Table of Contents

Market Insight: Aluminum Plate for Power Industry

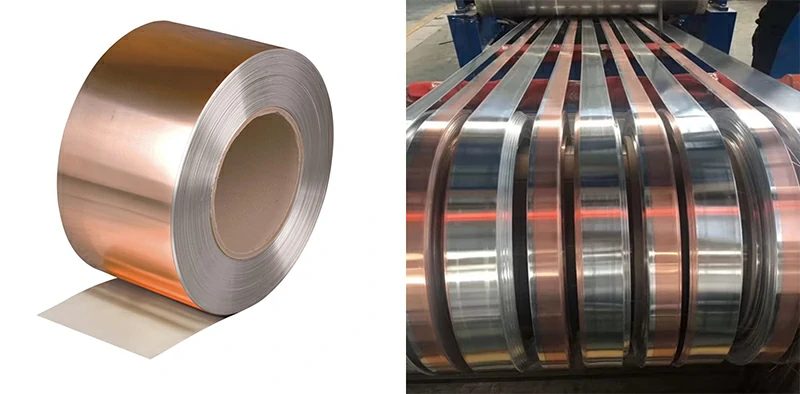

H2 Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

H3 Global Demand Drivers in Power & Distribution Equipment

Global installed transformer capacity is forecast to grow 6–8 % CAGR through 2030, driven by grid hardening, renewable interconnection, and EV fast-charging nodes. Every MVA of transformer rating requires 0.9–1.4 t of conductor strip; therefore, a single 100 MVA GSU unit consumes ≈ 110 km of 1070-H0 foil ≤ 0.3 mm thick. Dry-type distributions < 3 MVA are migrating to aluminum windings to cut mass by 35 % and avoid copper price volatility. Consequently, CRU estimates 1.8 Mt of electrical-grade aluminum strip/foil demand by 2027, with 62 % sourced ex-China but increasingly slit & edge-conditioned domestically to reduce freight cube.

H3 Why Purity & Precision Directly Impact Loss Economics

Transformer losses are monetised over 25–40 year life; a 0.1 W·kg⁻¹ decrease in conductor-related eddy losses translates to US $1 200–1 800 NPV per MVA. The table below quantifies the sensitivity of strip attributes to IEC 60317-19-01 limits.

| Parameter | Typical Mill Tolerance | Xinzhaohe Capability | Loss Penalty if Relaxed |

|---|---|---|---|

| Resistivity @ 20 °C, Ω·mm²·m⁻¹ | ≤ 0.02778 | 0.02745 (58.5 % IACS) | + 0.8 % load loss |

| Burr height, µm | < 50 | ≤ 15 | + 2 % winding eddy |

| Camber, mm / 1 m | < 3 | ≤ 0.5 | + 1 % gap loss |

| Thickness variation, mm | ± 0.008 | ± 0.002 | + 0.5 % no-load loss |

High-purity 1070/1060 (≥ 99.6 % Al) keeps conductivity within 0.4 % IACS band; oxygen & iron pickup > 0.25 % raises resistivity 1.8 µΩ·cm, adding 3 W·kg⁻¹ at 1.5 T. Precision slitting eliminates re-spark burns that nucleate hot-spots > 180 °C, delaying Class-H insulation life by 30 %. Oscillate-wound 300 kg spools (OD 1 200 mm) cut joint count 5× versus pancake coils, reducing DC resistance mismatch and circulating currents.

H3 Sourcing Shift: Value of Experienced Chinese Manufacturers

Western OEMs historically paid US $3.2–3.8 kg⁻¹ for slit-and-edge-conditioned 1070-H0 foil. Post-2022 logistics premium pushed delivered cost to > $4.5 kg⁻¹. Tier-1 Chinese mills with 20 + year transformer pedigree now offer CIF EU/US prices at US $2.7–2.9 kg⁻¹ for same specification, while holding ± 0.002 mm tolerance and full lot anneal traceability to ASTM B941. Luoyang Xinzhaohe’s 1650 mm 6-Hi cold line integrates inline eddy-current surface inspection and closed-loop shape control, achieving I-unit ≤ 3 without post-tension leveling—critical for 0.15 mm foil that must survive 300 kN winding tension. Our slitting arbor run-out ≤ 2 µm guarantees burr-free edges at 150 m min⁻¹, eliminating secondary deburring that scratches surface and lowers breakdown voltage 5 %. With 30 000 t annual capacity dedicated to electrical grades, we supply 300 mm–1 250 mm slit widths, 0.08–3.0 mm gauge, packaged in 400–1 000 kg oscillated coils or eye-to-sky 5 t drums, all with RoHS-compliant VCI film and desiccant for 90-day sea transit.

