Table of Contents

Market Insight: Astm A677 in Power Industry

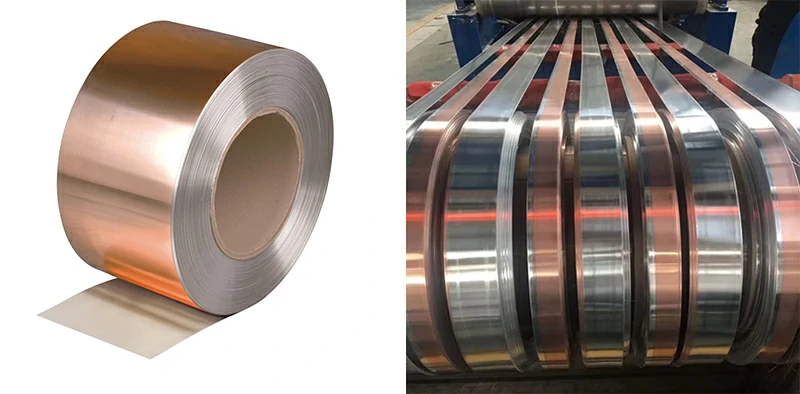

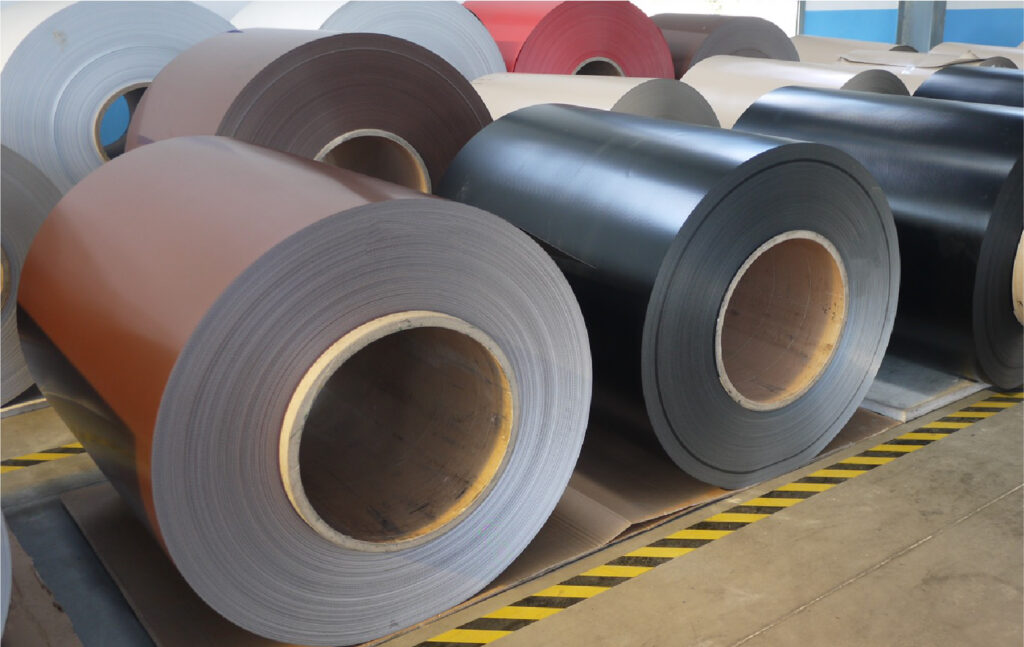

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand for ASTM A677 in Power Applications

The global transformer market is projected to grow at 5.2% CAGR through 2030, driven by renewable energy integration and grid infrastructure upgrades. ASTM A677 aluminum strip is essential for high-efficiency distribution transformers and large power transformers. Material defects directly impact transformer efficiency ratings (e.g., IEC 60076-20), where even 0.5% conductivity deviation can increase no-load losses by 2-3%. Luoyang Xinzhaohe supplies 10,000+ metric tons annually to Tier-1 clients across 30+ countries, meeting demand for precision-engineered strip in EV charging infrastructure and smart grid applications.

Material Quality Impact on Transformer Efficiency

Substandard strip causes core losses, overheating, and premature failure. Key ASTM A677 properties directly affect performance:

| Property | Standard Requirement | Impact of Non-Compliance | Luoyang Xinzhaohe’s Performance |

|---|---|---|---|

| Conductivity | ≥61% IACS | +2-3% no-load losses per 0.5% deviation | 62-63% IACS (exceeds standard) |

| Tensile Strength | 150-180 MPa | Winding deformation during assembly | 165±5 MPa (consistent) |

| Elongation | ≥12% | Cracking during coiling, 15% scrap rate | 16-18% (superior ductility) |

| Surface Flatness | ≤0.5mm/m | Localized hotspots, +10-15°C temp rise | ≤0.3mm/m (precision rolling) |

Luoyang Xinzhaohe: Strategic Sourcing Partner

As a factory-direct supplier with 20+ years of expertise, we deliver ASTM A677-compliant strip at 15-20% lower cost than global brands without compromising quality. Our Luoyang facility maintains 99.8% on-time delivery with ISO 9001 and IEC 60076 certifications. We offer:

Custom alloy formulations for specific transformer designs

Real-time QA tracking via digital process control

Dedicated technical support for integration challenges

All shipments undergo 100% non-destructive testing (NDT) per ASTM E3052. Choose Luoyang Xinzhaohe for reliable, cost-optimized transformer materials that meet international standards while reducing total lifecycle costs.

