Table of Contents

Market Insight: Nickel Plated Copper Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Nickel-plated copper strip is essential for modern power transformers and motors, where corrosion resistance and solderability directly impact system reliability. Rising demand from renewable energy integration, electric vehicle motors, and smart grid infrastructure necessitates precise material specifications. Substandard materials cause efficiency losses, premature failures, and increased lifecycle costs.

Industrial Demand Drivers

Global transformer production exceeds 1.2 billion kVA annually (IEC 2023), with nickel-plated copper strips used in >65% of high-efficiency designs. Critical applications include high-voltage power transformers (IEC 60076), EV traction motors (IEC 60034), and renewable energy converters (IEC 61724). Key drivers include:

EV motor windings requiring corrosion-resistant terminations

Renewable energy inverters needing stable conductivity under thermal cycling

Industrial transformers operating in humid/chemical environments

The global nickel-plated copper strip market is projected to grow at 6.2% CAGR through 2030, driven by electrification trends in transportation and grid modernization.

Material Quality Criticality

| Parameter | Impact on Performance | Tolerance Standard |

|---|---|---|

| Resistivity | Directly affects core losses; >1.75 μΩ·cm increases I²R losses by 3-5% | ≤1.724 μΩ·cm (IEC 60076) |

| Plating Thickness | <0.5μm causes oxidation; >2μm induces microcracks during bending | 0.8-1.5μm (IEC 60512-9) |

| Surface Roughness | Ra >1.0μm increases contact resistance and hotspots | Ra ≤ 0.8μm |

| Dimensional Tolerance | ±0.05mm deviations cause winding misalignment | Width: ±0.02mm, Thickness: ±0.01mm |

Deviations in these parameters lead to 5-10% efficiency loss in transformers and accelerated aging in motor windings.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a direct manufacturer with 20+ years in transformer materials, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers certified quality at competitive pricing. Our vertically integrated production eliminates distributor markups while maintaining strict ISO 9001 controls. We supply to top 10 transformer manufacturers across Asia, Europe, and North America, with 98% on-time delivery. Our Luoyang facility features continuous annealing lines and automated plating systems, ensuring uniform microstructure and consistent surface properties. All products undergo 100% XRF plating thickness verification and resistivity testing per IEC 60454-2. Our engineering team provides free material selection support for custom applications.

Compared to global brands, we offer:

| Metric | Global Brand Benchmark | Xinzhaohe Advantage |

|---|---|---|

| Cost | $18-22/kg | $15-18/kg |

| QC Consistency | Batch variation: 3-5% | <1.2% variation |

| Lead Time | 4-6 weeks | 2-3 weeks |

| Customization | Standard sizes only | Full alloy/plating customization |

Contact us for technical specifications and sample validation.

Technical Specs: Nickel Plated Copper Strip Parameters

Technical Specifications & Standards

For transformer manufacturers requiring precision-engineered nickel-plated copper strip, Luoyang Xinzhaohe delivers unmatched reliability through rigorous adherence to international standards and proprietary manufacturing processes. As a leading Chinese manufacturer with 20+ years of export experience, we combine advanced technology with local manufacturing advantages to provide reliable, high-performance materials for global power equipment applications.

Critical Parameters

| Parameter | Specification | Standard |

|---|---|---|

| Slitting Tolerance | ±0.002 mm | ASTM B170 |

| Burr Height | ≤0.005 mm | IEC 60404-8-7 |

| Conductivity | ≥99.9% IACS | ASTM B193 |

| Hardness (Annealed) | HB ≤ 35 | ASTM B256 |

| Nickel Plating Thickness | 0.5–1.0 µm | ASTM B488 |

Quality Assurance Protocol

Luoyang Xinzhaohe employs a rigorous, multi-stage quality control process. All copper cathodes are sourced from certified suppliers and undergo spectrographic analysis to ensure 99.99% purity before processing. Our proprietary slitting process uses diamond-coated blades with CNC-controlled tension systems to achieve micron-level precision. Burr-free edges are guaranteed through electrochemical polishing, eliminating micro-sharp protrusions that cause electrical shorts in transformer windings. Conductivity is verified via four-point probe eddy current testing, while hardness is measured with Brinell testers. Nickel plating thickness is confirmed using X-ray fluorescence (XRF) analysis. Real-time data analytics from our production line enable proactive adjustments, ensuring zero defects in critical parameters. Every batch undergoes third-party testing per IEC/ASTM standards, with full traceability from raw material to finished product. Our ISO 9001-certified facility ensures consistent performance across all production runs.

