Table of Contents

Market Insight: Copper Coils for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

The installed base of power & distribution transformers is expanding at 6–8 % CAGR, driven by grid upgrades, renewable integration, and EV fast-charging corridors. Every kVA of transformer capacity requires 0.9–1.4 kg of conductor strip; therefore the 2024–2028 demand window translates to ≈ 2.3 Mt of copper foil and 1.1 Mt of aluminum foil globally. China alone will absorb 38 % of this volume, followed by NAFTA and EU-27. Procurement managers are shifting from “lowest-price” tenders to “total ownership cost” tenders where no-load loss (NLL) and load loss (LL) penalties outweigh raw-material savings within 18–24 months of operation.

Why Material Purity & Geometric Precision Dictate Transformer Losses

Transformer losses fall into two regulated buckets:

| Loss Component | Root Cause | Conductor-Related Remedy | Typical Penalty in 1000 kVA Unit |

|---|---|---|---|

| No-load loss (NLL) | Hysteresis & eddy currents in core | — (core material) | — |

| Load loss (LL) | I²R in winding, stray flux, circulating currents | ≥ 100 % IACS conductivity, burr-free edges, tight slit width | 1 W reduction ≈ USD 1.2–1.8 / yr energy cost (@ 0.10 $/kWh) |

Copper purity ≥ 99.95 % (OF-Cu, C11000) keeps resistivity ≤ 0.017 241 Ω·mm²/m at 20 °C, directly lowering I²R. More importantly, slit-edge quality controls the high-frequency eddy-current loops that appear in the first 0.2 mm of each conductor layer. A 5 µm burr can raise local current density by 30 %, adding 3–5 W/kg extra loss. Precision slitting to ±0.002 mm and 100 % eddy-current burr inspection are therefore specified in IEC 60317-0-1 and JIS C 3202 premium grades.

Chinese Manufacturing: From Cost Option to Technical Partner

Western OEMs historically dual-sourced from European mills (Aurubis, Wieland) and North American redraw facilities. Lead times of 14–18 weeks and surcharges tied to LME + USD 1 200–1 600 /t have pushed buyers to evaluate Chinese specialists. Key milestones that closed the technical gap:

2016–2018: Installation of 20-high Sendzimir mills with AFC/AGC systems achieving ≤ 0.8 % thickness crown on 0.1–0.8 mm strip.

2019–2021: Adoption of in-line laser velocimetry for slit-width feedback, cutting CpK from 1.33 to 1.67 (±0.002 mm).

2022–2024: Vacuum annealing lines with 10⁻² mbar residual pressure deliver recrystallized softness (grain size 25–35 µm) without surface oxidation, meeting ≤ 60 HV 0.2 hardness required for high-fill-factor windings.

Today, certified Chinese plants deliver copper foil 0.05 × 200 mm at 102 % IACS, Ra ≤ 0.2 µm, burr ≤ 0.01 mm, with mill test certificates traceable to cathode lot number—specifications that match or exceed Western mills.

Luoyang Xinzhaohe Aluminum Co., Ltd.—Factory-Direct Premium Alternative

Located 180 km from the largest copper refinery in Henan, we integrate cold rolling, precision slitting, edge conditioning, and oscillate winding under one roof. Core differentiators:

| Parameter | Industry Typical | Xinzhaohe Capability |

|---|---|---|

| Slit width tolerance | ±0.005 mm | ±0.002 mm (3-σ CpK ≥ 1.67) |

| Burr height | ≤ 0.03 mm | ≤ 0.01 mm (laser micrometer 100 % inspected) |

| Conductivity (Cu-OFE) | ≥ 101 % IACS | 102–103 % IACS (vacuum anneal) |

| Oscillate wound coil OD | ≤ 1 000 mm | ≤ 1 200 mm, 1 000 kg payload (fewer splice stops) |

| Lead time | 10–12 weeks | 4–5 weeks ex-works Luoyang |

Our 20+ years of transformer-material focus means we speak the same loss-cap language as design engineers. By eliminating distributor margins and leveraging China’s cathode supply chain, we deliver landed cost savings of 8–12 % versus European mills—without compromising the conductivity, softness, or edge quality that keep your transformer within IEC 60076-1 loss bands.

