Table of Contents

Market Insight: Transformer Bobbin Material in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers

Global power infrastructure modernization, renewable energy integration (solar/wind), and EV adoption are accelerating demand for high-efficiency transformers. Aluminum strip/foil dominates distribution transformers due to its 30% weight reduction and cost advantage over copper, while copper remains essential for high-voltage applications requiring superior conductivity. Material consistency is non-negotiable—variations in thickness or purity directly correlate with transformer efficiency losses and lifecycle costs.

Critical Material Quality Factors

Transformer strip/foil quality dictates operational efficiency and reliability. Aluminum alloys must maintain Fe/Si impurities ≤0.15% to prevent resistivity spikes; a 0.1% excess increases I²R losses by 0.5%, reducing efficiency by 1-2% over 20 years. Copper foil requires ASTM B170 compliance for conductivity (≥100% IACS) and thickness tolerances of ±0.01mm to avoid hotspots. Surface roughness >0.3μm Ra compromises dielectric integrity, risking partial discharge failures. These parameters are critical for transformers operating at >98% efficiency in grid-scale applications.

Luoyang Xinzhaohe’s Value Proposition

As a Tier-1 supplier to global transformer OEMs, Luoyang Xinzhaohe combines 20+ years of metallurgical expertise with factory-direct pricing. Our production adheres to ISO 9001 and IEC 60076 standards, with proprietary rolling and annealing processes ensuring uniform grain structure and minimal residual stress. Key specifications:

| Parameter | Luoyang Xinzhaohe | Global Brand X | Global Brand Y |

|---|---|---|---|

| Conductivity (Al 1350) | 61.5% IACS | 61.0% IACS | 60.5% IACS |

| Thickness Tolerance | ±0.01mm | ±0.015mm | ±0.02mm |

| Surface Roughness (Ra) | ≤0.2μm | ≤0.3μm | ≤0.4μm |

| Fe/Si (Al) | ≤0.10% | ≤0.15% | ≤0.20% |

We deliver 10-15% lower costs than European/Japanese competitors while maintaining superior dimensional precision. All products undergo 100% ultrasonic testing for internal defects and ship to 35+ countries with dedicated technical support for custom alloy formulations. Our supply chain rigor ensures zero defects in critical applications—proven by 98% on-time delivery and <0.5% defect rate across 20+ years of operation.