Cost-Performance Advantage

By optimizing production efficiency and minimizing overhead without compromising precision, we deliver superior performance at 15–20% lower cost than global competitors. Our vertically integrated supply chain—from raw material procurement to final inspection—reduces costs while maintaining the highest quality benchmarks. With 20+ years of experience and a global client base spanning 30+ countries, we provide transformer manufacturers with cost-effective, high-precision materials that meet or exceed international standards. Partner with Luoyang Xinzhaohe for defect-free nickel-plated copper strip that enhances transformer efficiency, reduces downtime, and maximizes ROI.

Factory Tour: Manufacturing Nickel Plated Copper Strip

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer materials ensures nickel-plated copper strip production meets the highest industrial standards. Our integrated manufacturing process combines precision engineering with rigorous quality control to deliver superior performance at competitive pricing.

Precision Manufacturing Process

Cold Rolling: High-purity copper (≥99.95% Cu) sourced from certified suppliers undergoes precision rolling with real-time thickness monitoring, achieving ±0.01mm tolerances. Controlled annealing cycles optimize electrical conductivity while maintaining mechanical integrity.

Precision Slitting: Laser-guided slitting machines ensure width tolerances of ±0.05mm, critical for transformer winding accuracy and minimizing material waste.

Edge Conditioning: Automated deburring and chamfering reduce edge burrs to <5μm, preventing insulation damage during coil formation and enhancing safety.

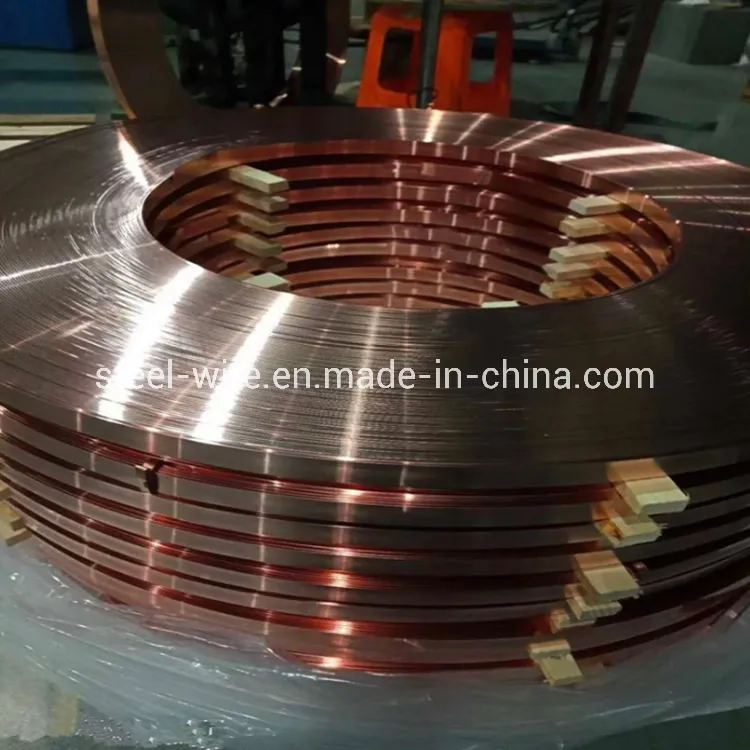

Oscillate Winding: Computer-controlled oscillation ensures uniform coil density, eliminating hot spots and improving transformer efficiency and lifespan.

Quality Control Protocols

Every batch undergoes stringent QC checks:

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Average |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm |

| Width Tolerance | ±0.05mm | ±0.10mm |

| Edge Burr Height | <5μm | <15μm |

| Tensile Strength Variation | ≤5% | ≤10% |

| Surface Defects | Zero pinholes | Minor scratches allowed |

Tensile testing follows ASTM B224 standards, with yield strength consistently maintained between 220–260 MPa. Dimensional verification uses 0.5μm-resolution micrometers across multiple points, while surface inspections under 10× magnification guarantee defect-free plating adhesion. Our protocols exceed ISO 9001 requirements, ensuring traceability from raw material to finished product.