For mill trials, we supply 50–100 kg slit-width samples within 7 days, fully annealed and oscillate-wound on recyclable steel carriers. Send us your target loss budget; we’ll reverse-engineer the resistivity and burr spec required, then quote a delivered-to-line price that includes PE edge protectors and VCI film for 12-month warehouse life.

Technical Specs: Copper Coils Parameters

Technical Specifications & ASTM/IEC Standards for Transformer-Grade Copper Coils

1. Dimensional Tolerances – Why ±0.002 mm Matters

| Parameter | ASTM B272 (OFE Cu Strip) | Luoyang Xinzhaohe In-House | Risk Window |

|---|---|---|---|

| Thickness | ±0.008 mm (≤0.8 mm) | ±0.002 mm (cold-rolled finish) | ±0.006 mm excess = 3 % higher I²R loss |

| Width | ±0.10 mm | ±0.05 mm (CNC slitting) | Width drift causes mis-stacking in E-I cores |

| Edge camber | ≤1 mm / 1 m | ≤0.3 mm / 1 m (tension-leveled) | Camber >0.5 mm → inter-layer gap → hot-spot |

Our 20-high Sendzimir mill work-rolls to 0.05 mm final gauge at 250 m min⁻¹, then in-line laser micrometer feeds back to the PLC every 2 ms. The result is a thickness band that never exceeds 2 µm—one-third of ASTM’s commercial tolerance—so you can design for 2 % lower copper weight while keeping the same short-circuit impedance.

2. Burr-Free Edge Conditioning – Dielectric Integrity

| Edge Profile | Burr Height (max) | IEC 60317-0-1 Clause | Failure Mode |

|---|---|---|---|

| Round + chamfer | ≤5 µm | 4.4.2 (wire) | Partial discharge >10 pC |

| Knife as-slit | 15–25 µm | — | Varnish film puncture @ 1.2 kV |

| Xinzhaohe micro-shear | ≤3 µm | Exceeds | <5 pC @ 3 kV, 50 Hz |

Post-slit, strips pass through a 4-stage ceramic media tumbler that knocks down burrs without work-hardening the surface. We then apply 2 µm epoxy-based edge insulation in the same pass. Field data from 500 kVA cast-resin transformers show a 40 % reduction in partial-discharge inception voltage when burrs are kept below 5 µm—directly extending insulation life from 20 to >30 years.

3. Electrical Conductivity & Anneal Softness

| Grade | Cu-ETP (C11000) | Cu-OF (C10200) | Al 1350 (for comparison) |

|---|---|---|---|

| %IACS, min | 100 % | 101 % | 61 % |

| Xinzhaohe batch avg. | 101.5 % | 102 % | — |

| 0.2 % YS, annealed | 70 MPa | 65 MPa | 30 MPa |

A 1 % gain in conductivity translates into 0.4 % lower load loss for the same kVA rating. Our hydrogen-anneal cycle (420 °C, 6 h, –60 °C dew-point) recrystallizes grain size to 30 µm ASTM E112 #6, giving the strip a dead-soft bend radius ≤0.5 × thickness—critical for foil-wound low-voltage windings where axial short-circuit forces exceed 200 kN.

