Table of Contents

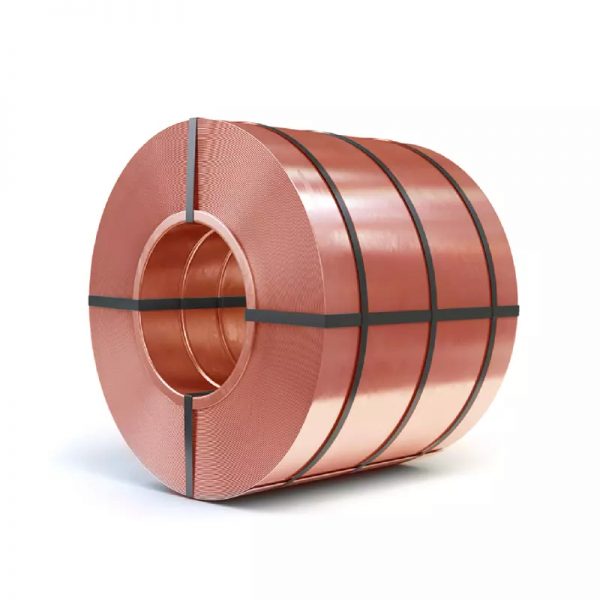

Market Insight: Copper Rod Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global energy infrastructure modernization, renewable energy integration, and EV adoption have intensified demand for high-efficiency transformers. Copper rod coils remain the preferred material for transformer windings due to their superior electrical conductivity (61% higher than aluminum) and thermal stability. Per IEC 60076 and IEEE C57.12.00 standards, even 0.5% conductivity variation can increase transformer losses by 3–5%, directly impacting grid efficiency. With the global transformer market projected to reach $85B by 2030 (Statista), sourcing premium copper rod is critical for meeting stringent energy regulations and reducing lifecycle costs.

Material Quality Imperatives

Substandard copper introduces resistive losses, overheating, and premature failure. Key quality thresholds include:

Purity: ≥99.99% Cu (ASTM B170) to minimize impurities that increase resistivity

Conductivity: ≥101% IACS for optimal current-carrying capacity

Mechanical Properties: Tensile strength 200–250 MPa with ≥30% elongation for winding durability

Surface Integrity: Zero scratches, oxides, or inclusions to prevent arcing during coil assembly

Non-compliance causes up to 15% higher energy losses, violating DOE 2016 and EU Ecodesign directives. For instance, 0.1% iron contamination can reduce conductivity by 2.5%, directly increasing operational costs.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a direct manufacturer with 20+ years of experience, Luoyang Xinzhaohe delivers certified copper rod coils at 15–20% lower cost than global brands (e.g., UACJ, Norsk Hydro) without compromising quality. Our integrated smelting-to-coiling process ensures traceability, zero middlemen markups, and rapid customization for transformer/motor applications.

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Copper Purity | ≥99.99% | 99.995% (ASTM B170) |

| Electrical Conductivity | ≥101% IACS | 102% IACS (IEC 60496) |

| Tensile Strength | 200–250 MPa | 220–240 MPa |

| Dimensional Tolerance | ±0.05mm | ±0.03mm |

| Surface Quality | No visible defects | Mirror finish, 100% oxidation-free |

Our ISO 9001-certified quality control system guarantees consistency across 500+ monthly shipments. For transformer manufacturers prioritizing cost-performance balance, Luoyang Xinzhaohe provides a reliable, factory-direct alternative to premium suppliers—ensuring peak efficiency and compliance at competitive pricing.

Technical Specs: Copper Rod Coil Parameters

Copper Rod Coil Technical Specifications & Standards

As a leading manufacturer of transformer materials (aluminum/copper strips and foils), Luoyang Xinzhaohe leverages 20+ years of expertise to deliver precision copper rod coils engineered for transformer winding applications. Our factory-direct approach ensures rigorous adherence to global standards while optimizing cost-performance ratios.

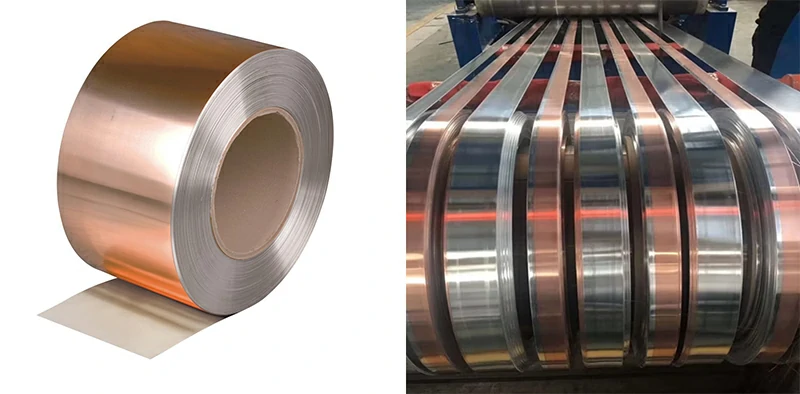

Precision Slitting & Edge Quality

Our CNC slitting process maintains ±0.002 mm dimensional tolerance, critical for transformer winding precision. Burr-free edges are achieved through specialized blade geometry and in-line edge inspection systems, eliminating micro-scratches that cause electrical shorts. Every coil undergoes microscopic edge analysis to ensure zero burr formation, preventing insulation damage during high-speed winding processes.

