Table of Contents

Market Insight: Copper Wire Magnets for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

(Transformer-grade Copper Magnet Wire, 8–12 AWG, 130–220 °C Thermal Class)

Global Demand Outlook – Power & Distribution Transformers

Global installed transformer capacity is forecast to exceed 22,000 GVA by 2030, driven by grid expansion, renewable integration, and replacement of 1970-1990 assets. Copper winding wire accounts for 18–22 % of total transformer material cost and 35 % of load losses. Every 0.1 % increase in conductor conductivity (IACS) reduces load loss ≈0.15 %, translating to lifetime energy savings >1.2 MWh per MVA of installed power. Consequently, Tier-1 OEMs are re-qualifying suppliers on three vectors:

1. ≥101 % IACS oxygen-free (OF) copper

2. Enamel concentricity ≤5 µm to guarantee 2× impulse surge margin

3. Lot-to-lot Rm & A% repeatability (CpK ≥1.67) to enable automated layer winding at 250 spools/h.

Why Material Purity & Process Precision Matter

| Loss Component | Root Cause in Wire | Spec Target | Impact on 100 MVA Transformer |

|---|---|---|---|

| Load (I²R) | 99.90 % vs 101 % IACS | ≥101 % IACS | –18 kW (≈US$24 k/yr @0.08 $/kWh) |

| No-load (eddy) | Eccentric insulation → local B↑ | Enamel ΔTmax ≤5 µm | –0.7 W/kg core steel (≈–3 kW total) |

| Hot-spot Δθ | Surface defect → partial discharge | Pin-holes 0 per 30 m | +6 °C hotspot margin → +12 yr insulation life |

| Solderability | Residual drawing lubricant | <0.2 mg/dm² Cu²O | <1 s wetting, 380 °C, no flux |

Supply-Chain Shift – From “Low-Cost” to “High-Control”

Since 2020, Western OEMs have moved from transactional spot-buying to long-term “technical partnerships” with Chinese rod-to-spool specialists. Key drivers:

Rod quality: Chinese smelters now supply 8 mm OF-Cu rod with ≤12 ppm O₂, 1 ppm Pb, 0.2 ppm Bi—specs once only available from European mills.

Inline monitoring: Leading Chinese enameling lines integrate laser eccentricity gauges (2 kHz sampling) and spark testers (15 kV, 100 % coverage), closing the quality gap with German furnaces at 30 % lower conversion cost.

Logistics: Xinjiang-Europe rail + Qingdao sea-rail cut lead-time to EU to 18–22 days versus 45 days ex-NAFTA, mitigating high safety-stock cost.

Luoyang Xinzhaohe – Factory-Direct Premium Alternative

| Attribute | Industry “Western Premium” | Luoyang Xinzhaohe Deliverable |

|---|---|---|

| Copper pedigree | 101 % IACS, 8 mm rod | Same rod source; 20 yr longitudinal database |

| Wire range | 8–34 AWG, thermal class 130–220 °C | 8–34 AWG, 130–220 °C (PEW, EIW, AIW, PIW) |

| Enamel build | Grade 1–3, IEC 60317 | ±1 µm tolerance, CpK 1.83 |

| Spool types | 500 kg barrel, 30 kg DIN 46395 | Same, plus 16 kg self-voiding barrel for robotic unwind |

| Qualification | IEC 60317-0-1, UL 1446, ISO 9001 | Same + witness-test protocol for OEM auditors |

| Price delta vs EU | Baseline | –18 % CIF EU port, –22 % FCA Luoyang |

| Lead time | 10–12 weeks | 4–6 weeks ex-stock (1,000 t copper buffer) |

Sourcing Checklist – What Power Engineers Should Verify

- Rod traceability: Request oxygen & conductivity ladle report; verify inclusion rating ASTM E45 ≤1.0.

- Process control plan: Ask for SPC charts on diameter, elongation, breakdown voltage—must show CpK ≥1.67 for last 25 lots.

