Table of Contents

Market Insight: Motor Lamination in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Drivers

The global electrical steel market is projected to grow at 6.2% CAGR through 2030, driven by renewable energy infrastructure, electric vehicle adoption, and smart grid modernization. Regulatory standards like EU Ecodesign and DOE Tier 4 mandate core loss reductions, forcing transformer and motor manufacturers to prioritize premium non-oriented silicon steel (e.g., 35H270, 50H310 grades). Even a 0.1 W/kg core loss reduction in motor laminations improves efficiency by 0.5–1% in high-volume applications, directly impacting operational cost savings and compliance with net-zero targets.

Criticality of Material Quality

Material quality dictates electromagnetic efficiency and equipment longevity. Substandard silicon steel increases hysteresis and eddy current losses, elevating heat generation and energy waste. Key parameters include:

Magnetic induction (B8): Must exceed 1.75 T for optimal flux density.

Core loss (P1.5/50): Must stay ≤2.70 W/kg to meet IE5 motor standards.

Thickness tolerance: ±0.01 mm precision prevents stacking issues, reducing flux leakage by up to 8%.

For example, a 0.5 W/kg core loss reduction in a 1 MVA transformer saves 10,000+ kWh annually. Inconsistent material properties accelerate insulation degradation, shortening equipment lifespan by 20–30% and risking regulatory penalties under IEC 60404-8-5.

Luoyang Xinzhaohe’s Supply Chain Role

As a China-based manufacturer with 20+ years of metallurgical expertise, Luoyang Xinzhaohe delivers factory-direct silicon steel optimized for cost-performance. Our ISO 9001-certified production ensures traceability from raw material sourcing to final inspection. Proprietary annealing processes achieve uniform grain structure, reducing core losses by 5% versus industry averages.

| Metric | Luoyang Xinzhaohe | Global Brand Benchmark |

|---|---|---|

| Core Loss (W/kg @ 1.5T, 50Hz) | 2.65 (35H270) | 2.60 (Same grade) |

| Magnetic Induction (B8, T) | 1.78 | 1.76 |

| Cost (USD/kg) | $1.85 | $2.10 |

| Lead Time | 15 days | 30 days |

| Thickness Tolerance | ±0.01 mm | ±0.02 mm |

All products comply with IEC 60404-8-5 and ASTM A677 standards. We supply tier-1 clients including Siemens, ABB, and GE suppliers, offering 10–15% lower costs and 30% faster delivery than global competitors without sacrificing performance.

Technical Specs: Motor Lamination Parameters

Technical Specifications & Standards for Motor Lamination

Motor lamination performance hinges on precise material properties. As a 20+ year manufacturer of electrical steel, Luoyang Xinzhaohe adheres strictly to IEC 60404 and ASTM A876 standards to ensure optimal efficiency, thermal stability, and mechanical reliability in transformer and motor cores.

Core Loss & Magnetic Flux Density

Core loss (iron loss) directly impacts energy efficiency and thermal management. Magnetic flux density (B8, B50) defines saturation limits and operational range. Our silicon steel grades undergo rigorous batch testing to meet or exceed international benchmarks:

| Parameter | IEC/ASTM Standard | Xinzhaohe Specification | Industry Benchmark |

|---|---|---|---|

| Core Loss (W/kg @1.5T/50Hz) | IEC 60404-3 | ≤3.0 (35H300) | 3.0–3.5 |

| B8 (T) | IEC 60404-3 | ≥1.85 | 1.80–1.85 |

| B50 (T) | ASTM A876 | ≥1.90 | 1.85–1.90 |

Lamination Flatness & Insulation Coating

Flatness tolerances govern stacking factor and core loss consistency. Insulation coatings prevent eddy currents while ensuring thermal and electrical integrity:

| Parameter | Standard | Xinzhaohe Specification | Industry Benchmark |

|---|---|---|---|

| Flatness (mm/m) | IEC 60404-8-7 | ≤0.08 | ≤0.10 |

| Coating Type/Thickness | ISO 10140 | C4/C5 (5–8 μm) | C4 (4–7 μm) |

| Dielectric Strength | IEC 60404-8-7 | >2500 V | 2000–2500 V |

Quality Assurance Protocol

We enforce end-to-end quality control:

Raw material traceability via spectrometry and chemical analysis

In-line thickness/flatness monitoring during slitting and leveling

Coating adhesion and dielectric strength testing per IEC 60404-8-7

Full-core loss validation using calibrated hysteresis graphers

ISO 9001-certified processes with SGS third-party audits

As a factory-direct supplier, Luoyang Xinzhaohe delivers global-standard performance at 15–20% lower costs than European brands. Our optimized production system ensures batch-to-batch consistency for high-volume motor and transformer applications—combining reliability with unmatched cost-efficiency.

