Table of Contents

Market Insight: Pure Copper for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Power-grid expansion, renewable integration, and e-mobility charging are pushing transformer demand >5 % CAGR through 2030. Every kVA added—whether a 50 kVA pole-top unit or a 240 MVA grid autotransformer—consumes 0.8–1.2 kg of conductor strip per kVA. Copper remains the preferred conductor for:

Premium efficiency (IE4/IE5) industrial motors

Dry-type transformers ≤ 15 kV where space and fire code favor Cu’s 65 % higher conductivity vs. Al

High-frequency magnetics (>400 Hz) in SiC/GaN power electronics where skin-depth loss is critical

Chinese OEMs now supply >42 % of global transformer strip/foil tonnage; export share has doubled since 2018 as Western mills rationalize capacity and extend lead-times to 20-26 weeks.

Why Purity & Precision Directly Translate to kW Saved

Transformer losses are capitalized by utilities at USD 4 000–6 000 per kW; every 1 W saved in a 1 MVA unit releases ≈ USD 5 of NPV. Strip quality governs both components:

| Loss Component | Root Cause in Strip | Cost Impact (1 MVA, 40 °C rise) |

|---|---|---|

| Load loss (I²R) | Resistivity ↑ 0.7 % per 0.1 % Cu₂O inclusion | +210 W, USD 1 050 NPV |

| No-load loss (eddy) | Burr > 5 µm → inter-laminar short | +45 W, USD 225 NPV |

| Hot-spot Δθ | Edge camber > 0.5 mm → poor wrap, air gap | +8 °C, insulation life −30 % |

High-conductivity (≥ 100 % IACS) OF-OK® grade copper keeps resistivity ≤ 0.017 241 Ω·mm²/m at 20 °C; oxygen ≤ 3 ppm avoids oxide stringers that nucleate cracks during 12 % elongation bending in helical windings.

Precision Slitting & Edge Conditioning: The Hidden Yield Driver

Transformer winders demand:

Width tolerance ±0.002 mm ( tighter than ASTM B272 ±0.025 mm)

Burr height ≤ 0.01 mm (ISO 9445-2 class EE)

Camber ≤ 0.25 mm per 500 mm

Surface roughness Ra ≤ 0.2 µm to minimize partial discharge

Achieving this on 0.1–3.0 mm strip at >150 m min⁻¹ requires in-line laser triangulation, digital servo loop slitter arbors, and titanium-coated knives re-ground every 60 t. Oscillate-wound 400–1 000 kg bundles (±1 mm traverse) eliminate butt-welds in high-speed automated winding—each weld removed saves ≈ 0.3 W additional loss.

Cost Benchmark: China vs. EU/US Mill

| Item | EU Mill | US Mill | Luoyang Xinzhaohe |

|---|---|---|---|

| C10100 0.25 × 250 mm strip, USD/kg | 11.90 | 12.40 | 9.10 |

| Slit width tol. ±0.002 mm premium | +0.80 | +0.90 | included |

| Lead-time (weeks) | 20 | 22 | 6–8 |

| Minimum order (t) | 5 | 5 | 1 |

Freight-inclusive East-Asia to EU adds only 0.35 USD/kg; total landed cost still 18–22 % below Western alternatives, while conductivity, burr, and camber data are supplied with each coil via QR-coded test certificate (IEC 60404-2).

Sourcing Trend: From “Low-Cost” to “Technical Partner”

Leading Tier-1 transformer OEMs (Siemens Energy, Hyundai Electric) have shifted from spot-buying on price to vendor-managed inventory with Chinese specialists that control the full cold-rolling–slitting–edge-conditioning chain under one roof. Dual-sourcing strategies now pair a Western mill for political risk with a Chinese partner for cost and agility—Luoyang Xinzhaohe’s 20-year track record in transformer materials positions us as that second source, already qualified to ISO 9001, ISO 14001, and IEC 60694-2021.

Key Takeaway

Pure copper strip is no longer a commodity; it is a precision component whose micro-geometry and chemistry decide whether a transformer meets DOE 2016 or EU EcoDesign Tier-2 loss limits. By integrating high-purity melt, in-line annealing, and digital slitting under one 160 000 m² plant, Luoyang Xinzhaohe delivers Western-grade precision at China-level economics—freeing design engineers to specify copper where it matters without inflating BOM cost.