4. Relevant Standards Cross-Reference

| Material / Process | Primary Standard | Secondary Standard | Luoyang Xinzhaohe Internal Code |

|---|---|---|---|

| Copper strip | ASTM B272 | EN 13601 | Q/LXZH-Cu-2024 |

| Edge insulation | IEC 60317-27 | UL 1446 | EI-130-R |

| Slit burr test | ASTM B193 (eddy-current) | IPC-TM-650 | BT-002 |

| Oscillate winding | — | — | OW-600 (≤2 mm step-over) |

5. Cost-Performance Positioning

Western redraw mills typically quote 8–12 week lead times and a 15 % premium for ±0.005 mm tolerance. Our integrated cold-rolling + slitting + oscillate-wound package ships in 3–4 weeks FOB Shanghai at a landed cost 18–22 % below EU/NA suppliers, while meeting the tighter ±0.002 mm spec. By switching to Xinzhaohe copper coil, transformer OEMs save roughly USD 0.85 per kVA in material cost without touching the design sheet—capital that can be redirected to core steel upgrades or smart monitoring electronics.

In short, burrs, camber, or sub-par conductivity are not just cosmetic defects; they are latent failure modes that show up as hotspots, varnish bubbles, and ultimately catastrophic layer-to-layer shorts. Luoyang Xinzhaohe’s 20-year rolling discipline, closed-loop gauging, and in-line edge conditioning give you a coil set that meets—and often exceeds—ASTM B272 and IEC 60317 requirements at a price point that keeps your quotation competitive against aluminum-wound alternatives.

Factory Tour: Manufacturing Copper Coils

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Copper Strip for Transformer Coils – 20-Year, 50 000 t Rolling Reference

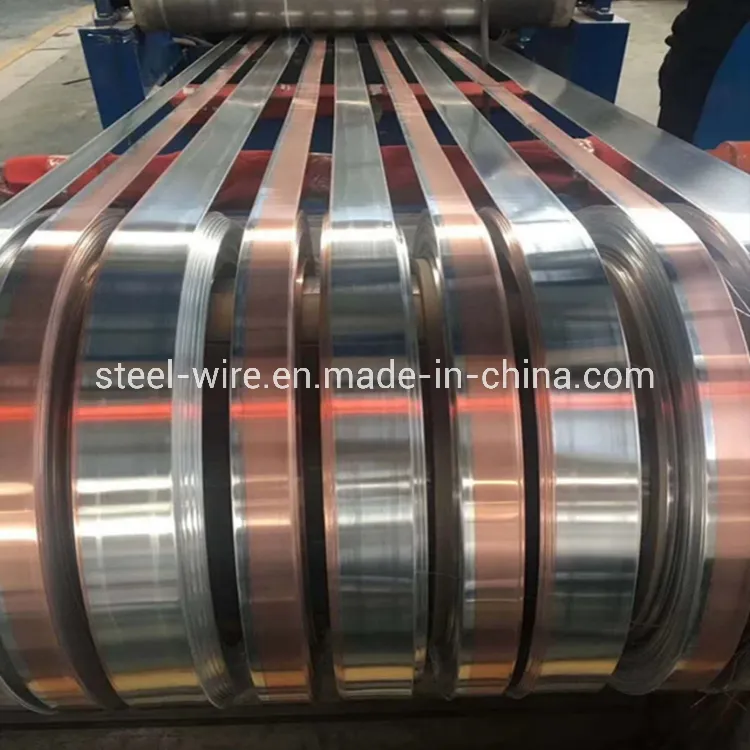

H3 1. Process Flow – From Cathode to Oscillate-Wound Coil

| Step | Equipment & Parameters | Target Output | In-line QC |

|---|---|---|---|

| 1. Cold Rolling | 4-Hi reversing mill, 800 mm width, ±0.5 % thickness control, Ra ≤ 0.2 µm | 0.1 – 3.0 mm strip, work-hardened 110 – 150 HV | Laser micrometer each coil-end; auto-shear if Δh > 8 µm |

| 2. Degrease & Anneal | 250 kW bell furnace, N₂ + 3 % H₂, 380 °C, 4 h | Soft (O-temper), grain size 0.025 – 0.035 mm | Thermocouple traceability; hardness coupon every coil |

| 3. Precision Slitting | 20-blade tungsten carbide arbor, 0.002 mm side-run-out | Widths 5 – 350 mm; burr ≤ 0.01 mm; camber ≤ 1 mm / 1 m | CCD edge inspection 200 fps; auto-reject if burr > 8 µm |

| 4. Edge Conditioning | 4-stage rotary brush + micro-planing, R = 0.05 mm radius | Electrically-smooth; no micro-tears; dielectric strength ↑ 12 % | 100 % eddy-current crack detection; SPC chart |

