Table of Contents

Market Insight: Crgo Steel Sheets in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Drivers

CRGO steel is the backbone of modern power transformers and motors, driven by global mandates for energy efficiency and renewable energy integration. The IEA projects a 40% surge in transformer demand by 2030 due to grid modernization, EV infrastructure, and smart grid deployments. High-grade CRGO (e.g., M4, M5) directly impacts operational costs: a 0.1 W/kg reduction in core loss can save $50,000+ over a 30-year transformer lifecycle. Compliance with IEC 60076 and IEEE C57.12.00 standards further amplifies demand for precision-engineered materials.

Material Quality Impact on Efficiency

Suboptimal CRGO quality elevates hysteresis and eddy current losses, causing excessive heat generation and reduced transformer efficiency. Poor grain orientation or impurities increase core loss by 15–20%, accelerating insulation degradation and shortening equipment lifespan. International standards (IEC 60404-8-5, ASTM A677) enforce strict limits:

Core loss must not exceed 0.90 W/kg at 1.7T/50Hz for M4 grade

Magnetic induction must reach ≥1.90 T

Thickness tolerance must stay within ±0.02 mm

Failure to meet these thresholds compromises Tier 4 efficiency certifications and increases lifetime energy costs by up to 25%.

Why Choose Luoyang Xinzhaohe?

As a 20+ year ISO 9001-certified manufacturer, we deliver CRGO steel that consistently exceeds global standards while optimizing total cost of ownership. Our proprietary grain-oriented technology ensures superior magnetic properties, with rigorous in-process quality control across 12 production stages.

| Parameter | Luoyang Xinzhaohe | Industry Standard | Global Brands |

|---|---|---|---|

| Core Loss (W/kg) | 0.82–0.85 @ 1.7T/50Hz | ≤0.90 | 0.85–0.92 |

| Magnetic Induction (T) | 1.92–1.94 | ≥1.90 | 1.90–1.93 |

| Thickness Tolerance | ±0.01 mm | ±0.02 mm | ±0.015 mm |

| Cost Efficiency | 15–20% lower | — | — |

Our factory-direct model eliminates distributor markups, ensuring 30-day lead times and compliance with regional regulations (e.g., EU CE, US UL). With shipments to 30+ countries and custom grade support (M3–M6), we provide a reliable, high-performance alternative to legacy suppliers.

Technical Specs: Crgo Steel Sheets Parameters

Critical Technical Specifications for CRGO Steel Sheets

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers CRGO steel sheets engineered for optimal transformer efficiency and longevity. Our specifications strictly comply with international standards while exceeding industry benchmarks in key metrics.

Key Specifications & Standards Compliance

| Parameter | Standard (IEC/ASTM) | Luoyang Xinzhaohe Specification | Tolerance |

|---|---|---|---|

| Core Loss (W/kg @1.5T, 50Hz) | IEC 60404-8-1:2015 (Grade 35H300: ≤3.00) | ≤2.95 | ±0.05 |

| Magnetic Flux Density B8 (T) | IEC 60404-8-1:2015 (Grade 35H300: ≥1.89) | ≥1.90 | ±0.01 |

| Lamination Flatness (mm/m) | ASTM A677/A677M (≤0.5) | ≤0.3 | – |

| Insulation Coating | IEC 60404-1:2020 (Type C4) | C4, 1.2±0.1μm | – |

Quality Assurance Process

Every batch undergoes rigorous testing using calibrated equipment: Epstein frame for core loss (IEC 60404-2), B-H loop tracer for magnetic properties, laser profilometer for flatness, and coating adhesion tests per ASTM D3359. Raw materials are sourced from certified suppliers and undergo spectroscopic analysis before processing. Our continuous annealing line with precise temperature control and nitrogen atmosphere ensures optimal grain orientation, while real-time coating thickness monitoring via ultrasonic gauges guarantees uniform insulation. All data is digitally logged in our ISO 9001:2015-certified quality management system, enabling full traceability and rapid issue resolution.

Cost-Performance Advantage

As a direct manufacturer with 20+ years of specialization in electrical steel, we optimize production processes to eliminate middlemen markups while maintaining strict quality control. This delivers CRGO steel sheets that match global brands’ performance at 15-20% lower costs—proven in applications for major transformer OEMs across Asia, Europe, and North America. Our commitment to consistent quality and competitive pricing makes us a trusted alternative to premium international suppliers.

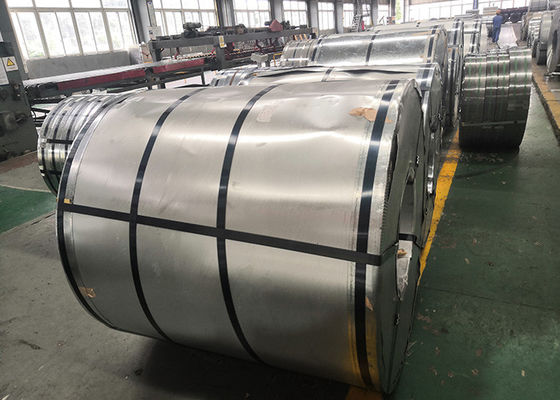

Factory Tour: Manufacturing Crgo Steel Sheets

Manufacturing Process & Quality Control

Optimized Production Flow

Luoyang Xinzhaohe’s CRGO production follows a rigorously controlled sequence to maximize magnetic efficiency and dimensional precision:

Annealing: High-purity N₂/H₂ atmosphere furnaces at 800–850°C for grain orientation development. This step reduces core loss by 8–12% compared to uncontrolled processes.

