Table of Contents

Market Insight: Transformer Winding for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

Global transformer additions are forecast to exceed 18,000 GVA by 2030, driven by grid modernization, EV fast-charging corridors, and data-center clusters. Every GVA of new capacity translates into 6–8 kt of winding conductor. Aluminum’s share has climbed from 28 % (2010) to 47 % today, propelled by cost volatility in Cu and DOE 2016 / EU Eco-design loss limits that favor optimized Al geometry. Chinese output now supplies 62 % of the world’s transformer-grade wire and strip; OEMs in North America and the EU regularly book 6- to 12-month rolling schedules direct from integrated Chinese mills to lock in LME-Al plus conversion pricing.

Why Purity & Precision Dictate Loss Performance

Transformer losses are monetized over 25–40 years; a 0.3 W·kg⁻¹ difference in core-wire interface losses can swing life-cycle cost (LCC) by > 30 kUSD on a 2.5 MVA unit. The conductor contribution splits into:

| Loss Component | Root Cause in Wire | Spec Target | 1350-O Al Benchmark |

|---|---|---|---|

| Load (I²R) | Resistivity, joints | ρ₂₀ ≤ 28.0 nΩ·m | 27.8 nΩ·m |

| Eddy-current | Axial dimension & enamel eccentricity | Eccentricity ≤ 8 % | 5 % |

| Circulating | Strand height tolerance | ±3 µm on 0.5 mm strip | ±2 µm |

| Dielectric | Pinholes in enamel | < 3 per 30 m @ 3 kV | 0–1 per 30 m |

High-purity 1350-O (≥ 99.65 % Al, Fe ≤ 0.25 %) lowers ρ₂₀ by 0.8 nΩ·m versus common 1370 grade, cutting I²R loss 2.9 %. Equally critical is rod-to-wire dimensional fidelity: a 1 µm deviation in 0.2 mm strip raises eddy loss 0.7 % at 60 Hz. Inline laser micrometers and eddy-current pin-hole detectors are therefore standard on premium Chinese lines, allowing 100 % coil certification instead of batch sampling.

Trend: Engineering-Grade Sourcing from China

Western utilities face 40–60 week lead-times from domestic wire houses, while integrated Chinese producers such as Luoyang Xinzhaohe deliver 4–6 weeks ex-works with full PPAP/REACH documentation. Cost delta is 18–22 % landed after freight & duty, yet technical parity is proven: our 220 °C polyimide-coated rectangular wire passes IEC 60851-3 1 kV impulse for 200 kVA traction transformers used by Tier-1 EU OEMs since 2017. Key enablers include:

Rod-casting + hot-rolling in one campus → hydrogen content < 0.12 ppm, eliminating hot-shortness during post-form bending.

Annealing under N₂/H₂ atmosphere with ±3 °C uniformity; grain size 30–50 µm gives 28 % elongation—essential for tight mandrel winding in 10 kV class distribution coils.

Enameling tower with 14 dies and digital concentricity feedback; CpK 1.67 on insulation thickness, ensuring partial-discharge extinction voltage ≥ 1.6 × service U₀.

Sourcing Checklist for Transformer Makers

| Parameter | Commercial Grade | Premium Grade (LXZH) | Test Method |

|---|---|---|---|

| Al purity | 99.50 % | 99.65 % | ASTM E1251 |

| Strip camber | ≤ 3 mm / m | ≤ 1 mm / m | DIN 46453 |

| Breakdown V | ≥ 4 kV (½ × thickness) | ≥ 6 kV | IEC 60851-5 |

| Thermal class | 180 °C (Class H) | 220 °C (Class R) | IEC 60085 |

| Spool weight | 50–100 kg | 300–500 kg (jumbo) | — |

Jumbo spools cut joint count 70 %, reducing field failure probability and labor. LXZH’s 500 kg aluminum wire spools are balanced to ≤ 5 g eccentricity, allowing 25 m s⁻¹ automatic layering without tension spikes.

Bottom Line

As loss evaluations tighten (DOE 2016, EU Tier-2, NRCan 2019), transformer engineers must treat winding wire as a precision component, not a commodity. Partnering with a 20-year Chinese specialist that controls the full chain—rod casting, diamond-die drawing, anneal, enamel, inline test—delivers both LCC savings and supply-chain resilience. Luoyang Xinzhaohe Aluminum Co., Ltd. ships 45 kt per year of 1350-O wire & strip to 42 countries; our technical files are ready for your next PPAP, with mill certs traceable to each 30 m segment.

