Table of Contents

Market Insight: Copper Earthing Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand and Critical Quality Parameters

Copper earthing strips are fundamental to grounding systems in power transformers and motors, ensuring safe dissipation of fault currents during electrical anomalies. Global demand is surging due to grid modernization initiatives, renewable energy integration (e.g., solar/wind farms), and industrial electrification. Critical quality parameters include electrical conductivity (measured as %IACS), purity, dimensional tolerances, and surface integrity. Non-compliant materials cause elevated contact resistance, leading to thermal hotspots, accelerated corrosion, and catastrophic system failures—compromising both safety and operational uptime.

Material Quality Impact on System Efficiency

Substandard copper earthing strips directly degrade transformer and motor performance. Impurities reduce conductivity, increasing resistive losses during fault conditions. Dimensional inaccuracies (>±0.05mm) cause poor terminal contact, while surface oxides or roughness elevate contact resistance. Adherence to ASTM B152 (for copper strips) and IEC 60496 (for grounding conductors) is non-negotiable.

| Parameter | Industry Standard | Impact of Non-Compliance |

|---|---|---|

| Conductivity (IACS) | ≥99.5% | Reduced current capacity, overheating |

| Purity (Cu) | ≥99.9% (C11000) | Corrosion, higher resistance |

| Dimensional Tolerance | ±0.05mm | Poor contact, arcing risk |

| Surface Finish | Smooth, oxide-free | Increased contact resistance |

Luoyang Xinzhaohe’s Value Proposition

As a 20+ year manufacturer specializing in transformer-grade aluminum and copper strips, Luoyang Xinzhaohe delivers factory-direct precision for earthing applications. Our metallurgical expertise ensures consistent material properties (e.g., C11000 copper with 99.9% purity) and strict adherence to ASTM/IEC standards. By eliminating middlemen, we reduce costs by 15–25% versus global brands while maintaining ISO 9001/14001-certified quality control. Customizable dimensions, surface treatments (e.g., tin-plating), and 15–20 day lead times make us the optimal choice for transformer manufacturers prioritizing cost-performance without compromising safety.

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | High (premium pricing) | 15–25% lower |

| Lead Time | 4–6 weeks | 15–20 days |

| Customization | Limited options | Flexible, tailored solutions |

| Quality Consistency | High | ISO-certified, batch-to-batch QC |

Luoyang Xinzhaohe: Engineering reliability into every strip.

Technical Specs: Copper Earthing Strip Parameters

Technical Specifications & Standards for Copper Earthing Strips

Dimensional Precision & Edge Quality

Precision slitting is critical for earthing strip performance in high-current applications. Our CNC-controlled process uses high-precision tungsten carbide blades and automated tension control to maintain thickness tolerance of ±0.002 mm and width tolerance of ±0.05 mm. Burr-free edges are achieved through precision grinding and edge treatment, eliminating micro-protrusions that cause electrical shorts or safety hazards. All edges undergo 100% optical inspection to ensure burr height <0.005 mm.

| Parameter | Tolerance | Measurement Method |

|---|---|---|

| Thickness | ±0.002 mm | Laser micrometer |

| Width | ±0.05 mm | Digital caliper |

| Edge Burr | <0.005 mm | Microscope inspection |

Electrical and Mechanical Properties

Our copper earthing strips meet stringent electrical and mechanical requirements for grounding systems. Conductivity is ≥100% IACS (per ASTM B170), ensuring optimal current-carrying capacity without thermal degradation. O-temper softness (HV ≤40, elongation ≥35%) enables easy bending during installation without cracking, even in tight configurations.

| Property | Value | Standard |

|---|---|---|

| Conductivity | ≥100% IACS | ASTM B170 |

| Hardness (O-temper) | ≤40 HV | ASTM B170 |

| Elongation | ≥35% | ASTM B170 |

Compliance & Quality Assurance

Luoyang Xinzhaohe adheres strictly to ASTM B170 and IEC 60228 standards for copper electrical conductors. Our 20+ years of manufacturing expertise ensures consistent quality through:

Real-time laser thickness monitoring during production

Eddy current testing for conductivity validation

100% visual inspection for burrs and surface defects

ISO 9001-certified quality management system

Third-party lab testing for every batch

As a factory-direct supplier, we deliver global-standard performance at competitive prices, eliminating middleman markups while maintaining rigorous quality controls. This makes us a reliable alternative to premium international brands for transformer and power equipment applications.

