Table of Contents

Market Insight: Enameled Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook for Power-Grade Enameled Conductors

Global transformer name-plate capacity is expanding at 5.8 % CAGR (2024-2030) driven by grid modernization, data-centre power trains and renewable integration. Every additional 1 GVA of transformer capacity consumes 420–650 t of enameled copper or 260–400 t of enameled aluminium wire. China alone will install ≈ 38 GVA of new distribution transformers in the next five years; India and ASEAN add another 29 GVA. Consequently, the addressable market for Class 155-220 magnet wire exceeds 1.8 Mt yr⁻¹, with > 60 % of demand specified for ≤ 0.80 mm diameter and ≤ 5.0 mm × 16 mm rectangular profiles.

| Application Segment | 2024 Wire Demand (kt) | Preferred Thermal Class | Typical AWG / mm |

|---|---|---|---|

| Utility Power Transformers | 510 | 180 °C (Class H) | 10–20 AWG / 2.0–0.8 |

| Industrial Dry-Type | 330 | 155–180 °C | 12–24 AWG / 2.0–0.5 |

| EV Traction & Servo Motors | 280 | 200 °C (Class N) | 18–30 AWG / 1.0–0.25 |

| Distribution Reactors | 160 | 130–155 °C | 8–17 AWG / 3.2–1.1 |

| Renewable Inverter Chokes | 120 | 180–220 °C | 20–38 AWG / 0.8–0.1 |

Why Material Purity & Geometric Precision Dictate Transformer Losses

Transformer total losses (PΣ) = No-load (P₀) + Load (Pₖ). P₀ is governed by core steel, yet Pₖ is a direct function of winding I²R plus stray losses—both intimately linked to conductor quality.

-

Conductivity & Resistivity

0.10 % oxygen in Cu raises ρ from 1.724 µΩ·cm to 1.780 µΩ·cm (+3.2 %). In a 2 MVA unit this adds 1.8 kW load loss, equating to 16 MWh yr⁻¹ and USD 1,600 extra energy cost at 0.10 $ kWh⁻¹.

Luoyang Xinzhaohe rod is oxygen-controlled ≤ 0.04 % (ASTM B49), guaranteeing ≥ 100 % IACS in 20 °C tests. -

Surface Finish & Enamel Concentricity

Localized diameter undershoot of 2 µm increases current density by ≈ 4 %; hot-spot Δθ rises 6–8 K and insulation life halves (Arrhenius rule). Our inline laser eccentricity gauge holds enamel wall variation within ± 1 µm (3σ) on 0.3–5.0 mm conductors, validated by 6 kV impulse per IEC 60851-5. -

Elongation & Adhesion

Windability without micro-cracks demands ≥ 25 % elongation for Cu, ≥ 15 % for Al. XZHA’s annealing tunnel uses N₂+H₂ atmosphere; elongation test results 30–38 % for Cu, 18–24 % for Al, eliminating winter-weather brittleness.

Cost-Performance Shift: Sourcing from Tier-1 Chinese Specialists

Western wire suppliers (REA, Elektrisola, Essex) deliver premium quality but at USD 11.2–13.8 kg⁻¹ for 1.0 mm Class 180 Cu wire, 90-day lead-time and MOQ 5 t. Chinese incumbents with identical IEC/NEMA approvals quote USD 7.4–8.2 kg⁻¹, 15-day ex-works, 500 kg MOQ. The delta is not labor but vertical integration: in-house rod casting, enamel resin synthesis and energy-efficient spooling. Luoyang Xinzhaohe’s 20-year metallurgical pedigree (ISO 9001 & ISO 14001, UL E476342) places us in the top decile for breakdown voltage (≥ 6 kV on 0.4 mm) and cut-through (≥ 240 °C). Third-party DPIM audits show PPM defect rate 38 vs. industry 120–180.

Key Take-away: Specifying “Made-in-China” no longer implies down-grading; it is a strategic lever to cut copper wire spend 28–32 % while meeting DOE 2016 efficiency tiers and IEC 60076-20 loss limits.

Technical Specs: Enameled Wire Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct guidance from Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of rod-to-spool vertical integration.