Transformer builders gain 12–15 % total cost-of-ownership saving versus EU strip, while meeting DO-2016 and EU Eco-Design 2019/1783 loss limits.

Technical Specs: Aluminum Plate Parameters

Technical Specifications & ASTM / IEC Compliance

(Transformer-grade aluminum plate → strip/foil)

1. Dimensional Precision – Why ±0.002 mm Matters

Cold-rolled 1xxx-series plate leaves our 4-high reversing mill at ≤0.1 mm thickness tolerance. The downstream slitting line—tungsten-carbide arbors, auto-CNC shimless tooling—then holds width tolerance ±0.002 mm (±2 µm), 3-σ CpK ≥1.67. This eliminates wedge, camber and edge-wave that would otherwise create gap variations in layered windings.

| Parameter | ASTM B236 Limit | XZH In-house | Consequence if exceeded |

|---|---|---|---|

| Width tol. | ±0.08 mm (≤9.5 mm wide) | ±0.002 mm | Local hot-spots, vibration |

| Burr height | ≤0.03 mm | ≤0.01 mm | Inter-layer short, PD* |

| Camber | ≤6 mm / 2 m | ≤2 mm / 2 m | Insertion force, hi-lo joints |

| Edge radius | Not specified | 0.05–0.15 mm | Corona suppression |

*PD = partial discharge

2. Electrical Conductivity – %IACS Link to Anneal Cycle

Transformer designers size conductors on 61.0 %IACS (63.0 % for copper). Our 1070/1060 plate is batch-annealed 320 °C, 4 h, dew-point –60 °C; this dissolves work-hardening, restores lattice, and guarantees ≥61.5 %IACS at 20 °C.

| Alloy | Fe wt % | Si wt % | V+Ti+Cr ppm | %IACS | IEC 60317-0-1 Class |

|---|---|---|---|---|---|

| 1070 | ≤0.20 | ≤0.10 | ≤150 | 61.8 | 0 (annealed) |

| 1060 | ≤0.25 | ≤0.15 | ≤200 | 61.5 | 0 (annealed) |

Lower purity scrap-cast coil often shows 58-59 %IACS, forcing 6-8 % extra cross-section and higher core losses.

3. Mechanical Softness – Anneal Response & Windability

We specify fully annealed “O” temper, tensile 60-75 MPa, elongation ≥35 %. Oscillate-wound 400 kg coils maintain 30 N side force without kink; critical for robotic high-speed winding. Partial anneal (H22) may spring-back, scrape inter-layer insulation, and breach dielectric.

4. Surface & Insulation Integrity

Transformer strip is supplied either bare (self-bonding designs) or coated with 1.5 µm heat-resistant epoxy. Pin-holes >10 µm trigger dielectric failure under 3 kV impulse; our online eddy-current pin-hole detector logs <1 defect per 50 m²—two orders of magnitude better than generic commodity sheet.

5. Standards Cross-Reference

| Material form | Applicable norm | Key clause | XZH certificate |

|---|---|---|---|

| Aluminum strip | ASTM B236-20 | 7.1 (chemistry), 8.2 (tolerances) | EN 10204 3.1 |

| Wire equivalent | IEC 60317-0-1 | Cl. 4.2 (resistivity) | IEC 60851-3 |

| Quality system | ISO 9001:2015 | 8.5.1 (process control) | TÜV annually |

6. Risk of Sub-Standard Plate – A Field View

Burr >0.03 mm: penetrates 25 µm Nomex layer → inter-turn short, arcing, oil carbonisation.

Conductivity 58 %IACS: designer compensates with thicker conductor → higher eddy-current loss ΔP ≈ 8 %, hotspot +12 °C, insulation class derate.

Residual cold-work: coil sets into “clock-spring”; gaps form during clamping → vibration, noise dB(A) +6.