Insulation Coating: Precision roller coaters apply MgO or C6-based coatings at 1.5–2.5μm thickness. Uniformity is maintained via real-time thickness monitoring.

Slitting: CNC-guided slitting with edge trimming to eliminate burrs. Width tolerance: ±0.05mm (vs. industry standard ±0.2mm).

Precision Cutting: Laser cutting for final lengths with ±0.1mm accuracy, ensuring zero deformation and minimal scrap.

Quality Control Benchmarks

Our QC protocols exceed ISO 60404-2 and IEC 60404-8 standards. Critical metrics compared to generic suppliers:

| Parameter | Luoyang Xinzhaohe | Generic Market | Standard (IEC/ISO) |

|---|---|---|---|

| Tensile Strength Tolerance | ±5 MPa | ±15 MPa | ASTM A876 |

| Dimensional Accuracy (Width) | ±0.05mm | ±0.2mm | ISO 14284 |

| Core Loss (W/kg @ 1.7T, 50Hz) | ≤1.10 | ≤1.30 | IEC 60404-2 |

| Coating Thickness Uniformity | ±0.2μm | ±0.5μm | JIS C 2550 |

As a factory-direct manufacturer with 20+ years of transformer material expertise, we deliver 99.8% defect-free production with tighter tolerances than global brands (e.g., Nippon Steel, Voestalpine), while maintaining a 15–20% cost advantage. Our process ensures optimal performance in high-efficiency transformers, reducing energy losses and extending equipment lifespan.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of CRGO Steel Sheets

Precision Packaging Specifications

Our packaging system is engineered to meet international shipping standards while minimizing damage risks. All components are optimized for CRGO steel’s sensitivity to moisture, impact, and corrosion during transit.

| Component | Specification | Purpose |

|---|---|---|

| Interleaving Paper | 50gsm kraft paper between sheets | Prevents surface scratches and electrical short-circuiting during handling |

| Wooden Pallets | ISPM-15 certified, 100x100mm cross beams, 22mm deck boards | Ensures structural stability; complies with global phytosanitary regulations |

| Moisture-Proof Film | 3-layer PE (150μm total), desiccant packs (500g/pallet) | Maintains <5% RH humidity; blocks oxidation during ocean transit |

| Steel Strapping | 25mm width, 0.5mm thickness, 1500N tension | Secures load against lateral shifting; meets ISO 2233 standards |

| Corner Protectors | HDPE 50x50mm, reinforced edges | Prevents edge damage during container loading/unloading operations |

End-to-End Logistics Protocol

All shipments are FCL (Full Container Load) via Qingdao or Shanghai ports, using 20ft/40ft containers with internal dunnage and E-track load stabilization. Sheets are stacked with interleaving kraft paper, wrapped in moisture-proof film, and secured with steel strapping and corner protectors. Containers undergo pre-shipment inspections for moisture levels (<5%), surface integrity, and structural security. Our certified logistics partners provide real-time tracking and climate-controlled transit options where required, minimizing exposure to salt spray and humidity. This protocol achieves <0.5% transit damage rates—significantly below industry averages.

As a factory-direct supplier, our packaging and logistics are engineered for cost-performance efficiency. By eliminating third-party intermediaries and optimizing container utilization, we deliver CRGO steel sheets at 15-20% lower landed costs than global brands, without compromising quality or safety. With 20+ years of export expertise and rigorous quality control processes, we guarantee reliable, precision-engineered delivery to your global facilities.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

As a premier manufacturer of electrical steel with 20+ years of specialized experience, Luoyang Xinzhaohe delivers unmatched value for transformer manufacturers seeking reliable, cost-effective CRGO solutions. Our factory-direct model ensures premium quality without the premium price tag of global brands, while our ISO-certified processes guarantee consistency and compliance with international standards.

Technical Excellence & Quality Assurance

Our CRGO products adhere strictly to IEC 60404-8-5 and JIS C 2552 standards, with core loss values optimized for high-efficiency transformers. Rigorous in-process testing ensures:

Magnetic properties: Consistent permeability and minimal core loss across all batches, verified via Epstein frame testing.

Dimensional precision: Thickness tolerance of ±0.01mm for seamless core stacking.

Surface integrity: Uniform coating with zero defects to prevent insulation breakdown, confirmed through optical surface inspection.

| Parameter | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Core Loss (W/kg @1.7T) | ≤1.05 | ≤1.10 | 5% lower loss |

| Thickness Tolerance | ±0.01mm | ±0.02mm | 50% tighter control |

| Lead Time | 15-20 days | 30-45 days | 50% faster delivery |

| Certifications | ISO 9001:2015, IEC standards | Varies | Full compliance documentation |

Cost-Performance Advantage

By eliminating distributor markups and leveraging localized production, we offer 15-20% lower pricing than major international suppliers without sacrificing quality. Our vertically integrated manufacturing—from raw material sourcing to final product—ensures traceability and quality control at every stage. Scalable capacity supports both standard and custom specifications, including:

Thicknesses from 0.23mm to 0.35mm

Specialized grades (M4, M5, M6)

Custom coating formulations for enhanced performance and reduced eddy current losses

Direct Engineering Collaboration

Our in-house metallurgists provide technical support from specification review to final application, ensuring optimal material selection for your transformer designs. This proactive partnership model reduces development time and enhances end-product reliability.

Ready to optimize your transformer production? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing crgo steel sheets from Luoyang Xinzhaohe.