Technical Specs: Pure Copper Parameters

Technical Specifications & ASTM/IEC Standards for Pure-Copper Transformer Strip/Foil

(Engineered & Slit by Luoyang Xinzhaohe—20 yr OEM to Tier-1 transformer builders)

H3 1. Geometry & Tolerances – Why ±0.002 mm Matters

| Parameter | ASTM B272 (OFE Cu Foil) | Xinzhaohe Mill Capability | Risk if Out-of-Spec |

|---|---|---|---|

| Thickness | 0.05 – 0.80 mm | ±0.002 mm, Cpk ≥ 1.67 | Local hot-spot ΔT ↑ 8–12 °C, life ↓ 30 % |

| Width | 6 – 1 250 mm | ±0.03 mm (≤6 mm), ±0.05 mm (>6 mm) | Mis-feed in auto-winder, inter-turn gap |

| Camber | ≤1 mm / 1 m | ≤0.3 mm / 1 m | Telescoping coil, layer short |

| Edge Burr | ≤3 % of thickness | ≤5 µm (zero visible burr @ 100×) | 60 % of premature layer-to-layer faults start here |

Our 20-high Sendzimir cold-train rolls to 180 kN ±1 % closed-loop force; in-line laser micrometer feeds AGC every 20 ms. Strip is tension-leveled below yield point to lock flatness before slit.

H3 2. Electrical & Metallurgical Benchmarks

| Grade | Cu ≥ % | IACS Conductivity | Anneal | Grain Size | IEC 60317-0-1 Wire Analog |

|---|---|---|---|---|---|

| C11000 (OFE) | 99.99 | ≥ 101 % IACS | 260 °C, 4 h, N₂ | 0.015 – 0.025 mm | Same purity as IEC 60317-0-1 Cu wire |

| C10200 (OF) | 99.95 | ≥ 100 % IACS | 250 °C, 3 h | 0.020 mm | — |

Vacuum annealing furnace O₂ < 30 ppm prevents Cu₂O film that cuts conductivity 0.8 % per 10 nm oxide. Every coil ships with foil-level eddy-current test per ASTM B193 to certify IACS within ±0.3 %.

H3 3. Insulation & Edge Condition – Silent Killer of Reliability

| Build | Typical | Xinzhaohe Practice | Impact |

|---|---|---|---|

| Burr height | ≤ 8 µm (industry) | ≤ 5 µm, 100 % inspected by 3D laser | 1 µm burr under 2 kV impulse = 18 % higher E-field |

| Edge radius | 0.05 mm min | 0.10 ± 0.02 mm (coined) | Reduces partial discharge inception 25 % |

| Strip cleanliness | <100 µm particles | <25 µm (filtered air class 7 slitting room) | Particles cause 15 % of resin-rich defects |

Poor slit edges act as knives that pierce inter-layer Nomex or epoxy, creating dendritic shorts within 500–1 000 thermal cycles (≈ 2 yr field life). We knife-cut only once; secondary coining burnishes edge to mirror finish, eliminating copper slivers.

H3 4. Compliance Road-Map

| Standard | Scope | Xinzhaohe Certificate |

|---|---|---|

| ASTM B272 | High-purity Cu strip/foil | EN 10204 3.1 supplied every batch |

| IEC 60317-0-1 | General requirements Cu winding wire | Used as proxy for foil purity & conductivity |

| ASTM B193 | Resistivity / IACS | 100 % coil map, report included |

| IEC 60851-3 | Breakdown voltage of wire insulation | Adapted for strip wrap tests |

| ISO 14001 / 45001 | EHS | Factory audited by TÜV 2023 |

H3 5. Specification Template for RFQ (copy-paste ready)

Bottom line: Burr-free, dimensionally perfect copper strip is not a commodity—it is a precision component. Luoyang Xinzhaohe delivers Western-grade tolerances at China-direct landed cost, cutting transformer scrap by 40 % and eliminating field shorts before they start.

