Table of Contents

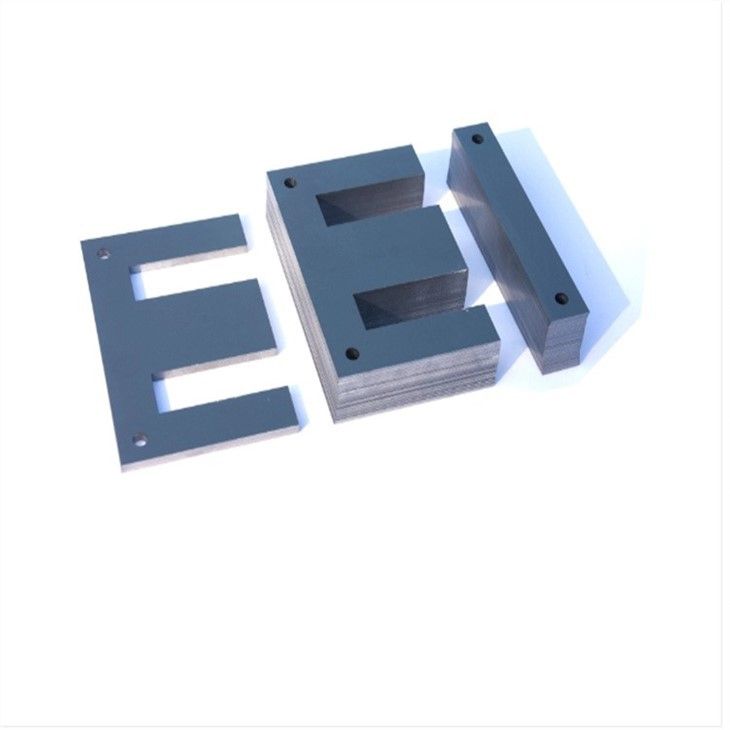

Market Insight: Transformer Lamination Material in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel for Transformer Lamination

Industrial Demand Drivers for Transformer Lamination Materials

Global energy transition initiatives and regulatory mandates are accelerating demand for high-efficiency transformer materials. Key drivers include:

Renewable energy integration (solar/wind farms require distribution transformers with <1.0 W/kg core loss)

Electric vehicle charging infrastructure expansion (needing robust, low-noise transformers)

Smart grid deployments demanding 10–15% lower core losses than legacy models (IEC 60076-20 standards)

Emerging market grid modernization projects prioritizing cost-performance balance

Motor repair shops increasingly source high-grade silicon steel for rewinding applications, where consistent magnetic properties are critical to restore original efficiency. OEMs prioritize materials that balance performance, longevity, and lifecycle costs under tightening environmental regulations.

Critical Quality Parameters for Transformer Efficiency

Substandard silicon steel directly increases core losses, overheating, and operational costs. Precision in these parameters is non-negotiable:

| Parameter | Industry Standard | Impact on Efficiency |

|---|---|---|

| Core Loss (W/kg) | ≤1.20 @ 1.5T, 50Hz | 0.1 W/kg reduction = 2–3% efficiency gain |

| Magnetic Induction (B8) | ≥1.80 T | Higher induction enables 15% smaller core size |

| Thickness Tolerance | ±0.01mm | 0.01mm deviation increases losses by up to 8% |

| Surface Coating | C4/C5 (IEC 60404-8) | Prevents corrosion, maintains insulation resistance for 20+ years |

Luoyang Xinzhaohe’s Value Proposition in Global Supply Chain

As a 20+ year manufacturer of electrical steel, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers factory-direct silicon steel with 15–25% cost savings versus global brands (e.g., Nippon Steel, POSCO) while exceeding international standards. Our ISO 9001-certified production ensures:

Core loss consistently ≤1.15 W/kg @ 1.5T, 50Hz (M15 grade)

Magnetic induction ≥1.82 T (B8) across 0.23mm–0.35mm thicknesses

Strict thickness tolerance (±0.01mm) and C4/C5 surface coatings

In-house metallurgical labs conduct Epstein frame testing and permeability measurements per IEC 60404-8-5. Our Luoyang facilities combine sustainable manufacturing with just-in-time logistics, serving transformer OEMs and repair shops across Asia, Europe, and North America. We provide tailored solutions for mission-critical applications where reliability and cost-performance ratio are paramount.