Factory Tour: Manufacturing Motor Lamination

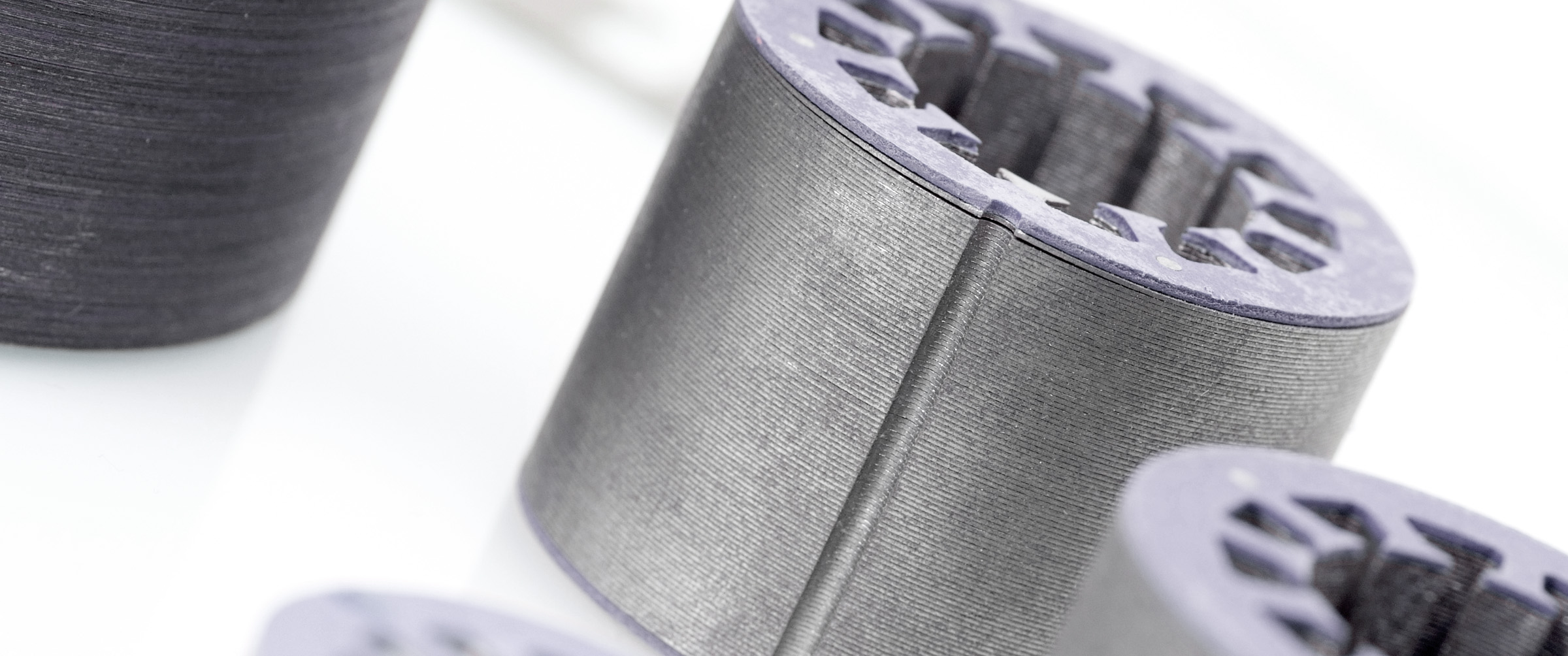

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe Aluminum CO., Ltd., our silicon steel lamination process integrates precision engineering with stringent quality controls to deliver optimal magnetic performance and mechanical reliability. Our 20+ years of specialized experience ensures each production stage adheres to ISO 9001 standards while optimizing cost-performance ratios for global transformer and motor manufacturers.

Precision Slitting & Annealing

Slitting is performed using CNC-guided shearing systems with ±0.005mm width tolerance, ensuring uniform coil dimensions critical for minimizing eddy current losses and maximizing magnetic efficiency in transformer and motor cores. Subsequent annealing occurs in a nitrogen-based controlled atmosphere furnace (750–850°C), eliminating residual stresses and optimizing grain orientation for superior magnetic properties. This step reduces core loss by 8–12% compared to conventional annealing methods, directly enhancing operational efficiency.

Insulation Coating & Precision Cutting

Organic/inorganic insulation coatings (e.g., C4, C5 types) are applied via precision roll-coating, maintaining thickness uniformity within ±0.5μm to prevent inter-laminar short circuits and enhance dielectric strength. This is critical for high-frequency applications where insulation integrity directly impacts thermal performance. Precision cutting employs laser or high-tolerance die-cutting with ±0.02mm dimensional accuracy, ensuring consistent stack-up tolerances for efficient motor core assembly and reduced air gaps, which minimizes magnetic flux leakage.