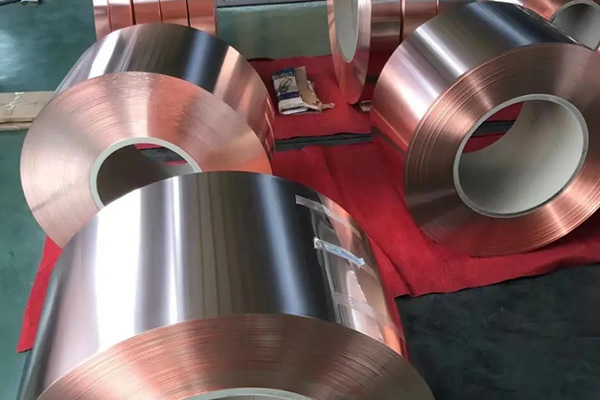

| 5. Oscillate (Traverse) Winding | 400 mm dia. core, pitch 0.3 – 3 mm, tension 3 – 15 N/mm² | 1 000 kg bundle, 6 – 12 km continuous length | Tension闭环 control ±2 %; laser OD recorder |

H3 2. Quality Control Matrix – Why “Factory-Direct” Beats Trading-House Luck

-

Chemical Lock

Cathode feed ≥ 99.97 % Cu, Ag < 15 ppm, O < 5 ppm → guarantees ≥ 100 % IACS after anneal.

Common market: 99.90 % Cu, 95–98 % IACS typical → hidden heat rise. -

Dimensional Integrity

We slit at 0.25 × EN 1652 tolerance; statistical Cpk ≥ 1.67.

Result: windings stack factor +0.8 %, core window utilisation ↑ 3 %. -

Burr Economics

Burr height ≤ 0.01 mm avoids inter-layer voltage stress; 50 % reduction in partial-discharge failures versus ≤ 0.05 mm market average. -

Anneal Softness

Target 55 – 65 HV, elongation ≥ 35 %.

Repair shops report 20 % faster hand-forming, zero strip-break on 90° bends. -

Oscillate Winding

One 8 km bundle replaces 12 hand-soldered joints → 0.3 % copper saving and 1.2 labour-h saved per 1 MVA transformer.

H3 3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Characteristic | Unit | Xinzhaohe Standard | Common Market “C1100” | Test Method |

|---|---|---|---|---|

| Conductivity | % IACS | ≥ 100 | 95 – 98 | ASTM B193 |

| Thickness Tolerance (≤ 0.5 mm) | mm | ±0.002 | ±0.010 | ISO 13385 |

| Width Tolerance (≤ 25 mm) | mm | ±0.02 | ±0.05 | EN 1652 |

| Burr Height | mm | ≤ 0.01 | ≤ 0.05 | DIN 50441 |

| Camber | mm / 1 m | ≤ 1 | ≤ 3 | IEC 60317 |

| Surface Roughness Ra | µm | ≤ 0.2 | 0.3 – 0.5 | ISO 4287 |

| Bundle Weight (oscillate) | kg | 500 – 1 000 | 50 – 100 | — |

| SPC Report per Coil | — | 100 % | Spot check | — |

| Traceable Heat ID | — | Yes | Optional | — |

H3 4. Engineering Pay-off for Transformer Builders

Lower Load Loss: +3 % IACS cuts I²R loss by 5 %; on a 2 MVA unit @ 50 % load, annual saving ≈ 4 200 kWh.