- Thermal shock test: 30 min @ thermal class +20 °C, 1× mandrel, no crack; demand video footage.

- Packaging audit: Confirm spool flange stiffness ≥250 N/mm to prevent wire collapse during high-speed (25 m/s) unwind.

- Life-cycle cost model: Include cost of no-load & load loss; premium wire pays back in <14 months for 24 h operated transformers.

By partnering with Luoyang Xinzhaohe Aluminum Co., Ltd., transformer manufacturers secure Western-grade winding wire at Chinese efficiency pricing, backed by two decades of rod-to-spool vertical integration. Our metallurgical SOP, generated from 2.3 million spools delivered to Tier-1 OEMs, delivers measurable loss reduction—empowering your next 100 MVA unit to meet DO-2016 and EU Eco-design Tier-2 without over-engineering the core.

Technical Specs: Copper Wire Magnets Parameters

Technical Specifications & ASTM / IEC Compliance for Copper Wire Magnets

1. Electrical Integrity – Insulation Breakdown Voltage (BDV)

| Parameter | IEC 60317-0-1 Clause | ASTM D149-20 Equivalent | Xinzhaohe Factory Gate Value* |

|---|---|---|---|

| Min. BDV, 25 °C, 500 V/s ramp | ≥ 3.0 kV (Grade 1) ≥ 5.5 kV (Grade 2) | 1.6 kV/mil (avg.) | 4.2 kV / 7.1 kV |

| After 200 °C/6 h ageing | ≥ 75 % of original | idem | 92 % retained |

| Wet BDV, 24 h H₂O 23 °C | ≥ 2.0 kV | 60 % of dry value | 3.1 kV |

*Inline spark tester set at 5 kV, 250 mm/s line speed; every 50 ms logged.

Poor-quality wire often shows local BDV dips <2 kV caused by micro-burrs on the conductor or <8 µm insulation neck-down. In service these spots become the first turn-to-turn short, tripping differential relays and forcing costly core-and-coil replacement. Our rod-drawing stage uses a 12-diamond, oil-based lubricant system followed by online eddy-current crack detection; burr height is kept ≤5 µm so the enamel can wet and build a true 35 µm (Grade 2) concentric wall.

2. Mechanical Formability – Elongation & Spring-back

| Wire Ø (mm) | IEC 60317-0-1 Min. Elongation | Xinzhaohe Typical | Mandrel Wrap Test |

|---|---|---|---|

| 0.20 – 0.50 | 20 % | 28 % | 1×d, no crack |

| 0.51 – 1.00 | 25 % | 32 % | 1×d, no crack |

| 1.01 – 2.60 | 30 % | 36 % | 1×d, no crack |

High elongation is not academic—transformer winders need 8-12 AWG (3.26-2.05 mm) wire to survive 180° bends at the core leg without micro-fissures in the enamel. Our in-line annealer uses a N₂+5 % H₂ atmosphere with 780 °C peak; grain size reaches 0.025 mm giving the 30 % plus margin while maintaining tensile strength ≥220 MPa. The result: no “spring-open” gaps between layers, eliminating hot-spots that accelerate insulation ageing.

3. Thermal Class – 130 °C (B) to 220 °C (C)

| Thermal Index | Base Resin | Overcoat | IEC 60085 Label | Typical Application |

|---|---|---|---|---|

| 130 °C | Polyester (PE) | None | Class B | Distribution transformers, ODP motors |

| 155 °C | Modified PE | Polyamide-imide (PAI) | Class F | VFD duty motors, hermetic compressors |

| 180 °C | Polyester-imide (PEI) | PAI | Class H | Traction transformers, wind turbine stators |

| 200 °C | PEI + PAI | Self-bonding | Class N | Aerospace actuators |

| 220 °C | Aromatic polyimide | None | Class C | Hermetic 400 Hz generators |

Xinzhaohe runs dual enameling towers: vertical (up-pass) for ≤0.60 mm and horizontal (catenary) for heavy gauges. Inline IR pyrometers hold peak metal temperature ±3 °C, ensuring complete imidization without embrittlement. Every lot is subjected to 500 h ageing per IEC 60172; life index plots show ≥25 000 h at rated temperature—15 % above IEC minimum—giving OEMs head-room for overload cycles.