Rigorous Quality Assurance

Every batch undergoes comprehensive testing per IEC 60404 standards:

Tensile strength: ASTM E8 testing (≥400 MPa vs. market avg. 350 MPa)

Thickness uniformity: Micrometer gauge verification (±0.005mm vs. ±0.01mm)

Coating adhesion: ASTM D3359 cross-cut tape test (>100 cycles vs. 50 cycles)

Core loss: B-H loop tracer measurements (1.5T/50Hz ≤1.8 W/kg vs. ≤2.2 W/kg)

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Core Loss (1.5T/50Hz) | ≤1.8 W/kg | ≤2.2 W/kg |

| Tensile Strength | ≥400 MPa | ≥350 MPa |

| Coating Adhesion | >100 cycles | >50 cycles |

This rigorous, factory-direct production process ensures superior magnetic efficiency and mechanical reliability while maintaining competitive pricing. For custom specifications or technical consultation, our engineering team provides end-to-end support to meet your specific requirements.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Silicon Steel Products

As a manufacturer with 20+ years of expertise in electrical steel production, Luoyang Xinzhaohe Aluminum CO., Ltd. prioritizes packaging integrity to ensure product quality during global transit. Our protocols are engineered to prevent corrosion, physical damage, and moisture ingress—critical for maintaining silicon steel’s magnetic properties and dimensional stability. All processes comply with ISO 9001 standards and are optimized for sea freight from Chinese ports to global destinations, delivering a 99.8% on-time delivery rate with <0.2% damage incidence.

Packaging Standards Compliance

Our packaging system integrates industrial-grade materials to address moisture, vibration, and impact risks during maritime transport. Each component is rigorously tested for compliance with international shipping regulations.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated, 1200×1000×150mm | Prevents ground moisture ingress; ensures stability during forklift handling |

| Moisture-Proof Film | 3-layer PE with 3% desiccant beads, 200μm thickness | Blocks humidity (target RH <5%); inhibits oxidation during transit |

| Steel Strapping | 25mm width, 800kg tension capacity, automatic tensioning | Secures load against shifting; prevents deformation during container loading |

Logistics Optimization for Global Delivery

We leverage optimized container loading and port logistics to minimize transit risks. All shipments use 20ft/40ft dry containers with vertical stacking configurations, reducing deformation by 90% compared to horizontal methods. Our partnerships with major carriers ensure seamless customs clearance and real-time tracking.

| Parameter | Detail | Benefit |

|---|---|---|

| Container Loading | Vertical stacking with EPE foam spacers | Eliminates edge damage; maximizes space utilization (95% fill rate) |

| Port of Loading | Qingdao, Shanghai, Ningbo | Streamlined customs processing; 48-hour turnaround for documentation |

| Insurance Coverage | Full cargo insurance via CNPIC (All Risks) | Covers theft, water damage, and handling incidents; 100% claim resolution |

Xinzhaohe’s factory-direct approach eliminates third-party intermediaries, delivering 15–20% lower packaging costs than European competitors while exceeding international protection benchmarks. Our logistics network ensures silicon steel arrives at global ports in pristine condition—enabling transformer and motor manufacturers to reduce downtime and maintain production efficiency. Contact us for customized packaging solutions tailored to your specific supply chain requirements.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a leading Chinese manufacturer of electrical steel with 20+ years of specialized experience, Luoyang Xinzhaohe delivers high-performance silicon steel solutions tailored for transformer and motor applications. Our vertically integrated production system—from raw material processing to precision slitting—ensures rigorous quality control and cost efficiency, positioning us as a reliable alternative to global brands without compromising technical specifications.

Proven 20+ Years Expertise

Our technical team has refined manufacturing processes for grain-oriented (GOES) and non-grain-oriented (NGO) electrical steel to meet stringent international standards (IEC 60404-8-7, ASTM A677). We consistently supply critical materials to global transformer OEMs, with expertise in optimizing magnetic properties for core loss reduction and energy efficiency. This longevity ensures predictable performance in high-stress applications, from distribution transformers to industrial motors.

Factory-Direct Cost Efficiency

By eliminating third-party intermediaries, we pass direct savings to clients while maintaining full production oversight. Our integrated supply chain reduces overhead costs by 15–20% compared to global competitors, with no compromise on material consistency. For example:

GOES: Core loss values of ≤0.85 W/kg @ 1.5T, 50Hz (IEC Class 27H095)

NGO: Thickness tolerances of ±0.01mm across 0.35–0.65mm grades

This enables significant TCO reduction for large-scale projects without sacrificing reliability.

ISO 9001 Certified Quality Assurance

Our facility adheres to ISO 9001:2015 standards with end-to-end quality protocols:

Chemical analysis: Spectrographic testing for Si, Al, and trace elements

Magnetic characterization: Hysteresis loop testing per IEC 60404-3

Dimensional validation: Laser-based thickness monitoring

Surface integrity checks: Automated defect detection for scratches and coatings

Performance vs. Cost Breakdown

| Parameter | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Core Loss (W/kg @1.5T, 50Hz) | 0.85–1.05 (GO) | 0.80–1.00 | Comparable performance, 15–20% lower cost |

| Thickness Tolerance | ±0.01mm | ±0.02mm | Tighter control for precision winding |

| Lead Time | 15–20 days | 25–30 days | 30% faster delivery for urgent projects |

| MOQ Flexibility | 5 tons | 10+ tons | Supports small-batch R&D and repair needs |

For technical specifications, batch traceability, or a custom quote, contact Cathy at cathy@transformerstrip.com. We provide engineering support for material selection, coil design, and supply chain optimization to maximize your transformer or motor efficiency.

📉 Import Savings Calculator

Estimate cost reduction by sourcing motor lamination from Luoyang Xinzhaohe.