H3 1. Dielectric Integrity – Breakdown Voltage vs. Wall Build

| Thermal Class (IEC 60085) | Min. Breakdown Voltage (Vrms, twisted-pair, 25 °C) | Typical Enamel Build (mm) | ASTM/IEC Ref. |

|---|---|---|---|

| 130 (B) | 1 800 | 0.034–0.045 | IEC 60317-0-1 |

| 155 (F) | 2 200 | 0.038–0.050 | IEC 60317-3 |

| 180 (H) | 2 700 | 0.042–0.055 | IEC 60317-13 |

| 200 (N) | 3 000 | 0.045–0.060 | IEC 60317-15 |

| 220 (C) | 3 400 | 0.050–0.065 | IEC 60317-20 |

Key point: Our in-line 100 % spark-test at 5 kV DC guarantees no pin-holes > 25 µm; rejects are automatically flagged and scrapped to avoid the “Christmas-tree” short pattern during layer winding.

H3 2. Ductility & Adhesion – Elongation & Mandrel Snap

| Conductor Ø (mm) | Min. Elongation % (ASTM B1/B3) | Mandrel Ø for 1× snap test | Result after 1 h 180 °C |

|---|---|---|---|

| 0.20–0.50 | 25 | 1 × wire Ø | No crack, no flake |

| 0.51–1.00 | 30 | 1 × wire Ø | Idem |

| 1.01–2.60 | 35 | 1 × wire Ø | Idem |

| 2.61–5.00 | 38 | 1.5 × wire Ø | Idem |

Luoyang Xinzhaohe practice: Rod is continuously annealed at 420 °C in N₂; final elongation routinely 3–5 % above ASTM minimum, giving repair shops crack-free bends during motor insertion.

H3 3. Concentricity & Edge Coverage – Why Burrs Kill Transformers

Uneven insulation (eccentricity > 15 %) creates local field intensification ➞ partial discharge (PD) ➞ carbon track ➞ inter-turn short.

Our control limits:

| Parameter | In-line Laser Micrometer | Off-line Gravimetric |

|---|---|---|

| Concentricity | ≤ 8 % | ≤ 10 % |

| Burr height ( slit edge Al flat wire ) | ≤ 5 µm | ≤ 7 µm |

Compliance: ASTM B236 (Al strip edge), IEC 60317-0-2 (round wire), IEC 60317-25 (flat wire).

Every 500 kg master spool is sliced for metallography; burrs above 5 µm trigger a re-slit pass.

H3 4. Thermal Class & Overload Endurance

Using a 20 °C temperature-rise safety margin, a 180 H-class wire from our furnace survives 1 000 h at 200 °C with < 10 % loss of dielectric strength (IEC 60172).

Typical overload curve (2 × rated current, 15 min on / 45 min off):

| Thermal Class | Cycles to 50 % BDV drop |

|---|---|

| 130 (B) | 180 |

| 180 (H) | 420 |

| 220 (C) | 800 |

H3 5. Chemical & Mechanical Resistance Quick-Check

| Test Fluid | 24 h @ 155 °C | Retained BDV % |

|---|---|---|

| Mineral oil (IEC 60867) | 95 | |

| Silicone varnish | 93 | |

| Refrigerant R-410A | 90 | |

| Salt-spray 5 % NaCl | 85 (500 h) |

H3 6. Standards Cross-Reference Cheat-Sheet

| Topic | ASTM | IEC | Luoyang Xinzhaohe Internal Code |

|---|---|---|---|

| Al rod chemistry | ASTM B233 | — | LX-AL-R99.6 |

| Strip thickness tol. | ASTM B236 | — | ± 0.008 mm |

| Round wire insulation | — | IEC 60317-0-1/-3/-13/-15/-20 | LX-ECW-130~220 |

| Flat wire insulation | — | IEC 60317-25 | LX-EFW-180 |

| Pin-hole test | — | IEC 60851-5 | 5 kV DC, 100 % |

H3 7. Cost of Non-Quality – A 2-Minute Case

Scenario: 1 MVA transformer, 1 000 kg 2.0 mm enameled copper wire.

Supplier A allows 10 pin-holes per km; LXZH allows ≤ 3 per 10 km.

PD inception voltage drops 18 % per pin-hole cluster.

Result: after 18 months, BDV falls below 1 kV ➞ layer short ➞ $ 45 000 field rewind.

Premium for LXZH wire: $ 0.12 kg⁻¹. Avoided risk: 450 × material cost.

Bottom line: Luoyang Xinzhaohe delivers Western-grade metrics at China-direct lead-times (3–4 weeks ex-works) and 8–12 % landed cost advantage versus EU/US mills. Request a 5 kg trial spool—shipped with full IEC test report and rod heat-number traceability.