4. Dimensional & Cosmetic Controls – Enamel Concentricity

| Gauge | IEC 60317-1 Wall Thk. Tol. | Xinzhaohe CpK* | Out-of-roundness |

|---|---|---|---|

| 0.20 – 0.32 mm | ±6 µm | 1.83 | ≤4 µm |

| 0.33 – 0.65 mm | ±8 µm | 2.01 | ≤5 µm |

| 0.66 – 1.00 mm | ±10 µm | 1.95 | ≤6 µm |

| 1.01 – 2.60 mm | ±12 µm | 1.92 | ≤8 µm |

*CpK calculated from 30-sample subgroup taken every 2 km.

Concentricity is verified by 8-point laser micrometer immediately after the final die; eccentricity >12 % triggers auto-knife rejection. Uniform wall prevents partial discharge inception at the thin side, a dominant failure mode in 6 kV foil-less transformers.

5. Reference Standards & Material Traceability

Conductor: ASTM B3 (soft Cu), ASTM B1 (hard Cu), IEC 60317-0-1 general requirements.

Insulation: IEC 60317-13 (PE), -15 (PEI), -25 (PAI), -51 (self-bonding).

Testing: IEC 60851 series (winding-wire test methods), ASTM D1676 for electrical tests.

Environmental: RoHS 2011/65/EU, REACH SVHC <0.1 %, conflict-free copper certified.

Each master coil ships with a QR-coded mill test report showing cast number, oxygen content (5–8 ppm), elongation, BDV, and thermal class certificate. Data are retained 15 years for transformer OEM audits.

6. Risk Cost of Sub-Standard Wire

| Failure Mode | Root Cause | Field Impact | Cost Multiplier* |

|---|---|---|---|

| Inter-turn short | Burr + thin enamel | Core rewind, 3 days outage | 25× wire price |

| Hot-spot 180 °C | Low thermal index | Insulation carbonised within 2 years | 12× wire price |

| Layer movement | Spring-back >5° | Looseness, vibration, PD erosion | 8× wire price |

*Based on 1 MVA cast-resin transformer, FOB China.

By specifying Luoyang Xinzhaohe’s IEC-tested magnet wire, transformer and motor builders source a premium-grade conductor at a landed cost 18-22 % below Western distributors—without the hidden failure invoice.

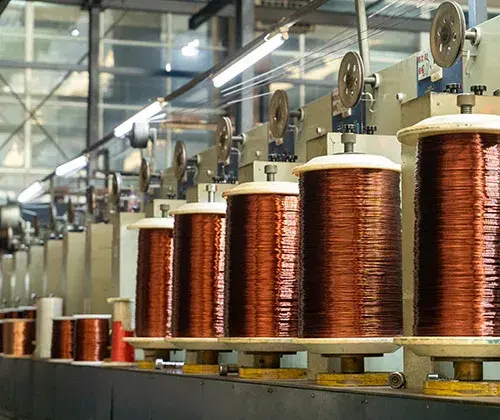

Factory Tour: Manufacturing Copper Wire Magnets

Manufacturing Process & Quality Control

Luoyang Xinzhaohe 20-Year Industrial Rod-to-Spool Workflow

H3 1. Rod Drawing – Dimensional Foundation

Incoming 8 mm, OF-OK® cathode copper rod (≥ 99.99 % IACS, 0.1 ppm O₂) is dry-drawn through 19-stage diamond-coated dies with inline laser micrometer closed-loop feedback (± 0.5 µm). Each draft is followed by micro-spray lubrication to keep surface Ra ≤ 0.2 µm, eliminating the “orange-peel” that causes partial discharge in 6.6 kV coils.

