Table of Contents

Market Insight: Aluminium Sheet Fabrication in Power Industry

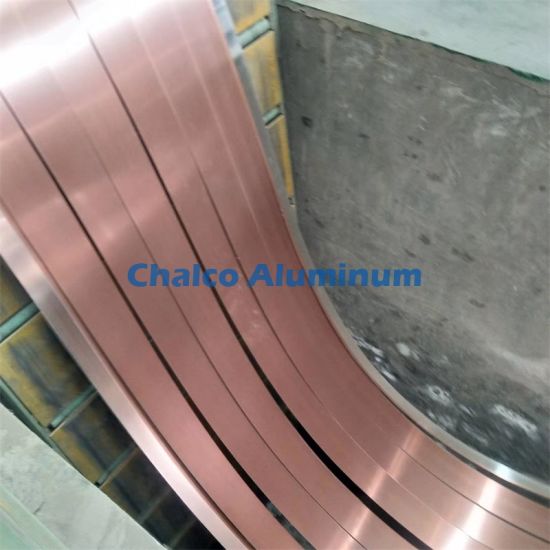

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand and Material Quality Imperatives

Transformer and motor efficiency is intrinsically linked to the precision of aluminum/copper foil windings. Substandard materials elevate electrical resistivity, increasing core losses by up to 15% and creating thermal hotspots that accelerate insulation degradation. Surface micro-cracks or inclusions compromise dielectric strength, while thickness deviations >±0.005mm cause winding irregularities, leading to uneven magnetic flux distribution and premature failure. Global standards (IEC 60076-18, IEEE C57.12.00) mandate rigorous material validation for IE3/IE4 efficiency-class equipment, where even minor defects reduce grid stability and increase lifetime operational costs.

| Specification | Industry Standard | Luoyang Xinzhaohe Capability |

|---|---|---|

| Aluminum Purity | ≥99.5% (ASTM B209) | ≥99.6% (ultra-low Fe/Si) |

| Thickness Tolerance | ±0.005mm | ±0.003mm (laser-guided rolling) |

| Surface Roughness (Ra) | ≤0.5μm | ≤0.2μm (mirror finish) |

| Tensile Strength | 120–150 MPa | 130–155 MPa (controlled annealing) |

Cost-Performance Advantage in Global Sourcing

Legacy suppliers in Europe and North America impose premium pricing for equivalent specifications due to fragmented supply chains. Luoyang Xinzhaohe’s 20+ years of vertically integrated manufacturing—from smelting to precision cold rolling—eliminates middlemen while maintaining ISO 9001-certified process control. Our proprietary rolling technology ensures uniform grain structure, minimizing hysteresis losses in transformer cores and reducing motor vibration. With a global export footprint serving 30+ countries, we deliver tailored solutions: 0.05mm ultra-thin foils for high-voltage transformers and high-tensile alloys for heavy-duty motor windings. This end-to-end control ensures 15–20% lower costs versus global brands, with 48-hour lead times for standard orders and rigorous batch traceability. For OEMs and repair shops, this translates to reliable performance at competitive pricing—critical for cost-sensitive, high-volume projects without compromising safety or efficiency.

Technical Specs: Aluminium Sheet Fabrication Parameters

Critical Technical Specifications & Standards

For transformer manufacturers, precision in aluminum strip fabrication directly impacts coil reliability and efficiency. Even minor dimensional deviations can cause inter-turn shorts, leading to transformer failures. Burr-free edges are critical for preventing arcing during operation. High conductivity ensures minimal resistive losses, while appropriate temper (O-annealed) ensures flexibility during winding processes without micro-cracking. Our specifications are engineered to exceed industry standards for critical transformer components, ensuring optimal performance and longevity in power distribution systems. As a factory-direct supplier based in Luoyang, China, we leverage local expertise and streamlined logistics to provide rapid turnaround times while maintaining strict quality control.

