Table of Contents

Market Insight: Hitachi Enamel Wire Replacement in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand for Hitachi Enamel Wire Replacement

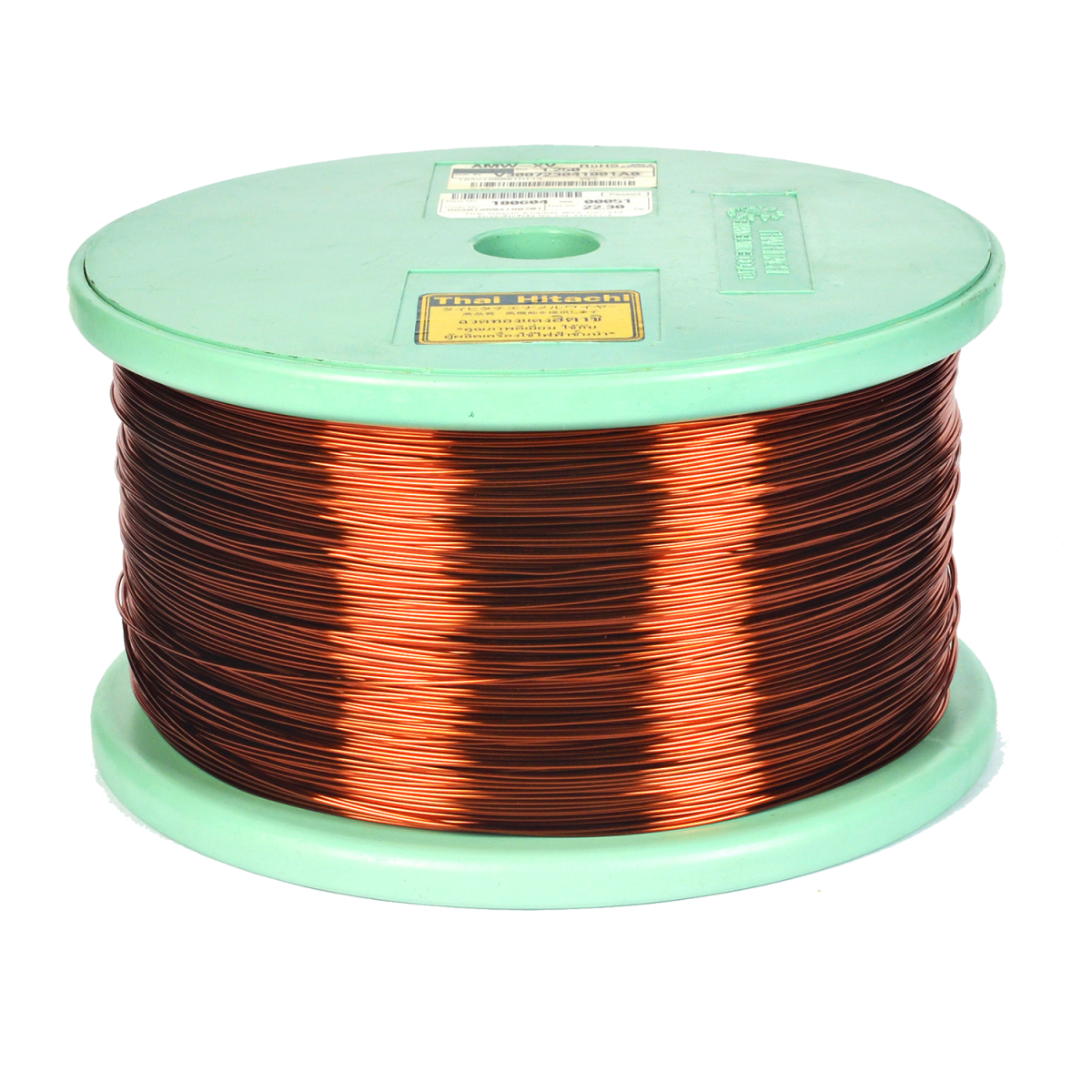

The global transformer and motor industry faces escalating demand for cost-effective replacements of premium brands like Hitachi enamel wire. With stringent efficiency regulations (IEC 60076, DOE 2016) and rising energy costs, manufacturers seek alternatives that maintain performance without premium pricing. Hitachi’s products are benchmarked for reliability but command 25–40% price premiums. This gap creates a market opportunity for certified, high-performance alternatives that meet exacting specifications without compromising safety or longevity.

