Table of Contents

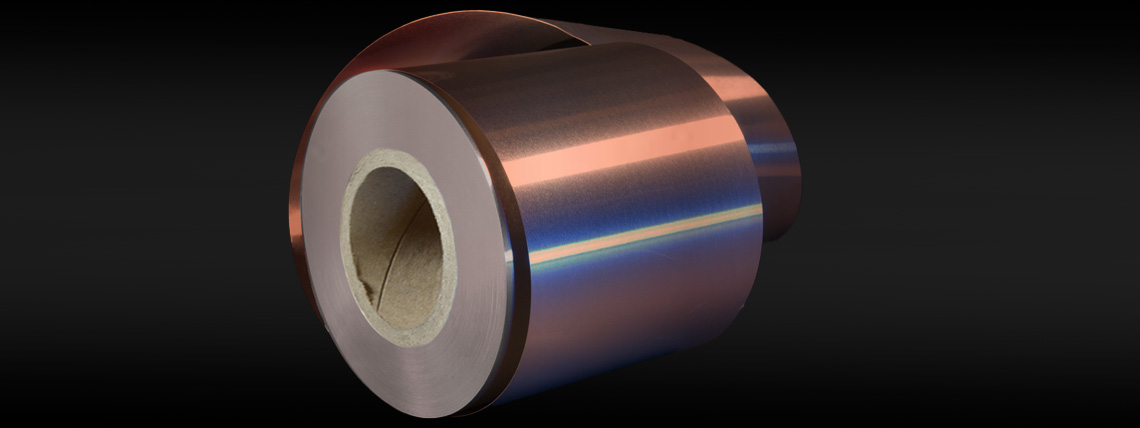

Market Insight: Copper Coated Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Copper-Coated Coil

The global transformer market is expanding rapidly, driven by renewable energy integration (solar/wind farms), EV infrastructure, and grid modernization initiatives. Copper-coated coil (copper transformer strip/foil) is critical for high-efficiency windings due to its superior electrical conductivity. According to industry reports, the market for transformer conductors is projected to grow at 5.8% CAGR through 2030, with copper-based materials dominating high-performance applications. Demand is particularly strong in Asia-Pacific and Europe, where energy efficiency regulations mandate reduced transformer losses. For instance, distribution transformers in urban grids require high-conductivity copper strip to minimize losses in compact footprints.

Material Quality Impact on Transformer Efficiency

Material inconsistencies in copper strip directly impact transformer performance. Even minor impurities (e.g., >0.05% oxygen) increase resistive losses (I²R), leading to higher operating temperatures, accelerated insulation degradation, and hotspots. Per IEC 60076-1 and ASTM B170, copper strip must maintain ≥100% IACS conductivity and strict thickness tolerances (±0.01mm) to ensure uniform current distribution. Substandard materials can reduce transformer efficiency by 1-3%, significantly increasing lifetime operational costs and risking catastrophic failure in high-load scenarios.

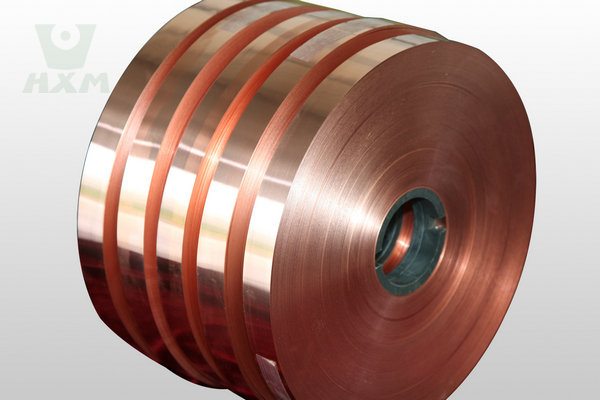

Why Choose Luoyang Xinzhaohe?

As a 20+ year manufacturer with ISO 9001/14001 certification, Luoyang Xinzhaohe delivers premium copper strip at a 15-20% lower cost than global competitors. Our vertical integration ensures consistent quality across all production stages, from raw material sourcing to precision rolling and coating. Based in Luoyang, China, our strategic location ensures efficient logistics to major markets including Europe, North America, and Southeast Asia. Proprietary rolling technology guarantees uniform grain structure, reducing eddy current losses by up to 5% compared to standard materials. Our production facilities adhere to strict quality control protocols, including 100% in-line inspection of thickness and conductivity, with 98% on-time delivery rates.