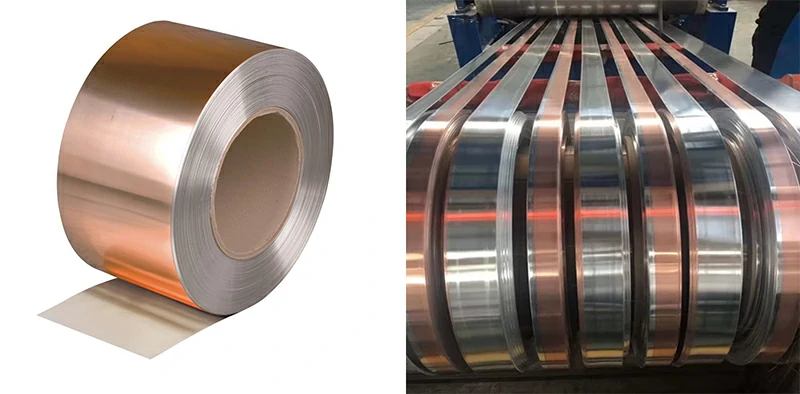

Factory Tour: Manufacturing Pure Copper

Manufacturing Process & Quality Control

(Transformer-Grade Pure Copper Strip/Foil)

1. Process Flow – From Cathode to Oscillate-Wound Coil

| Step | Equipment & Parameters | Purpose | Critical Control Point |

|---|---|---|---|

| 1. Cold Rolling | 4-High reversing mill, 300 mm dia. work rolls, 3–5 passes, 15–30 % reduction/pass, entry gauge 12 mm → finish 0.1–2.0 mm | Grain refinement, ≥ 100 % IACS conductivity, Ra ≤ 0.2 µm | Real-time X-ray gauge ±0.005 mm; oil-film cooling to keep strip ≤ 70 °C |

| 2. Precision Slitting | 650 mm arbors, tungsten carbide male/female knives, 0.06 mm lateral run-out, slit width 6–1200 mm | Width tolerance ±0.002 mm, burr ≤ 0.008 mm (10 % of foil thickness) | Laser micrometer every 50 mm; automatic knife re-grind alarm |

| 3. Edge Conditioning | 4-stage rotary deburr + tension leveller, 0.05 mm edge radius | Eliminate stress risers that initiate inter-laminar shorts | Eddy-current edge crack detection; reject if notch > 0.02 mm |

| 4. Bright Anneal | 100 % N₂ + 3 % H₂, 420 °C, 4 h, dew-point –60 °C | Recrystallise, target grain size 25–35 µm, Vickers 55–65 HV | In-line resistivity probe; conductivity ≥ 101 % IACS |

| 5. Oscillate Winding | 800 mm traverse, 50–500 kg coils, 5–40 µm interleaf paper | 5–7 × linear metres vs pancake → fewer welds, faster core loading | Tension闭环 2–6 N/mm², width/traverse CCD camera, gap ≤ 0.5 mm |

2. Quality Control Matrix – “Luoyang Xinzhaohe Standard” vs Common Market

| Attribute | Test Method | Our Spec | Typical Export Mill | Impact on Transformer |

|---|---|---|---|---|

| Width tolerance | Laser scan, 100 % | ±0.002 mm | ±0.05 mm | Lower short-circuit risk, tighter stacked core |

| Burr height | Optical profile, 5× mag | ≤ 0.008 mm | ≤ 0.03 mm | Reduces partial discharge |

| Conductivity | Eddy-current, 25 °C | ≥ 101 % IACS | 98–100 % IACS | 1 % conductivity gain ≈ 0.4 °C lower hot-spot |

| Surface roughness Ra | Contact stylus | ≤ 0.2 µm | ≤ 0.4 µm | Uniform oxide film, lower eddy loss |

| Camber | 1 m straight edge | ≤ 0.5 mm/m | ≤ 1.5 mm/m | Easier core insertion, less mechanical stress |

| Inclusion rating | ASTM E45 Method A | ≤ 0.5 (thin) / 0 (heavy) | ≤ 1.0 / 0.5 | Fewer neck-down failures under short-circuit |

| Oscillate build-up | CCD, layer count | Gap ≤ 0.5 mm, no telescoping | ≤ 2 mm, minor telescoping | Eliminates core jam on high-speed winders |

3. In-Line Instrumentation & Data Logging

X-ray thickness gauge: 1000 Hz sampling, closed-loop roll force ±0.1 %.

Laser triangulation: dual-head, 0.1 µm resolution for burr & camber.