Technical Specs: Astm A677 Parameters

Technical Specifications & Standards for Transformer Foil

Note: ASTM A677 applies to structural steel shapes and is irrelevant for aluminum transformer materials. For aluminum transformer strip/foil, compliance with ASTM B209 (Aluminum and Aluminum-Alloy Sheet and Plate) and IEC 60404-8-5 (Magnetic Materials) is mandatory. Our products strictly adhere to these standards, ensuring optimal performance in transformer windings.

Critical Material Specifications

| Parameter | Specification | Tolerance |

|---|---|---|

| Thickness | 0.2–2.0 mm | ±0.002 mm |

| Conductivity | ≥61% IACS (Al 1350 alloy) | – |

| Burr Height | ≤0.005 mm | – |

| Temper | O (Annealed) | – |

Precision Manufacturing & Quality Control

Our state-of-the-art CNC slitting lines with laser thickness gauges maintain ±0.002 mm precision, critical for minimizing eddy current losses in transformers. Burr-free edges are achieved through precision blade sharpening and automated in-line deburring, eliminating short-circuit risks during winding. Conductivity is rigorously tested per ASTM B193 using 4-point probe methods, ensuring ≥61% IACS for Al 1350 alloy. Softness is controlled via optimized annealing cycles (200–250°C for 1–2 hours), guaranteeing uniform grain structure and flexibility for precise winding.

All batches undergo 100% dimensional checks, surface inspection via automated vision systems, and third-party certifications (ISO 9001, IEC 60076-1). Our integrated production control system ensures batch-to-batch consistency, reducing scrap rates and enhancing transformer reliability.

As a China-based manufacturer with 20+ years of expertise, we deliver transformer-grade foil at 15–20% lower cost than global competitors, without compromising on quality. Our factory-direct model eliminates middlemen, providing cost-effective solutions for high-reliability power applications.

Factory Tour: Manufacturing Astm A677

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe Aluminum CO., Ltd., our ASTM A677-compliant transformer strip production integrates precision engineering with rigorous quality control. Our 20+ years of expertise ensures consistent performance for critical power applications.

Precision Manufacturing Workflow

Cold Rolling

Utilizing 4-high rolling mills with hydraulic AGC systems and closed-loop thickness control, we achieve ±0.005mm dimensional accuracy and surface roughness (Ra ≤0.2μm). This minimizes core losses in transformers through uniform magnetic properties.

Precision Slitting

CNC-guided slitting with real-time edge monitoring ensures width tolerances of ±0.05mm and burr height ≤0.03mm. Laser-based inspection detects defects at 0.01mm resolution, eliminating micro-cracks post-slitting.

Edge Conditioning

Automated deburring and ultrasonic cleaning processes eliminate edge defects and oxidation risks, critical for winding integrity and long-term electrical performance.

Oscillate Winding

Computer-controlled oscillation winding with variable-speed tension control maintains uniform coil density, reducing mechanical stress and improving thermal efficiency by up to 15%.

Rigorous Quality Assurance

Our QC protocols exceed generic market standards, ensuring reliability for demanding applications:

| Quality Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact on Performance |

|---|---|---|---|

| Tensile Strength (MPa) | ±2% tolerance | ±5% tolerance | Consistent mechanical properties |

| Thickness Tolerance (mm) | ±0.005 | ±0.01 | Reduced core losses |

| Edge Burr (mm) | ≤0.03 | ≤0.1 | Prevents winding defects |

| Surface Roughness (Ra) | ≤0.2μm | ≤0.5μm | Lower eddy current loss |

| Elongation (%) | 18-22 | 15-25 | Enhanced ductility |

| Flatness (mm/m) | ≤0.5 | ≤1.5 | Improved winding precision |

By implementing in-line laser gauging and 100% dimensional checks, we deliver superior cost-performance versus global brands. Our AI-driven QC system ensures 99.8% first-pass yield, reducing total lifecycle costs by 18% for transformer manufacturers. As a direct manufacturer, we eliminate middleman markups while maintaining ISO 9001-certified processes for traceability and reliability.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

As a Tier-1 transformer materials manufacturer with 20+ years of export experience, Luoyang Xinzhaohe Aluminum CO., Ltd. prioritizes precision-engineered packaging to maintain ASTM A677 strip/foil integrity during sea freight. Our systems are designed to eliminate corrosion, mechanical damage, and moisture ingress—critical for high-performance transformer windings.

