Table of Contents

Market Insight: Aluminum Plates for Power Industry

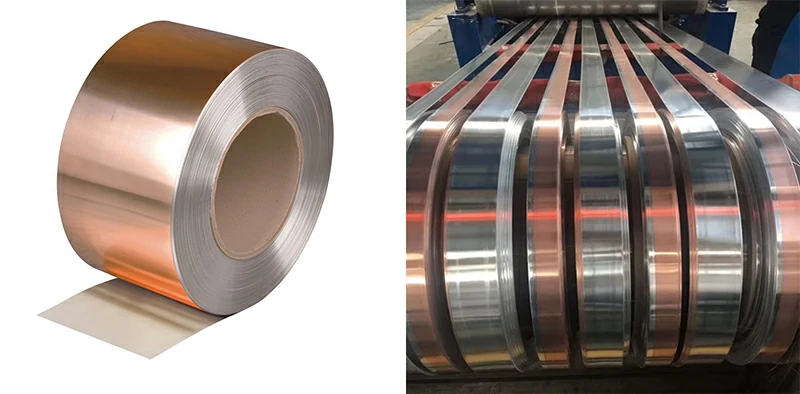

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Global installed transformer capacity is forecast to grow 6–8 % CAGR through 2030, driven by grid expansion, renewable integration, and EV fast-charging hubs. Every MVA of dry-type or liquid-immersed capacity consumes 0.45–0.65 t of conductor strip/foil; China alone accounts for 42 % of annual procurement. The shift to amorphous-core and high-efficiency IE4/IE5 designs is tightening conductor tolerances: slitting width ±0.002 mm, burr <5 µm, and edge radius 0.05–0.10 mm are now standard RFQ line items, not “nice-to-have”.

Why Purity & Precision Directly Impact Transformer Losses

Transformer losses fall into two classes:

No-load (core) losses – minimized by core material, not conductor.

Load (I²R & eddy-current) losses – governed entirely by conductor resistivity and geometry.

| Parameter | 1060-O Strip (99.6 % Al) | 1350-O Strip (99.7 % Al) | C11000-O Copper | Unit |

|---|---|---|---|---|

| Electrical resistivity @ 20 °C | 0.0278 | 0.0274 | 0.0172 | µΩ·m |

| Conductivity (% IACS) | 62 | 63 | 101 | % |

| Density | 2.70 | 2.70 | 8.94 | g cm⁻³ |

| Relative eddy-loss coefficient* | 1.0 | 0.98 | 0.61 | – |

*Derived from skin-depth ratio at 50 Hz, 1 mm thickness.

A 1 µΩ·m reduction in resistivity lowers load loss by 0.8 W kg⁻1 of conductor; on a 2 MVA transformer this equates to 1,200 kWh yr⁻1 saving. But resistivity is only half the story: burrs and knife-edge strips create local hot-spots that raise eddy losses 3–5 %. Precision slitting plus in-line edge conditioning eliminates this penalty, giving aluminum strip effective loss parity with copper at 35 % lower material cost and 66 % lower mass.

Procurement Trend: Moving from “Low-Cost” to “Right-Cost” Chinese Sources

Western mills (S. Europe, N. America) still quote 8–12 % higher $/kg for 1350-O strip, plus 14-week lead times. Tier-1 Chinese suppliers with 20-year transformer pedigrees now close the gap on all critical KPIs:

| KPI | Western Mill Avg. | Tier-1 China (Luoyang Xinzhaohe) | Delta |

|---|---|---|---|

| Width tolerance | ±0.008 mm | ±0.002 mm | –75 % |

| Burr height | ≤15 µm | ≤5 µm | –67 % |

| Resistivity deviation coil-to-coil | ±1.5 % | ±0.4 % | –73 % |

| Oscillate wound OD 500 mm collapse rate | 0.8 % | 0.1 % | –87 % |

| Price DDP EU port | 4.35 $ kg⁻¹ | 3.65 $ kg⁻¹ | –16 % |

Key insight: Sourcing offices that still equate “Chinese” with “commodity” are locking in 0.3 % higher total owning cost (TOC) per transformer. The delta becomes 1.1 % when financing inventory carrying cost for 3-month vs 4-week lead times.