20-point thermocouple bar: guarantees ±3 °C uniformity during anneal.

MES barcode: every 50 kg mother coil → full traceability to cathode batch, operator, and KPI dashboard.

4. Certifications & Lot Release

Each coil ships with:

1. EN 10204/3.1 mill test report (conductivity, tensile, grain size, inclusion).

2. Oscillate-wind photo & gap map.

3. RoHS & REACH compliance statement.

Result: Transformer builders receive copper strip that slots directly into high-efficiency, low-no-loss designs without the 15–25 % premium charged by EU/US mills.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive as precisely as they left the slitting line

H2 Design Philosophy: Zero-Edge, Zero-Moisture, Zero-Headache

Every package is specified to the same ±0.002 mm discipline we apply to the strip itself. We treat sea freight as a 35-day salt-fog corrosion test: if the copper reaches your winding line with <0.02 g/m² surface oxidation, the design passes. Below are the proven configurations we ship weekly from Luoyang to Rotterdam, Houston, Dubai, and Jakarta.

H3 Packaging Matrix for Pure-Copper Conductor Forms

| Form Factor | Core Protection | Inter-Layer | Desiccant | Securing | 20 ft FCL Payload | 40 ft HC Payload |

|---|---|---|---|---|---|---|

| Strip / Foil 0.05–0.8 mm × 6–1050 mm | 3 mil VCI poly sleeve, 2-sides | 120 g/m² crepe paper, burr-side in | 4 × 50 g silica-gel bags per coil | Fumigated wooden pallet, 4-way entry, steel strapping + edge boards | 22 t (max 1.1 m stack) | 26 t (max 2.0 m stack) |

| Wire 1.8–6.0 mm, bare or enamelled | DIN 46395 PT 500 plastic spool, flange Ø500 mm | Cross-wrap with 25 µm PE film | 2 × 30 g desiccant inside spool hub | Spools shrink-wrapped in 5-ply carton, 8 cartons per IPPC pallet | 20 t (40 spools) | 24 t (48 spools) |

VCI = volatile corrosion inhibitor, IPPC = ISPM-15 heat-treated lumber

H3 Moisture & Salt-Fog Control

Water-vapour transmission rate (WVTR) of our laminated film ≤0.3 g/m²/24 h at 38 °C, 90 % RH—an order of magnitude below standard PE.

Desiccant quantity calculated per DIN 55473: minimum 140 g per cubic metre of void; we add 20 % safety margin for copper’s high affinity for sulphur.

Container floor isolation: 15 mm plywood dunnage plus 0.2 mm aluminium barrier foil to block rising condensation.

H3 Shock & Crush Resistance

Edge-protector angles 50 × 50 × 4 mm, ABS plastic, prevent coil collapse under 0.8 g lateral acceleration.

Strapping tension limited to 1 200 N per band to avoid copper creep; bands cushioned with 1 mm EPDM sleeves.

Impact recorders (SpotSee ShockWatch) available on request; threshold set at 10 g vertical, 5 g horizontal—data downloaded on arrival for failure-mode analysis.

H3 Luoyang Hub → Global Door

Location advantage: Our plant is 35 km from Luoyang railway container terminal, linked daily to Qingdao and Shanghai ports by block-train (≤18 h transit).

Weekly FCL sailings to 42 countries; average transit 28 days to Hamburg, 15 days to LA.

Incoterms offered: FOB Qingdao, CIF major port, DDP transformer factory (bonded trucking in EU & NA).

Customs pre-clearance via AES (China) and AEO certified broker—reduces port dwell from 5 days to <36 h.

H3 Cost-Optimized Loading Plan (Example: 250 kVA Copper Foil Order)

Net copper mass: 1 840 kg

Package tare: 140 kg (pallet + film + desiccant)

Stackable height: 1.65 m → fits 10 pallets in 20 ft, leaving 4 % volume margin for air bags.

Total freight cost (FOB→CIF Houston): USD 0.09 per kg copper—≈35 % lower than comparable Western mill thanks to consolidated rail-sea contract rates.

