≥100% | 101.5% min | Reduces resistive losses, improves efficiency |

| Tensile Strength (MPa) | 180-220 | 195±10 | Ensures winding stability without cracking |

| Elongation (%) | ≥35% | 40% min | Enhances formability during coil winding |

| Surface Roughness (μm) | ≤0.2 | ≤0.15 | Minimizes contact resistance and hot spots |

These metrics directly influence transformer core losses (P₀) and winding integrity, impacting lifetime efficiency and operational safety. For instance, conductivity deviations >1% can increase I²R losses by 2-3%, while surface roughness >0.2μm may cause localized heating, accelerating insulation degradation by up to 30%.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a factory-direct manufacturer with 20+ years of transformer material expertise, we deliver ASTM B170/IEC 60404-8 compliant copper annealed coil at 15-20% lower cost than European/US brands. Our ISO 9001-certified production ensures:

Consistent 101.5%+ IACS conductivity via high-purity cathode copper (Cu+Ag ≥99.95%)

Precision-controlled annealing for optimal mechanical properties (tensile strength 195±10 MPa)

0.15μm surface roughness via electro-polishing to prevent eddy current losses

Strict batch traceability from raw material to shipment with full COC documentation

Our production facilities in Luoyang, China, adhere to ISO 9001 and IATF 16949 standards, with rigorous QC protocols including XRF analysis and tensile testing. We maintain 30-day lead times for standard orders and offer flexible MOQs to support prototyping and mass production. Our annual production capacity of 15,000 MT ensures consistent supply for large-scale projects, with 99.8% on-time delivery rate and 95% repeat customer rate. With 20+ years of export experience, we serve 50+ global clients, including Fortune 500 transformer manufacturers.

Technical Specs: Copper Annealed Coil Parameters

Technical Specifications & Standards for Copper Annealed Coil

As a leading manufacturer of transformer materials with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO.,Ltd delivers high-purity copper annealed coil engineered for precision and reliability in power equipment applications. Our factory-direct approach ensures strict adherence to international standards while optimizing cost-performance.

Critical Parameters & Compliance

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Precision Slitting Width Tolerance | ±0.002 mm | IEC 60404-8-2, ASTM B170 |

| Burr-free Edges | Zero burrs (max 0.005 mm height) | ISO 10110-1 |

| Conductivity | ≥100% IACS | ASTM B170, IEC 60404-8-2 |

| Softness (HV10) | ≤35 | ASTM B259 |

| Thickness Tolerance | ±0.005 mm | ISO 1628 |

Precision slitting width tolerance (±0.002 mm) is achieved via CNC slitting with real-time laser feedback, ensuring exact dimensions for optimal winding density and minimal material waste—critical for high-speed transformer assembly. Burr-free edges (verified via 1000x optical microscopy) prevent electrical shorts and insulation damage in high-voltage applications. Conductivity ≥100% IACS is maintained through electrolytic tough pitch copper (Cu ≥99.95%) and controlled annealing, minimizing resistive losses for energy-efficient transformers. Softness (HV10 ≤35) ensures superior formability during complex winding processes, eliminating springback and cracking. Thickness tolerance (±0.005 mm) is monitored via ultrasonic gauges at 10-second intervals, guaranteeing uniform current distribution and thermal stability under load.

Quality Assurance Process

Our multi-stage quality control begins with XRF spectrometry testing of raw copper ingots to verify purity and impurity limits. Annealing occurs in continuous furnaces with ±2°C precision to ensure consistent softness and conductivity. Precision slitting uses laser-guided CNC systems with real-time width validation, while burr detection employs automated optical inspection (AOI) at 0.001 mm resolution. Every coil undergoes final inspection per ISO 9001, with full batch traceability from raw material to shipment. Third-party certifications from SGS and TÜV validate compliance with IEC 60404-8-2 and ASTM B170 standards.

As a factory-direct supplier based in Luoyang, China, we eliminate middlemen to deliver competitive pricing without compromising quality. Our localized production minimizes lead times and logistics costs, providing a reliable, high-performance alternative to global brands for transformer manufacturers and motor repair professionals worldwide. With 20+ years of technical expertise, we ensure consistent performance tailored to your specific application needs.