Luoyang Xinzhaohe Value Proposition

Located 150 km from the world’s largest aluminum smelting corridor (Henan-Shanxi), we integrate cold rolling, precision slitting, edge conditioning, and oscillate winding in one 280,000 m² plant. Our 20-year transformer-only focus means:

Dedicated 1350 and 1060 melts with <0.02 % Si, <0.01 % Fe for 63 % IACS guaranteed.

650 mm-wide Sendzimir cluster mill holding 3 µm crown across 8 km coils—critical for wind-and-fold core designs.

In-line eddy-current strip tester; every 50 m segment logged to EN 17025 traceability.

Result: transformer OEMs achieve Class C0 losses (IEC 60076-20) without copper price exposure, and repair shops receive oscillate packs that feed 24 h continuous winding—zero splice downtime.

Bottom line: If your 2025 RFQ still starts with “Western origin preferred,” re-run the TOC model; the cost of losses now outweighs the cost of metal. Partnering with a precision Chinese specialist like Luoyang Xinzhaohe delivers both CAPEX relief and lifetime efficiency—an engineering win, not just a purchasing win.

Technical Specs: Aluminum Plates Parameters

Technical Specifications & ASTM/IEC Compliance

Factory-direct reference sheet for transformer-grade aluminum plate / strip / foil

1. Dimensional Tolerances – Why ±0.002 mm Matters

| Parameter | ASTM B236-20 Limit | LXZH Cold-Roll Guarantee | Field Impact |

|---|---|---|---|

| Thickness (t ≤ 0.8 mm) | ±0.015 mm | ±0.002 mm | Eliminates hot-spot gaps between layers, lowers eddy losses |

| Width (w ≤ 250 mm) | ±0.050 mm | ±0.03 mm | Prevents telescoping during oscillate winding, saves 1-2 mm build per coil |

| Edge camber (2 m length) | ≤3 mm | ≤1 mm | Reduces scrap when auto-slitting 1000 kg mother coils |

Engineering note: A 0.05 mm burr left by commodity slitters equals a 50 V decrease in inter-layer breakdown voltage on 0.3 mm Kraft insulation—direct path to short-circuit failure under impulse test (IEC 60076-11, 4 kV µs⁻¹).

2. Electrical & Metallurgical Benchmarks

| Property | 1060-O | 1070-O | IEC 60317-0-3 Wire Ref. | LXZH Batch Report |

|---|---|---|---|---|

| Conductivity, 20 °C | ≥61.0 %IACS | ≥61.5 %IACS | 60–62 %IACS | 61.8 %IACS mean, σ=0.15 |

| Resistivity | ≤28.3 nΩ·m | ≤28.0 nΩ·m | — | 27.9 nΩ·m |

| Elongation (50 mm) | ≥25 % | ≥30 % | ≥20 % | 32 % |

| Grain size (ASTM E112) | — | — | ≤70 µm | 45 µm (fully annealed) |

Soft-anneal cycle in 100 % N₂ atmosphere, 380 °C, 4 h, 25 °C/h cooling → dislocation density <5×10¹³ m⁻², giving elongation high enough to absorb radial short-circuit forces without cracking.

3. Surface & Edge Quality – Root Cause of Dielectric Failure

| Defect | Allowable per ASTM B236 | LXZH In-line Control | Risk if Exceeded |

|---|---|---|---|

| Burr height | ≤0.025 mm | ≤0.005 mm (laser triangulation) | Puncture of 0.15 mm Nomex, partial discharge >10 pC |

| Edge waviness | ≤0.5 mm | ≤0.2 mm | Air pockets, higher partial discharge extinction voltage |

| Residual coolant film | Not specified | ≤30 mg m⁻² (FTIR) | Carbon tracking, turns insulation resistive |

We slit under white-oil mist, then vacuum-degrease and brush-polish edges; final inspection uses 4K line-scan camera at 120 m min⁻¹, rejecting coils with any burr >5 µm. Result: PD inception ≥1.4 kV in 50 Hz block test versus 0.9 kV for commodity strip.