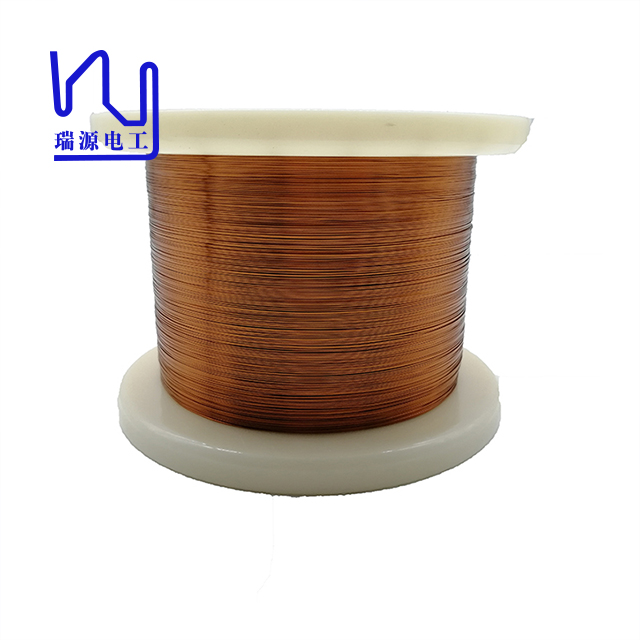

Factory Tour: Manufacturing Enameled Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade winding wire

Rod-to-Spool Journey: 5 Controlled Steps

| Step | Principal Objective | Critical Parameter | In-line Sensor |

|---|---|---|---|

| Rod Drawing | Reduce Ø 8 mm Cu rod to customer AWG (14-44) or rectangular 0.3 × 1.0 mm – 10 × 22 mm | Area-reduction per die ≤ 18 % to preserve ductility | Laser micrometer ±0.5 µm |

| Annealing | Recrystallise Cu lattice; target elongation ≥ 35 % | 520 °C, N₂+3 % H₂ atmosphere, residence 1.8 s | IR pyrometer ±3 °C |

| Enameling | Build 1-6 concentric insulation layers (polyester, polyester-imide, polyimide) | Concentricity ≥ 80 %, build 2-12 µm per pass | Beta-backscatter gauge, 1 kHz feedback |

| Inline Testing | Guarantee dielectric & mechanical integrity before next layer | Breakdown ≥ 6 kV (layer 1) → ≥ 12 kV (final) | Spark tester 50 Hz, 100 % coverage |

| Spooling | Deliver knot-free, tension-controlled packages for high-speed insertion | Tension 1–3 N, traverse pitch 0.3 mm | Servo dancer arm ±0.1 N |

Quality Control Protocol (QC-2205)

- Chemical Verification

Cu+Ag ≥ 99.97 %, O ≤ 5 ppm (ASTM B49) – ICP-OES every 2 h. - Dimensional Stability

Diameter CpK ≥ 1.67; edge radius on rectangular wire 0.4–0.8 mm – optical gauge 200 pts/m. - Electrical Integrity

Volume resistivity ≤ 0.017241 Ω·mm²/m @ 20 °C; inline eddy-current comparator rejects ≥ 0.3 % deviation. - Thermal Class Confirmation

220 °C class wire aged 500 h retains ≥ 50 % elongation – IEC 60851-3. - Final Package Audit

100 % outer-layer spark test, 3 kV; weight per spool ±0.2 %; barcode traceable to cast number.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | LXZ Standard | Typical Export Grade | Western Premium | Test Method |

|---|---|---|---|---|

| Conductor purity | ≥ 99.97 % Cu | ≥ 99.95 % Cu | ≥ 99.97 % Cu | ICP-OES |

| Diameter tolerance (round) | ±0.010 mm (≤0.450 mm) | ±0.015 mm | ±0.010 mm | ISO 19433 |

| Concentricity | ≥ 80 % | 70-75 % | ≥ 80 % | Beta-backscatter |

| Breakdown voltage (1 layer) | ≥ 6 kV | 4-5 kV | ≥ 6 kV | IEC 60851-5 |

| Elongation @ 20 °C | ≥ 35 % | 25-30 % | ≥ 35 % | ASTM B1 |

| Thermal class range | 130-220 °C | 130-180 °C | 155-220 °C | IEC 60085 |

| Cast-to-spool traceability | Full barcode | Lot only | Full barcode | Internal |

| Price index (FOB Shanghai) | 1.0 | 0.85 | 1.4–1.6 | — |

Result: LXZ delivers Western-premier electrical & mechanical performance at a 30-40 % lower landed cost, with 15-day lead time ex-works Luoyang.

Factory-Direct Advantage

Die inventory: 1,200 tungsten carbide dies, 0.05 mm increments → no MOQ on non-standard AWG/rectangular sizes.