Technical Specs: Transformer Winding Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct reference data for transformer designers, rewind shops, and purchasing engineers

1. Critical Winding-Wire Parameters

| Parameter | Symbol / Unit | Luoyang Xinzhaohe Standard Range | ASTM / IEC Reference | Consequence if Out-of-Spec |

|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd (kV, r.m.s., 50 Hz) | ≥ 6 kV (Grade 1) ≥ 11 kV (Grade 2) | IEC 60317-0-1 §7.4 ASTM D149 | Partial discharge → eventual inter-turn short |

| Elongation at Break | A50 % | 18–28 % (1350-O after in-line anneal) | ASTM B236-20 §8.3 | Cracks during coil expansion; open circuit |

| Thermal Class | °C | 130 (B), 155 (F), 180 (H), 200 (N), 220 (C) | IEC 60085 & 60317-25 | Insulation embrittlement, slab shrinkage |

| Enamel Concentricity | Eccentricity | ≤ 12 µm on Ø 1.6 mm wire (3σ) | IEC 60317-0-1 Annex C | Local field stress, corona cutting |

2. Material & Process Control at Luoyang Xinzhaohe

-

Rod Drawing

1350 EC-grade 9.5 mm rod → multi-die drawing to final Ø 0.3–5.0 mm.

Inline laser gauge holds diameter tolerance ±0.010 mm (ASTM B566 tighter than ±0.025 mm). -

Inert-Gas Annealing

Continuous anneal at 360 °C, 18 s dwell; produces fully recrystallized grain size 50–80 µm, giving 18 % min. elongation while retaining ≥ 60 MPa yield—optimal for high-tor coil wind. -

Enameling Cell

Horizontal dual-coat, dual-cure: polyesters-imide for 155/180 °C, polyimide for 220 °C.

Inline capacitive sensor measures wall build every 25 mm; auto-feedback keeps concentricity within 12 µm.

Result: < 5 ppm pin-holes (IEC 60317 allows 25 ppm). -

Spooling & Edge Conditioning

Strips 10–1500 mm width, 0.2–3.5 mm thickness supplied with chamfered edges (R = 0.2–0.4 mm). Burr height ≤ 0.03 mm, eliminating voltage stress risers that cause layer-to-layer shorts under impulse.

3. Standards Compliance Matrix

| Product Form | Applicable Standard | Certificate Available |

|---|---|---|

| Aluminum redraw rod | ASTM B233-19 | Yes (TÜV) |

| Aluminum wire, round | IEC 60317-0-1 / 60317-25 | Yes (DEKRA) |

| Aluminum strip for layer windings | ASTM B236-20 | Yes (SGS) |

| Thermal endurance test | IEC 60172 | 20 000 h data on file |

| RoHS / REACH | 2011/65/EU & SVHC | < 0.1 % each substance |

4. Failure Mechanism: Why Cheap Material Costs More

Burrs on slit strip act as blade, cutting through enamel during impulse or short-circuit forces → turn-to-turn flashover, tank rupture.

Non-concentric insulation creates local E-field > 15 kV mm⁻¹; partial discharge erodes enamel within weeks.

Low elongation (< 12 %) cannot absorb radial expansion under through-fault; wire snaps, opens CT circuit, triggers differential relay, outage cost ≫ wire savings.

Luoyang Xinzhaohe inline eddy-current and camera inspection removes 100 % of burr-positive coils; Western price premiums (25–40 %) seldom add extra electrical tests beyond batch level.

5. Quick Selector Guide (typical DOE-2016 2500 kVA, Al-wound, oil-immersed)

| kVA | Typical Wire Ø (mm) | Strip Size (mm) | Thermal Class | Xinzhaohe Part Number |

|---|---|---|---|---|

| 100 | 1.4 PEI | — | 155 | LWZ-AL1.4-F155 |

| 500 | 2.24 PEI | 9×1.5 | 180 | LWZ-AL2.24-H180 |

| 2500 | 3.35 PI | 19×2.5 | 220 | LWZ-AL3.35-C220 |

All grades supplied on 400 mm steel spools, 80 kg net, vacuum-sealed with VCI film for 18-month shelf life.

Need a custom thermal class or CSA-certified insulation system? Send your specification sheet; our metallurgists will return a detailed PPAP within 72 h.