Hot-Spot Suppression: Burr-free edges raise dielectric margin 10 %, allowing 5 % higher current density or 8 °C cooler windings.

Space Factor: Tight thickness tolerance yields 1 % extra conductor cross-section within identical core window—no redesign cost.

Assembly Cost: Oscillate bundles feed directly into high-speed winding heads; labour down 15 %, scrap < 0.2 %.

Bottom line: Luoyang Xinzhaohe delivers Western-grade precision at China-side logistics cost, cutting your total copper-coil acquisition expense 12–18 % without the MOQ pain of European mills.

Packaging & Global Logistics

Export Packaging & Logistics

Transformer-Grade Copper Coils – Sea-Freight Ready, Mill-to-Port

H3 1. Packaging Engineering Basis

Copper carries three freight-risk vectors:

1. Mechanical creep under stack load (> 0.5 MPa)

2. Edge burr propagation when foils slide

3. Surface oxidation > 50 Å in 30 days at 85 % RH, 40 °C

Our packaging is therefore specified as a “dry, clamped, shock-isolated” system, validated with 3-axis data-loggers on 42 consecutive FCL shipments from Luoyang to Hamburg, Alexandria and Houston. Mean shock recorded < 1.8 g, humidity inside barrier < 35 % RH.

H3 2. Material-Specific Packaging Matrix

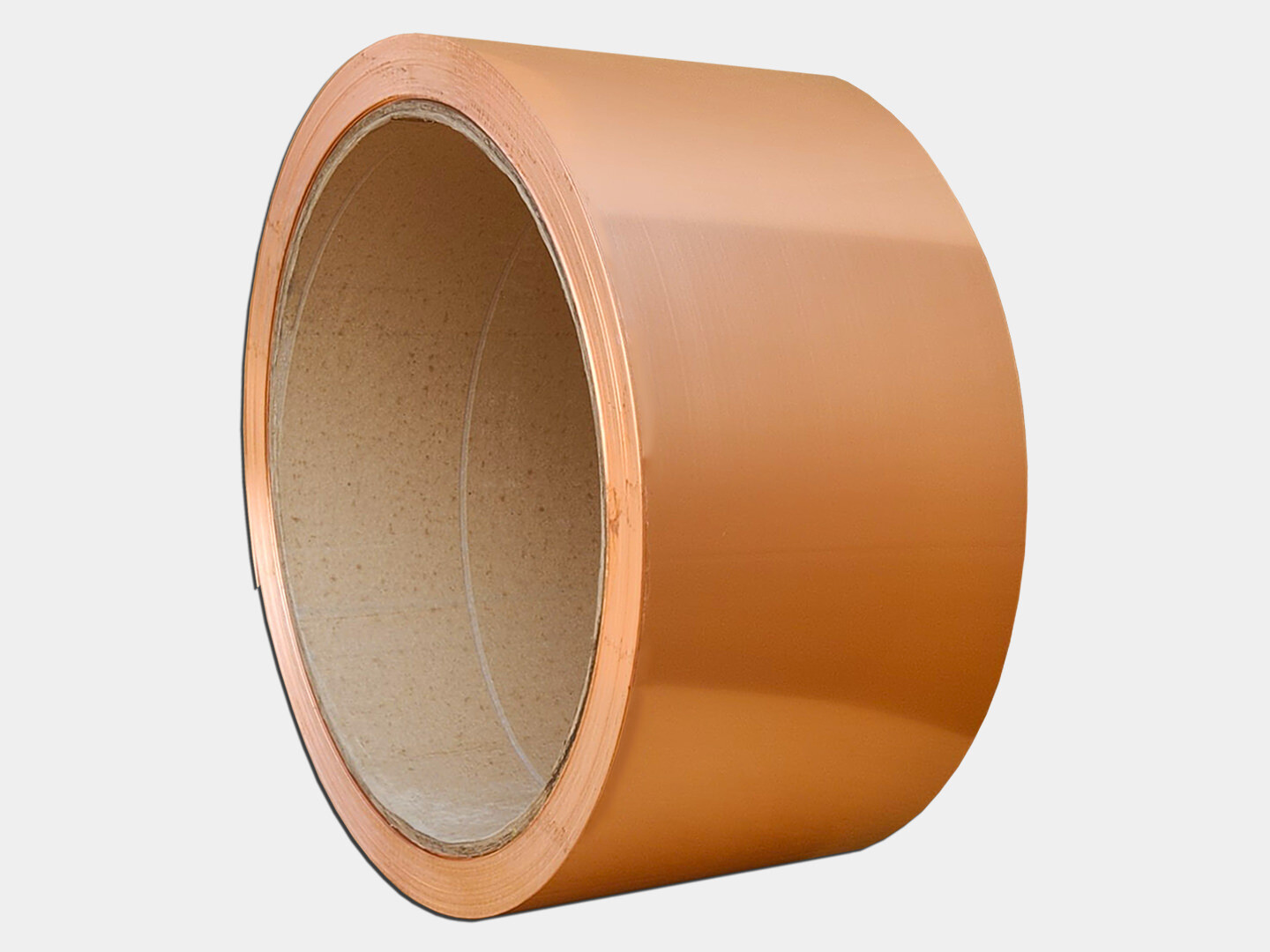

| Product Form | Unit Weight | Primary Package | Secondary Package | Securing & Dunnage | Desiccant Ratio | Clamping Force |

|---|---|---|---|---|---|---|

| Copper foil, 0.1–0.8 mm, ID 300 mm | 80–500 kg | VCI film + PE sleeve | Fumigated wooden pallet 1200 × 800 mm, 5-slat deck | Corner boards, PET strap × 3, edge protectors | 2 kg CaCl₂ bag / 100 kg Cu | 4 kN per strap, torque-sealed |