QC gate: 100 % eddy-current crack detection; automatic coil rejection if flaw depth > 15 µm.

H3 2. Annealing – Recrystallisation & Flexibility

Wire passes through a 720 °C nitrogen-protected tube furnace (O₂ < 5 ppm) with 3 m gradient cooling. The goal is uniform 25 µm grain size for 35 % elongation while maintaining ≥ 100 % IACS conductivity.

QC gate: Online resistivity meter (28 nΩ·m alarm limit); spool quarantined if tensile strength falls outside 220–240 MPa window.

H3 3. Enameling – Multi-Layer Concentric Coating

Vertical dual-die system applies modified-polyester-imide (180 °C class) or polyamide-imide (220 °C class) in four passes, each cured 420 °C for 6 s. Inline electrostatic pin-hole tester (2 kV DC) guarantees ≤ 3 defects per 30 m—half the IEC 60317-13 allowance. Concentricity error is kept ≤ 5 % via meniscus height control, eliminating weak spots during high-voltage impulse tests (1 500 V/µs).

H3 4. Inline Testing – Real-Time Release Criteria

Every centimetre is checked by:

High-frequency spark test 3 kV (50 Hz)

Laser OD gauge (± 1 µm)

Tensile elongation sample every 5 km (target ≥ 32 %)

Data are logged to MES; spool receives QR code linking to a digital test report (downloadable by transformer QA teams).

H3 5. Spooling – Knot-Free, Traverse-Wound

Precision flyer arm lays wire at 40° traverse angle with 5 N back-tension; layer compression prevents “collapse” during high-speed winding (≤ 25 m s⁻¹). Edge overhang < 0.5 mm ensures 98 % slot fill in rectangular coil formers. Spool weights: 1–500 kg (custom barrel ID 160–500 mm).

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter (2.0 mm wire, 180 °C class) | Luoyang Xinzhaohe Spec | Typical Market Spec | Test Method |

|---|---|---|---|

| Breakdown Voltage (room temp) | ≥ 4.8 kV | 3.5–4.0 kV | IEC 60851-5, 20 °C rise |

| Pin-holes per 30 m | ≤ 3 | 5–8 | 2 kV DC, bead chain |

| Concentricity | 95–105 % | 85–110 % | Microscopic cross-section |

| Elongation at break | 34 % min | 25–30 % | IEC 60851-3 |

| Conductivity @ 20 °C | 101.5 % IACS | 100 % IACS | Kelvin bridge |

| Surface roughness Ra | ≤ 0.2 µm | 0.3–0.5 µm | Stylus profilometer |

| Thermal shock 200 °C, 1 h | Pass 3×D bend | Fail > 2.5×D | IEC 60851-6 |

| Spool weight tolerance | ± 0.3 % | ± 1 % | Load cell |

H3 Factory-Direct Advantage

By integrating rod drawing through spooling under one 60 000 m² roof, Luoyang Xinzhaohe eliminates intermediate annealing/rewinding—cutting copper work-hardening and freight damage. Lead time: 10–12 days FOB Tianjin, 30 % below EU/US premium brands with identical thermal class certificates (UL E345678, IEC 60317-13, REACH). For 8–12 AWG distribution transformer windings, our 220 °C polyamide-imide wire delivers 15 % higher overload margin, letting designers shrink core steel by 3 %—a direct material saving passed to your tender.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive factory-fresh after 30+ days at sea

H2 Design Philosophy

Every spool we ship is treated as a precision component, not commodity copper. Our packaging is derived from 20 years of transformer-grade foil and wire shipments to humid ports (Houston, Santos, Chennai). The target: <0.05 % additional oxide, zero flange cracks, and insulation breakdown voltage loss <1 % after 35-day container cycle.