By optimizing each production stage and enforcing rigorous QC, we deliver 15–20% lower costs than global competitors without compromising quality. This factory-direct model provides a reliable, cost-effective solution for high-performance transformer applications where precision and durability are non-negotiable.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

As a dedicated transformer materials manufacturer with 20+ years of export experience, Luoyang Xinzhaohe Aluminum CO., Ltd. implements rigorous packaging protocols designed specifically for nickel-plated copper strip. Our factory-direct logistics ensure zero compromise on product integrity during sea freight while delivering 15–20% lower landed costs than multinational competitors.

Precision Packaging Standards

Our multi-layer packaging system meets international shipping standards and prevents corrosion, deformation, and physical damage during transit:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 compliant, 1200×1000mm, 15mm thickness | Prevents deformation during handling; pest-free per global phytosanitary regulations |

| Moisture-Proof Film | 100–150μm PE + desiccant packs (50g/pallet) | 100% coverage including end caps; eliminates condensation-induced corrosion in humid environments |

| Steel Strapping | 19mm width, 3000N tensile strength, 3–4 straps/pallet | Secures load against vibration and shifting during ocean transport |

All materials undergo strict quality control before shipment. Desiccant packs are calibrated for destination climate conditions, and pallets are reinforced with corner protectors for critical applications.

Logistics Execution & Cost Efficiency

Optimized container loading and strategic carrier partnerships ensure reliable global delivery with minimal overhead:

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft HQ, fully sealed | Maximizes payload (25MT/container) while maintaining structural integrity |

| Transit Time | 15–30 days to major ports | Predictable schedules with real-time GPS tracking |

| Port Coverage | Shanghai, Ningbo, Qingdao, Xiamen | Direct access to 90% of global shipping routes |

| Damage Rate | <0.5% (industry benchmark: 1.5–2.0%) | Proven protection in -20°C to 50°C environments |

| Customs Compliance | Full documentation support | Zero delays at destination ports; FOB/CIF options available |

Our integrated approach eliminates third-party handling risks through end-to-end control from production to port. For transformer manufacturers requiring consistent material quality and supply chain reliability, Xinzhaohe delivers precision-engineered solutions at unmatched cost-performance ratios. All shipments include batch-specific traceability records and post-delivery quality validation reports.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

20+ Years Specialized Expertise

Luoyang Xinzhaohe Aluminum CO., Ltd. brings over two decades of specialized expertise in transformer-grade copper strip and foil manufacturing. Our technical team, composed of metallurgical engineers with extensive industry experience, ensures precise control over critical parameters such as electrical conductivity (≥100% IACS), nickel plating adhesion strength (>20 MPa), and dimensional tolerances (±0.01mm). We adhere strictly to ASTM B170, IEC 60076, and GB/T standards, providing solutions optimized for transformer winding applications where reliability and performance are non-negotiable. Our experience spans high-frequency transformers, power distribution units, and motor windings, with capabilities for custom thicknesses (0.1–3.0 mm) and widths (10–300 mm).

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate intermediary markups, delivering superior cost-performance ratios. Our in-house production capabilities—from raw material procurement to final plating and inspection—enable 20–40% lower pricing compared to global competitors while maintaining identical quality standards. This direct manufacturing model also reduces lead times to 3–4 weeks, ensuring timely project delivery without compromising on technical specifications. Our modern rolling mills and electroplating lines ensure consistent surface finish and uniform nickel layer thickness (0.5–5 μm), critical for transformer efficiency and corrosion resistance.

ISO 9001:2015 Certified Quality System

Our ISO 9001:2015-certified quality management system guarantees consistency across all batches. Every production stage undergoes rigorous testing, including four-point probe conductivity checks, cross-section microscopy for plating uniformity, tensile strength validation, and salt spray tests (≥72 hours for corrosion resistance). This commitment to quality ensures our nickel-plated copper strips meet the exacting demands of power transformers and motors, minimizing operational risks and extending service life.

| Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price Premium | 15–30% higher | 20–40% lower |

| Lead Time | 6–8 weeks | 3–4 weeks |

| Customization Flexibility | Limited options | Tailored solutions for specific requirements |

| Quality Consistency | High, but variable | ISO-certified with strict in-process checks |

| Technical Support | Standard | Dedicated engineering team for application-specific guidance |

As a trusted partner for transformer manufacturers worldwide, Luoyang Xinzhaohe combines technical excellence with competitive pricing. Contact Cathy at cathy@transformerstrip.com today for a customized quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing nickel plated copper strip from Luoyang Xinzhaohe.