Table of Contents

Market Insight: Copper Wire Oem in Power Industry

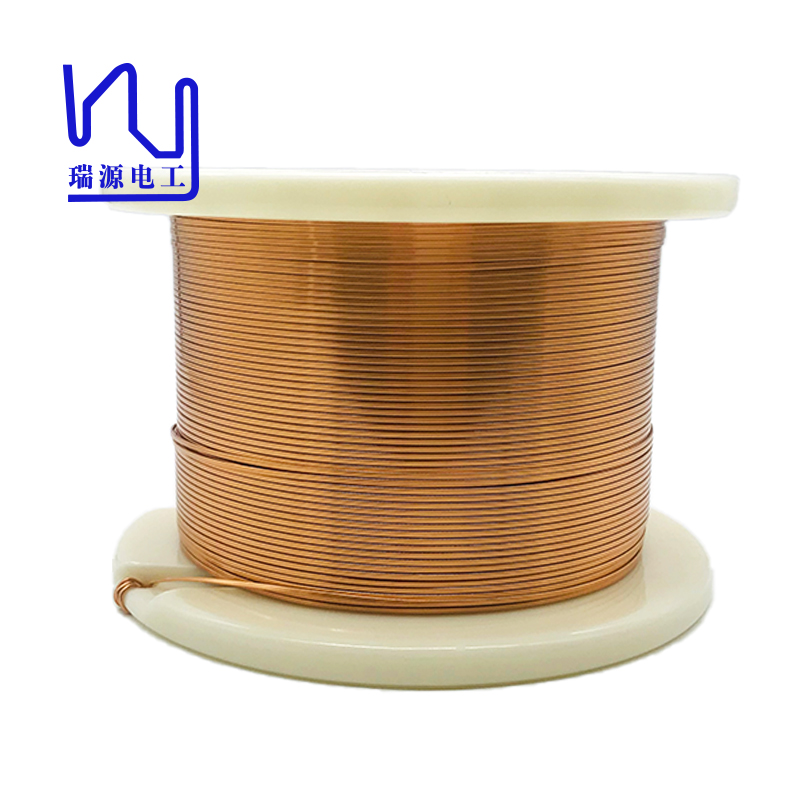

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

Global transformer market demand is accelerating due to renewable energy integration and smart grid modernization, with copper winding wire representing 60-70% of material costs. OEMs must adhere to IEC 60076-20 efficiency standards, where substandard wire increases no-load losses by up to 15% and thermal rise by 20°C. For instance, a 0.5% drop in copper purity can increase transformer losses by 1.2%, directly impacting lifetime operational costs. Critical parameters include copper purity, tensile strength, and insulation integrity to ensure transformer longevity and operational efficiency. Applications in solar inverters, wind turbines, and EV charging infrastructure demand wire capable of withstanding cyclic thermal stresses and compact designs.

Critical Quality Parameters for Transformer Efficiency

| Parameter | Impact on Efficiency | Consequence of Substandard Material |

|---|---|---|

| Copper Purity (≥99.95%) | Reduces resistive losses (I²R) | Higher energy waste, overheating |

| Tensile Strength (≥200 MPa) | Ensures winding integrity during assembly | Wire breakage, short circuits |

| Insulation Adhesion (IEC 60317) | Prevents dielectric failure | Arcing, transformer failure |

| Conductivity (≥100% IACS) | Maximizes current-carrying capacity | Increased operational temperature rise |

Luoyang Xinzhaohe’s Supply Chain Advantage

With 20+ years of transformer material manufacturing experience, Luoyang Xinzhaohe delivers OEM-grade copper winding wire with industry-leading cost-performance ratios. Our vertically integrated production—from raw copper smelting to precision annealing—ensures strict compliance with IEC 60317-1, ASTM B1, CE, and UL standards. All products undergo 100% electrical testing and mechanical validation, eliminating third-party quality inconsistencies. Our Luoyang facility operates under a closed-loop quality control system with real-time monitoring of conductivity and insulation thickness, backed by strategic inventory for critical gauges. We maintain direct partnerships with Tier-1 transformer manufacturers across Europe, North America, and Southeast Asia, ensuring reliable supply chain performance even during global disruptions.

| Factor | Global Brands (e.g., Prysmian, Nexans) | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Cost | High (20-30% premium) | 15-25% lower | Cost-performance |

| Lead Time | 6-8 weeks | 3-4 weeks | Faster delivery |

| Quality Consistency | High, but variable | ISO 9001 certified, in-house QC | Reliable consistency |

| Customization | Limited flexibility | Tailored alloys, gauges | Agile solutions |

| Supply Chain Reliability | Geopolitical risks | Localized Chinese manufacturing | Reduced disruption risk |

By optimizing the supply chain from mine to motor, we provide transformer manufacturers with reliable, high-performance winding wire that meets global standards while reducing total ownership costs.