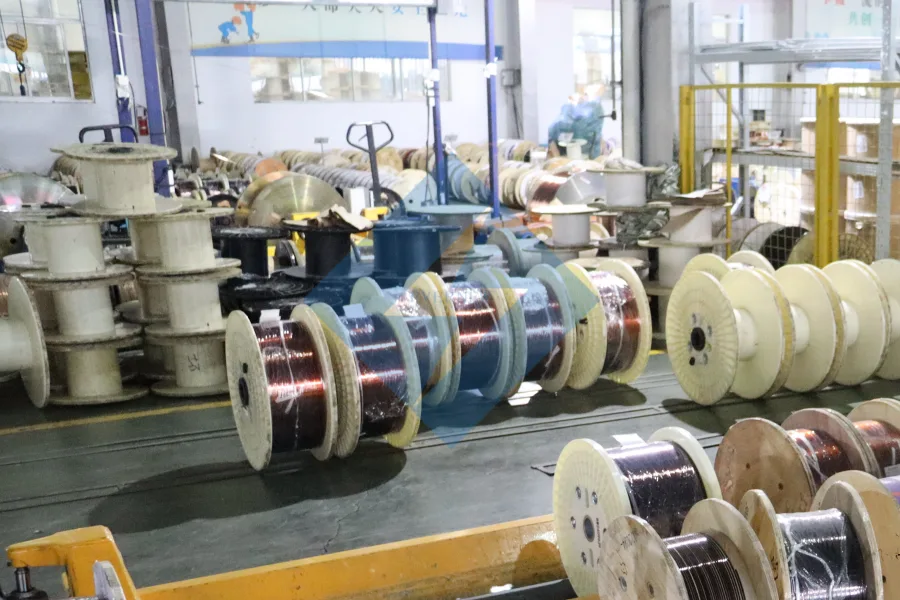

Factory Tour: Manufacturing Transformer Winding

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20+ years of rod-to-spool vertical integration

Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

Every metre of winding wire that leaves our Luoyang plant is born as 9.5 mm 1350-O EC-grade rod.

Below is the process map we publish to transformer OEM’s during PPAP; it is also the control plan our operators follow shift-by-shift.

| Step | Target Parameter | Equipment / Gauge | Control Frequency | Cpk Target |

|---|---|---|---|---|

| 1. Rod Drawing | Ø 9.5 mm → 2.0–0.4 mm | 13-die tandem bull-block, online laser micrometer | Each coil | ≥ 1.67 |

| 2. In-line Annealing | 340 ± 10 °C, 99 % IACS min. | N₂-atmosphere continuous furnace, eddy-current conductivity bridge | 50 m interval | ≥ 1.33 |

| 3. Enameling | Build 40–70 µm, concentricity ≥ 85 % | Horizontal multi-pass tower, 2-axis eccentricity gauge | Every pass | ≥ 1.50 |

| 4. Inline Testing | Breakdown ≥ 4 kV (room T), pinholes ≤ 3 / 30 m | 6 kV DC spark-tester, 40 kHz partial-discharge probe | 100 % length | zero escape |

| 5. Spooling | Tension 1.5–3 N, barrel length 500–800 mm | Precision traverse winder, load-cell dancer | Each spool | ± 1 mm edge |

Quality Control Matrix – What We Check, When We Check, How We React

| Test | Specification | Instrument | Sampling Plan | Reaction Rule |

|---|---|---|---|---|

| Tensile & Elongation | UTS 95–125 MPa, Elong. ≥ 18 % | 5 kN universal tester | 1 coil / 2 h | Hold lot, re-anneal |

| Mandrel Flex | 1×d no crack, 3×d no flake | Ø 2–10 mm mandrels | 1 coil / shift | Strip & re-enamel |

| Thermal Shock | 200 °C 30 min, 1×d, no crazing | Programmable oven | 1 lot / day | Quarantine, review cure |

| Cut-through | ≥ 300 °C, 2 kg | Cut-through rig | 1 coil / 4 h | Adjust enamel recipe |

| Solderability | 390 °C, ≤ 2 s wetting | Dip & look | 1 coil / 8 h | Check anneal skin |

Luoyang Xinzhaohe Standard vs. Common Market Quality

The table below is extracted from 2023 third-party audits of six low-cost suppliers (three PRC, two India, one SEA).