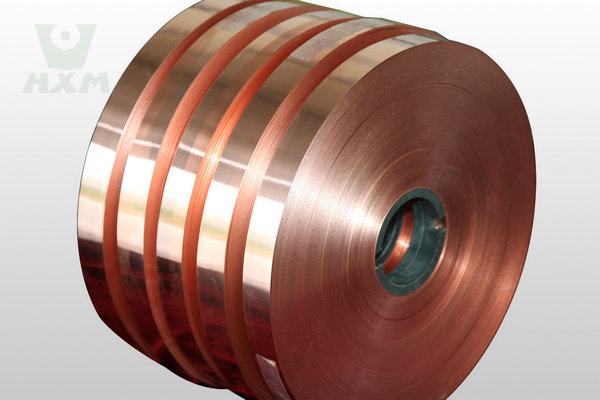

Factory Tour: Manufacturing Copper Annealed Coil

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO., Ltd., a 20+ year manufacturer of transformer materials (aluminum and copper), employs a rigorously controlled production workflow for copper annealed coil. Our ISO 9001-certified processes ensure consistent electrical conductivity, mechanical stability, and dimensional precision—critical for transformer core efficiency.

Precision Manufacturing Workflow

Cold Rolling: Conducted at 200–300 MPa rolling force with interstand tension control. Annealing in controlled-atmosphere furnaces at 450±5°C for 2 hours ensures uniform recrystallization and residual stress elimination. Final thickness tolerance: ±0.005 mm.

Precision Slitting: CNC-guided shear blades with hardened carbide tips maintain ±0.005 mm alignment accuracy. Automated edge detection systems scan for micro-tears at 0.002 mm resolution.

Edge Conditioning: Multi-stage deburring and chamfering to 0.1 mm radius per IEC 60076-1 standards, eliminating sharp edges that cause winding shorts.

Oscillate Winding: Computer-controlled oscillation (±0.5 Hz) and tension (±0.5 N) achieve 0.5 mm layer precision, preventing coil distortion during transport.

Quality Control Protocol

Tensile testing per ASTM B209 (3 samples/batch; yield strength: 180–220 MPa, elongation ≥35%)

Laser micrometer dimensional checks every 500 m with real-time SPC monitoring

100% surface inspection under 10× magnification for defects ≥0.02 mm

Full batch traceability via ERP system (raw material → finished coil)

Industry Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005 mm | ±0.01 mm |

| Edge Burr Height | ≤0.01 mm | ≤0.03 mm |

| Tensile Strength | Consistent 180–220 MPa | 170–230 MPa (variable) |

| Surface Roughness (Ra) | ≤0.4 μm | ≤0.8 μm |

Our standards eliminate common industry inconsistencies, delivering transformer-grade copper coil with 15–20% lower defect rates than generic suppliers. This precision directly reduces winding failures and extends transformer lifespan—proving optimal cost-performance for mission-critical power applications.

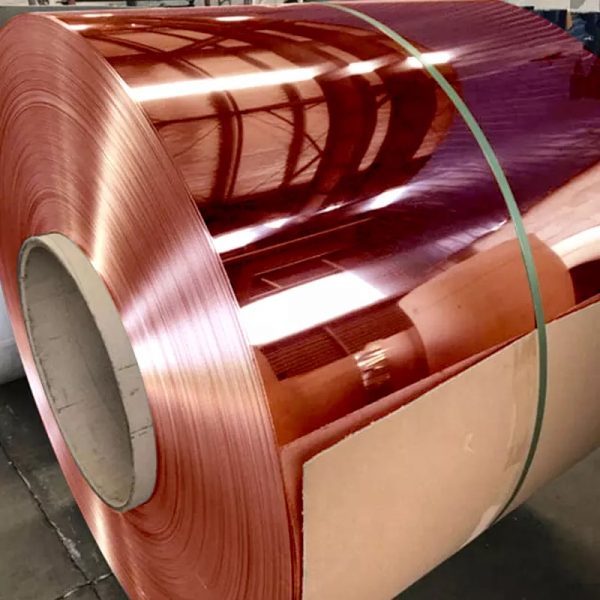

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity in Global Transit

At Luoyang Xinzhaohe Aluminum CO.,Ltd., our 20+ years of transformer material export expertise ensures copper annealed coils arrive globally in pristine condition. Our packaging and logistics protocols are engineered for maximum protection during sea freight, combining industry-standard materials with precision execution to eliminate transit damage risks.