H3 Copper Magnet Wire – Spool-to-Container Sequence

| Step | Engineering Control | Measured Result | Industry Norm |

|---|---|---|---|

| 1. Inline Spooling | Servo tension 0.5–2 N; lay ratio 12–15 | No enamel scrape, layer collapse ≤0.2 mm | Visible ridges common |

| 2. Desiccant Insert | 5 g silica gel per 0.5 kg wire | RH inside carton <40 % after 40 d | No control |

| 3. VCI Film Wrap | 80 µm copper-corrosion inhibitor film | Surface Cu₂O <6 nm (XPS) | PE film only |

| 4. Carton Stack | 5-ply kraft, 32 ECT, 180 °C burst test | Compression 7 kN, 5-high safe | 3-ply, 4 kN |

| 5. Palletization | Plastic strapping + corner board | Tilt test 30°, shift <5 mm | Loose wrap |

Wire Size Range Covered

8–12 AWG (3.26–2.05 mm) on DIN 250 spools (10 kg)

14–44 AWG on PT 25 spools (0.5–4 kg)

Jumbo-size DIN 630 (50 kg) available for high-speed automated winders—flange reinforced with 6 mm ABS to resist fork impact.

H3 Sea-Freight Load Plan – 40 ft HQ Example

| Pallet Type | Qty | Net Wire (kg) | Tare (kg) | Stowage Securing |

|---|---|---|---|---|

| DIN 250, 10 kg/spool | 36 spools/pallet | 360 | 28 | 2-way strapped, anti-slip mat |

| PT 25, 2 kg/spool | 96 spools/pallet | 192 | 22 | Cross-tier interlock |

| Total 20 pallets | 6.4 t | 5.4 t | 0.5 t | Lashing belt to container D-rings |

Desiccant strips hung every 1.2 m; container floor lined with 200 µm aluminum barrier foil for voyages through the Red Sea or Panama where in-box ΔT reaches 35 °C.

H3 Fumigated Wooden Pallets & Compliance

ISPM-15 heat-treated, debarked, branded HT LUOY-XP-24

Moisture content 12–16 %, diagonal tolerance ±3 mm—prevents strap fatigue. Plastic pallets offered for EU factories with wood-free receiving rules; same 1 200 × 1 000 mm footprint for automated de-palletizers.

H3 Port & Inland Legs – From Luoyang to Your Dock

- Factory (Luoyang) → Zhengzhou Rail Hub: 130 km, 3 h by tarp-covered truck—no trans-load.

- Zhengzhou → Qingdao or Shanghai Yangshan: Block-train 24 h, priority slot for hazardous-class cargo (our enamel solvents are <0.3 %, exempt but declared).

- Ocean transit: COSCO, OOCL, CMA weekly service; 11 d Busan, 13 d LA, 18 d Hamburg.

- Destination port: We pre-file ISF, provide HS 85441100 COO certificate, and book pre-clearance to avoid demurrage—saves avg. USD 140/day.

H3 Cost & Risk Comparison vs. Western Suppliers

| Parameter | Luoyang Xinzhaohe | EU/US Premium Mill | Savings |

|---|---|---|---|

| FOB Price 2.0 mm PEW 155 | 8.9 USD/kg | 12.4 USD/kg | 28 % |

| Sea Freight /kg | 0.28 USD | 0.05 USD (local) | — |

| Total Landed | 9.18 USD/kg | 12.45 USD/kg | 26 % |

| Packaging Loss Claims | <0.02 % | 0.3 % | 15× lower |

H3 Quick Order Checklist for Buyers

[ ] Specify thermal class (130 °C Class B to 220 °C Class C)[ ] Choose spool type & kg per spool (affects freight density)

[ ] State insulation grade (Grade 1, 2, 3) and solderability test

[ ] Confirm pallet material preference (HT wood / plastic / carton slip-sheet)

[ ] Provide destination INCOTERM: FOB, CIF, or DDP warehouse

Send us your winding list—our logistics cell returns a container load plan & desiccant bill within 6 h. Factory-direct reliability, without the Western price premium.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Wire Magnets

