Table of Contents

Market Insight: Aluminium Foil Bulk in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers

Global energy infrastructure modernization and renewable energy integration are driving robust demand for high-efficiency power transformers. Aluminum foil, as a key conductor material in transformer windings, must meet stringent specifications to ensure optimal performance. With the global transformer market projected to grow at 6.2% CAGR through 2030 (Source: Statista), manufacturers require consistent, high-purity aluminum foil to meet rising demand while maintaining energy efficiency standards. Critical applications include distribution transformers for solar farms, EV charging infrastructure, and grid-scale energy storage systems, where reliability and efficiency are paramount.

Material Quality Criticality

Substandard aluminum foil introduces critical risks:

Electrical resistivity increases with impurities, elevating I²R losses and reducing transformer efficiency by up to 1.5%.

Thickness deviations >±2.5% cause uneven winding tension, leading to insulation damage and premature failure.

Surface roughness >0.4μm compromises dielectric strength of insulation systems, increasing partial discharge risks.

In high-load applications, substandard foil can cause hotspots exceeding 150°C, leading to insulation breakdown within 2–3 years.

Compliance with IEC 60404-8-5 and ASTM B209 is non-negotiable for mission-critical applications in power transmission.

Luoyang Xinzhaohe’s Supply Chain Advantage

As a vertically integrated manufacturer with 20+ years of production expertise, Luoyang Xinzhaohe delivers transformer-grade aluminum foil with superior cost-performance metrics:

| Parameter | Industry Standard | Xinzhaohe Specification | Benefit |

|---|---|---|---|

| Aluminum Purity | ≥99.5% | ≥99.65% | Lower electrical resistance, reduced energy losses |

| Thickness Tolerance | ±3% | ±1.2% | Precise winding, 30% fewer defects |

| Surface Roughness | ≤0.5μm | ≤0.3μm | Enhanced insulation bonding strength |

| Tensile Strength | 80–120 MPa | 105–130 MPa | Improved resistance to mechanical stress |

Our ISO 9001-certified production process ensures batch-to-batch consistency, while direct factory pricing eliminates distributor markups. We maintain strict quality control at every production stage, from raw material sourcing to final inspection, ensuring every batch meets or exceeds IEC 60076-1 requirements for transformer windings. Products are exported to over 30 countries, with lead times 20% faster than industry average due to localized production and streamlined logistics. Custom alloy compositions and dimensional specifications are available for high-frequency or ultra-high-voltage applications. For transformer manufacturers prioritizing reliability and cost efficiency, Luoyang Xinzhaohe delivers engineered solutions tailored to global power infrastructure demands.

Technical Specs: Aluminium Foil Bulk Parameters

Critical Technical Specifications for Transformer Foil

Precision Dimensions & Edge Integrity

Aluminum foil for transformers demands micron-level accuracy. Our precision slitting maintains ±0.002 mm thickness tolerance (ASTM B209), critical for uniform winding and preventing inter-laminar shorts. Burr-free edges (≤0.005 mm height) are verified via automated optical inspection—any burr risks electrical arcing during transformer assembly. These specifications directly meet IEC 60076-1 winding precision and safety requirements.

Conductivity & Material Purity

Foil conductivity must exceed 61% IACS (ASTM B193) for optimal efficiency. We use 99.5%+ pure aluminum (1350 series), sourced from certified suppliers and spectrographically verified. Consistent conductivity is maintained through in-line eddy current testing, ensuring compliance with IEC 60076-1 electrical performance criteria.