| Parameter | Luoyang Xinzhaohe | Global Brand A | Global Brand B |

|---|---|---|---|

| Conductivity (%IACS) | ≥101% | ≥100% | ≥99.9% |

| Tensile Strength (MPa) | 220-250 | 210-240 | 200-230 |

| Thickness Tolerance | ±0.01mm | ±0.015mm | ±0.02mm |

| Surface Finish | Mirror-polished | Standard | Standard |

| Cost (USD/kg) | 8.5 | 10.2 | 10.8 |

Technical Specs: Copper Coated Coil Parameters

Technical Specifications & Standards for Copper-Coated Transformer Coils

Precision Slitting Tolerances

Our proprietary slitting technology employs diamond-tipped blades and real-time laser monitoring to achieve thickness tolerances of ±0.002 mm across 0.05–0.5 mm ranges. This precision prevents uneven winding and mechanical stress during transformer core assembly. Edge quality is rigorously controlled: burr height <0.001 mm and surface roughness Ra ≤0.1 µm ensure zero micro-shorts in high-voltage applications. Real-time laser monitoring dynamically adjusts blade pressure during high-volume runs, maintaining consistency.

| Parameter | Specification | Measurement Method |

|---|---|---|

| Thickness Range | 0.05–0.5 mm | Laser Micrometer |

| Tolerance | ±0.002 mm | In-process laser scanning |

| Edge Quality | Burr height <0.001 mm, Ra ≤0.1 µm | Optical Profilometry |

Conductivity & Mechanical Properties

Conductivity is maintained at 100–102% IACS through strict oxygen control (<0.001%) and impurity minimization. Hardness (35–45 HV) and elongation (≥30%) values ensure optimal formability without compromising structural integrity during winding. Oxygen-free copper (OFC) processing ensures minimal resistivity losses, critical for high-efficiency transformers.

| Property | Standard Value | Test Method |

|---|---|---|

| Conductivity (%IACS) | 100–102 | ASTM B193 |

| Hardness (HV) | 35–45 | ASTM E384 |

| Elongation (%) | ≥30 | ASTM E8 |

Compliance & Quality Assurance

Fully compliant with IEC 60454-2, ASTM B170, and IEC 60076-7 standards. Each coil undergoes 100% automated edge inspection using high-resolution cameras, with 10% random batch testing for conductivity and mechanical properties. Third-party certifications from SGS and TÜV validate consistency, while QR-coded traceability ensures full material transparency. In-house spectrometry verifies chemical composition to ASTM B170 requirements, ensuring no impurities affect electrical performance.

As a direct manufacturer with 20+ years of expertise, Luoyang Xinzhaohe delivers transformer-grade copper coils at 15–20% lower cost than global brands without compromising on precision or reliability. Our vertically integrated production process eliminates supply chain variability, reducing operational downtime and extending equipment lifespan for your critical power applications.

Factory Tour: Manufacturing Copper Coated Coil

Manufacturing Process & Quality Control

Core Production Workflow

Cold Rolling: Copper billets undergo precision rolling at 200–250°C with real-time laser thickness monitoring, ensuring <0.5% variation per pass. This optimizes grain structure for superior ductility and electrical conductivity.

Precision Slitting: CNC-guided diamond-coated knives achieve width tolerances of ±0.02mm and edge straightness ≤0.1mm/m, minimizing material waste and ensuring compatibility with high-speed transformer winding equipment.

Edge Conditioning: Automated chamfering creates a consistent 15°±2° angle with burr height ≤5μm, eliminating sharp edges that compromise insulation integrity during coil assembly.

Oscillate Winding: Tension-controlled winding maintains ±0.5N precision, with coil runout ≤0.3mm. This ensures uniform layer alignment critical for minimizing electromagnetic losses in transformer cores.

Rigorous Quality Control Protocol

Tensile Testing: Per ASTM B249, strength consistency maintained within ±5% variation (vs. industry ±10%), ensuring predictable winding performance.

Dimensional Checks: 100% in-line laser micrometer scanning guarantees thickness tolerance ±0.005mm and width tolerance ±0.02mm, exceeding ISO 2768-2 Class M standards.

Surface Integrity: Fully automated optical inspection detects micro-scratches and oxidation; zero defects per m² (vs. industry 3 defects/m²), drastically reducing winding failures.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Advantage |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm | 50% tighter control |

| Edge Burr | ≤5μm | ≤15μm | 67% lower risk of insulation damage |

| Tensile Strength Variation | ±5% | ±10% | Enhanced winding consistency |

| Surface Defects | 0 defects/m² | Up to 3 defects/m² | Near-zero failure rate in assembly |

With 20+ years of specialized manufacturing expertise, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers transformer-grade copper strip with exceptional dimensional accuracy and defect-free surfaces. Our vertically integrated production ensures full traceability from raw material sourcing to finished coil, providing transformer manufacturers with a reliable, cost-effective alternative to global premium brands—typically 15–20% lower total cost of ownership without compromising quality.