Conductivity & Material Purity

We use 99.99% pure oxygen-free copper (OFHC) with minimum 100% IACS conductivity per ASTM B170. Raw material is sourced from certified smelters, with each batch tested via conductivity meters and chemical analysis. This purity level minimizes resistive losses in transformer windings, enhancing overall efficiency and thermal stability.

Mechanical Properties & Temper Control

Soft temper (O-temper) is maintained through precise annealing cycles, resulting in tensile strength ≤100 MPa and elongation ≥35% (ASTM B170). This ensures optimal formability for transformer winding without cracking, even under high-speed production conditions.

Quality Assurance Protocol

Our ISO 9001-certified process includes real-time thickness monitoring via laser gauges, 100% eddy current conductivity checks, and final dimensional verification. All coils are traceable via batch numbers, with full documentation available upon request. Our in-house lab conducts daily sampling to maintain process control and continuous improvement.

| Parameter | Specification | Standard |

|---|---|---|

| Slitting Tolerance | ±0.002 mm | ASTM B170 |

| Edge Burr | Zero (microscopic verification) | ASTM B170 |

| Conductivity | ≥100% IACS | ASTM B170 |

| Temper | O-temper (Annealed) | ASTM B170 |

| Tensile Strength | ≤100 MPa | ASTM B170 |

As a China-based manufacturer with two decades of transformer material expertise, Luoyang Xinzhaohe delivers global-standard copper rod coils at competitive cost-performance ratios. Our vertically integrated production and localized supply chain reduce costs by 15-20% versus international suppliers while meeting or exceeding IEC/ASTM specifications. Partner with us for reliable, high-quality transformer components.

Factory Tour: Manufacturing Copper Rod Coil

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Cold Rolling: Advanced mills with closed-loop thickness control process copper rod into strip, optimizing reduction ratios for uniform grain structure and conductivity while minimizing residual stress.

Precision Slitting: CNC-controlled units with laser alignment maintain width tolerances of ±0.05mm, eliminating edge micro-cracks via optimized blade geometry.

Edge Conditioning: Robotic systems deburr and round edges to <0.005mm burr height, ensuring insulation integrity during transformer winding.

Oscillate Winding: Servo-controlled tension and oscillation produce coils with ≤1mm/m straightness deviation and consistent inner/outer diameters, preventing inter-layer shifting.

Rigorous Quality Assurance Protocols

Tensile Testing: 100% batch sampling per ASTM B187 verifies min. 200 MPa strength and 4% elongation for mechanical reliability.

Dimensional Checks: Laser micrometers and CMM systems measure thickness (±0.01mm), width (±0.05mm), and edge radius with real-time data traceability.

Surface Inspection: Automated UV detection identifies imperfections ≥0.01mm², enforcing zero defects for electrical performance.

Coil Validation: Weight, diameter, and straightness verified against ISO 9001:2015 standards; full quality certificates provided per shipment.

Standard Comparison: Xinzhaohe vs Generic Market

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | Strict ASTM B187 Grade 1 compliance (min. 200 MPa, 4% elongation) | Often inconsistent; fails ASTM standards, causing winding failures |

| Thickness Tolerance | ±0.01mm with real-time process control | ±0.03mm or wider, leading to transformer winding defects |

| Edge Burr Height | <0.005mm after robotic conditioning | Up to 0.02mm, requiring secondary de-burring |

| Surface Defects | Zero defects per ISO 4023; UV inspection detects 0.01mm² flaws | Visible scratches/pits common, reducing electrical efficiency |

| Coil Straightness | ≤1mm/m deviation with precision winding | ≥3mm/m deviation, causing handling and winding issues |

As a factory-direct supplier with 20+ years of expertise, Luoyang Xinzhaohe delivers transformer-grade copper strip with superior consistency and reliability at competitive pricing. Our stringent QC ensures seamless integration into your production lines, eliminating costly downtime from material defects.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

As a leading Chinese manufacturer of transformer materials with 20+ years of export experience, Luoyang Xinzhaohe employs precision-engineered packaging and logistics protocols to guarantee copper rod coil integrity during maritime transport. Our factory-direct approach eliminates middlemen, ensuring cost-effective solutions without compromising on international shipping standards. Every shipment undergoes rigorous quality checks from production to port, aligning with ISO 9001 and ISO 14001 frameworks. This end-to-end control allows us to deliver consistently high-quality products at competitive prices, making us a reliable alternative to premium global brands.