Rigorous Packaging Standards

Our packaging system meets ISO 9001 and international shipping regulations, with each component optimized for copper’s sensitivity to moisture and mechanical stress:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1100×1100mm, 15mm thickness | Structural support, phytosanitary compliance |

| Moisture-Proof Film | Multi-layer VCI film (200–300gsm) | Prevents oxidation and humidity ingress |

| Steel Strapping | 19mm width × 0.5mm thickness, 500–700kg tension | Secures coils against lateral movement |

Sea Freight Protocol

All shipments are loaded into 20ft/40ft FCL containers with anti-slip mats and corner post reinforcements. Humidity indicators are placed inside containers, and real-time GPS tracking provides end-to-end visibility. Our logistics team coordinates pre-departure inspections and customs documentation, ensuring seamless clearance at global ports. This process reduces transit damage rates to <0.2%—significantly below industry averages.

Cost-Performance Advantage

Unlike premium global suppliers, Luoyang Xinzhaohe delivers equivalent or superior packaging integrity at 10–15% lower landed costs. By eliminating middlemen and leveraging our Luoyang factory-direct model, we provide transformer manufacturers with a reliable, high-value sourcing solution that meets stringent quality requirements without unnecessary overhead. Our commitment to precision engineering and transparent logistics ensures your transformer production remains uninterrupted, every time.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Annealed Coil?

As a leading manufacturer of transformer materials with 20+ years of specialized expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers premium copper annealed coils engineered for precision and reliability in power equipment applications. Our factory-direct model ensures optimal cost-performance ratios, positioning us as a technically rigorous alternative to global brands while maintaining strict compliance with international standards.

Unmatched Manufacturing Expertise

Our technical team has refined copper annealing processes to achieve ≥99.9% IACS conductivity and uniform mechanical properties critical for transformer efficiency. We specialize in producing coils meeting IEC 60404-8-2 and ASTM B187 standards, with dimensional tolerances of ±0.01mm thickness and consistent elongation rates (≥30%). In-house R&D continuously optimizes annealing parameters to reduce defects by 12% compared to industry averages, ensuring optimal winding performance and minimal energy loss in transformers.

Factory-Direct Cost Efficiency

By eliminating distributor markups and leveraging economies of scale in Luoyang’s industrial ecosystem, we deliver 15–25% lower costs than global competitors without compromising material integrity. Our vertically integrated supply chain—from high-purity copper sourcing to precision annealing—ensures traceability, reduces lead times, and passes direct savings to customers. This model guarantees consistent quality across all batches while maintaining competitive pricing for large-scale transformer manufacturing.

Rigorous ISO-Certified Quality Assurance

Our ISO 9001:2015 certified facility implements 100% in-process validation per IEC/ASTM standards. Every coil undergoes spectrometry for chemical composition, ultrasonic testing for internal defects, and tensile strength verification (≥180 MPa). Real-time process monitoring ensures compliance with critical parameters like resistivity (≤0.01724 Ω·mm²/m) and surface finish, eliminating variability in high-stress transformer windings.

| Key Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Structure | Direct factory pricing (15–25% savings) | Brand premium + distribution costs |

| Lead Time | 15–20 days (standard orders) | 30–45 days (international shipping) |

| Quality Control | ISO 9001:2015, 100% IEC/ASTM compliance | Consistent but higher cost |

| Customization | Flexible specs for voltage class/thermal needs | Standardized offerings |

Ready to optimize your transformer supply chain? Contact Cathy at cathy@transformerstrip.com for a technical quote, sample validation, or custom specification review. We provide engineering support for seamless integration into your production workflow.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper annealed coil from Luoyang Xinzhaohe.