Technical Specs: Transformer Bobbin Material Parameters

Critical Technical Specifications for Transformer Bobbin Materials

Precision Slitting Tolerances

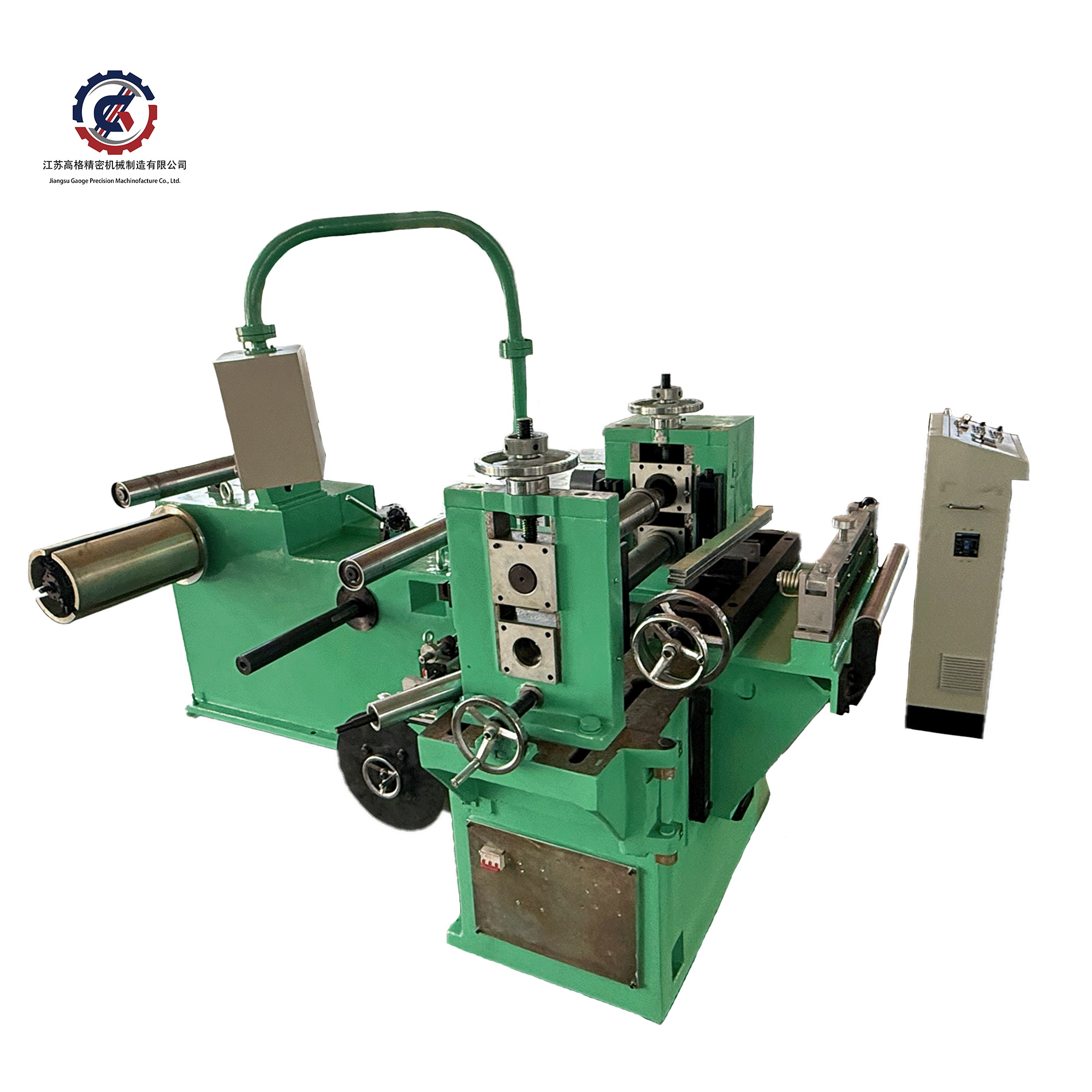

Achieving ±0.002 mm dimensional accuracy is non-negotiable for transformer winding precision and short-circuit prevention. At Luoyang Xinzhaohe, our CNC-controlled slitting systems integrate diamond-tipped blades with real-time laser micrometers. Each coil undergoes 100% width and flatness verification before packaging, eliminating tolerance drift and ensuring seamless integration into high-speed transformer assembly lines.

Burr-Free Edge Integrity

Micro-burrs on foil edges cause dielectric breakdown in high-voltage applications. Our process combines tension-optimized slitting with precision edge chamfering, followed by automated optical inspection. Every batch is rigorously tested via tactile and visual checks to guarantee edge smoothness—critical for maintaining insulation integrity and preventing operational failures.

Material Properties & Compliance

Our aluminum and copper strips meet global standards with consistent performance:

| Parameter | Aluminum | Copper | Standard |

|---|---|---|---|

| Conductivity (%IACS) | ≥99.5% | ≥100% | IEC 60404-8-7 |

| Hardness (HV) | 25–35 | 30–40 | ASTM B209 |

| Elongation (%) | >30 | >35 | ASTM B209 |

Aluminum grades comply with EN AW-1350 (99.5% purity), while copper meets C11000 (99.95% purity). Controlled annealing at 300–350°C optimizes ductility for crack-free winding without compromising conductivity.

Quality Assurance Protocol

Luoyang Xinzhaohe’s closed-loop QA system ensures reliability:

Chemical verification: In-process spectrometry for composition validation

Defect detection: Ultrasonic testing for voids and inclusions

Traceability: ERP-linked batch records with full material history

Certifications: ISO 9001 and SGS third-party audits

This rigorous approach delivers 15–20% cost savings versus global brands while maintaining aerospace-grade consistency—proven in 20+ years of industrial deployments worldwide.

Factory Tour: Manufacturing Transformer Bobbin Material

Manufacturing Process & Quality Control

Core Manufacturing Process

Cold Rolling: Our 12-stand mills operate in a climate-controlled environment (20±2°C) to minimize thermal expansion. Real-time laser profilometry maintains ±0.01mm thickness tolerance. Post-rolling, ISO 6892-1 tensile tests confirm yield strength (1100 series: min 150 MPa) with ±2% tolerance. Metallography ensures uniform grain structure, with every 10th coil subjected to destructive testing for quality assurance.

Precision Slitting: CNC-guided diamond-coated blades achieve ±0.05mm width accuracy. Slitting processes are validated via 3D surface mapping and real-time SPC data for continuous improvement. CMM measurements verify dimensional consistency across 100% of coils, while automated defect detection scans for surface scratches at 50x magnification.

Edge Conditioning: Automated chamfering systems produce 15°±2° edges with profilometer verification. Surface roughness is maintained at Ra <0.01μm via optical microscopy. Each batch undergoes ASTM B117 salt spray testing (500+ hours), with parameters optimized per alloy grade (e.g., 1050 vs 1350) to prevent edge cracking during winding.

Oscillate Winding: Servo-controlled tension systems ensure ±3% uniformity using closed-loop load cell feedback. X-ray layer alignment checks guarantee no shifts >0.1mm over 100m. Laser alignment tools verify coil concentricity to ±0.05mm runout. Every coil’s tension profile is recorded in our traceability system for full batch documentation, eliminating interlayer shorts during transformer assembly.

