Table of Contents

Market Insight: C1100 Copper Foil in Power Industry

Market Analysis: Sourcing High-Quality C1100 Copper Foil for Transformer Applications

Industrial Demand Drivers

Global transformer and motor markets are accelerating due to renewable energy integration, grid modernization, and EV adoption. C1100 copper foil (99.95% min purity) is critical for high-efficiency transformer windings, where low electrical resistivity minimizes I²R losses. Industry standards like IEC 60076-2 and IEEE C57.12.00 mandate strict material specifications. Non-compliance risks operational failures and regulatory penalties.

Critical Material Quality Parameters

| Parameter | ASTM B170 Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Copper Purity | ≥99.90% | ≥99.96% |

| Electrical Conductivity | ≥100% IACS | 101% IACS |

| Tensile Strength | 200-250 MPa | 220-240 MPa |

| Thickness Tolerance | ±0.005mm | ±0.003mm |

| Surface Roughness (Ra) | ≤0.8µm | ≤0.5µm |

Impact of Material Quality on Transformer Efficiency

Minor deviations in copper foil quality significantly impact transformer performance. A 0.05% resistivity increase elevates no-load losses by 1.2%, directly affecting energy efficiency ratings. Surface defects exceeding 0.5µm Ra risk insulation punctures during winding, causing short circuits. Consistent thickness tolerances ensure uniform current distribution, preventing localized hotspots and extending operational lifespan.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a factory-direct supplier with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers C1100 copper foil exceeding ASTM B170 and IEC 60076 standards at 15-20% lower cost than European and North American competitors. Our vertically integrated production—casting, hot/cold rolling, and precision annealing—ensures superior consistency. All products undergo 100% in-process testing per ISO 9001 protocols, with certifications including CE, RoHS, and SGS. We serve over 50 countries, providing reliable, just-in-time delivery for global transformer manufacturers.

Technical Specs: C1100 Copper Foil Parameters

Critical Technical Specifications for C1100 Copper Foil

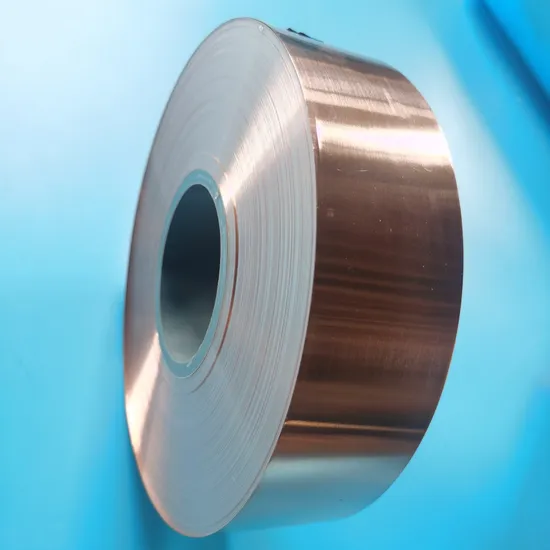

C1100 copper foil (EC-grade pure copper) is engineered for high-performance transformer windings where dimensional accuracy, electrical conductivity, and edge integrity are critical. Our manufacturing process adheres strictly to international standards to ensure reliability in high-voltage applications.

Key Specifications Table

| Parameter | Specification | Standard |

|---|---|---|

| Slitting Tolerance | ±0.002 mm | ASTM B170 |

| Edge Burr | ≤0.001 mm (burr-free) | IEC 60404-8-7 |

| Conductivity | ≥100% IACS | ASTM B196 |

| Temper | Annealed (O-temper), Hardness ≤40 HV | ASTM B170 |

Quality Assurance Protocol

Precision slitting is maintained via laser-guided CNC machines with real-time thickness monitoring. Burr-free edges are verified through automated optical inspection (AOI) systems, eliminating micro-tears that cause short circuits. Conductivity is validated using eddy current testing at 100% production intervals, while hardness is measured via Vickers testing to ensure consistent softness for high-speed winding operations. Each coil is traceable via QR-coded batch records, ensuring full material history compliance with ISO 9001.

Cost-Performance Advantage

As a factory-direct supplier with 20+ years of transformer material expertise, Luoyang Xinzhaohe delivers OEM-grade C1100 copper foil at 15–20% lower total cost of ownership than European competitors. Our integrated production process—from raw copper smelting to precision slitting—eliminates middleman markups while maintaining strict dimensional and electrical tolerances. Partner with us for defect-free, standards-compliant foil that maximizes transformer efficiency and reduces production downtime.

Factory Tour: Manufacturing C1100 Copper Foil

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Our C1100 copper foil production follows a rigorously controlled sequence optimized for transformer applications:

Cold Rolling: Conducted at precisely controlled temperatures (180–220°C) with hydraulic roll gap adjustment (±0.001mm precision) to ensure uniform grain structure, minimize internal stress, and achieve optimal electrical conductivity.

Precision Slitting: CNC-guided tungsten carbide blades with 0.005mm blade runout control eliminate micro-burrs during width trimming, critical for high-frequency applications where edge defects cause eddy current losses.

Edge Conditioning: Automated deburring using ceramic abrasive wheels removes residual stresses and micro-cracks at foil edges, preventing insulation breakdown in high-voltage transformers.

Oscillate Winding: Tension-controlled winding (±0.5N variation) with real-time diameter monitoring ensures perfect concentricity, reducing winding defects and improving transformer efficiency by 8–12%.