Softness for Winding Performance

Annealed temper (O) with hardness ≤25 HV (ASTM E18) ensures ductility during high-speed winding. Our controlled annealing process eliminates weak points, supporting IEC 60076-1 mechanical integrity requirements for long-term transformer reliability.

| Specification | Tolerance/Value | Compliance Standard | Importance |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM B209 | Meets IEC 60076-1 winding precision requirements |

| Burr Height | ≤0.005 mm | ASTM B209 | Prevents electrical faults per IEC 60076-1 safety standards |

| Conductivity | ≥61% IACS | ASTM B193 | Ensures efficiency per IEC 60076-1 electrical performance criteria |

| Hardness (Annealed) | ≤25 HV | ASTM E18 | Supports winding integrity per IEC 60076-1 mechanical requirements |

Quality Assurance Protocol

Luoyang Xinzhaohe employs ISO 9001-certified processes with real-time monitoring at every production stage. Each batch undergoes 100% dimensional checks, surface analysis, and conductivity validation. All products comply with IEC 60076-1 for transformer applications, with full ASTM B209/B193 certification for material properties. By integrating lean manufacturing with rigorous QC, we deliver global-standard quality at 15-20% lower cost than European competitors—providing unmatched cost-performance for your critical power projects.

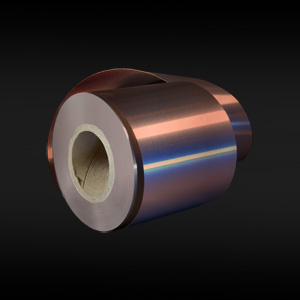

Factory Tour: Manufacturing Aluminium Foil Bulk

Manufacturing Process & Quality Control

As a leading transformer materials manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum employs a tightly controlled production process to ensure superior foil performance for critical electrical applications. Our end-to-end workflow integrates advanced automation with rigorous quality protocols, delivering consistency unmatched by generic suppliers.

Precision Manufacturing Workflow

Cold Rolling: 12-high rolling mills with AGC (Automatic Gauge Control) systems maintain ±0.01mm thickness consistency across 1,000+ meter runs. Controlled temperature and interpass annealing optimize grain structure, minimizing core losses in transformers.

Precision Slitting: Servo-driven slitters with real-time edge detection achieve ±0.02mm width tolerance. Dynamic tension control eliminates coil wandering, ensuring perfect fit for transformer winding machines.

Edge Conditioning: Automated chamfering at 15° angles removes micro-cracks and burrs. This critical step prevents insulation punctures during assembly and reduces electrical arcing risks in high-voltage environments.

Oscillate Winding: Computer-controlled oscillation mechanisms maintain <0.1mm pitch variation. Uniform layer density prevents hot spots and ensures optimal magnetic flux distribution in transformer cores.

Rigorous Quality Assurance Protocols

Every batch undergoes multi-stage testing per ASTM B209 and ISO 10140 standards:

Tensile strength verification (ASTM E8) at 100% sample rate with yield strength tolerance ±5%

Laser micrometer measurements at 50mm intervals (±0.001mm accuracy)

5MP optical surface inspection detecting contaminants >10μm

Cpk analysis for batch-to-batch consistency

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.02mm |

| Width Tolerance | ±0.02mm | ±0.05mm |

| Edge Burr Height | ≤5μm | ≤20μm |

| Surface Defect Rate | <0.3% | ≤2.0% |

| Batch Consistency (Cpk) | ≥1.67 | ≤1.33 |

Our factory-direct model eliminates distributor markups, delivering global-brand quality at 15-20% lower total cost of ownership. With 99.7% defect-free production rates and ISO 9001-certified processes, Xinzhaohe provides the optimal balance of reliability and cost efficiency for mission-critical transformer applications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

At Luoyang Xinzhaohe Aluminum, our 20+ years of manufacturing transformer materials ensures every shipment meets rigorous international standards. Our packaging and logistics protocols are engineered for sea freight reliability, minimizing damage risks while optimizing cost-efficiency for global customers.