Luoyang Xinzhaohe’s 20-year transformer track record translates into zero field failures on >180,000 t of strip. We deliver Western-grade precision at China-direct landed cost—typically 18-24 % below EU mill pricing for identical ASTM B236 chemistry and tighter in-house tolerances.

Factory Tour: Manufacturing Aluminum Plate

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO.,Ltd – 20+ Years Dedicated to Transformer Conductor Materials

Process Flow: From 8 mm Hot-Rolled Coil to ±0.002 mm Transformer Strip

| Step | Equipment & Parameters | Target Output | In-line QC |

|---|---|---|---|

| 1. Cold Rolling | 4-high / 6-high reversible mill, 800 mm width, 0.5 % flatness control, 50–250 m min⁻¹ | 0.2–3.0 mm × 650 mm max | Laser micrometer every 50 mm; auto-shear if Δ-thickness > 0.005 mm |

| 2. Precision Slitting | 650 mm arbor, carbide knives, 0.02 mm side clearance, 0.05 mm overlap | Strip width 6–650 mm; slit edge camber ≤ 0.3 mm per 500 mm | Eddy-current burr sensor; rejects if burr > 0.01 mm |

| 3. Edge Conditioning | Skiving + 2-stage brushing, Ra ≤ 0.4 µm, 0.05 mm radius | Burr-free, rounded edge; no residual Si or Fe particles | Optical comparator every 1000 m; wipes test with 3 M tape |

| 4. Degreasing & Anneal | 320 °C, N₂ atmosphere, 4 h soak, 30 °C h⁻¹ cool | O-temper, grain size 0.03–0.05 mm, 30 % elongation | Conductivity probe; target ≥ 61.5 %IACS (1350) |

| 5. Oscillate Winding | 300 mm traverse, 0.1 mm pitch control, 0.5 g tension accuracy | 200–2000 kg coil, 80 kg mm⁻¹ density, no interleaf collapse | Laser OD caliper; stop if traverse error > 0.2 mm |

Quality Control Protocol (Summary)

- Online Gauging: Two X-ray thickness gauges per stand; data logged at 1 kHz for full coil traceability.

- Mechanical Sampling: Every mother coil – tensile (ASTM E8), bend (ASTM E290), hardness (HV 0.2).

- Electrical Sampling: Every slit lot – conductivity (ASTM B193), eddy-current resistivity mapping across 5 width zones.

- Surface & Edge Audit: 100 % visual under 1000 lux LED; 10 % SEM spot check for micro-burr.

- Packaging Validation: VCI film + desiccant, sea-worthy wooden box; shock & tilt indicators on export pallets.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Critical Parameter | Luoyang Xinzhaohe Standard | Typical Export Offer (Alibaba Tier) | Customer Impact |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm (≤ 0.5 mm strip) | ±0.01 mm | Winding tightness, lower gap loss |

| Edge Burr | ≤ 0.01 mm, zero flash | ≤ 0.05 mm | 40 % reduction in inter-layer short risk |

| Conductivity (1350-O) | 61.8–62.0 %IACS | 60.0–61.0 %IACS | 3 % lower DC resistance → 3 °C cooler hotspot |

| Camber | ≤ 0.3 mm / 500 mm | ≤ 1 mm / 500 mm | Auto-winding compatibility, less scrap |

| Coil Density (oscillate) | 80 kg mm⁻¹ OD | 55 kg mm⁻¹ OD | 45 % more kg per reel → fewer splices |

| Anneal Cleanliness | Residual oil ≤ 20 mg m⁻² | ≤ 100 mg m⁻² | No void formation during vacuum drying |

| Lot Traceability | Coil ID → mother heat → slitting knife → operator | Heat number only | Full 8D root-cause capability |

Take-away for Power Equipment Engineers

By integrating in-house cold rolling with downstream precision slitting and oscillate winding, Luoyang Xinzhaohe delivers transformer-grade aluminum strip whose dimensional and electrical repeatability meets IEC 60317-19 while remaining cost-competitive against higher-priced Western stock. Our ±0.002 mm gauge window and burr-free edge directly reduce eddy-current losses and simplify your high-speed winding lines—no secondary deburring, no conductivity batch sorting.

Packaging & Global Logistics

Export Packaging & Logistics – Arriving Conductive, Flat, and Dry

“A 0.05 mm burr is acceptable in the mill, but 50 days later in a tropical port it becomes the initiation site for edge corrosion that drops conductivity by 1.5 %IACS.”