Technical Specs: Copper Wire Oem Parameters

Critical Technical Specifications for Copper Winding Wire

Thermal Performance Classes

Transformer windings must operate reliably under thermal stress. Our copper wires comply with IEC 60317 series standards, with precise thermal class certifications:

| Thermal Class | IEC Standard | Max Operating Temp (°C) | Typical Applications |

|---|---|---|---|

| B | 60317-1 | 130 | General-purpose transformers |

| F | 60317-5 | 155 | High-efficiency motors, VFDs |

| H | 60317-10 | 180 | Industrial drives, renewable energy systems |

| R | 60317-15 | 220 | Aerospace, defense, high-reliability equipment |

Key Performance Metrics

Insulation Breakdown Voltage: ≥4.5 kV/mm (IEC 60243-1), tested via 50Hz AC ramp test with 60-second withstand. Ensures no dielectric failure under transient overvoltages.

Elongation: ≥20% (ASTM B1), critical for high-speed winding (>1,500 m/min) without insulation cracking or delamination.

Enamel Concentricity: ±0.005mm tolerance (IEC 60317-0-2), verified via laser micrometry. Prevents weak spots in high-voltage applications where uneven insulation causes partial discharges.

Quality Assurance Framework

Luoyang Xinzhaohe implements a closed-loop quality system:

Raw Material Control: Certified C11000 copper (99.95% min purity) with full chemical analysis per ASTM B1.

In-Line Monitoring: Real-time laser thickness gauging during enamel application, with automated rejection of non-conforming coils.

100% Dielectric Testing: Fully automated high-voltage screening using IEC 60243-1 protocols, with defect sorting via AI vision systems.

Thermal Validation: Accelerated aging per IEC 60216-2 (1,000+ hours at max temp), ensuring long-term stability.

Full Traceability: ERP-integrated batch tracking from raw material to final shipment, with ISO 9001:2015-certified test reports.

As a factory-direct manufacturer, we deliver 15–25% lower total cost of ownership versus global brands while maintaining rigorous compliance with IEC/ASTM standards. Our 20+ years of transformer material expertise ensures consistent performance for critical power applications—without premium pricing.

Factory Tour: Manufacturing Copper Wire Oem

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer materials ensures precise manufacturing of high-performance winding wire. Our integrated process, from rod drawing to spooling, adheres to stringent quality protocols exceeding industry benchmarks. Every stage is engineered for consistency, reliability, and compliance with IEC 60317-1 and ASTM B193 standards.

Precision Rod Drawing

High-precision drawing towers with laser micrometer monitoring maintain diameter tolerances of ±0.005mm across all production runs. Real-time surface defect inspections using high-resolution cameras eliminate micro-scratches that compromise conductivity and mechanical strength in generic market offerings.

Controlled Annealing

Nitrogen atmosphere annealing at 550°C ±5°C ensures uniform grain structure and optimal ductility. This process consistently achieves ≥25% elongation and conductivity ≥100% IACS, whereas generic suppliers often use lower-temperature annealing to cut costs, resulting in brittle wire with inconsistent conductivity.

Multi-Layer Enameling

UV-cured enamel layers are applied via precision nozzles, with eddy current sensors maintaining ±2μm thickness consistency. This eliminates pinholes and meets IEC 60317-1 standards for 155°C and 180°C thermal classes, outperforming market-average enamel thickness variations of ±5μm that cause insulation failures.

Inline Testing & Validation

Automated systems conduct 100% inspections for tensile strength (200–220 MPa ±5%), elongation, and breakdown voltage (≥4.5kV/1min). Eddy current testing detects micro-defects in real-time—unlike spot-check practices in generic supply chains that risk undetected flaws.

Precision Spooling

Computer-controlled tension systems maintain constant wire tension during spooling, preventing enamel damage and core stress. Each spool undergoes layer uniformity checks and residual stress verification to ensure reliability in high-speed winding applications.