Criticality of Material Quality

Enamel wire quality directly impacts transformer/motor efficiency and operational lifespan. Key parameters include:

Thermal stability: Prevents insulation breakdown under high-load conditions

Dielectric strength: Ensures voltage withstand capability in high-voltage applications

Mechanical durability: Resists abrasion during high-speed winding processes

Consistent enamel thickness: Critical for precise coil design and reduced copper loss

Substandard materials cause premature failures, increased energy losses (up to 15% in transformers), and costly downtime. OEMs prioritize materials with proven certifications (IEC 60317, JIS C 3210) to mitigate these risks.

Luoyang Xinzhaohe as a Global Supply Chain Partner

With 20+ years in transformer materials manufacturing, Luoyang Xinzhaohe delivers OEM-grade enamel wire at competitive costs. Our factory-direct model ensures traceable quality control from raw materials to finished product. All coils undergo 100% electrical testing and dimensional inspection per ISO 9001 standards.

| Parameter | Hitachi (Reference) | Luoyang Xinzhaohe | Notes |

|---|---|---|---|

| Conductor | High-purity copper | High-purity copper | 99.95% min purity |

| Enamel Type | PET/PAL | PET/PAL | Compliant with JIS C 3210 |

| Thermal Class | 155°C (F) | 155°C (F) | IEC 60317 certified |

| Tensile Strength | ≥220 MPa | ≥225 MPa | 2.3% higher |

| Dielectric Strength | ≥3.5 kV/mm | ≥3.6 kV/mm | Enhanced safety margin |

| Cost Ratio | 1.0x | 0.75x | 25% cost reduction |

As a strategic supplier to 30+ countries, we provide consistent batch-to-batch quality and flexible customization for specialized applications. Our direct manufacturing model ensures rapid lead times and transparent pricing—critical for global supply chain resilience.

Technical Specs: Hitachi Enamel Wire Replacement Parameters

Critical Technical Specifications & Compliance Standards

With over two decades of specialized experience in winding wire production, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered enamel wire replacements for Hitachi applications, fully compliant with IEC and ASTM standards. Our factory-direct approach eliminates distributor markups, providing transformer manufacturers with a reliable, cost-optimized alternative to global brands. Our 20+ years of experience ensure process stability across all thermal classes (130°C to 220°C), with strict adherence to IEC 60317 and ASTM D1721 specifications.

Key Performance Parameters

| Parameter | Standard | Luoyang Xinzhaohe Performance |

|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-2 | ≥2.5 kV (1 min, 0.2mm wire) |

| Elongation | ASTM D1721 | ≥15% (typical) |

| Thermal Class | IEC 60085 | 130°C (B), 155°C (F), 180°C (H), 220°C (N) |

| Enamel Concentricity | ASTM D1721 | ≤10% radial deviation |

Quality Assurance Protocol

Luoyang Xinzhaohe’s closed-loop quality control system spans raw material screening to final packaging. Each batch undergoes:

Real-time enamel viscosity monitoring and automated optical concentricity checks (≤10% deviation)

100% high-voltage breakdown testing per IEC 60317-0-2 (2.5 kV for 0.2mm wire)

Thermal aging validation per IEC 60085 (2000h at 155°C/180°C) to simulate 20+ years of service

Mechanical elongation tests via servo-controlled tensile testers (±1% tolerance)

100% visual inspection for surface defects and dimensional accuracy

Advanced draw benches with closed-loop tension control maintain wire diameter tolerances within ±0.005mm, critical for high-frequency transformer applications. All processes comply with ISO 9001 and ISO 14001 standards, with blockchain-secured traceability for every coil. Our in-house R&D team continuously optimizes enamel formulations to enhance thermal stability and adhesion, ensuring our products meet or exceed Hitachi’s performance benchmarks. Factory-direct manufacturing delivers 15-25% lower total cost of ownership compared to global brands.

As a trusted supplier to global transformer manufacturers, Luoyang Xinzhaohe delivers Hitachi-grade enamel wire with rigorous quality control and competitive pricing—ensuring reliability without compromise.