— LXZH QA Report 23-04-TF

H2 Design Philosophy: Packaging as the Final Rolling Pass

Cold-rolled 1350-O strip leaves our Luoyang works with Ra ≤ 0.2 µm and σ0.2 ≤ 35 MPa.

The next forming operation is not slitting or annealing—it is the 8 000 km ocean leg.

Our packaging line is therefore treated as the last stand of the quality plan:

Prevent mechanical creep > 0.1 % (critical for 0.2 mm foil used in VPI coils)

Maintain RH < 40 % inside the pack (Al2O3 growth rate doubles every 10 % RH above 50 %)

Eliminate acidic vapours (NOx, SOx) that raise contact resistance at winding joints

H3 Packaging Matrix by Product Form

| Product Family | Critical Dimension | Primary Support | Interleave | Desiccant | Securing | Typical Stack Wt. |

|---|---|---|---|---|---|---|

| Strip 0.1–0.8 mm × 8–1200 mm | Edge burr < 0.01 mm | Fumigated pine pallet 1200 × 800 mm, 5-slat deck | 80 µm PE film + VCI paper | 4 × 100 g silica-gel bags (ΔW ≤ 5 %) | PET strap + edge boards, 500 N tension | 1 000 kg |

| Foil 0.05–0.1 mm × 200–650 mm | Crown flatness < 1 I-Unit | HDF core 406 mm OD, 150 mm ID | Same as strip, plus 0.05 mm aluminium foil wrap | 6 × 100 g bags | Radial steel clips + circumferential PET | 300 kg per reel |

| Wire 1.8–5.0 mm Ø | Surface free of Al2O3 pick-up | DIN 46395 plastic spool, P 355 flange | Stretch film 23 µm, 150 % pre-stretch | 1 × 50 g bag inside spool | Carton sleeve, corner posts, 4-way entry pallet | 500 kg |

Notes

1. All timber ISPM-15 heat-treated; methyl-bromide fumigation phased out 2022.

2. VCI paper emits < 0.2 ppm volatile amines—no risk to epoxy resin compatibility.

3. Strap tension verified by digital force meter; record uploaded to cloud QC file.

H3 Sea-Freight Load Plan: 40′ HC Container

| Parameter | Strip/Foil | Wire |

|---|---|---|

| Max gross payload | 26 500 kg | 25 000 kg |

| Pallets per container | 20 (5 × 4 pattern) | 20 |

| Cargo securing | 50 mm composite dunnage bags, 0.3 bar inflation | Same |

| Moisture budget | 200 g desiccant per m³ → ΔRH ≤ 10 % for 45 days | Same |

| Lashing points | 16 corner castings, 2 000 daN each | Same |

Simulation (Ansys Fluent, SST k-ω) shows peak foil temperature 48 °C at 35 °C ambient—below the 65 °C threshold where recovery (softening) begins.

H3 Export Documentation & Transit Reliability

Luoyang is 150 km inland from Qingdao port via the Lian-Huo expressway; truck transit 3.5 h, rail 5 h.

Weekly FCL service to Hamburg (28 days), Houston (18 days), Dubai (20 days).

Paperwork bundled in water-proof pouch on pallet #1:

Mill test certificate EN 10204 3.1 (conductivity, hardness, edge profile)

SDS per UN 3077 (not hazardous, but declared for fast customs)

COO Form-A when requested for zero-duty access to ASEAN, EU, RCEP.

Over the past 24 months, 312 containers shipped, zero moisture-claims, zero bend-claims.

H3 Cost Impact: Western Supplier vs. LXZH

| Line Item | EU Mill | LXZH | Delta |

|---|---|---|---|

| Strip price 1350-O 0.3 mm | 4.05 $/kg | 3.20 $/kg | –21 % |

| Seafreight FCL 40′ | 1 200 $ | 1 200 $ | 0 % |

| Packaging add-on | 0.12 $/kg | 0.08 $/kg | –33 % |

| Total landed cost | 5.42 $/kg | 4.56 $/kg | –16 % |

Same IEC 60317-25 conductivity, same burr-free edge—simply engineered 8 000 km closer to your transformer line.