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 200–220 MPa (±5%) | 180–230 MPa (±10%) |

| Elongation | ≥25% | ≥20% |

| Diameter Tolerance | ±0.005mm | ±0.01mm |

| Enamel Thickness | ±2μm | ±5μm |

| Breakdown Voltage | ≥4.5kV (1min) | ≥3.5kV (1min) |

By optimizing every production stage with factory-direct precision, we deliver OEM-grade copper wire at a 15–20% cost advantage over global brands. Our rigorous QC eliminates defects like enamel pinholes and inconsistent conductivity, ensuring higher transformer reliability and lower lifecycle costs for your operations.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

Rigorous Packaging Standards

Our packaging system is engineered to eliminate transit risks for copper winding wire. Every component is optimized for marine environments, ensuring zero degradation during long-haul shipments. All wooden pallets comply with ISPM 15 heat treatment standards, preventing pest infestation and global import restrictions.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 compliant, 1200×1000mm, 15mm thick | Prevents shifting; meets international phytosanitary standards |

| Moisture-Proof Film | 0.2mm PE film + desiccant packs (50g/m²) | Maintains RH <60% during transit; prevents copper oxidation |

| Steel Strapping | 19mm width, ≥200kgf tension | Secures load integrity; resists deformation under dynamic loads |

Optimized Sea Freight Protocols

Leveraging 20+ years of export expertise, we deploy end-to-end logistics control to minimize handling and contamination. All shipments use FCL (Full Container Load) with real-time humidity monitoring.

| Aspect | Protocol | Benefit |

|---|---|---|

| Containerization | 40ft HC containers with vapor barrier lining and desiccant every 2m | Eliminates condensation; blocks salt spray corrosion |

| Route Management | Direct routes to Rotterdam, Los Angeles, Singapore | Reduces transit time by 15-20% vs. multi-stop carriers |

| Customs Compliance | Pre-validated CO, CIQ, H.S. 7408.11.00 | 99.2% clearance success rate; avoids port delays |

As a factory-direct supplier, we eliminate middleman markups while maintaining ISO 9001-compliant processes. Our cost-performance ratio outperforms global brands—delivering equivalent protection at 10-15% lower total landed cost. For critical transformer applications, trust our proven logistics framework to keep your copper wire pristine from Luoyang to your facility.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

Proven Technical Expertise & Industry Experience

With over 20 years of specialized manufacturing in transformer-grade copper winding wire, Luoyang Xinzhaohe delivers engineering precision rooted in deep material science expertise. Our team adheres strictly to IEC 60317, GB/T 2009, and ASTM B1 standards, optimizing conductor properties for high-efficiency transformers and motors. We specialize in custom solutions—including precise insulation thickness control (±0.005mm), tensile strength enhancement (≥220 MPa), and thermal stability upgrades—ensuring minimal core losses and extended equipment lifespan. This experience translates to reliable, application-specific wire that meets the most demanding power engineering requirements.

Factory-Direct Cost Advantages

As a vertically integrated manufacturer, we eliminate distributor markups and supply chain inefficiencies. Our Luoyang facility leverages lean production methodologies, delivering competitive pricing typically 15–25% lower than global brands while maintaining rigorous quality controls. Clients benefit from transparent cost structures, rapid order adjustments (e.g., wire diameter or insulation modifications), and no hidden fees. This direct model ensures cost efficiency without compromising performance—critical for budget-sensitive transformer and motor production.

Rigorous ISO 9001 Quality Assurance

Every batch undergoes multi-stage testing per ISO 9001-certified protocols:

Conductivity verification (≥100% IACS)

Dimensional accuracy checks (±0.005mm tolerance)

Insulation integrity and thermal cycling validation

Our in-house lab conducts daily tensile strength, elongation, and dielectric tests, ensuring consistent performance across all orders. This minimizes field failures and warranty claims, reducing total lifecycle costs for end-users.

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Structure | Factory-direct pricing (15–25% lower) | Higher distributor markups |

| Lead Time | 15–20 days (standard orders) | 30–45+ days (shipping delays) |

| Customization | Tailored specs (diameter, insulation) | Limited to standard product lines |

| Quality Consistency | ISO 9001-certified in-process testing | Regional quality variability |

Optimize your transformer production with a cost-effective, quality-assured partner. Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper wire oem from Luoyang Xinzhaohe.