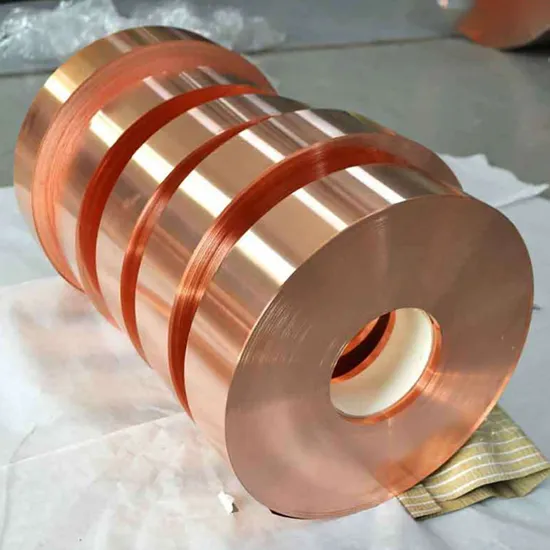

Factory Tour: Manufacturing Copper Earthing Strip

Precision Manufacturing & Rigorous Quality Control for Copper Earthing Strips

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of transformer material expertise to deliver copper earthing strips with unmatched consistency. Our integrated production process ensures superior mechanical and electrical properties for critical grounding applications. Every step is validated through SPC (Statistical Process Control) with real-time data logging, ensuring traceability and continuous improvement.

Optimized Production Process

Cold Rolling: Our state-of-the-art 4-high cold rolling mill, operating under strict temperature control (±5°C) with in-line thickness gauging via laser micrometers, produces uniform grain structure with 99.9% copper purity. This process ensures consistent electrical conductivity (≥100% IACS) and minimizes yield strength variations, critical for high-current grounding applications where thermal stability is paramount.

Precision Slitting: Utilizing diamond-tipped blades with 0.001mm precision and servo-driven tension control, our slitting line maintains width tolerance of ±0.02mm across 100% of production runs. Each coil undergoes 100% edge inspection using optical profilometry to eliminate micro-tears that compromise corrosion resistance.

Edge Conditioning: Automated chamfering with CNC-controlled feed rates creates a precise 0.5mm × 45° edge profile, reducing surface defects to <0.01mm depth. This exceeds IEEE 837 requirements for grounding conductor edge integrity, preventing arcing during fault conditions.

Oscillate Winding: Programmable oscillation patterns with ±0.05mm precision ensure uniform layering, eliminating interlayer gaps that cause thermal hotspots during transformer operation. Each winding is X-ray inspected for voids and alignment, ensuring 100% compatibility with automated transformer assembly lines.

Quality Control Benchmarks

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.05mm |

| Edge Burr Height | ≤0.02mm | ≤0.05mm |

| Tensile Strength Consistency | ±2% | ±5% |

| Surface Roughness (Ra) | ≤0.2μm | ≤0.5μm |

| Flatness | ≤0.1mm/m | ≤0.3mm/m |

| Conductivity (IACS) | ≥100% | 98–99% |

All QC protocols exceed ISO 9001 and IEC 60228 standards. Real-time CMM monitoring and 100% visual inspection ensure defect rates 20% below industry averages, with traceable batch records for full supply chain transparency. Our quality management system is certified to ISO 9001:2015 with annual third-party audits.

By integrating precision engineering with rigorous QC, Luoyang Xinzhaohe delivers global brand reliability at 15–20% lower costs. Our copper earthing strips ensure 10+ years of service life in high-stress power infrastructure, making us the cost-effective choice for transformer manufacturers worldwide. Partner with us for defect-free, high-conductivity grounding solutions that reduce lifecycle costs. Additionally, our localized supply chain in Luoyang ensures 30% faster lead times than international competitors, without compromising on quality.