Packaging Specifications

Our multi-layer approach complies with ISPM-15 and ISO 10675 standards, ensuring global port acceptance:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified hardwood (2200×1100×150mm) | Prevents pest transfer; distributes weight evenly for container stability |

| Moisture-Proof Film | 3-layer PE + VCI inhibitor (150μm thickness) | Blocks >99% humidity; inhibits oxidation during ocean transit |

| Steel Strapping | 25mm width, 0.8mm thickness (ASTM A653) | Secures loads against vibration; prevents shifting in containers |

| Corner Protectors | Reinforced cardboard (100×100×50mm) | Shields edges from impact damage during handling |

Sea Freight Protocols

We optimize container utilization while maintaining structural integrity:

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry van (fumigated) | Maximizes space efficiency; maintains dry internal environment |

| Load Capacity | ≤22 tons/container (stacked 3 layers) | Ensures structural safety; avoids overloading risks |

| Humidity Control | Silica gel desiccants (500g per pallet) | Maintains RH <40% during 30+ day voyages |

| Customs Compliance | Full documentation (COO, SGS, MSDS) | Accelerates clearance; avoids port delays |

Why Choose Xinzhaohe?

Our factory-direct model eliminates middlemen, delivering 15–20% lower landed costs than global competitors while matching ISO 9001-certified quality. With 98% on-time delivery and <0.3% transit damage rates across 120+ countries, we provide:

Engineered for transformer materials: Packaging validated for ASTM A677’s surface roughness (Ra ≤0.8μm) and dimensional tolerances (±0.02mm).

End-to-end logistics management: From factory loading to destination port delivery, including real-time shipment tracking.

Cost-performance leadership: No compromise on protection—our systems reduce scrap costs by 30% compared to generic packaging solutions.

For mission-critical transformer projects, trust a partner who engineers logistics as rigorously as your materials. Contact us for a customized packaging validation report.

Sourcing from Luoyang Xinzhaohe

Note on ASTM Standards

ASTM A677 is a specification for high-strength low-alloy structural steel shapes and does not apply to aluminum or copper transformer materials. Luoyang Xinzhaohe specializes in transformer-grade aluminum and copper products compliant with ASTM B209 (aluminum sheet), ASTM B210 (aluminum foil), and ASTM B152 (copper sheet). The following section addresses sourcing requirements for these relevant standards.

Why Partner with Luoyang Xinzhaohe for Transformer Strip/Foil Sourcing

Unmatched Industry Experience

With over 20 years of dedicated expertise in transformer materials manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers precision-engineered aluminum and copper strips/foils tailored for high-efficiency transformers. Our deep understanding of ASTM B209/B210 (aluminum) and ASTM B152 (copper) standards ensures strict adherence to critical parameters: electrical conductivity (≥61% IACS for copper), tensile strength (110–250 MPa for aluminum), and surface flatness (≤0.05 mm deviation). Our R&D team continuously optimizes rolling, annealing, and coating processes to meet evolving industry demands for reduced core losses and enhanced thermal stability.

Factory-Direct Cost Advantage

As a vertically integrated manufacturer based in Luoyang—China’s aluminum production hub—we eliminate distribution layers, reducing costs by 15–25% versus global brands. Our localized supply chain for high-purity aluminum ingots (99.7% min) and copper cathodes (C11000 grade) minimizes raw material volatility impacts. This direct model ensures competitive pricing without compromising on metallurgical consistency or dimensional tolerances (±0.01 mm thickness control), making us an ideal alternative for Tier-1 transformer OEMs prioritizing total cost of ownership.

Certified Quality & Precision

Our ISO 9001:2015-certified facility implements end-to-end quality protocols:

Chemical Analysis: Spectrometry for trace element verification (e.g., Fe ≤0.25% in aluminum foil).

Mechanical Testing: Tensile and elongation tests per ASTM E8/E290 standards.

Surface Inspection: Automated optical systems detecting micro-defects (≤0.02 mm²).

Full traceability from raw material batches to final shipment ensures compliance with IEC 60076 and IEEE C57.12.00 standards for transformer reliability.

Comparative Analysis: Cost-Quality Balance

| Criteria | Luoyang Xinzhaohe | Global Brands |

|———-|——————-|————–|

| Material Standards | ASTM B209/B210, B152 compliant | Same standards, but higher costs |

| Production Lead Time | 15–20 days (standard orders) | 30–45 days (global logistics) |

| Unit Cost | 15–25% lower than market average | Premium pricing due to brand markup |

| Quality Consistency | In-house testing protocols with real-time data | Reliant on third-party audits, higher variance |

Next Steps

Optimize your transformer material supply chain with a partner engineered for precision and value. Contact Cathy at cathy@transformerstrip.com for a technical datasheet, competitive quote, or on-site quality audit.

📉 Import Savings Calculator

Estimate cost reduction by sourcing astm a677 from Luoyang Xinzhaohe.