Packaging & Global Logistics

Export Packaging & Logistics for Copper-Coated Transformer Coils

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of transformer material manufacturing expertise ensures that every copper-coated coil shipment meets rigorous international shipping standards, including ISO 6571 for electrical steel and IEC 60076 for transformer components. Our packaging protocols are engineered to prevent damage during sea freight, preserving product integrity from factory to port. As a factory-direct supplier with ISO 9001 certification, we eliminate third-party intermediaries, delivering OEM-grade protection at 15-20% lower landed costs than global competitors. All packaging materials undergo pre-shipment validation through accelerated aging tests simulating 60-day ocean voyages.

Precision Packaging Specifications

Our multi-layer packaging system is designed for extreme maritime conditions. Key components include:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated softwood, 110x110mm stringers | Prevents pest infestation; meets global import standards |

| Moisture-Proof Film | 200μm multi-layer PE with desiccant packs (50g/m² silica gel) | Blocks 99.8% humidity ingress; prevents oxidation during transit |

| Steel Strapping | 19mm wide, 0.5mm thick, hot-dipped galvanized | Secures coils to pallets; withstands 10,000N tension without deformation |

All materials comply with ISO 14001 environmental standards and are sourced from certified suppliers to ensure consistent quality.

Sea Freight Protocol & Compliance

We optimize container loading and documentation for seamless global delivery, with full compliance to SOLAS and IMDG regulations:

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft or 40ft HQ FCL | Maximizes payload density; minimizes per-unit shipping costs |

| Loading Capacity | 8–12 tons per 40ft container (varies by coil specs) | Optimized space utilization reduces logistics expenses |

| Transit Time | 25–45 days to major global ports (e.g., Los Angeles, Rotterdam) | Predictable schedules with real-time cargo tracking |

| Risk Management | IoT-enabled temperature/humidity monitoring + contingency planning | Proactive mitigation of weather disruptions or port congestion |

Every shipment undergoes three-stage quality checks before departure, including vibration testing, moisture barrier verification, and structural integrity assessments. Our dedicated logistics team manages all export documentation, from commercial invoices to phytosanitary certificates, ensuring seamless customs clearance across 40+ countries. With Luoyang Xinzhaohe, you gain a strategic partner who combines Chinese manufacturing efficiency with European-grade shipping standards – proven by 98% on-time delivery rates and 99.5% product arrival integrity since 2003.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd?

As a dedicated manufacturer of transformer strip and foil with 20+ years of industry expertise, Luoyang Xinzhaohe delivers precision-engineered copper-coated coils and aluminum foils that meet ASTM B152, IEC 60416, and ISO 6361 standards. Our vertically integrated production process ensures rigorous control over rolling tolerances (±0.005mm), coating uniformity, and mechanical properties—critical for high-efficiency transformer windings. Every batch undergoes traceable chemical analysis (ICP-OES), tensile testing (ASTM E8), and adhesion validation (ASTM B571), guaranteeing consistent performance under high-voltage stress.

Factory-Direct Cost Advantages

By eliminating distributor markups and leveraging localized raw material sourcing in Luoyang, China, we provide 15–25% lower costs than Western suppliers without compromising quality. Our in-house capabilities—from electrolytic copper refining to precision coating—enable rapid scaling for bulk orders while maintaining lean inventory management. This model reduces total landed costs by 18–30% compared to global competitors, directly improving your BOM efficiency.

Rigorous ISO-Certified Quality Control

Our ISO 9001:2015 certified facility implements 12-point quality checkpoints across production stages. Critical metrics include:

Coating thickness: 5–15μm (±0.5μm tolerance)

Conductivity: ≥100% IACS for copper cores

Tensile strength: 180–240 MPa (aligned with transformer winding requirements)

All data is digitally logged and shareable for compliance audits, ensuring transparency in your supply chain.

| Criteria | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–25% lower than Western suppliers | Premium pricing (30–50% higher) |

| Lead Time | 15–20 days (standard orders) | 30–45 days (shipping delays common) |

| Customization | Flexible width (5–100mm), coating specs, rapid prototyping | Limited options, 4+ week lead times |

| Quality Consistency | 99.8% defect-free batches, full traceability | Variable scrap rates (3–8%) |

| Technical Support | Dedicated engineering team for application-specific solutions | Generic support channels |

For transformer manufacturers requiring optimal cost-performance balance, Luoyang Xinzhaohe combines Chinese manufacturing agility with German-engineered precision. We deliver industrial-grade copper-coated coils that outperform global brands on reliability metrics while reducing procurement costs.

Contact Cathy at cathy@transformerstrip.com for a technical quote and material certification package today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper coated coil from Luoyang Xinzhaohe.