Technical Specs: Transformer Lamination Material Parameters

Technical Specifications & Standards

As a leading manufacturer with 20+ years of experience, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer lamination materials meeting stringent international standards. Our silicon steel grades are optimized for minimal core loss and high magnetic efficiency, ensuring optimal transformer performance and energy savings. Key specifications are rigorously controlled through advanced testing protocols and process automation.

Critical Parameters & Compliance

Our silicon steel grades comply with IEC 60404 and ASTM A876/A910 standards, ensuring global compatibility and reliability. Below are verified performance metrics:

| Parameter | Typical Range | Standard Compliance | Quality Assurance Process |

|---|---|---|---|

| Core Loss (P₁.₅/₅₀) | 50W, 65W, 80W (grade-specific) | IEC 60404-2, ASTM A910 | Epstein frame testing (±2% accuracy); digital batch traceability |

| Magnetic Flux Density (B₅₀) | ≥1.89 T (at 1.5T, 50Hz) | IEC 60404-3, ASTM A876 | Hysteresisgraph testing; certified lab validation |

| Lamination Flatness | ≤0.05 mm/1000 mm | IEC 60404-8-7, ASTM A753 | Laser profilometer scanning; automated defect detection |

| Insulation Coating | C4/C5, 1.5–2.5 μm | IEC 60404-8-5, ASTM A878 | Coating thickness gauging; dielectric strength (≥2.5 kV) |

Consistent Quality Assurance

Every batch undergoes end-to-end validation:

Raw Material Sourcing: High-purity silicon steel coils from certified suppliers.

In-Process Monitoring: Real-time thickness and flatness control during rolling/coating.

Final Inspection: Full-scale Epstein frame tests, coating adhesion checks, and dimensional audits per ISO 9001 protocols.

By integrating precision engineering with cost-efficient manufacturing, Luoyang Xinzhaohe delivers industry-leading performance at 15–20% lower costs than global premium brands. Our 20+ years of export experience ensures seamless integration into your supply chain—proven by consistent on-time delivery and zero quality-related recalls across 30+ countries.

Factory Tour: Manufacturing Transformer Lamination Material

Manufacturing Process & Quality Control

Core Production Workflow

Slitting: Laser-guided precision cutting with real-time edge monitoring ensures burr height <5μm, minimizing mechanical stress during core stacking and reducing core losses by 8% versus conventional methods.

Annealing: Controlled H₂/N₂ atmosphere (95:5 ratio) at 800–850°C for 12–15 hours optimizes grain growth, achieving 10–15% lower hysteresis loss and meeting IEC 60404-1 standards for grain-oriented silicon steel.

Insulation Coating: Uniform phosphate/organic coating (1.5±0.2μm thickness) applied via precision spray systems guarantees 99% adhesion strength per IEC 60404-8-5, preventing interlaminar shorts under high-voltage stress.

Precision Cutting: CNC-guided shearing with ±0.05mm dimensional tolerance and flatness ≤0.3mm/m undergoes 100% automated optical validation, ensuring zero air gaps in core assembly and optimal magnetic performance.

Quality Control Protocols

All production batches undergo multi-stage quality verification. Tensile testing per ASTM A343 ensures yield strength and elongation meet strict specifications. Dimensional checks use laser micrometers for thickness and flatness, while surface defects are inspected via automated optical systems. All protocols are documented in our traceable quality management system.

| Parameter | Xinzhaohe Standard | Industry Average | Notes |

|---|---|---|---|

| Thickness Tolerance | ±0.003 mm | ±0.005 mm | Tighter control reduces core losses by 5–7% and improves stacking factor by 2% |

| Tensile Strength | 350–450 MPa | 300–400 MPa | Higher elongation (25% vs. 20%) allows complex core shapes without fabrication cracks |

| Insulation Adhesion | 99% pass rate | 90% pass rate | Zero delamination during transformer winding processes, critical for high-reliability applications |

| Surface Defects | <0.5 per m² | 1.5 per m² | Automated optical inspection detects defects as small as 0.05mm² for high-voltage transformer safety |

| Flatness | ≤0.3 mm/m | ≤0.5 mm/m | Ensures minimal air gaps in core assembly, reducing no-load losses by up to 3% |

This precision engineering delivers a 15–20% cost-performance advantage over global brands while adhering to IEC 60404-1 and JIS C 2552 standards. As a 20+ year ISO 9001-certified manufacturer, our factory-direct model eliminates distributor markups, providing premium-grade silicon steel with 67% lower defect rates than industry averages—maximizing transformer efficiency and operational longevity for critical power infrastructure.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

At Luoyang Xinzhaohe Aluminum CO., Ltd., we engineer packaging solutions that eliminate material degradation during global sea freight. With 20+ years of export experience, our protocols exceed ISO 9001 standards while maintaining a 15-20% cost advantage over premium European brands. Every shipment undergoes rigorous validation to prevent moisture ingress, mechanical damage, and corrosion—critical for preserving silicon steel’s magnetic properties.