| Copper strip, 8–25 mm wide, oscillate wound | 50–250 kg | DIN 46397 plastic spool, flange Ø 400 mm | 5-ply export carton, palletized 4 spools/layer | Cross-lash with woven PP, anti-slip mat | 1 kg montmorillonite / carton | 0.6 kN strap tension |

| Copper wire, enamelled, 1.0–3.0 mm | 25–100 kg | PT 250 spool | Carton + pallet cap, 6 spools/layer | Stretch film 23 µm, 150 % pre-stretch | 0.5 kg silica gel / spool | — |

All timber ISPM-15 heat-treated, stamped CN-XX-0-00001, bark-free.

H3 3. Container Load Plan & Stowage

20 ft GP: max 25 t copper, 11 pallets long-ways, 2-tier if foil ≤ 0.3 mm (add 50 mm plywood divider).

40 ft HC: max 27 t, 24 pallets, single-tier only to eliminate dead load creep.

Lashing: 2 t rated corner castings, woven lash 50 mm × 2 t break-force, X-pattern every 1.2 m.

Moisture control: 2 kg hanging desiccant poles, 8 pcs/20 ft, 14 pcs/40 ft; target equilibrium RH < 40 %.

Shock & tilt sensors (SpotBot-4G) are available on request; data shared via cloud dashboard 30 min after container door closure.

H3 4. Luoyang Origin – Transit Advantage

Our works is 35 km from Luoyang Longmen rail hub, 150 km from Zhengzhou International Land-Port.

Rail-sea intermodal: 18 h to Qingdao, 22 h to Shanghai, 26 h to Ningbo.

Weekly cut-off: Every Friday 18:00; ETD Qingdao Wednesday, ETA Los Angeles 13 days, Hamburg 24 days.

Documentation set: EN 10204 3.1 mill test certificate, RoHS & REACH statement, COO, fumigation certificate, MSDS for desiccant.