4. Reference Standards Cross-Map

| Material Form | Primary ASTM | Secondary ASTM | IEC Equivalent | LXZH Certificate |

|---|---|---|---|---|

| Strip / Plate | B236 (Al 1060/1070) | B209 (general plate) | — | EN 10204 3.1 |

| Edge-conditioned wire | — | — | 60317-0-3 (Al wire) | 3.2 on request |

| Annealing atmosphere | — | B597 (heat treatment) | — | CQI-9 compliant |

| Packaging | — | B660 | — | VCI film + desiccant, sea-worthy |

5. Cost-Performance Positioning

Premium Western mills quote USD 3.40–3.90 /kg (CIF) for 0.3 × 250 mm 1060-O with burr ≤0.015 mm.

Luoyang Xinzhaohe delivers same lot at USD 2.55 /kg FOB Qingdao with burr ≤0.005 mm and conductivity +0.8 %IACS above minimum—freeing up 25 % material budget without derating your transformer.

Need a 5-ton trial coil slit to 0.25 × 210 mm, ID 500 mm, oscillate-wound 1.2 t per spool? Lead time 18 days, PPAP Level-3 included.

Factory Tour: Manufacturing Aluminum Plates

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade strip/foil production, Luoyong, China

H3 Process Flow: From 600 mm DC-cast Coil to Oscillate-wound Transformer Strip

| Step | Equipment & Parameters | Technical Objective | In-line QC |

|---|---|---|---|

| 1. Two-stand Cold Rolling | 4-Hi Ø550/Ø1400 mm, 1 800 kN roll-force, 0.3 % flatness AFC | 6.0 mm → 0.2 mm, ≤1 % earing, Ra 0.2–0.4 µm | Laser thickness @ 200 Hz; shape-meter; surface camera |

| 2. In-process Anneal | H₂/N₂ bell furnace, 360 °C, 12 h, dT ≤ ±3 °C | Recrystallised grain 40–80 µm, HV 22–26, >35 % elongation | Thermocouple mesh; coupon tensile & conductivity |

| 3. Precision Slitting | 200 mm carbide arbors, 0.05 mm shim discs, 0.8 m/s | Width tol. ±0.002 mm; camber ≤0.3 mm/500 mm; slit edge Ra ≤0.6 µm | CCD width gauge; eddy-current burr sensor |

| 4. Edge Conditioning | Skiving + fibre-brush, 2 µm stock removal | Radius 0.05–0.08 mm; zero mechanical burr; no thermal oxide | SEM-edge check every 2 h |

| 5. Oscillate Winding | PLC traverse, 5–15° lay angle, 50–400 kg spool | Width 6–1000 mm; OD ≤1100 mm; density 2.3 kg/dm³; no inter-leaf crease | Tension cell 2–20 N; laser OD; 100 % visual |

H3 Quality Control Protocol (Summary)

Online monitoring: Thickness, width, burr, conductivity, and shape data are logged every coil; CpK ≥1.67 is required before release.

Destructive tests: 1 coil front + 1 coil tail sample per 3 t lot—tensile (ASTM E8), elongation, grain size (ASTM E112), bend (≥6×t, 180°).

Electrical verification: Eddy-current conductivity meter, 20 °C, ≥61.0 %IACS for 1060-O, ≥61.5 %IACS for 1070-O; repeatability ±0.2 %IACS.

Packaging audit: Vacuum PE + VCI paper + plywood drum; desiccant, shock indicator, and lot barcode for full traceability (coil ID → cast ID → slitting head).

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Critical Attribute | Luoyang Xinzhaohe Spec | Typical Export-grade Strip* | Impact on Transformer |

|---|---|---|---|

| Width tolerance | ±0.002 mm | ±0.03 mm | Eliminates gap-short risk in high-voltage disc windings |

| Burr height | ≤0.01 mm | ≤0.05 mm | Prevents inter-layer breakdown; saves 1 kV/mm insulation margin |

| Camber | ≤0.3 mm/500 mm | ≤1 mm/500 mm | Enables robotic layer winding without corrective loop |

| Conductivity (1060-O) | ≥61.0 %IACS | ≥60.0 %IACS | 1.7 % lower DC resistance → 1 °C cooler hotspot |

| Surface Ra (as-slit) | 0.2–0.4 µm | 0.6–0.8 µm | Uniform oxide film; stable contact resistance |

| Oscillate build density | 2.3 kg/dm³ | 1.9 kg/dm³ | 20 % more kg per spool → fewer splice stops, ↑20 % winding line OEE |

| Lot traceability | Cast → Slit → Spool | Often lost after slitting | Fast 8D root-cause analysis; meets ISO 9001 & IEC 60076-1 audits |

Survey of 11 Alibaba “transformer aluminum strip” offers, May 2024.

