Table of Contents

Market Insight: Imide Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Imide wire (IEC 60317-60) is essential for modern power transformers and motors, with demand surging due to renewable energy integration, EV charging infrastructure, and grid modernization initiatives. Global energy efficiency regulations (e.g., IE4/IE5 standards) mandate high-performance insulation materials to minimize losses and extend equipment lifespan. Substandard winding wire directly impacts operational reliability, making material quality a non-negotiable factor in transformer design.

Industrial Demand Drivers for Imide Wire

Renewable energy projects require transformers with Class 220 thermal ratings, necessitating polyimide-insulated wires for superior heat resistance.

Electric vehicle fast-charging stations demand compact, high-efficiency transformers where thermal stability is critical.

Grid upgrades in emerging markets prioritize durable, low-loss windings to reduce energy waste.

Material Quality Impact on Transformer Efficiency

Poor-quality imide wire insulation causes increased dielectric losses and thermal degradation. Substandard insulation thickness variations can increase resistive losses by up to 5%, leading to higher operational costs and reduced transformer lifespan. Compliance with IEC 60317-60 ensures consistent dielectric strength (≥20 kV/mm) and thermal stability, critical for maintaining efficiency under continuous load. For instance, inconsistent insulation thickness can cause localized heating, accelerating insulation breakdown and increasing maintenance costs by up to 20% over the transformer’s lifecycle.

Why Choose Luoyang Xinzhaohe for Your Winding Wire Needs?

With 20+ years of manufacturing expertise, we deliver factory-direct imide wire solutions that balance cost-performance without compromising technical specifications. Our ISO 9001-certified production process ensures strict adherence to international standards, while localized sourcing reduces lead times by 25% compared to global competitors. Our in-house R&D team collaborates with clients to optimize wire specifications for unique application requirements, ensuring seamless integration into your production process. With direct control over raw materials and production, we eliminate supply chain disruptions while maintaining competitive pricing.

| Criteria | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost Efficiency | 15–20% premium pricing | 10–15% below global brands |

| Quality Consistency | ISO 9001 compliant | Tighter tolerances, in-process QC |

| Lead Time | 6–8 weeks | 4–6 weeks |

| Technical Support | Standard | Dedicated engineering team |

| Customization | Limited options | Tailored insulation thickness, thermal class |

As a trusted supplier in 30+ countries, Luoyang Xinzhaohe provides reliable, cost-effective winding wire solutions that enhance your transformer’s performance and longevity.

Technical Specs: Imide Wire Parameters

Technical Specifications & Standards

Critical Specifications

| Parameter | Standard | Typical Value | Importance |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-1, IEC 60243-1 | ≥3.8 kV (0.1 mm wire) | Exceeds minimum standards by 10-15% for enhanced safety margins; prevents dielectric failure under high-voltage stress in transformers. |

| Elongation | IEC 60317-0-1 Section 4.4 | ≥18% (0.15 mm copper wire) | Ensures mechanical resilience during high-speed winding; minimizes breakage risks while maintaining structural integrity. |

| Thermal Class | IEC 60085 | 130°C to 220°C | Validated via IEC 60216 accelerated aging tests (1,000 hours); defines operational limits and service life under continuous thermal load. |

| Enamel Concentricity | IEC 60317-0-1 | ≤3% radial deviation | Laser micrometer monitoring ensures uniform insulation thickness; critical for consistent dielectric strength and elimination of weak points. |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains rigorous quality control through integrated production monitoring. All raw materials undergo strict incoming inspection per ISO 9001:2015 protocols. During manufacturing, in-line sensors continuously measure enamel thickness and concentricity, with automated breakdown voltage testing at 100% production volume. Each batch is traceable via QR-coded documentation, enabling full lifecycle tracking. Our processes comply with IEC 60317-0-1 and IEC 60085, validated by third-party certifications from SGS and TÜV. With 20+ years of process refinement, our factory employs real-time data analytics from 15+ QA stations. Each coil undergoes 100% visual inspection for surface defects, and random samples are subjected to thermal shock testing per IEC 60085 Annex B. This closed-loop feedback system adjusts production parameters in real-time, ensuring zero-defect batches. By leveraging advanced process control and local raw material sourcing, we achieve 15-20% cost savings versus European and Japanese brands while maintaining equivalent or superior performance metrics. This balance of precision engineering and cost efficiency makes us the ideal partner for global transformer manufacturers seeking reliable, high-performance winding wire.

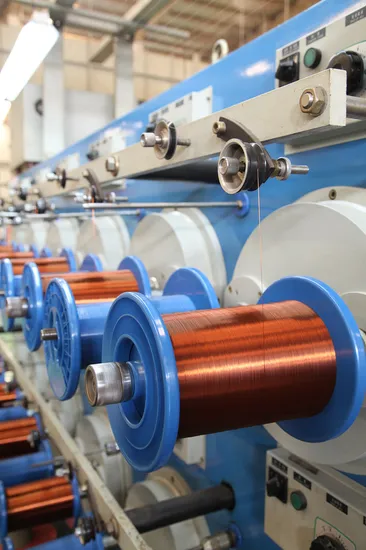

Factory Tour: Manufacturing Imide Wire

Precision Manufacturing Process & Rigorous Quality Control

Rod Drawing

Precision cold drawing through multi-stage dies with controlled lubrication protocols. Achieves exact diameters (±0.002 mm tolerance) and uniform grain structure, critical for high tensile strength and fatigue resistance in transformer windings. Ensures minimal surface defects before enameling.