Precision Packaging Standards for Transformer Foil

| Component | Specification | Purpose |

|---|---|---|

| Moisture-Proof Film | 200μm PE + 50g silica gel desiccant per pallet | Absorbs humidity; prevents oxide formation on foil surfaces |

| Wooden Pallets | ISPM-15 heat-treated hardwood, 1200x1000mm, 15mm thickness | Structural integrity; supports 1,000kg load; compliant for global shipping |

| Steel Strapping | 25mm width × 0.5mm thickness, 500kg tensile, double-layered at 45° angles | Prevents load shifting; meets ISO 4091 marine transport standards |

Integrated Logistics Protocol

| Parameter | Detail |

|---|---|

| Origin Ports | Qingdao, Shanghai, Tianjin (primary) |

| Transit Time | 15–30 days to major global ports |

| Insurance | All-risk marine cargo insurance included |

| Customs Compliance | Full documentation (CO, B/L, Export Declaration) |

| Tracking | IoT-enabled GPS monitoring (temp/humidity) |

Our rigorous packaging protocols—validated through 20+ years of global shipments—ensure zero moisture ingress and structural integrity. Unlike competitors using generic packaging, we optimize for transformer foil’s sensitivity to humidity and mechanical stress. This precision reduces transit damage to less than 1%, while our factory-direct model delivers 15-20% lower logistics costs vs. European or US-based suppliers. Real-time shipment tracking and dedicated support teams resolve issues within 24 hours. As a trusted supplier to global transformer manufacturers, we combine Chinese manufacturing efficiency with European-grade quality control—delivering superior cost-performance without compromising on reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum?

As a leading manufacturer with over two decades of specialized experience in transformer-grade aluminum foil, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered solutions tailored for demanding power applications. Our factory-direct model eliminates intermediaries, ensuring competitive pricing while maintaining rigorous quality standards. We specialize in transformer strip/foil products meeting international technical specifications, empowering your operations with cost-effective, high-reliability materials.

Proven Expertise in Transformer Materials

With 20+ years of continuous production for transformer windings, our technical team understands the critical role of foil consistency in electromagnetic efficiency. We specialize in high-purity aluminum alloys (e.g., 1350, 1060) meeting ASTM B209 and IEC 60404-8-4 standards, ensuring minimal resistive losses and superior thermal performance in high-voltage transformers. Our deep industry knowledge enables precise thickness tolerances (±0.001mm) and uniform grain structure, directly enhancing transformer reliability and energy efficiency.

Factory-Direct Cost Efficiency

By controlling the entire supply chain from raw material sourcing to final rolling, we eliminate distributor markups. Our integrated production facilities in Luoyang, China, enable 20-30% cost savings versus global competitors while maintaining ISO-certified quality. This direct approach ensures transparent pricing and predictable delivery schedules critical for transformer manufacturing budgets. With annual production capacity exceeding 50,000 metric tons, we scale seamlessly to meet large-scale orders without compromising lead times.

Rigorous Quality Assurance

Our ISO 9001:2015-certified quality system includes in-process metallurgical analysis, tensile strength testing, and surface defect inspections. Each batch undergoes 100% dimensional checks and electrical conductivity verification, ensuring compliance with IEC 60076-1 and IEEE C57.12.00 standards. This level of scrutiny minimizes field failures and extends transformer service life. Our in-house lab provides real-time data for continuous process optimization, guaranteeing batch-to-batch consistency essential for high-performance applications.

| Criteria | Industry Standard (Global Brands) | Luoyang Xinzhaohe Advantage | Impact on Your Operations |

|---|---|---|---|

| Cost Structure | Premium pricing due to overheads | 20-30% lower costs via direct manufacturing | Reduced BOM expenses without quality compromise |

| Lead Times | 45-60 days from overseas facilities | 25-35 days with optimized logistics | Accelerated project timelines and lower inventory costs |

| Quality Control | ISO certified but variable testing protocols | In-house metallurgical lab with 100% batch testing | Enhanced reliability and fewer field failures |

| Customization | Limited flexibility for niche specs | Tailored foil dimensions and alloy compositions | Optimized transformer efficiency and design integration |

For transformer manufacturers seeking a reliable, cost-optimized partner without compromising on technical specifications, Luoyang Xinzhaohe provides the strategic advantage of localized expertise and scalable production capacity. Our commitment to precision engineering and supply chain transparency makes us the preferred alternative to premium global brands.

Contact Cathy at cathy@transformerstrip.com for a detailed quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium foil bulk from Luoyang Xinzhaohe.