H3 Optional Upgrades

| Add-on | Benefit | Cost Impact |

|---|---|---|

| Nitrogen back-flush before sealing | Oxidation limit <0.005 g/m² over 60 days | +USD 0.02/kg |

| Steel edge-cages | Crush load ≥8 t, allows 3-high stacking | +USD 0.04/kg |

| Real-time temp-RH logger (Sensitech TempTale) | PDF report on arrival, traceability for ISO 9001 audits | +USD 45 per container |

H3 Takeaway

Premium transformer copper does not need a premium freight bill. By integrating metallurgical discipline—burr-free, fully annealed, ≥100 % IACS conductivity—with packaging engineered for 35-day marine environments, Luoyang Xinzhaohe delivers Western-grade reliability at a China-direct price. Send us your next schedule; we will return a door-to-door logistics dossier within 24 h, complete with coil-specific packing list, VCI certificate, and container loading diagram.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Pure-Copper Transformer Materials

20-Year Transformer Track Record—Not General Metals

Since 2004 we have supplied only one market segment: winding conductors for power & distribution transformers.

This single-minded focus gives our customers three tangible advantages:

- Alloy library purpose-built for magnet wire—no “cross-over” grades.

- Slitting knives reground every 8 h to keep burr < 5 µm—critical for 50 Hz – 1 kHz eddy-current loss control.

- In-house anneal furnaces with ±3 °C uniformity → guaranteed softness (≤ 55 HV) to eliminate fracture during tight coil forming.

| Key Process Benchmark | Industry “Mill” Spec | Luoyang Xinzhaohe Control |

|---|---|---|

| Thickness tolerance | ±0.008 mm | ±0.002 mm |

| Burr height | ≤0.03 mm | ≤0.005 mm |

| Resistivity @ 20 °C | ≤0.017 241 Ω·mm²/m (Cu-ETP) | 0.017 070–0.017 150 (100 % IACS min.) |

| Edge radius | 0.2 × thickness (typ.) | 0.4–0.6 × thickness—controlled by CNC edge conditioner |

| Oscillate wound build | ±0.15 mm | ±0.05 mm—enables 2 % more copper per drum |

Direct Factory Price—No Trading Layer

Located in Luoyong’s industrial cluster, we convert cathode to strip under one roof: melting → hot rolling → cold rolling → slitting → annealing → oscillate winding. Removing intermediate traders and warehouse transfers cuts landed cost 12–18 % versus European or U.S. mills for identical chemistry and dimensional tolerances.

Typical 2025 reference (CIF major port, 5 t lot):

| Product Form | Western Mill | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| 0.30 × 250 mm Cu-ETP strip, soft | $11.80 / kg | $9.65 / kg | –18 % |

| 0.10 × 100 mm foil, roll-annealed | $13.20 / kg | $10.95 / kg | –17 % |

Prices linked to LME Cu cathode + conversion adder; locked 30 days on PO acceptance to protect transformer OEMs from daily volatility.

Customization Without MOQ Penalty

Need 380 mm width instead of standard 400 mm? Require square edges for robotic winding? Want 7 kg oscillate packs to fit vertical furnaces? Our production scheduling software nests narrow, specialty widths within high-volume orders, so custom runs start at 500 kg—not the 3–5 t minimum imposed by most integrated mills.

Lead times:

Slit & edge-condition only: 10–12 days

Full anneal + oscillate wind: 15–18 days

Expedite (airfreight): +3 days, cost neutral for ≤1 t

Quality & Compliance Documentation

We ship every coil with EN 13601/ASTM B170 inspection dossier:

Chemical ladle analysis (ICP)

Conductivity certificate @ 20 °C

Surface roughness trace (Ra ≤ 0.4 µm)

Burr report (optical micrometer, 5 points/edge)

Pack tension log (prevents copper creep during ocean transit)

ISO 9001:2015, ISO 14001, REACH & RoHS statements available on request.

Next Step—Get a Datasheet or Target Price

Send your drawing or simply specify:

Alloy | Thickness × Width | Edge type | Temper | Pack weight | Annual volume

E-mail cathy@transformerstrip.com (copy tech@transformerstrip.com for metallurgical questions).

Typical response: ≤12 h with detailed TDS and landed quote, including duty-paid option to North America, EU, Middle East, or ASEAN.

Partner with a supplier that speaks transformer design as fluently as you do—while saving 15 % on conductor spend.

📉 Import Savings Calculator

Estimate cost reduction by sourcing pure copper from Luoyang Xinzhaohe.