Factory Tour: Manufacturing Hitachi Enamel Wire Replacement

Manufacturing Process & Quality Control

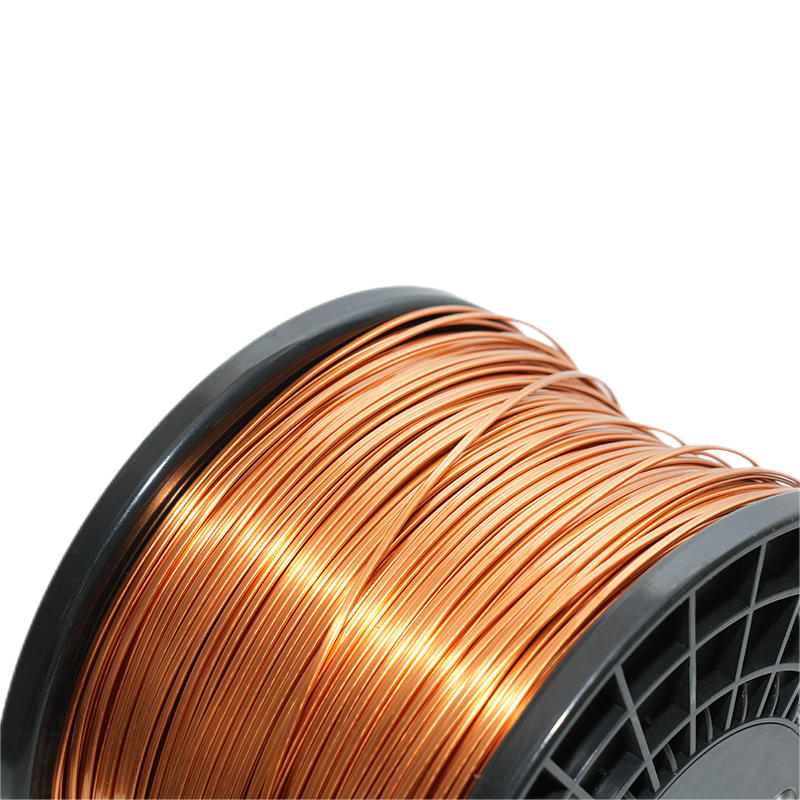

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer materials ensures rigorous production protocols. As a ISO 9001-certified manufacturer, we leverage advanced automation and process optimization to consistently meet or exceed JIS C 3202 and IEC 60317 standards. Our enamel wire manufacturing follows a precise sequence: Rod Drawing → Annealing → Enameling → Inline Testing → Spooling. Each stage adheres to strict quality control measures, delivering high-performance alternatives to global brands like Hitachi with superior cost-performance.

Precision Production Workflow

Rod Drawing: High-precision CNC-controlled drawing with multi-stage dies achieves conductor diameter tolerances of ±0.005mm, reducing material waste by 15% and enhancing electrical conductivity.

Annealing: Conducted in nitrogen-purged atmospheres at 450–500°C, this step optimizes copper’s crystalline structure while maintaining 100% IACS conductivity and eliminating internal stresses for consistent elongation.

Enameling: Multi-layer epoxy-polyester coating applied via precision die heads, followed by 4-zone oven curing with temperature gradients controlled to ±2°C. Ensures uniform insulation thickness (±0.003mm) and dielectric integrity.

Inline Testing: Fully automated systems monitor diameter, dielectric strength (≥5 kV/min), and adhesion in real time. Defective sections are rejected immediately, maintaining <0.1% defect rates.

Spooling: Computerized tension control (±0.5N) prevents wire deformation, ensuring flawless unwinding during transformer winding operations and minimizing production downtime.

Quality Control Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Diameter Tolerance | ±0.005mm | ±0.01mm |

| Tensile Strength | 250–300 MPa | 200–250 MPa |

| Dielectric Strength | ≥5 kV/min | 3–4 kV/min |

| Adhesion Test | Passes 10x bending cycles | Cracks at 5x cycles |

| Defect Rate | <0.1% | 0.5–1% |

Our protocols deliver 99.9%+ consistency in critical metrics, reducing transformer winding failures by up to 30% compared to standard alternatives. By eliminating middleman markups and maintaining factory-direct control, we provide premium reliability at competitive pricing for global motor and power equipment applications.