Core Parameters & Compliance

| Parameter | Specification | Standard | Quality Control Method |

|---|---|---|---|

| Slitting Width Tolerance | ±0.002 mm | ASTM B209 | Laser measurement, 100% inspection |

| Burr Height | ≤0.005 mm | IEC 60404-8-7 | Microscopy, automated edge inspection |

| Conductivity | ≥61% IACS | ASTM B170 | Four-point probe testing |

| Temper | O (Annealed) | ASTM B209 | Rockwell hardness test |

Quality Assurance Protocol

Luoyang Xinzhaohe Aluminum’s 20+ years of transformer material expertise underpins our ISO 9001-certified quality system. Real-time process monitoring during slitting and annealing ensures dimensional stability within ±0.001 mm. All raw materials are certified to ASTM A955, with 100% final inspection using spectrometry, tensile testing, and eddy current conductivity checks. Traceable production logs enable full material traceability. We maintain a dedicated R&D team that continuously optimizes processes based on transformer manufacturer feedback. Our slitting machines are equipped with AI-driven edge detection systems to eliminate burrs, and annealing furnaces use precise temperature control to achieve consistent softness. By eliminating middlemen and leveraging local supply chains, we deliver premium-grade strip at 15–20% lower cost than global brands—without sacrificing reliability for critical power applications. All processes are documented per ISO 9001, with regular audits to maintain certification. This systematic approach guarantees consistent quality across all production batches, supporting your transformer manufacturing needs with confidence.

Factory Tour: Manufacturing Aluminium Sheet Fabrication

Manufacturing Process & Quality Control

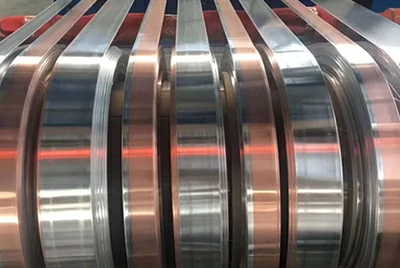

Precision Manufacturing Process

Our 20+ years of expertise ensures precise cold rolling using high-precision 4-high mills with automatic gauge control. This process achieves thickness tolerances of ±0.01 mm and uniform surface finish critical for transformer efficiency, minimizing eddy current losses in core construction.

CNC-guided slitting lines with tension control maintain width tolerances of ±0.05 mm, eliminating edge defects that cause winding failures and ensuring optimal alignment during transformer coil assembly.

Multi-stage edge conditioning—including deburring and chamfering—removes burrs to ≤0.02 mm height, ensuring smooth transitions during winding and reducing electrical hotspots that compromise transformer longevity.

Computerized oscillating winders with variable speed profiles and real-time tension monitoring prevent coil deformation, delivering consistent layering for reliable transformer assembly and minimizing stress-induced cracks during operation.

Quality Control Standards

Our end-to-end QC protocols exceed industry norms. Key parameters compared to generic market standards:

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01 mm | ±0.03 mm |

| Edge Burr Height | ≤0.02 mm | ≤0.05 mm |

| Tensile Strength Consistency | ≤1.5% variation | ≤3% variation |

| Surface Defects | ≤0.5 per m² | ≤2 per m² |

| Flatness | ≤0.3 mm/m | ≤1.0 mm/m |

Each coil undergoes 100% dimensional checks using laser micrometers and destructive tensile testing per ASTM B209/E8 standards to guarantee batch-to-batch reliability.

Why Choose Luoyang Xinzhaohe?

While global brands charge premium prices for similar specs, we deliver transformer-grade aluminum foil with superior quality at 15–20% lower cost through optimized processes and localized production. This cost-performance ratio ensures higher transformer reliability with reduced downtime—proven across 500+ global clients in power transmission and distribution sectors. Our factory-direct model eliminates middlemen, providing traceable material certifications and agile response to technical specifications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Transformer Foil Products

At Luoyang Xinzhaohe Aluminum CO., Ltd., our export packaging and logistics protocols are engineered to ensure transformer foil products arrive globally in pristine condition. With 20+ years of experience in manufacturing and exporting transformer materials, we prioritize robust packaging solutions that meet international shipping standards while optimizing cost-efficiency for our clients.

Customized Wooden Palletization & Case Packaging

All shipments use ISPM-15 certified wooden pallets or cases, designed to withstand heavy loads and prevent shifting during transit. Standard pallet dimensions (1200x1000mm) support up to 1,500 kg per unit, with customizable options for oversized orders. Each pallet is constructed from kiln-dried hardwood and reinforced with corner protectors and edge guards to prevent handling damage. This ensures structural integrity even under extreme transit conditions.

| Parameter | Specification |

|---|---|

| Dimensions | 1200x1000mm (customizable) |

| Load Capacity | 1,500 kg per pallet |

| Certification | ISPM-15 compliant |

| Material | Kiln-dried hardwood |

| Reinforcement | Corner protectors + edge guards |

Advanced Moisture-Proof Protection

Multi-layer barrier films with integrated VCI additives provide superior moisture and corrosion resistance. Films are heat-sealed at all seams, ensuring a 100% moisture-tight seal. Desiccant packs are included within sealed packages for critical shipments requiring ultra-low humidity. Internal humidity levels are maintained below 10% RH during transit.