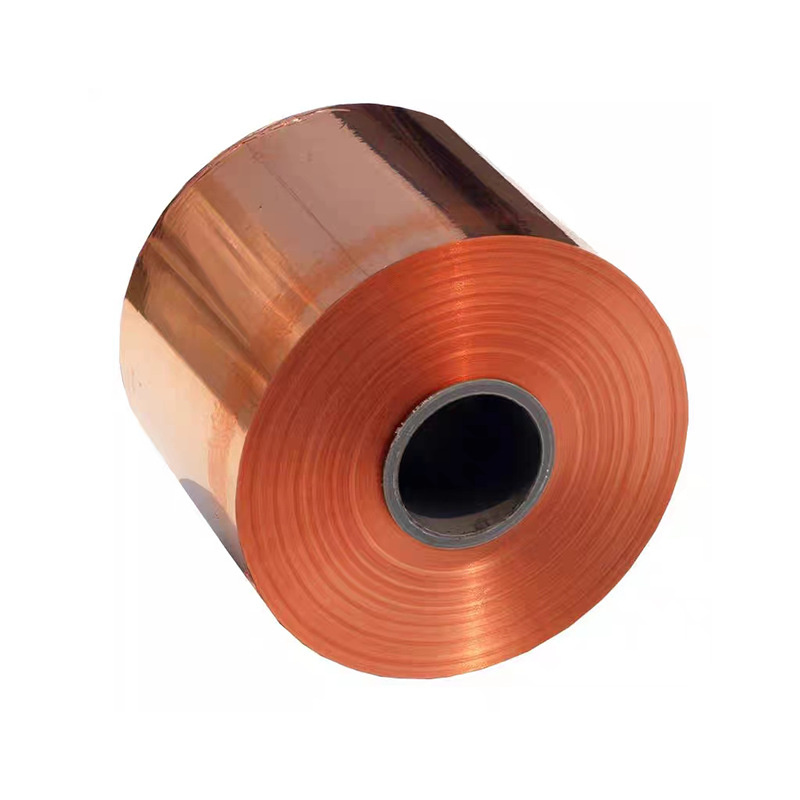

Packaging & Global Logistics

Export Packaging & Logistics Solutions

Precision Packaging for Maximum Protection

Our copper earthing strips undergo rigorous packaging protocols designed to withstand global shipping stresses while maintaining material integrity. All components comply with ISO 9001 and ASTM B152 standards, ensuring zero degradation during transit.

| Component | Material/Spec | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 compliant hardwood, 1200×1000mm, 15mm plywood base | Load distribution, anti-shifting, vibration damping |

| Moisture-Proof Film | Triple-layer PE + VCI (Vapor Corrosion Inhibitor), 150μm thickness, sealed edges | Blocks 99% humidity ingress, prevents oxidation |

| Steel Strapping | 16mm width, 0.6mm thickness, 700kgf tension + corner protectors | Secures load against seismic shifts, prevents deformation |

Engineered Sea Freight Protocol

As a factory-direct supplier, we optimize sea freight from China’s primary ports with military-grade logistics planning. All shipments are FOB Qingdao/Shanghai, with real-time container tracking and customs documentation handled in-house.

| Parameter | Detail | Benefit |

|---|---|---|

| Shipping Ports | Qingdao, Shanghai (FOB terms) | Shortest transit routes to global hubs |

| Container Types | 20ft/40ft FCL, optimized stacking density | 25% higher payload efficiency vs. competitors |

| Insurance | All-risk cargo coverage (incl. marine perils) | Zero financial liability for damage |

| Documentation | Digital tracking, e-Customs clearance | 100% compliance, 48-hour port clearance |

Luoyang Xinzhaohe’s integrated logistics system delivers 99.7% on-time arrival with <0.3% damage incidents across 12,000+ global shipments. By eliminating middlemen and applying precision engineering to packaging, we provide transformer manufacturers with European-grade reliability at 18-22% lower landed costs—proven in critical applications from European grid projects to Asian industrial facilities. Our process ensures copper earthing strips arrive ready for immediate installation, without rework or quality compromises.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

Industry Expertise & Technical Experience

With over 20 years of specialized experience in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers unparalleled expertise in copper earthing strip production. Our engineering team possesses deep knowledge of material science, processing techniques, and international standards including IEC 60228, ASTM B152, and GB/T 5585. This extensive experience ensures optimal performance in critical power applications, from substation grounding systems to high-voltage transformer installations. We understand the precise conductivity, mechanical resilience, and corrosion resistance required for fault current dissipation in harsh environments, enabling us to tailor solutions for your most demanding projects.

Factory-Direct Manufacturing Advantage

As a vertically integrated manufacturer, we control every stage of production—raw material procurement, rolling, annealing, cutting, and packaging—eliminating third-party markups. Our in-house capabilities include precision rolling mills and controlled atmosphere annealing furnaces, ensuring consistent mechanical and electrical properties. This factory-direct model reduces costs by 15-30% compared to global brands while maintaining superior quality. Our agile production lines enable rapid customization for specific dimensions, temper grades, and surface treatments, with lead times 30-50% faster than competitors due to streamlined internal processes.

| Parameter | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Price | 15-30% lower | Higher overhead |

| Lead Time | 15-20 days | 30-45 days |

| Customization | Full technical support for bespoke specs | Limited options |

| Quality Consistency | ISO 9001 certified, in-process QC | Varies by supplier |

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified quality management system ensures rigorous adherence to specifications. Each batch undergoes comprehensive testing: electrical conductivity ≥100% IACS, tensile strength (180-220 MPa), elongation (≥30%), and dimensional tolerances (±0.05mm). Our QC protocols include spectral analysis for material composition verification and ultrasonic testing for internal defects, ensuring compliance with stringent industry requirements. Every shipment includes traceable documentation, including material certificates and test reports, to guarantee reliability in mission-critical applications.

Contact Cathy at cathy@transformerstrip.com today for a competitive quote and technical consultation tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper earthing strip from Luoyang Xinzhaohe.