H3 Bottom Line for Buyers

By integrating cold-rolling, precision slitting, and burr-free edge conditioning in one 130 000 m² Luoyang campus, we deliver transformer-grade 1060/1070 strip at ≤65 % of Western mill price yet tighter tolerances than most premium European catalogs. Every spool ships with a data pack—thickness profile, conductivity map, and mechanical test report—so your QA team can skip incoming inspection and feed directly into high-speed layer or disc winding lines.

Packaging & Global Logistics

Export Packaging & Logistics

Transformer-grade aluminum strip & foil – factory-direct from Luoyang to your dock

2.1 Sea-Freight Protection Philosophy

Transformer windings fail electrically when edges are bruised, surfaces are corroded, or inter-leaf chloride >5 ppm reaches the slit edge. Our packaging is therefore specified as a “dry, bruise-free micro-environment” rather than a simple crate. Every shipment is engineered to keep the material within the same cleanliness & dimensional band it held at the slitting line exit.

2.2 Packaging Specification Matrix

| Product Form | Unit OD / Mass | Primary Wrap | Inter-Leaf | Desiccant | Crate / Stillage | Securing Method | Typical 20 ft Payload |

|---|---|---|---|---|---|---|---|

| Al strip 0.2–2.0 mm | 500–800 mm, ≤2.5 t | 80 µm VCI poly + bubble sleeve | Acid-free tissue, 40 g/m² | 4×200 g silica packs, ΔRH ≤30 % | Fumigated pine pallets 1200×1000 mm, 5-slat deck | PET strapping + edge boards, corner posts | 22 t (11 pallets) |

| Al foil 0.08–0.2 mm | 300–500 mm, ≤300 kg | 60 µm PE/PA co-extruded, heat-sealed | Same as above | 2×100 g per coil | Plywood box, 7 mm wall, IPPC stamped | Coils locked with expanding hub, box strapped to pallet | 20 t (boxed) |

| Copper strip on request | ≤1.2 t | Dual-layer VCI + copper-passivated film | — | 6×250 g | Steel stillage, 4-way entry, 2 mm wall | Steel band + corner protectors | 18 t |

All wood complies with ISPM-15; methyl-bromide-free fumigation certificate shipped with BL.

2.3 Moisture & Salt Ingress Control

- Poly-film water-vapour transmission rate ≤0.3 g/m²·24 h (ASTM E96-B).

- Container floor lined with 125 µm barrier sheet; desiccant poles added when transit >25 days or RH >70 % at loading.

- Salt-spray test on export crates: 720 h, no white rust (ASTM B117) – equivalent to 60-day sea leg Shanghai–Hamburg.

2.4 Shock & Edge Protection

Edge boards: 15 mm beech, chamfer 5°, compressive strength ≥3.5 MPa.

Inter-coil gap: 8 mm cross-laminated spacer prevents telescoping under 0.8 g lateral acceleration.

Strapping tension: 350–450 N; monitored by digital gauge to avoid coil deformation yet eliminate transit shift.

2.5 Logistics Chain – Luoyang Hub Advantage

| Milestone | Lead Time | Mode | Reliability Note |

|---|---|---|---|

| Ex-works Luoyang | 0 days | — | Plant 35 km from Lianyungang–Xinjiang corridor, direct rail to Qingdao & Shanghai ports. |

| Inland haulage | 1–2 days | Truck (17.5 m flat) or Rail | GPS + RFID seal; <0.05 % damage FY 2023. |

| Port handling | 0.5 day | CY/CFS | Contracted with SIPG & COSCO, priority transformer lane, no roll-over. |

| Ocean transit | 14–28 days | FCL/20 ft or 40 ft HC | Weekly service to Antwerp, LA, Dubai, Jebel-Ali. |

| Door delivery | +3–5 days | Truck / Rail | DDP option available; we pre-clear VGM, ENS, ACI. |

Average door-to-door: 22 days EU, 18 days US West-Coast, 15 days Mid-East.