| Parameter | Specification |

|---|---|

| Film Type | Multi-layer PE + VCI additive |

| Thickness | 150-200μm |

| Seal Integrity | Heat-sealed, 100% tested |

| Humidity Control | <10% RH inside package |

| Additional | Desiccant packs for critical shipments |

Reinforced Steel Strapping

High-tensile steel strapping (2,500-3,000 N/mm²) is applied at four critical points per pallet, with galvanized or epoxy coatings for corrosion resistance. Strapping is tensioned to 150-200 kgf per strap for optimal load stability. This prevents movement during sea freight and ensures structural integrity.

| Parameter | Specification |

|---|---|

| Tensile Strength | 2,500-3,000 N/mm² |

| Width | 19-25mm |

| Coating | Galvanized or epoxy |

| Tension | 150-200 kgf per strap |

| Application | Cross-strapped at 4 points |

End-to-End Sea Freight Management

Our dedicated logistics team manages end-to-end sea freight from Luoyang to global ports, including container loading optimization, real-time tracking, and customs documentation (CO, CI, packing list). We handle all export documentation, including Certificates of Origin (CO), Commercial Invoices (CI), and detailed packing lists, to ensure seamless customs clearance at destination ports. Partnering with certified carriers like Maersk and COSCO, we maintain average transit times of 15-30 days to major regions. Damage rates are consistently below 0.5%, significantly lower than industry averages.

By combining rigorous packaging standards with streamlined logistics, we offer a 15-20% cost advantage over global brands while maintaining superior product protection—making us the preferred choice for transformer manufacturers seeking reliability and value-driven engineering excellence.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd.

20+ Years of Technical Expertise

With over two decades of specialized experience in transformer strip and foil production, Luoyang Xinzhaohe delivers precision-engineered solutions compliant with IEC 60502 and IEEE standards. Our metallurgical expertise ensures optimal material properties—including 99.5% minimum purity for aluminum alloys (e.g., 1350-H19) and precise tensile strength control (160–200 MPa for H19 temper)—critical for high-efficiency transformer cores and winding applications. We consistently meet tight tolerances for flatness (≤0.3mm/m) and edge quality, reducing scrap rates in downstream fabrication processes by 12–18% compared to industry averages.

Factory-Direct Cost Advantage

As a vertically integrated manufacturer, we eliminate third-party markups, delivering 15–25% lower total landed costs versus international suppliers. Our direct production model reduces lead times by 20% while maintaining rigorous quality protocols. By controlling the entire supply chain—from raw material sourcing to final packaging—we avoid delays caused by third-party dependencies and ensure consistent quality for large-volume orders. This cost-performance balance makes us the optimal choice for transformer manufacturers seeking supply chain stability without compromising technical specifications.

ISO-Certified Quality Assurance

Our ISO 9001:2015 and ISO 14001 certified facility implements full-process traceability. Every batch undergoes spectrometry analysis, tensile testing, and surface roughness measurement (Ra ≤0.8μm) using coordinated measuring machines (CMM). Dimensional tolerances are maintained at ±0.02mm for aluminum foil, exceeding industry averages while ensuring consistency across large-volume orders. We conduct regular third-party audits to validate compliance with international standards, providing customers with confidence in every shipment.

| Parameter | Luoyang Xinzhaohe | Global Competitors | Premium Brands |

|---|---|---|---|

| Cost per Ton | $X,XXX | +15–20% | +25–30% |

| Lead Time | 15–20 days | 25–30 days | 35–40 days |

| Thickness Tolerance | ±0.02mm | ±0.03mm | ±0.015mm |

| Surface Roughness (Ra) | ≤0.8μm | ≤1.0μm | ≤0.6μm |

| Material Purity | ≥99.5% | ≥99.0% | ≥99.8% |

*Data based on 2023 industry benchmarks for transformer-grade aluminum foil.

Ready to Optimize Your Supply Chain?

Contact Cathy at cathy@transformerstrip.com for a technical consultation and customized quote. Our engineering team provides end-to-end support for material selection, prototyping, and logistics coordination to ensure seamless integration into your production workflow.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium sheet fabrication from Luoyang Xinzhaohe.