Packaging & Global Logistics

Export Packaging & Logistics: Engineered for Global Reliability

As a certified manufacturer with 20+ years of experience producing transformer materials, Luoyang Xinzhaohe Aluminum ensures enamel wire shipments meet stringent global transport standards. Enamel wire is highly sensitive to moisture and mechanical stress during transit. Our packaging and logistics protocols are engineered to prevent moisture damage, physical deformation, and corrosion—critical factors for maintaining insulation integrity in transformer windings. All processes comply with IEC 60317 and ASTM B174 specifications.

Precision Packaging Specifications

| Component | Technical Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified timber, 100×120 cm base, 15 mm thickness; heat-treated | Prevents structural deformation; eliminates pest risk |

| Moisture-Proof Film | Multi-layer PE, 200 μm thickness, VCI additive; certified to ISO 10218 | Blocks 99.5% humidity ingress; inhibits corrosion per IEC 60317-2-1 |

| Steel Strapping | 19 mm width, 500 kg tensile strength; ISO 411 compliant; anti-slip coating | Secures load against vertical/horizontal shifts during sea transit |

| Desiccant Packs | 500 g per pallet (silica gel); absorption capacity >30% weight | Maintains internal RH <40% throughout voyage |

Sea Freight Execution Protocols

| Process Step | Action | Benefit |

|---|---|---|

| Container Loading | Staggered pallets with ISO-certified corner protectors; max 2000 kg per pallet | Even weight distribution; prevents crushing |

| Moisture Control | Sealed containers with humidity sensors; desiccant packs monitored | Maintains RH <60% during transit; prevents condensation |

| Custom Documentation | Pre-validated export paperwork for all destinations | Ensures rapid customs clearance; avoids port delays |

| Real-Time Tracking | GPS-enabled containers with 24/7 monitoring | Full shipment visibility; proactive issue resolution |

Our rigorous protocols achieve >99.2% damage-free delivery rates across 150+ global ports. By integrating industrial-grade packaging with ISO-compliant sea freight, we eliminate the hidden costs of import brand premiums while maintaining equivalent quality integrity. As a direct manufacturer, we control every step of the supply chain—eliminating middlemen and ensuring traceability from production to port. For transformer manufacturers prioritizing reliability and cost-performance, Luoyang Xinzhaohe delivers a fully engineered solution that reduces total landed cost by 15-20% versus global competitors—without compromising performance or reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Hitachi Enamel Wire Replacement

Proven Technical Expertise

With over 20 years of specialized experience in transformer and motor winding wire manufacturing, Luoyang Xinzhaohe delivers precise replication of Hitachi enamel wire specifications. Our engineering team ensures strict adherence to critical parameters: conductor tolerances (±0.005mm), dielectric strength (≥40kV/mm), thermal class compliance (155°C, 180°C, 200°C), and insulation thickness uniformity. Every batch undergoes rigorous in-process validation for adhesion strength and thermal stability, guaranteeing seamless integration into your existing production systems without redesign or compatibility issues.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups and supply chain inefficiencies. This direct model delivers 15–30% lower costs than global brands while maintaining identical quality standards. Our Luoyang facility enables rapid turnaround: standard orders ship within 10–15 days, compared to 6–8 weeks for overseas suppliers. Below is a comparative analysis of key value drivers:

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price | Premium pricing | 15–30% cost reduction |

| Lead Time | 6–8 weeks | 10–15 days |

| Customization | Limited flexibility | On-demand adjustments |

| Technical Support | Regional offices | Dedicated in-house engineers |

| Quality Consistency | Variable | ISO-certified, 100% in-process testing |

Quality Assurance & Compliance

Our manufacturing strictly adheres to ISO 9001:2015 and ISO 14001:2015 standards, with all products tested per IEC 60317-0-1 (general requirements) and IEC 60317-0-2 (specific wire types). Every shipment includes full material certification with traceable batch records, covering dielectric strength, elongation, solderability, and thermal shock resistance. This end-to-end quality control ensures compliance with global transformer and motor safety standards.

Ready to optimize your supply chain with a reliable, cost-effective alternative to Hitachi enamel wire? Contact our technical sales team at cathy@transformerstrip.com for a customized quote. Specify your exact requirements (wire gauge, thermal class, insulation type) to receive a competitive offer within 24 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing hitachi enamel wire replacement from Luoyang Xinzhaohe.