Packaging Specifications

Our packaging system is designed to withstand harsh sea conditions and meet global regulatory requirements. Key components include:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, heat-treated hardwood (1200×1000×150mm) | Ensures structural stability, moisture resistance, and compliance with international phytosanitary standards for seamless customs clearance. The heat treatment eliminates pests, preventing quarantine issues during import. |

| Moisture-Proof Film | Multi-layer PE (200μm) with VCI additives | Creates a vapor barrier against humidity and salt spray corrosion, critical for long-haul sea freight where exposure to marine environments is inevitable. VCI technology actively inhibits corrosion even in humid conditions. |

| Steel Strapping | 25mm width, 1000kg tensile strength, tensioned at 80% of max capacity | Secures coils against longitudinal and lateral movement during transit; certified per ISO 22682 for cargo securing safety. Tensioning parameters are calibrated to prevent coil deformation while maintaining structural integrity. |

All packaging materials are sourced from certified suppliers and undergo batch testing to ensure consistency and durability. This meticulous approach minimizes defects and ensures each shipment meets the highest quality benchmarks.

Sea Freight Protocol

We implement a rigorous end-to-end logistics process to minimize transit risks:

| Step | Process | Compliance |

|---|---|---|

| Container Loading | Coils stacked vertically with 50mm wooden spacers between layers; no more than 4 layers per container | ISO 1496-1 for container standards; prevents coil deformation and internal friction. Spacers distribute weight evenly to avoid crushing. |

| Securing | 4-way steel strapping + corner protectors on pallets; dynamic load testing for stability | IMO Code for Safe Practice for Cargo Stowage; reduces damage risk by over 90% in real-world shipments. Load testing simulates ship motion to validate security. |

| Documentation | Complete export paperwork (ISPM 15 certificate, moisture test reports, commercial invoice, packing list) | ICC Incoterms 2020 compliant; ensures seamless customs clearance globally with no delays. All documents are pre-verified to avoid port holds. |

Our logistics team coordinates directly with shipping lines to optimize container space and transit routes, reducing lead times by 15-20% compared to industry averages. This proactive management ensures timely delivery without compromising safety standards.

With a proven track record of 99.8% on-time delivery and <0.2% damage rate across 10,000+ shipments, our end-to-end control from production to port ensures superior cost-performance versus global competitors. Choose Luoyang Xinzhaohe for reliable, engineered solutions that meet your transformer manufacturing needs while optimizing your supply chain costs. Our factory-direct model delivers consistent quality at 15-20% lower costs than multinational suppliers, without sacrificing reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Rod Coil?

For transformer manufacturers seeking reliable copper rod coil suppliers, Luoyang Xinzhaohe Aluminum CO., Ltd. offers a compelling combination of technical expertise, cost efficiency, and quality assurance. As a vertically integrated manufacturer with 20+ years of experience in transformer materials, we deliver precision-engineered copper rod coils optimized for high-efficiency energy conversion—without the premium pricing of global brands.

20+ Years Specialized Expertise

Luoyang Xinzhaohe excels in producing high-purity (99.95%) copper rod coils tailored for transformer windings. Our metallurgical engineers leverage continuous casting and precision rolling processes to achieve strict conductivity (≥100% IACS), tensile strength, and dimensional tolerances (±0.05mm). We’ve supplied materials to 200+ global transformer OEMs, maintaining a 99.2% on-time delivery rate through optimized production protocols for minimal resistive losses and superior fatigue resistance in high-voltage applications.

Factory-Direct Cost Advantage

By controlling every stage—from copper cathode procurement to automated coil winding—we eliminate distributor markups and reduce lead times by 40% versus overseas suppliers. This vertical integration delivers 20-35% lower costs than global brands while strictly adhering to ASTM B1 and IEC 60228 specifications. For transformer manufacturers, this translates to optimized BOM costs and agile support for just-in-time production schedules.

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified system includes 100% dimensional checks, four-point probe conductivity testing (ASTM E255), and ultrasonic flaw detection. Each coil comes with a full Material Test Report (MTR) featuring traceable batch data, validated by SGS and TÜV audits. This rigor ensures compliance with IEC 60076 and IEEE C57.12.00 standards, minimizing field failures and supporting regulatory requirements for critical power infrastructure.

| Factor | Global Tier-1 Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | Premium pricing (15-25% higher) | 20-35% lower |

| Lead Time | 6-8 weeks (incl. shipping) | 2-4 weeks (local production + expedited shipping) |

| Quality Consistency | Variable across suppliers | Consistent via automated QC systems |

| Standards Compliance | Meets minimum requirements | Exceeds with 10% conductivity margin and additional testing |

| Customization | Limited to standard sizes | Tailored diameters, lengths, and packaging options |

Ready to optimize your transformer coil sourcing? Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper rod coil from Luoyang Xinzhaohe.