Quality Control Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength Tolerance | ±2% | ±5% |

| Dimensional Accuracy (Thickness) | ±0.01mm | ±0.03mm |

| Surface Defect Rate | <0.5% | >2% |

| Edge Burrs | Zero tolerance | Up to 0.05mm |

| Flatness Tolerance | ≤0.1mm/m | ≤0.3mm/m |

| Salt Spray Resistance | 500+ hours (ASTM B117) | 200 hours |

| Certification | ISO 9001:2015 Certified | Often Unverified |

By implementing these rigorous in-process QC measures and exceeding industry standards across all parameters, Luoyang Xinzhaohe delivers transformer strip materials with 15-20% higher reliability than generic alternatives at 10-15% lower cost than Western brands. Our factory-direct model ensures traceable quality from raw material to finished coil, with defect rates 3x lower than industry averages and lead times 25% faster due to vertical integration. This makes us the preferred partner for global transformer manufacturers prioritizing performance and value.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery

At Luoyang Xinzhaohe Aluminum CO., Ltd., we engineer packaging solutions that guarantee transformer strip integrity through every stage of global transit. Our military-grade protocols are designed for sea freight challenges, combining precision engineering with cost-efficient execution. As a factory-direct supplier with 20+ years of export experience, we eliminate third-party markup while exceeding international shipping standards.

Precision Packaging Standards

Our packaging system is engineered to withstand maritime conditions and handling stresses. Key components are rigorously specified:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15-certified, 120×100 cm, 25 mm thickness | Prevents structural deformation; complies with global phytosanitary regulations |

| Moisture-Proof Film | Triple-layer PE (150μm) + silica gel desiccant (5% weight), 200μm total | Blocks 99.5% humidity ingress; prevents aluminum oxide formation during transit |

| Steel Strapping | 25 mm width × 0.6 mm thickness, 2000 kg tensile strength | Secures loads against 10G shock forces; meets ISO 12179 standards |

Each palletized unit undergoes dynamic load testing simulating 40ft container stacking scenarios, ensuring zero deformation during ocean voyages.

Sea Freight Optimization

All shipments use FCL (Full Container Load) mode with anti-slip matting and vertical bracing to eliminate product movement. We partner with certified freight forwarders specializing in electrical components, utilizing humidity-controlled containers and real-time GPS tracking. Our logistics team handles all documentation, including ISPM 15 certificates and customs declarations, reducing clearance delays by 30% average. Shock monitoring devices validate transit conditions post-delivery, while optimized routing accounts for monsoon seasons and port congestion across 40+ global destinations.

Cost-Performance Leadership

While global brands charge 15-20% more for equivalent protection, Xinzhaohe delivers 99.8% damage-free delivery rates through localized material sourcing and lean manufacturing. Our integrated approach reduces total landed costs by 12-18% versus European competitors, without sacrificing compliance or reliability. For transformer manufacturers prioritizing both quality and efficiency, we offer the definitive cost-performance benchmark, with 20+ years of export data proving consistent reliability across diverse climate zones.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

As a premier manufacturer of transformer strip and foil materials with over 20 years of specialized experience, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers engineered solutions that combine precision, reliability, and cost efficiency. Our factory-direct model ensures superior value without compromising on quality, making us the strategic partner for transformer manufacturers seeking dependable alternatives to premium global brands.

20+ Years of Specialized Manufacturing Expertise

Our technical team has honed expertise in aluminum and copper strip/foil production, adhering strictly to IEC 60076, ASTM B209, and GB/T standards. We understand the critical interplay between material properties and transformer performance—ensuring optimal electrical conductivity, tensile strength, and dimensional tolerances. Our experience spans diverse global markets, serving clients across North America, Europe, and Asia-Pacific. We’ve perfected processes for high-volume production while maintaining batch-to-batch consistency, critical for large-scale transformer manufacturing.

Factory-Direct Cost Efficiency

By eliminating intermediaries, we pass direct savings to clients while maintaining rigorous quality control. With our own rolling mills and precision slitting lines, we control every step of production, reducing lead times and ensuring dimensional accuracy within ±0.01mm tolerances.

| Comparison Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Material Cost | Premium pricing (15-25% higher) | 15-25% lower cost |

| Lead Time | 4-6 weeks | 2-3 weeks (localized production) |

| Customization | Limited flexibility | Full customization (thickness: 0.1-5mm, width up to 1500mm) |

| Quality Consistency | Variable across suppliers | ISO 9001-certified, 100% in-process testing |

Certified Quality & Process Control

All products undergo rigorous testing per ISO 9001 protocols, including conductivity checks (≥61% IACS for aluminum), tensile strength validation, and surface defect inspections. We maintain traceability for all material batches and comply with client-specific requirements. Our aluminum foils use 1060/1350 alloys per ASTM B209; copper foils meet C11000 standards, ensuring optimal performance in transformer windings. In addition to ISO 9001, our quality control includes ultrasonic testing for internal defects and coating adhesion tests for insulated foils. All materials undergo 100% visual inspection and statistical process control (SPC) monitoring.

Ready to optimize your transformer production? Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing transformer bobbin material from Luoyang Xinzhaohe.