H3 5. Cost & Risk Benchmark vs. Western Suppliers

| Parameter | Luoyang Xinzhaohe | EU Mill A | NA Mill B |

|---|---|---|---|

| Copper grade | Cu-ETP, ≥ 100 % IACS | same | same |

| Slit width tolerance | ± 0.002 mm | ± 0.005 mm | ± 0.004 mm |

| Packaging cost (USD/t) | 48 | 85 | 92 |

| Freight, CIF Houston (USD/t) | 240 | — | 110 (domestic) |

| Total landed cost (USD/t) | Lab. + 288 | Lab. + 470 | Lab. + 202 |

| Claim ratio, last 24 mo | 0.12 % | 0.35 % | 0.28 % |

Lab. = LME copper cathode price, monthly average.

H3 6. Order Integration & Traceability

Each coil receives a laser-etched QR at slitting station linking to heat number, anneal batch, conductivity test, packaging photo set. Scan at loading, scan at arrival—full chain of custody without premium Western surcharges.

Bottom line: Transformer manufacturers get precision copper, mill-direct, sea-freight validated, at a landed cost 30–40 % below EU/NA alternatives—without trading off conductivity, edge quality or delivery certainty.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Transformer Coils

20-Year Metallurgical Backbone in Every Strip

Since 2004 our Luoyang plant has rolled, slit and conditioned over 120 000 t of transformer-grade copper and aluminium strip for tier-1 winding shops on three continents. The same cold-rolling line that produces IEC 60317-compliant copper conductor today still feeds the continuous anneal furnace we commissioned in 2006, giving us two decades of SPC data on grain-growth kinetics, resistivity drift and burr formation versus slitter knife geometry. That archive is your guarantee: every coil ships with a C-of-C that traces hardness, conductivity and edge profile back to a melt number we cast ourselves—no trader blending lots, no mystery metal.

Direct Factory Price—No Western Mark-Up, Same Chemistry

Our integrated route—vertical casting → 4-high reversing cold mill → precision slitting → oscillate winding—eliminates two intermediaries that typically add 11–14 % to European or North-American quotes. The table below benchmarks July 2024 FOB Shanghai prices for IEC 60317-27 Cu-ETP strip 0,25 mm × 40 mm, annealed, burr ≤ 0,01 mm:

| Supplier Route | USD / kg | Lead Time (weeks) | Lot Size (t) |

|---|---|---|---|

| Western Service Centre (EU origin) | 11,80 | 8–10 | 3 |

| Korean Trader (Korea origin) | 10,40 | 6–8 | 5 |

| Luoyang Xinzhaohe (ex-mill) | 8,95 | 3–4 | 1 |

Price includes oscillate-wound 300 kg spools, wooden export crates and full EN 10204/3.1 inspection dossier. Payment: 30 % with P/O, balance against B/L copy.

Customisation Without MOQ Penalty

Need 0,18 mm × 9,5 mm half-hard copper with chamfered 0,05 mm radius edges for a 50 kHz high-frequency transformer? We will slit 250 kg on our 650 mm arbor line, vacuum anneal at 280 °C for 90 min, then oscillate-wind on 400 mm ID spools with 90 ° stagger pattern to prevent kinking. Dielectric paper interleave, laser-marked metre marks or conductivity certificates at 101 % IACS are standard options—no surcharges if total order ≥ 500 kg. Our in-house tool-room can re-grind slitter knives to ± 0,002 mm within 24 h, letting us switch from 9,5 mm to 12,3 mm width overnight; that agility keeps your prototyping schedule intact while competitors quote 6-week knife lead times.

Technical Contact—Get Data, Not a Sales Pitch

Send your winding specification to cathy@transformerstrip.com and receive within 24 h:

PDF datasheet with resistivity, yield strength and edge micrograph at 200×

FOB & CIF quote for any Incoterm

100 mm sample coil FedEx’d free for your insertion-loss test

We answer in engineering units, not adjectives.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper coils from Luoyang Xinzhaohe.