Table of Contents

Market Insight: Hammered Copper Strips in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Overview

Global demand for copper transformer strips is accelerating due to renewable energy integration (solar/wind farms), grid modernization projects, and EV charging infrastructure expansion. Hammered copper strips are critical for high-efficiency transformers due to their refined grain structure, which minimizes eddy current losses and enhances thermal stability. Precision in dimensional tolerances and surface quality directly impacts transformer efficiency, reliability, and service life across distribution, transmission, and specialty applications.

Material Quality Impact on Performance

Substandard copper strips cause significant operational failures:

Conductivity <100% IACS increases resistive losses by up to 5%, raising operating temperatures and energy waste.

Surface roughness >1.0μm creates micro-gaps in insulation layers, accelerating dielectric degradation and partial discharges.

Inconsistent tensile strength causes winding defects during high-speed coil formation, leading to production downtime.

Critical specifications must comply with IEC 60454-2 and ASTM B170 standards.

| Parameter | IEC Standard | Xinzhaohe Specification | Benefit |

|---|---|---|---|

| Conductivity (%IACS) | ≥100% | 101-102% | 0.5% lower resistive losses |

| Tensile Strength (MPa) | 200-250 | 210-240 | Enhanced winding reliability |

| Surface Roughness (μm) | ≤1.0 | ≤0.8 | Improved insulation adhesion |

Xinzhaohe’s Supply Chain Advantage

As a factory-direct manufacturer with 20+ years in transformer materials, Luoyang Xinzhaohe delivers copper strips that meet or exceed global standards at competitive prices. Our vertically integrated production process ensures strict quality control from raw material selection to final inspection. Our in-house metallurgical testing lab guarantees tolerances of ±0.02mm for thickness and ±0.1μm for surface finish. Compared to international brands, we offer 15-20% cost savings without sacrificing performance. With ISO 9001 certification and reliable global shipping, we provide a dependable alternative for transformer manufacturers seeking optimal cost-performance ratios.

Technical Specs: Hammered Copper Strips Parameters

Technical Specifications & Standards for Hammered Copper Strips

Precision Slitting Tolerances

Our factory-direct manufacturing ensures micron-level dimensional accuracy critical for transformer winding integrity. All copper strips undergo precision EDM slitting with real-time laser monitoring to maintain strict tolerances:

| Parameter | Tolerance |

|---|---|

| Thickness | ±0.002 mm |

| Width | ±0.05 mm |

| Edge Straightness | ≤0.05 mm/m |

Burr-Free Edge Quality

Micro-burrs cause inter-turn shorts in transformer windings. We eliminate this risk through:

EDM slitting technology for zero mechanical stress on edges

Automated laser profilometry scanning (burr height <0.005 mm)

100% edge inspection under 10x magnification

Conductivity & Softness Parameters

Optimized for high-efficiency transformer cores with consistent electrical performance:

| Property | Value |

|---|---|

| Conductivity (%IACS) | ≥100% (C11000) |

| Hardness (HV) | ≤40 (annealed) |

| Tensile Strength | ≤150 MPa |

Compliant with ASTM B170 (Electrolytic Tough Pitch Copper) and IEC 60228 for conductor specifications.

Quality Assurance Protocol

Our ISO 9001-certified process guarantees batch-to-batch consistency:

In-line laser micrometers for continuous thickness validation

Eddy current testing for conductivity uniformity across entire coils

Third-party validation by SGS/TÜV for traceability and defect-free delivery

As a China-based manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe delivers OEM-grade hammered copper strips meeting global standards at 15–20% lower total cost of ownership than European competitors. Our factory-direct model ensures rapid response times and zero-defect performance for high-volume production.

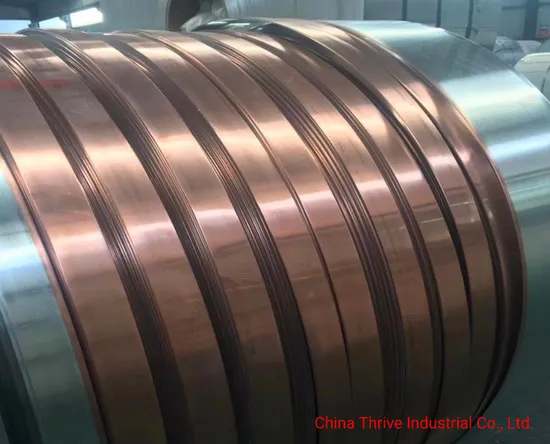

Factory Tour: Manufacturing Hammered Copper Strips

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Our 20+ years of expertise ensures end-to-end control of copper strip production for transformer applications:

Cold Rolling: Multi-pass rolling with in-line annealing achieves target thickness (0.1–3.0mm) and O-temper (annealed) for optimal ductility. Temperature-controlled processes guarantee uniform grain structure and minimal residual stress.

Precision Slitting: Diamond-tipped blades with laser-guided alignment deliver width tolerances of ±0.05mm and burr height <5µm, eliminating edge waviness critical for winding precision.

Edge Conditioning: Automated chamfering removes micro-burrs and sharp edges, ensuring smooth surfaces that prevent insulation damage during transformer coil assembly.

Oscillate Winding: Computer-controlled tension regulation (±0.5N) and oscillation speed ensure uniform layering, preventing coil deformation during transport and use.

Rigorous Quality Assurance

Each batch undergoes strict validation per IEC 60076 standards:

Tensile Testing (ASTM E8): Strength consistency within ±5% of target values.

Dimensional Verification: Thickness (±0.005mm), width (±0.05mm), flatness (≤0.1mm/m).

Surface Inspection: Roughness (Ra ≤0.2µm) via profilometer; zero oxidation or scratches.