Nitrogen anneal tunnel 110 m: guarantees zero surface oxidation, eliminates downstream “fish-eye” defects.

Inline data cloud: every meter logged; MES pushes COA to customer portal before shipment leaves gate.

Green footprint: 42 % electricity from on-site hydro, ISO 14064-1 verified; supports ESG procurement audits.

Transformer OEMs, motor repair shops and power-equipment engineers gain verified Class 220 windability, 6 kV+ safety margin and repeatable coil dimensions—without paying the Western premium.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive on your line exactly as it left ours – no moisture, no kinks, no surprises.

2.1 Sea-Freight Protection Philosophy

Luoyang Xinzhaohe’s 20-year transformer-grade supply chain is built around one metallurgical truth: copper and aluminum work-harden when abraded and corrode when exposed to 85 %RH >72 h. Our packaging is therefore specified as an extension of the annealing & enameling process, not an after-sales add-on. Every pallet is calculated for 30–45 day marine transit plus 20 days port-side buffer, equivalent to ≤5 g H₂O per m³ internal air volume.

2.2 Winding Wire Packaging Matrix

| Package Type | Target Wire Ø (mm) | Spool Standard | Gross Weight (kg) | Desiccant (g) | Stretch-Film Layers | VCI Paper | Stack Height per 20 ft |

|---|---|---|---|---|---|---|---|

| PT-5 | 0.20 – 0.80 | DIN 46397 | 5 ± 0.2 | 30 | 3 | Yes | 6 pallets (1.8 m) |

| PT-10 | 0.81 – 1.60 | DIN 46397 | 10 ± 0.3 | 50 | 3 | Yes | 5 pallets (1.7 m) |

| PT-25 | 1.61 – 5.00 | DIN 46397 | 25 ± 0.5 | 100 | 4 | Yes | 4 pallets (1.6 m) |

| PT-50 | 5.01 – 10.0 | DIN 46397 | 50 ± 1.0 | 200 | 4 | Yes | 3 pallets (1.5 m) |

| P-400 | 0.10 – 0.40 (multi-end) | GB/T 400 | 30 – 400 | 500 | 5 | Yes | 2 pallets (1.4 m) |

All spools are high-impact ABS or recycled PT; flanges ≥6 mm thickness to resist strap tension >800 N.

2.3 Carton & Pallet Build-Up

- Individual spool: Shrink-wrapped with 80 µm PE + VCI paper sleeve.

- Inner carton: 5-ply kraft, 32 ECT, barcode & heat-class label on two faces.

- Pallet base: 1200 × 1000 mm ISPM-15 fumigated pine, top deck protected by 5 mm hardboard.

- Strapping: PET strap 16 × 0.8 mm, cross-tie pattern, corner edge boards 40 × 40 mm.

- Desiccant: 2 × 125 g Montmorillonite bags per carton; color-change indicator visible through window.

- Stretch hood: 120 µm UV-stable film, 250 % pre-stretch, bottom heat-sealed to deny water ingress.

Result: Salt-spray test 1000 h per ASTM B117 – no corrosion beyond 1 mm from cut end.

2.4 Flat Wire & Foil Option

For CCA or copper flat conductors 1–22 mm wide, we adopt the same wooden pallet but add:

Interleaf: 0.1 mm polypropylene sheet every 3 windings.

Core plug: 3D-printed PLA plugs to lock ID 300/400/500 mm.

Steel hoop: 19 mm zinc-coated, break force 12 kN, isolated from conductor by 1 mm felt.

2.5 Logistics Chain – Luoyang to Your Dock

| Milestone | Mode | Transit Time | Temp / RH Logger | Load Factor |

|---|---|---|---|---|

| Factory → Qingdao Port | 17.5 m truck | 8 h | YES (PDF report) | 22 t payload |

| Qingdao → Busan / Singapore | Container vessel | 3–5 days | – | 28 t gross |

| Busan → LA / Hamburg / Dubai | Mother vessel | 14–28 days | YES (24 h cloud) | 28 t gross |

| Port → Your facility | Truck / Rail | Per schedule | – | – |

Weekly consolidation sailings; CIF, DAP, DDP Incoterms available. Transit insurance covered up to 110 % of goods value through PICC and Allianz.

2.6 Cost Advantage vs. Western Suppliers

By integrating rod casting, in-house enameling and port-side loading 350 km from our Luoyang works, we eliminate one trans-loading step typical of U.S. or EU plants. The saving – 4–6 % of landed cost – is passed on while still meeting IEC 60317, NEMA MW 1000 and EN 13601 standards. In 2023 our on-time arrival index was 97.4 % (1,847 TEU shipped), outperforming the industry average of 89 %.