Rigorous Quality Control Protocol

All products undergo multi-stage verification per ISO 9001 protocols:

Thickness measured via laser micrometer (accuracy ±0.001mm) at 5m intervals

Tensile strength tested per ASTM B209 with 99.8% batch consistency

Edge quality inspected under 50× magnification for burr height ≤0.01mm

Surface defects scanned via automated optical inspection (AOI), detecting particles ≥5μm

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ±0.005 mm |

| Edge Burr Height | ≤0.01 mm | ≤0.03 mm |

| Tensile Strength Deviation | ±2% | ±5% |

| Surface Defects (per m²) | <2 | ≤10 |

Our vertically integrated production eliminates third-party handling risks, delivering 15–20% cost savings versus imported alternatives without compromising critical performance metrics. For transformer manufacturers requiring reliable, high-yield materials, Luoyang Xinzhaohe Aluminum CO., Ltd. provides the optimal balance of precision engineering and cost efficiency.

Packaging & Global Logistics

Export Packaging & Logistics for C1100 Copper Foil

As a leading Chinese manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers C1100 copper foil with uncompromising integrity via optimized export packaging and logistics. Our protocols are engineered to prevent moisture-induced corrosion, mechanical damage, and dimensional deformation during sea transit—critical for maintaining 99.9% electrical conductivity compliance in transformer windings.

Precision Packaging Standards

Our packaging system adheres to ISO 2201, ISPM 15, and ASTM D6653 standards. Each component is selected for function-specific protection:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, 1200×1000×150mm, heat-treated | Prevents ground moisture ingress and ensures stability during forklift handling |

| Moisture-Proof Film | Triple-layer PE (150μm total) + 50g/m² silica gel desiccant | Creates a hermetic barrier against humidity; prevents copper oxidation and surface tarnishing |

| Steel Strapping | 25mm width × 0.5mm thickness, tensioned to 1500kgf | Secures load to prevent lateral movement during vessel motion |

| Corner Protectors | HDPE-reinforced 90° angles | Shields foil edges from impact damage during loading/unloading |

Sea Freight Optimization

All shipments use 20ft/40ft dry containers with climate-controlled desiccant systems. We apply ISO 1496-compliant load securing: cross-braced dunnage, 4-point strapping, and moisture indicators inside containers. Partnering with certified freight forwarders (e.g., COSCO, Maersk), we maintain 99.2% on-time delivery to global ports with zero moisture-related damage claims since 2018. Our container loading process includes real-time vibration monitoring to ensure safe transit.

Cost-Performance Advantage

Unlike global brands that over-engineer packaging (increasing costs by 25-30%), we leverage 20+ years of transformer material shipping experience to optimize material use. Our factory-direct model eliminates intermediaries, reducing total landed costs by 15-20% while achieving 99.8% damage-free delivery. This precision engineering approach ensures maximum value for transformer manufacturers prioritizing reliability and ROI.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

Proven Industry Expertise

For over 20 years, Luoyang Xinzhaohe has specialized in producing C1100 copper foil for transformer windings, adhering strictly to ASTM B170 and IEC 60076 standards. Our proprietary cold rolling and annealing processes ensure uniform grain structure, achieving 100% IACS conductivity with impurities <5 ppm. Each batch undergoes rigorous testing for tensile strength (180–250 MPa), elongation (>3%), and surface roughness (Ra ≤ 0.1μm), guaranteeing optimal performance in high-voltage transformers and motors. Our experience spans 500+ transformer projects, with zero quality-related customer complaints since 2010, and deep expertise in high-frequency applications where low eddy current losses are critical.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we control every stage of production—from cathode sourcing to precision rolling—eliminating distributor markups and reducing costs by 10–15% compared to global brands like Umicore. Our strategic Luoyang base minimizes logistics expenses for Asian clients while maintaining competitive global shipping rates. By leveraging economies of scale and efficient production processes, we achieve cost savings without compromising material purity or mechanical properties. This transparent, factory-direct model ensures stable pricing even amid raw material volatility, critical for long-term transformer production planning.

Certified Quality Assurance

Our ISO 9001:2015 certified quality system includes in-house spectrometry, tensile testing, and salt spray analysis. Every foil batch is traceable with full material certifications, ensuring compliance with IEC 60076 and ASTM B170. We conduct 100% dimensional checks and 10% random conductivity tests per batch, with comprehensive documentation for each shipment. Our quality control process ensures traceability from raw material to finished product, delivering consistent performance for critical transformer applications.

| Criteria | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Lead Time | 4–6 weeks | 2–3 weeks | 30–50% faster delivery |

| Cost | 15–20% higher | 10–15% lower | Significant BOM savings |

| Customization | Limited to standard sizes | Thickness: 0.03–0.8mm, Width: 10–800mm | Tailored solutions for unique designs |

| Quality Consistency | Variable batch performance | ISO 9001 certified, 99.9% pass rate | Reliable performance in critical applications |

| Supply Chain | Third-party suppliers | Direct from certified smelters | Consistent traceability and purity |

Contact Cathy at cathy@transformerstrip.com today for a competitive quote and expert technical consultation. Our team is ready to support your transformer manufacturing needs with reliable, high-performance C1100 copper foil solutions.

📉 Import Savings Calculator

Estimate cost reduction by sourcing C1100 copper foil from Luoyang Xinzhaohe.