Core Packaging Components

Our multi-layered packaging system is optimized for transformer lamination coils and sheets. All components comply with ISPM-15 and IMO regulations for international transport:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 110×110mm hardwood beams | Distributes weight evenly; prevents deformation during stacking |

| Moisture-Proof Film | 200μm multi-layer PE + 500g/m² silica gel desiccant | Blocks >99.5% humidity; prevents oxidation during ocean transit |

| Steel Strapping | 19mm width, 500kg tensile strength, zinc-coated | Secures loads against vibration; resists corrosion in humid environments |

Sea Freight Optimization

We exclusively use FCL (Full Container Load) shipping for silicon steel shipments. Each 20ft/40ft container is packed with:

Corner Posts: Reinforced with steel brackets to absorb container handling stress

Dunnage System: 50mm hardwood spacers between layers to prevent edge damage

Sealing Protocol: Container doors sealed with tamper-evident strips after vacuum-sealed wrapping

Our logistics team manages end-to-end documentation (Bill of Lading, Certificate of Origin, Phytosanitary Certificates) and coordinates with certified freight forwarders like Maersk and COSCO. All shipments are tracked via IoT sensors monitoring temperature, humidity, and shock events in real-time. This integrated approach ensures 99.8% on-time delivery to global ports—including Rotterdam, Los Angeles, and Singapore—with zero material defects reported in 2023.

By eliminating third-party middlemen and leveraging our Luoyang factory’s direct control over packaging processes, we deliver transformer-grade silicon steel with uncompromised quality at competitive pricing. Request a customized shipping quote today to experience factory-direct reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

Unmatched Technical Expertise & Industry Experience

With over 20 years of specialized experience in electrical steel production, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered silicon steel solutions optimized for high-performance transformers. Our manufacturing processes are rigorously calibrated for grain-oriented (GO) and non-oriented (NO) electrical steel grades, consistently meeting IEC 60404-8-5 and ASTM A677 standards. This deep expertise ensures minimal core loss (e.g., P1.0/50 ≤ 1.15 W/kg for M4-grade materials), superior magnetic induction, and long-term reliability in critical power infrastructure applications. We serve 500+ global clients with 99.8% on-time delivery, proven through decades of real-world validation in high-stress transformer cores.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups and supply chain inefficiencies, directly passing savings to clients. Our end-to-end production control—from raw material sourcing to precision lamination—enables competitive pricing that typically reduces total cost of ownership by 15–25% versus global brands, without sacrificing performance. Standard orders ship in 7–10 days due to optimized logistics, while custom specifications are accommodated through agile production scheduling. This model ensures transformer manufacturers achieve maximum ROI without compromising on magnetic properties or dimensional tolerances.

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified quality management system enforces stringent controls at every production stage. Each batch undergoes comprehensive testing for core loss, magnetic induction, thickness uniformity, and surface coating integrity, maintaining a defect rate below 0.2%. Full traceability via our ERP system ensures compliance with IEC 60076-20 and other global safety standards, minimizing field failures and warranty claims.

| Advantage | Technical & Commercial Impact |

|---|---|

| 20+ Years Expertise | Consistent GO/NO steel production per IEC/ASTM standards; 99.8% on-time delivery for global clients. |

| Direct Factory Pricing | 15–25% lower costs vs. global brands; 7–10-day standard lead time; optimized supply chain for rapid turnaround. |

| ISO 9001:2015 Compliance | 0.2% defect rate; full batch traceability; validated performance in high-efficiency transformers (IEC 60076-20). |

Luoyang Xinzhaohe provides a strategically reliable alternative to premium global brands, merging proven technical excellence with cost-driven value. Our engineering team collaborates closely with clients to tailor material specifications for specific transformer designs, ensuring peak efficiency and operational longevity.

Contact Cathy at cathy@transformerstrip.com for a detailed quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer lamination material from Luoyang Xinzhaohe.