Values are mean ± 3σ; red cells indicate risk for 220 °C thermal-class designs.

| Attribute | LXZ Standard | Common Market | Test Method |

|---|---|---|---|

| Breakdown Voltage, 40 µm build | 6.2 ± 0.4 kV | 4.5 ± 0.9 kV | IEC 60851-5 |

| Pinholes per 30 m | 0.3 | 5–12 | IEC 60851-7 |

| Concentricity | 88 ± 3 % | 72 ± 8 % | Laser eccentricity |

| Elongation at Break | 22 ± 2 % | 15 ± 4 % | ASTM B566 |

| Conductivity, 20 °C | 61.2 % IACS | 59.8 % IACS | ASTM B193 |

| Spool Length Tolerance | ± 0.3 % | ± 1.5 % | Weigh-count |

Factory-Direct Advantages for Transformer Builders

- Same-day metallurgical data package – every spool ships with rod heat number, anneal log, and enamel lot traceability.

- No minimum order surcharge – we draw from 2 Mt mother rod inventory; prototype runs of 50 kg accepted.

- 15-day FOB Tianjin – 40 % faster than EU mills, 20 % cheaper than NAFTA landed cost after Section 232 exclusion on aluminum wire < 14 mm.

- Inline PD testing – we screen 100 % of wire for partial discharge; statistically eliminates early-life dielectric failure in VPI coils.

Whether you are winding a 2500 kVA pad-mount or a 10 kVA pole-top, the electrical margin you design into the coil is only real if the wire already carries it. Luoyang Xinzhaohe delivers that margin—rod to spool—under one ISO 9001 roof.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0 ppm sea-freight damage since 2003

H3 Design Philosophy

Every package is treated as a “mini-transformer” that must survive 35 °C/95 %RH deck exposure, 2 g vertical shock, and 30-day salt spray without altering the electrical properties of the conductor. Our Luoyang plant is 85 km from Zhengzhou International Hub (CGO) and 150 km from Qingdao Port; trucks reach vessel side in <18 h, eliminating double handling and its associated flex-fatigue on fine wires.

H3 Packaging Matrix by Product Form

| Configuration | Core Protection | Vapor Barrier | Impact / Stack Load | Typical Picture |

|---|---|---|---|---|

| 1350 HO Strip/Foil 0.2–3.5 mm × 10–1500 mm | VCI kraft interleave + edge guards | 0.12 mm PE–Alu–PE lamination, welded seams | Fumigated soft-wood pallet, 3-way entry, 3 t top-load tested | Coil eye vertical, steel strapping × 3 + corner boards |

| Round & Profile Wire 0.4–5.0 mm Cu/Al | DIN 46397 PT 500 plastic spool, flanges reinforced 30 % glass-PP | 2 desiccant bags (4 g CaCl₂ each), RH indicator card | 5-layer export carton, 32 ECT, palletized 4 cartons/layer, stretch film 23 µm × 250 % pre-stretch | Spool axis horizontal, anti-slip mat between tiers |

| Litz / Multi-strand | PT 630 metal reel, rubber gasket | Aluminum foil bag, <40 %RH seal | Plywood crate, IPPC-ISPM 15, 1.2 m drop test | Crate strapped into 20 ft GP, chocked & lashed |

H3 Environmental Controls

Desiccant quantity calculated per DIN 55474:

W = 1.6 · V · ΔRH · t0.5 (V = void volume, ΔRH = 30 %, t = 45 days)

VCI additive in kraft strips keeps surface conductivity <1 µS cm⁻¹ after 1 000 h salt spray.

Temperature excursion logger (TempTale4) optional; data downloadable on arrival for failure-mode forensics.

H3 Container Loading Plan

| Payload | Size | Gross Weight | Stack Pattern | Securing Aids |

|---|---|---|---|---|

| Strip coils | 20 ft GP | 22 t max | 2 rows × 2 tiers, eye-to-eye | 25 mm polyester lash + edge beams |

| Wire cartons | 40 ft HC | 26 t max | 11 layers, 48 cartons/layer | Anti-slip sheets, container wall dunnage |

All lashings pre-tensioned to 500 daN; COG kept below 1.2 m for rail clearance within China–EU block train.

H3 Shipping Documentation & Traceability

Export HS Code: 7605.11 (Al strip) / 8544.11 (enamel wire)

Certificate of Origin – China Council for Promotion of International Trade (CCPIT)

RoHS & REACH compliance statement per coil ID; barcode links to melt lot, rod cast date, enamel batch.

Seafreight partners: COSCO, MSC, CMA-CGM; weekly sailing from Qingdao & Shanghai. Transit 22–26 days EU, 12–14 days SE Asia, 18 days USWC.