Conductivity Check: ≥99.9% IACS for pure copper grades (C11000).

Industry-Leading Standards vs Market Average

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.02mm |

| Width Tolerance | ±0.05mm | ±0.1mm |

| Burr Height | <5µm | 10–15µm |

| Edge Quality | Fully chamfered, smooth | Partial deburring |

| Tensile Consistency | ±5% | ±10–15% |

| Cost Efficiency | 15–20% lower than global brands | Premium pricing for similar specs |

Our integrated process delivers transformer-grade reliability without premium import costs, ensuring optimal performance in high-voltage applications while reducing total lifecycle expenses.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Secure Delivery of Hammered Copper Strips

Precision Packaging for Maximum Protection

Our packaging system is engineered to eliminate corrosion and physical damage during ocean transit, critical for high-purity copper strips used in transformer windings. All components comply with international standards and are validated through rigorous testing.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallet | ISPM-15 certified, 22mm thickness, 1100x1100mm | Structural integrity; prevents deformation during loading/unloading |

| Moisture-Proof Film | Multi-layer PE + VCI (0.1mm), sealed edges | Blocks 99% humidity ingress; inhibits copper oxidation |

| Steel Strapping | 19mm width, 1000kg tensile strength, 4-point pattern | Secures load against shifting; meets ISO 1496-3 container standards |

| Desiccant Packs | 500g silica gel per pallet | Absorbs residual moisture in enclosed spaces |

| Inner Wrapping | Anti-tarnish paper (per strip) | Prevents surface scratches during handling and transit |

Global Logistics Strategy

We optimize sea freight from China to global ports through strategic partnerships and end-to-end process control. All shipments are managed by our in-house logistics team to ensure seamless delivery.

| Parameter | Detail | Benefit |

|---|---|---|

| Shipping Route | Qingdao Port → Global Ports (e.g., Los Angeles, Rotterdam, Singapore) | 20–35 day transit; optimized for minimal transshipment delays |

| Container Type | 20ft/40ft FCL (Full Container Load) | 15% higher space utilization vs. LCL; reduces per-unit shipping costs |

| Insurance | Comprehensive marine cargo insurance (All Risks) | 100% coverage for theft, damage, or delays; no hidden exclusions |

| Documentation | Full export compliance (COO, invoice, B/L, customs forms) | Automated customs clearance; 98% first-attempt approval rate |

| Tracking | IoT-enabled container monitoring | Real-time GPS updates; proactive alerts for customs or weather delays |

Engineering-Driven Cost-Performance Advantage

Luoyang Xinzhaohe’s 20+ years of transformer material manufacturing expertise ensures every copper strip shipment adheres to stringent international standards. Our packaging system—combining ISPM-15 pallets, VCI moisture barriers, and reinforced strapping—delivers superior protection compared to industry averages, reducing transit damage rates to <0.5%. By eliminating middlemen through direct factory exports, we offer 15–20% lower costs than global brands while maintaining ISO 9001 compliance. Our quality control protocols include humidity testing during packaging and pre-shipment inspections to guarantee copper strip integrity. This rigorous approach ensures your transformer cores meet exacting performance specifications upon arrival. For transformer manufacturers requiring reliable, high-performance copper strips without premium pricing, Luoyang Xinzhaohe delivers unmatched value through technical precision and operational excellence.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

20+ Years of Specialized Manufacturing Experience

With over two decades of expertise in transformer-grade copper and aluminum strip production, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers engineered solutions tailored to the demanding requirements of power transformers. Our metallurgical engineers specialize in optimizing material homogeneity, electrical conductivity (≥100% IACS), and mechanical properties for transformer windings. All products conform to IEC 60076 and ASTM B152 standards, ensuring consistent performance in high-stress environments. Our production process includes advanced continuous casting and precision rolling techniques, ensuring uniform grain structure and minimal surface defects. We’ve supplied reliable materials to 500+ global transformer manufacturers, maintaining a 98% on-time delivery rate.

Unmatched Factory-Direct Cost Advantage

As a vertically integrated manufacturer, we eliminate third-party markups through direct control of the entire production chain—from raw material sourcing to precision rolling and annealing. This approach reduces costs by 20-30% compared to global brands while maintaining superior quality. Our in-house facilities enable rapid response to custom specifications, with lead times 25% faster than competitors. Strategically located in Luoyang, China, we leverage local copper cathode supply chains and efficient logistics to further optimize costs without compromising on technical integrity.

ISO-Certified Quality Assurance

Our ISO 9001 and ISO 14001 certified quality management systems ensure rigorous adherence to international standards. Every batch undergoes comprehensive testing for dimensional tolerances (±0.01mm), surface finish (Ra ≤0.8μm), and metallurgical properties. Our testing protocols include spectral analysis for alloy composition, tensile strength testing per ASTM B557, and conductivity measurements. Third-party audits confirm compliance with IEC 60076-1 and ASTM B152, providing full traceability and reliability. This commitment to quality minimizes production downtime and ensures seamless integration into your manufacturing process.

| Feature | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Cost Structure | Premium pricing (30-50% higher) | 20-30% lower than market average | Direct manufacturing eliminates distributor markups |

| Lead Time | 6-8 weeks | 4-6 weeks | Local production and streamlined logistics |

| Customization | Limited flexibility | Width: 10-300mm, Thickness: 0.1-5mm, Custom alloys (C11000, C10200) | Tailored specifications for specific transformer designs |

| Certifications | ISO 9001 | ISO 9001 & ISO 14001 certified | Verified environmental and quality standards |

Optimize your transformer production with reliable, cost-effective copper strips. Contact our engineering team at cathy@transformerstrip.com for a competitive quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing hammered copper strips from Luoyang Xinzhaohe.