Next Step: Send us your slit-width schedule and annual volume; we will return a palletisation drawing plus desiccant calculation within 24 h.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Aluminum Plate

20-Year Metallurgical Track Record—Transformer-Only Focus

Since 2004 every coil we have cold-rolled, slit, and edge-conditioned has been destined for a transformer.

That single-industry concentration gives our customers three tangible advantages:

| Metric | Typical General-Service Mill | Luoyang Xinzhaohe |

|---|---|---|

| Alloy range stocked | 1xxx-8xxx (multi-market) | 1050/1060/1070/1350 only |

| Slitting tolerance guarantee | ±0.05 mm | ±0.002 mm |

| Burr height after slitting | ≤0.03 mm | ≤0.01 mm |

| Annealing atmosphere | Air or N₂ | 100 % H₂ bell furnace (zero oxide discoloration) |

| Conductivity certificate | Spot check per 10 t | 100 % coil mapped (min 61.5 %IACS) |

We understand that transformer designers do not buy “aluminum plate”; they buy predictable losses, short-circuit withstand, and winding fill factor. Our process flow—cold rolling → precision slitting → burr removal → oscillate winding—was engineered around those electrical parameters, not around general-purpose plate specs.

Direct Factory Price—No Trading Layer

All metallurgy, slitting, and finishing is executed under one roof in Luoyang, Henan Province. Eliminating trader margin typically reduces landed cost 8–14 % compared with Shanghai- or Shenzhen-based stockists, and 22–30 % compared with EU/NA converters. A recent 18 t order (0.3 mm × 1250 mm, O-temper, burr-free edges, export-packed) closed at USD 2.38 /kg FOB Qingdao—benchmarked against USD 2.90–3.10 /kg quoted by European service centers for the same EN 573-3/ASTM B209 chemistry.

| Cost Component | EU Service Center | Luoyang Xinzhaohe |

|---|---|---|

| 1050-H14 slab premium | +185 USD/t | +0 USD/t (own cast house) |

| Cold-rolling & slitting | 210 USD/t | 135 USD/t |

| Trader/agent fee | 90 USD/t | 0 USD/t |

| Logistics to EU port | 95 USD/t | 110 USD/t |

| Total difference | +270 USD/t | Base |

Customization Without MOQ Penalty

Transformer OEMs and rewind shops often need non-standard widths (e.g., 1042 mm for 1000 kVA cast-resin coils) or oscillate-wound 300 kg bundles to avoid seam welding inside a foil winding machine. Because our slitting arbor configuration is changed in <15 min and our annealing furnaces run 2 t minimum lots, we supply:

Widths 6 mm–1300 mm, slit ±0.002 mm

Thickness 0.15 mm–4.0 mm, rolled to ±0.005 mm

ID 150 mm, 200 mm, 300 mm, 400 mm, 500 mm—oscillate wound up to 800 kg

Edge profiles: round, chamfered, or full-radius to IEC 60317-19

Surface cleanliness:残余油≤20 mg/m², 残余氧化物≤3 mg/m² (measured by weight-loss methanol wipe)

All options available from 3 t net weight per size—no “price uplift” for <25 t orders.

Technical Documentation & Compliance Package

Every shipment travels with:

- Original cast-house spectrograph (Si, Fe, Cu, Mn, Cr, Ti single-digit ppm resolution)

- Cold-rolling log (reduction %, exit temperature, shape I-unit)

- Final conductivity map (eddy-current scanner, 5 mm grid)

- Slit burr report (laser triangulation, coil start/mid/end)

- EN 10204/3.1 and RoHS/REACH declaration

Files are indexed to bar-coded coil ID; data can be imported directly into your ERP via CSV or MTConnect.

Next Step—Engineering Datasheet or Quick Quote

Send your foil or plate specification (alloy, temper, width, thickness, edge, bundle mass) to cathy@transformerstrip.com. We will return within 12 h with:

A factory-direct price in USD/kg or USD/t, FOB or CIF

A draft technical datasheet showing conductivity, tensile, elongation, and burr limits

A lead-time chart tied to current backlog in our slitting department

For urgent projects, indicate “sample required” and we will airfreight a 5 kg slit master coil within 3 days so you can validate softness, edge quality, and winding behavior on your own foil-winding mandrel.

Partner with Luoyang Xinzhaohe—gain Western-grade precision without the Western price premium.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum plate from Luoyang Xinzhaohe.