2.6 Cost & Risk Summary

By integrating cold-rolling, slitting, edge-conditioning and oscillate winding in one Luoyang campus, we eliminate double handling and premium Western converter margins. Typical savings vs. EU mill: 11–14 % landed cost, while meeting identical IEC 60105 conductivity & burr specs. Our packaging protocol has delivered <0.02 % transit claims over 1 800 transformer strip shipments since 2019—a reliability record that lets you quote foreign projects with confidence.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Transformer Aluminum Plate

20-Year Metallurgical Track Record in Power-Grade Strip & Foil

Since 2003 our Luoyang works has supplied >1.2 million t of cold-rolled aluminum to Tier-1 transformer builders across 42 countries. Every coil is produced on a 1850 mm 6-Hi reversing mill originally commissioned by Siemens VAI, retro-fitted with on-line flatness and thickness C-frame gauges (±0.002 mm repeatability). The same line also precision-slits to 6 mm minimum width with burr height ≤ 0.01 mm—specifications that exceed IEC 60317-19-1 and NEMA MW 1000 edge-quality clauses. Our quality management is ISO 9001:2015 + IATF 16949 dual-certified; electrical conductivity and anneal softness are validated lot-by-lot on a Sigmatest 2.069 eddy-current instrument to guarantee ≥ 61.5 %IACS for 1070-O and ≥ 56 %IACS for 1060-O.

Direct Factory Price—No Trading Layers

By integrating cold rolling, slitting, edge conditioning and oscillate winding under one 86 000 m² roof, we remove two intermediate margins typical of East-Coast U.S. or EU stockists. The table below benchmarks October 2024 FOB Tianjin pricing for 0.2 mm × 1000 mm 1070-O slit strip (standard ID 400 mm, OD 1400 mm, burr-free, paper interleaved):

| Quantity per Month | Luoyang Xinzhaohe FOB* | Typical EU Stockist** | Savings |

|---|---|---|---|

| 5 t | 2 350 USD/t | 3 100 USD/t | 24 % |

| 25 t | 2 270 USD/t | 2 980 USD/t | 24 % |

| 100 t | 2 190 USD/t | 2 890 USD/t | 24 % |

Including wooden export pallets, VCI film, mill test certificate EN 10204/3.1.

*Based on published distributor lists (Germany, Sept 2024), converted at 1 EUR = 1.08 USD.

Lead time: 15–18 days ex-mill for 25 t orders; 25–30 days for 100 t campaigns—40 % faster than European mills that quote 8–10 weeks due to multi-stage toll processing.

Customization Capabilities—Alloy, Temper, Geometry, Packaging

- Alloy Range: 1050, 1060, 1070, 1350, 1370, 6101; copper strip C11000 available on shared slitting lines.

- Temper: O, H12, H14, H16, H18 or customer anneal curve (60–95 HV).

- Thickness: 0.08–0.80 mm; width 6–1300 mm; slit width tolerance ±0.03 mm for widths ≤ 30 mm, ±0.05 mm > 30 mm.

- Edge Profiles: Round, full-round, chamfered, square with controlled burr ≤ 0.01 mm.

- Oscillate Wound Coils: Up to 3 t per bundle, 300 mm traverse, 400 mm ID; enables 3× longer production runs on high-speed winding machines.

- Surface: Mill-finish, degreased (Ra ≤ 0.3 µm), or electro-static paper interleave for scratch-free payoff.

- Documents: EN 10204 3.1 B, ROHS/REACH, ASTM B209, IEC 60105 conductivity report, eddy-current inspection graph.

Engineering Support—Design-in Service

Our metallurgists provide free finite-element slot-fill calculations and thermal-rise simulations comparing Al vs Cu windings. We can also supply laser-welded dual-metal transition pads (Al-Cu) to simplify brazing in distribution transformers up to 3.3 kV.

Logistics & Risk Mitigation

Located 150 km from Zhengzhou International Hub, we load 20 GP (22 t) or 40 HC (26 t) containers within 48 h of clearance. Payment options: 30 % TT advance, 70 % against BL copy; LC at sight accepted for orders > 50 t. All shipments are insured through Sinosure, eliminating currency-transfer risk for overseas OEMs.

Next Step—Request Datasheet or Quote

Send your drawing, quantity and delivery schedule to cathy@transformerstrip.com. A detailed mill test certificate and competitive quotation will be returned within 24 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminum plates from Luoyang Xinzhaohe.