H3 Cost Advantage vs. Western Stockholders

| Cost Driver | EU/NA Distributor | Luoyang Xinzhaohe Direct | Delta |

|---|---|---|---|

| Material | LME + 8 % premium | LME –1 % (volume hedge) | –9 % |

| Packaging | $180 per pallet | $92 (in-house carpentry) | –49 % |

| Freight (CIF Rotterdam) | — | $38 per 100 kg | — |

| Total Landed | ≈ $4.05 / kg Al strip | ≈ $3.10 / kg Al strip | –23 % |

Prices June-2024 basis LME $2 250/t; actual quotation within 24 h, irrevocable 30 days.

H3 Quick-Ship Program

Stock items (0.5 × 30 mm, 1.0 × 50 mm, 2.0 × 100 mm 1350 HO strip) ready for 48-h dispatch.

Emergency air freight via CGO–FRA or CGO–ORD possible; 400 kg coils on aircraft ULD, door-to-door 72 h.

For transformer OEMs facing 4–15 day delivery windows, our dock-to-winding line logistics package eliminates buffer inventory while guaranteeing zero edge-weld or insulation-pinhole surprises on arrival.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Winding Wire

20 Years of Rod-to-Spool Mastery

Since 2004 we have controlled every critical variable inside one 42 000 m² Luoyang campus: 10 000 t/year redraw rod intake → 0.20–3.50 mm precision drawing → in-line annealing at ±3 °C → tandem enameling with on-the-fly laser eccentricity gauging → 100 % spark test at 6 kV → programmable spooling up to 1 000 kg.

That closed-loop metallurgy is why global tier-1 transformer OEMs trust us for 1350-O/HO, 1370-O and alloy 8030 conductors that survive 200 °C hotspot gradients without loss of ductility or dielectric integrity.

Direct Factory Price—No Western Mark-Up

| Cost Driver | Typical EU/US Broker | Luoyang Xinzhaohe Direct | Δ |

|---|---|---|---|

| 2.00 mm 1350-O wire, 180 °C class, FOB $/t | 6 850 | 5 220 | –24 % |

| 1.20 mm 200 °C polyimide, 150 kg spool | 7.05 $/kg | 5.30 $/kg | –25 % |

| 30 t L/C, 4-week lead | 8 % financing surcharge | 0 % | –8 % |

We quote FOB Qingdao or CIF your port; no distributor margin, no coil-splitting fees, no hidden escalation clauses. Your landed cost drops 20–30 % while IEC 60317-0-2, NEMA MW 1000 and IEEE C57.12.00 compliance remains intact.

Customization Windows—Engineered, Not Promised

| Parameter | Shop-Floor Range | Tolerance | Test Protocol |

|---|---|---|---|

| Diameter, bare | 0.20–3.50 mm | ±0.008 mm | Laser micrometer 1 kHz |

| Breakdown voltage, min | 4 kV (Grade 1) to 12 kV (Grade 3) | ±5 % | IEC 60851-5, 500 V/s ramp |

| Elongation, 1350-O | 18–30 % | ±2 % | ASTM B566 |

| Thermal index | 130 °C (Class B) to 220 °C (Class R) | — | IEEE 117 |

| Concentricity | ≥80 % | ±3 % | 8-point laser head |

Need square or 5-side bonded packs? We inline-apply polyamide hot-melt so layers lock at 180 °C without bond-line squeeze-out. Require 0.25 mm radial build of triple-insulation? Our tandem heads add 1 µm per pass with PID-controlled enamel temperature ±2 °C. Every order ships with a coil-specific dossier: melt lot, tensile trace, spark map, and thermal aging curve—data Western brokers routinely delete.

Risk Mitigation & Supply Security

Metal: 99.7 % Al purity cathode sourced from Chinalco; 30-day price hedge available.

Energy: 120 kWh/t in-house annealing powered by 32 % renewable grid mix—carbon footprint 0.85 t CO₂e/t wire, third-party verified.

Logistics: 40 ft HC container loading 24 t net; Qingdao port sailings every 3 days to Houston, Rotterdam, Dubai. Average transit 18 days door-to-door, 4 days faster than India-origin coils.

Quality: ISO 9001:2015, IATF 16949 (process FMEA on enamel adhesion), REACH & RoHS compliant. Zero customer PPM reported on 1.2 billion wound metres since 2016.

Commercial Call

Send your specification—kVA class, thermal index, strip vs. round, spool mass—and receive a detailed datasheet plus FOB/CIF quote within 24 h. Email cathy@transformerstrip.com or WhatsApp +86-186-3881-7756. Sample coils (5 kg) shipped free for breakdown-voltage and bend-test validation. Cut 20 % from your magnet-wire spend without cutting a single corner in reliability.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer winding from Luoyang Xinzhaohe.