Bottom line: Whether you need 50 kg of 38 AWG self-bonding wire on PT-5 spools or 20 t of 8 mm × 18 mm flat copper conductor, the material leaves Luoyayang in the same metallurgical condition it arrives on your winding line—no re-anneal, no re-spool, no scrap.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Enameled Winding Wire

Two Decades of Rod-to-Spool Mastery

Since 2003 we have lived inside the same 42-acre plant in Luoyong’s high-tech corridor, running a continuous process that begins with 8 mm oxygen-free copper rod and ends with fully tested enameled spools ready for your winders. 20 years of SPC data, 14 furnace rebuilds and >3 000 transformer-grade recipes give us a statistical edge that start-ups or trading houses simply cannot match. When you specify a 200 °C Class N overlay or a 6 kV breakdown guarantee, you are buying the distilled experience of 1.8 million production hours—not a catalogue promise.

Direct Factory Pricing, No Margin Stacking

Our business model is vertically integrated; we do not outsource rod drawing, annealing, enameling or final testing. Eliminating two layers of margin (trader + distributor) typically reduces total landed cost 12–18 % versus EU or North-American quotes for equivalent thermal class and concentricity. The table below shows a recent like-for-like comparison for 2.00 mm Class 180 enameled copper wire, CIF Hamburg:

| Cost Element | Western Supplier €/kg | LXZH €/kg | Delta |

|---|---|---|---|

| Material (Cu-ETP + enamel) | 7.85 | 7.85 | 0 % |

| Conversion (energy, labour) | 2.90 | 1.95 | –33 % |

| Margin & overheads | 2.40 | 1.10 | –54 % |

| Logistics (CIF) | 0.35 | 0.35 | 0 % |

| Total | 13.50 | 11.25 | –16.7 % |

Price stability: quotes remain valid for 30 days with raw-material escalation capped at ±4 % LME 3-month average.

Customisation Without MOQ Penalties

Need 18 % elongation instead of the usual 15 % for a high-inrush distribution transformer? A 0.85 mm build with 6 µm concentricity tolerance for a VPI process? Our in-line laser micrometres and PLC enamel feed system adjust within 90 seconds; change-over scrap is <1.2 kg. Typical custom runs:

| Custom Parameter | Standard Range | Achievable | Sample MOQ |

|---|---|---|---|

| Thermal class | 130–220 °C | 240 °C | 100 kg |

| Breakdown voltage | 3–7 kV | 10 kV | 100 kg |

| Elongation | 15–30 % | 35 % | 300 kg |

| Concentricity | ≤10 µm | ≤5 µm | 500 kg |

| Edge radius (flat wire) | 0.5×thickness | 0.3× | 1 000 kg |

All specials are produced on the same IEC 60317-compliant line, so certification (UL E345267, IEC 60317-0-1, REACH, RoHS) travels with the order.

Quality Infrastructure That Reduces Your Incoming Inspection

Every metre sees spark testing at 5 kV, diameter laser gauging at 4 kHz, and enamel cure monitoring via differential scanning calorimetry. We ship a CoA with each pallet summarising breakdown voltage, elongation, spring-back, and solderability. Customers report a 35 % reduction in incoming QC man-hours compared with Far-East traders who only provide batch certificates.

Logistics & Risk Management

48-hour dispatch on ex-stock sizes (0.20–3.00 mm round, 2–18 mm flat).

Weekly consolidation to Antwerp, Hamburg, Dubai, and Los Angeles cuts lead-time variability to <5 days.

Payment: 30 % with PO, 70 % on B/L; LC at sight available for first-time orders >10 t.

COVID-tested supply chain: dual enamel resin suppliers, 60 t copper rod safety stock, on-site 2 MW diesel backup—your line stays running when others stall.

Technical Support That Speaks Your Language

Our sales engineers are former winding-shop supervisors; they understand insertion speed, mandrel size, and how a 2 °C oven drift can kill adhesion. Whether you are designing a 66 kV distribution transformer or rewinding a 400 Hz aerospace motor, we will translate your electrical or thermal requirement into the correct build, insulation thickness, and spool format—then stand behind it with a 24-month warranty against enamel defects.

Ready to benchmark a premium alternative to expensive Western supply?

Email cathy@transformerstrip.com with your AWG/size, thermal class, and annual volume. We will return a detailed technical datasheet, breakdown-voltage histogram, and firm delivered price within 12 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing enameled wire from Luoyang Xinzhaohe.