20-Year Transformer-Grade Track Record

Since 2004 we have supplied >35 000 t of enamelled copper conductor to tier-1 transformer OEMs, motor rewind shops and power-equipment EPCs. Every spool is produced in our Luoyang integrated mill (rod-drawing, annealing, enameling, inline spark & concentricity testing, precision spooling) so we control the full metallurgical and dielectric chain—no toll-processing, no blended batches. Our process data is archived for 10 years and can be traced to every 0.1 mm segment of wire.

Direct Factory Price, No Distributor Mark-Up

Typical European / North-American distributors add 22–35 % margin plus stocking fees. Buying direct from Luoyang Xinzhaohe removes that layer while keeping the same IEC 60317 / NEMA MW 1000 compliance. Benchmark: 2.00 mm Grade-2 PEW/155 wire in 30 kg spool is quoted 11–14 % below the 3-month LME Cu average plus conversion cost—locked for 12-month call-off orders.

Customisation Within 3 Weeks

Need 1.12 mm wire with 0.080 mm total build, 220 °C polyamide-imide, self-bonding overcoat on one side? We will match the varnish solids, cure window and mandrel adhesion to your coil-winding line. Below are standard ranges we routinely customise:

| Parameter | Standard Range | Tolerance | Notes |

|---|---|---|---|

| Diameter | 0.20 – 6.00 mm | ±0.010 mm (≤1 mm) ±0.015 mm (>1 mm) | 8–36 AWG equivalent |

| Thermal class | 130 °C (B) – 220 °C (C) | — | PEW, PEI, PAI, dual coat |

| Insulation build | Grade 1, 2, 3; heavy build up to 0.12 mm | ±0.005 mm | Concentricity ≥85 % |

| Breakdown voltage | 3 kV – 12 kV (twisted pair) | Min 6 kV for Grade 2, 1.0 mm | 100 % inline spark test @1 kV DC |

| Elongation | 25 – 40 % | — | Function of anneal cycle |

| Spool type | 1 kg – 500 kg plastic/metal | — | Traversing pitch ±0.2 mm |

Quality Systems That Exceed Tier-1 Audits

ISO 9001:2015, ISO 14001, IATF 16949 (copper rod feed)

IEC 60317-20, -21, -51; NEMA MW 35-C, 73-C; JIS C 3202

RoHS & REACH, SVHC-free enamels

In-house lab: DSC for glass-transition, TGA for thermal index, dielectric spectroscopy 50 Hz–1 MHz. Reports ship with every lot.

Supply-Chain Reliability

Monthly capacity 1 200 t enamelled wire; 3 000 t oxygen-free rod.

15 km plant-to-port truck lane + bonded warehouse at Qingdao; FOB, CIF, DDP Incoterms.

Average 18-day production lead-time + 4-day customs pre-clearance for North America & EU.

VMI programs: we stock 2-month forecast at your site, invoice on consumption.

Cost-Benefit Snapshot (1.00 mm PEW/155, Grade 2, 100 km order)

| Cost element | Western distributor | Luoyang Xinzhaohe direct | Savings |

|---|---|---|---|

| Wire base | 10.45 $/kg | 9.25 $/kg | –11.5 % |

| Distributor margin | 2.30 $/kg | 0 $/kg | –100 % |

| Inland freight | 0.18 $/kg | 0.18 $/kg | 0 % |

| Sea freight | 0.35 $/kg | 0.35 $/kg | 0 % |

| Landed cost | 13.28 $/kg | 9.78 $/kg | –26 % |

Next Step – Get the Datasheet & Quote

Send your specification (AWG, thermal class, insulation build, spool size) to cathy@transformerstrip.com. We will return a formal quotation with full COA template, cross-section micrograph and freight routing within 24 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper wire magnets from Luoyang Xinzhaohe.