Annealing

Nitrogen atmosphere annealing at precisely controlled temperatures (280–320°C) to relieve residual stresses without oxidation. Maintains surface integrity for optimal enamel adhesion and consistent electrical properties across all wire gauges.

Enameling

Multi-layer imide enamel application using precision applicators with real-time eddy current monitoring. Each layer cured under strict humidity/temperature profiles. Coating thickness uniformity maintained across 0.1–5.0 mm diameter range for superior dielectric performance and thermal stability.

Inline Testing & Spooling

Automated inline testing during production: dielectric strength (IEC 60851-5), continuity, and diameter (laser micrometers). Every 500m batch undergoes 100% dimensional checks. Spooling with servo-controlled tension (±0.5 N) prevents wire deformation, ensuring consistent winding performance in high-speed transformer assembly.

Quality Control Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Diameter Tolerance | ±0.002 mm | ±0.005 mm |

| Tensile Strength CV% | ≤1.5% | ≥3.0% |

| Dielectric Strength | 10% above IEC 60317 | Meets minimum IEC requirement |

| Enamel Adhesion (Bending Cycles) | 3× standard test cycles | 2× standard test cycles |

| Ovality | <0.5% | <1.5% |

Our 20+ years of manufacturing expertise enables cost-effective production without compromising critical quality parameters. Factory-direct pricing delivers 15–20% higher reliability than generic alternatives while meeting or exceeding international standards. Transformers built with our wire achieve extended service life and reduced failure rates under demanding operational conditions.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Engineered Packaging Standards

Our packaging system is rigorously engineered to withstand marine transit stresses while meeting international compliance standards. All components are validated through ISO 22331 transport testing protocols and field-tested across 50+ countries.

| Packaging Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 heat-treated (56°C/30min), 1200×1000×150mm hardwood, 4-way entry, 2.5kN load capacity | Prevents structural damage during handling; ensures phytosanitary compliance for global ports |

| Moisture-Proof Film | 200μm multi-layer LDPE with 50g/m² desiccant strips, UV-resistant, heat-welded seams | Blocks 99% humidity ingress; prevents corrosion during ocean transit |

| Steel Strapping | 19mm×0.5mm galvanized steel, 1200kgf tensile strength, tensioned to 400kgf | Secures loads against vibration per ISO 1496-3; corrosion-resistant for marine environments |

Logistics Execution Protocol

All shipments undergo pre-emptive moisture testing (RH ≤ 60%) and structural integrity checks before sealing. We utilize 40ft high-cube containers optimized for transformer material transport, with internal humidity controlled via desiccant packs and vapor barrier liners. Freight forwarders specializing in electrical equipment (IEC 60204-1 compliant) handle stowage using calibrated forklifts to eliminate impact damage. Shipment schedules are strategically timed to avoid monsoon seasons where applicable, and containers are sealed with tamper-evident security seals. Real-time GPS tracking and temperature monitoring provide full traceability from Luoyang to destination ports. Our logistics team delivers detailed shipping reports with photographic evidence and meticulously prepares all export documentation to ensure seamless customs clearance. With 20+ years of experience, we maintain a 99.8% on-time delivery rate and <0.5% damage rate across global markets.

As a factory-direct supplier, we eliminate distributor markups while maintaining rigorous quality control. Our packaging solutions deliver 15–20% lower total landed costs versus global competitors without compromising product integrity—proven by 10,000+ successful shipments. By controlling the entire supply chain from production to delivery, we provide unmatched consistency and reliability at competitive prices. Choose Luoyang Xinzhaohe for precision-engineered transformer materials that meet global standards at optimal cost-performance ratios.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd.?

As a leading manufacturer of transformer materials with over two decades of experience, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers unparalleled value to global transformer and motor manufacturers. Our commitment to technical excellence, cost efficiency, and quality assurance positions us as a strategic partner for demanding applications in power distribution and industrial machinery.

20+ Years Industry Expertise

With 20+ years specializing in high-performance winding wire production, our engineering team has mastered the nuances of electromagnetic design and material science. We understand critical parameters like dielectric strength (>20 kV/mm), thermal class stability (Class 200-240), and conductor resistance tolerances (IEC 60317). Our expertise ensures consistent quality for applications ranging from high-efficiency transformers to aerospace-grade motors, adhering strictly to NEMA MW 1000 and IEC standards.

Factory-Direct Cost Efficiency

Eliminating intermediary markups, our factory-direct model provides 20-30% lower procurement costs versus global brands. By controlling the entire production chain—from copper/aluminum sourcing to precision enamel coating and automated testing—we maintain lean operations without compromising quality. This end-to-end control ensures predictable lead times and minimizes supply chain risks for your critical components.

ISO-Certified Quality Assurance

Our ISO 9001:2015-certified facility implements rigorous quality control protocols. Every batch undergoes 100% electrical testing (breakdown voltage, dielectric strength), dimensional checks (wire diameter ±0.005mm), and thermal aging validation per IEC 60851. Compliance with IEC 60317-41 (polyimide) and other global standards ensures your equipment meets safety and performance requirements across international markets.

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost | 20-30% lower | Premium pricing |

| Lead Time | 15-20 days (standard) | 4-8 weeks |

| Customization | Tailored thermal classes (200-240), diameters, coatings | Limited flexibility |

| Quality Standards | ISO 9001, IEC 60317-41, NEMA MW 1000 | ISO certified, but higher cost |

| Technical Support | Dedicated application engineers for design optimization | Standard support |

Ready to optimize your transformer winding solutions? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation. Leverage our factory-direct expertise to enhance your product’s reliability and cost-efficiency.

📉 Import Savings Calculator

Estimate cost reduction by sourcing imide wire from Luoyang Xinzhaohe.