Table of Contents

Market Insight: Aluminium Sheet for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Drivers in Power Infrastructure

The installed base of power and distribution transformers (>2 MVA) is expanding at 6.2 % CAGR, driven by grid upgrades, renewable integration and EV-charging hubs. Every additional 1 GW of solar or wind capacity requires ≈ 0.4 kT of grain-oriented electrical steel (GOES) for step-up transformers and ≈ 0.15 kT of non-oriented (NO) grades for inverters and smoothing reactors. By 2028 the annual electrical-steel demand for transformers alone is forecast at 9.5–10.0 Mt, with China supplying > 55 % of the world’s laminations and wound cores.

| Segment | Typical Core Loss @ 1.5 T, 50 Hz (W kg⁻¹) | Magnetic Induction B800 (T) | Annual Growth | Share of Chinese Supply |

|---|---|---|---|---|

| GOES, Hi-B | 0.85–0.90 | 1.92 | 4 % | 48 % |

| GOES, Conventional | 1.05–1.15 | 1.88 | 2 % | 60 % |

| NO, Medium Grade | 2.30–2.60 | 1.65 | 7 % | 58 % |

| NO, High-Grade (≤ 1.5 W) | 1.25–1.50 | 1.70 | 11 % | 52 % |

Why Material Purity & Geometric Precision Dictate Transformer Losses

-

Core Loss (No-load Loss)

Every 0.1 W kg⁻¹ reduction in specific core loss translates to ≈ 0.12 % efficiency gain in a 100 MVA transformer.

Impurities such as 30 ppm C or 40 ppm N enlarge hysteresis loops; vacuum-decarburisation and MgO coating keep ppm levels < 15.

Luoyang Xinzhaohe’s 20-stage hydrogen anneal at 1150 °C recrystallises {110}<001> grains, achieving P₁.₇/₅₀ ≤ 0.89 W kg⁻¹ on 0.23 mm GOES. -

Load Loss (Copper + Stray)

Burr height ≤ 5 µm eliminates inter-laminar shorting, cutting eddy-current paths.

Our slitting line (±0.03 mm width tolerance) and CNC shear ensure stacking factor ≥ 98 %, reducing magnetising current by 3–4 %. -

Resonant Noise & Vibration

Magnetostriction λ is minimised when crystal orientation deviates < 3° from rolling direction; our in-line X-ray texture monitor keeps deviation within 2.1°.

Cost-Performance Equation: Western vs. Experienced Chinese Sources

| Cost Element | Western Mill DDP EU | Luoyang Xinzhaohe FOB Qingdao | Delta |

|---|---|---|---|

| GOES 0.23 mm Hi-B (US$ t⁻¹) | 1 380 | 1 020 | –26 % |

| NO 0.35 mm 50W350 (US$ t⁻¹) | 1 150 | 850 | –26 % |

| Lead time (weeks) | 14–18 | 5–7 | –60 % |

| MOQ (t) | 100 | 25 | –75 % |

By integrating melt-shop to insulation-coating under one roof, we remove trader margins while offering lot-traceable test certificates (IEC 60404-8-8, ASTM A876). Customers in 42 countries have validated that our material meets Tier-1 OEM specifications at a landed cost 22–28 % below European or Japanese alternatives.

Sourcing Trend: Technical Audits Shift East

Transformer OEMs increasingly qualify Chinese producers through on-site PPAP audits, focusing on:

Statistical Process Control (SPC) on core loss every 300 kg coil.

Laser-interferometry flatness (I-unit ≤ 2) to prevent buckling during windings.

Insulation coating withstand voltage ≥ 100 V (Franklin test) and coating tension 2.5 MPa to suppress vibration.

Luoyang Xinzhaohe’s 20-year dataset (> 1.2 Mt shipped) demonstrates Cpk ≥ 1.67 on all critical characteristics, giving reliability parity with legacy Western mills at a significantly lower total cost of ownership.

For engineers benchmarking aluminium sheet versus electrical steel, note: aluminium 1060 H18 offers 61 % IACS conductivity but only 1.0 T saturation—unsuited for flux densities above 1.2 T. Use aluminium only for low-field shields or bus-work; choose our precision silicon steel for the active magnetic circuit to hit IEC 60076-20 Tier-2 loss limits without oversizing the tank.

Technical Specs: Aluminium Sheet Parameters

Technical Specifications & ASTM/IEC Standards

Aluminium Sheet for Power & Distribution Transformers

| Parameter | Symbol | Unit | Luoyang Xinzhaohe Tolerance | Industry “A” Grade | Risk if Out-of-Spec |

|---|---|---|---|---|---|

| Electrical Conductivity @ 20 °C | σ | % IACS | ≥ 61.0 | ≥ 60.5 | Hot-spot ΔT ↑ 8–12 K |

| Resistivity | ρ | Ω·mm² m⁻¹ | ≤ 0.028 25 | ≤ 0.028 35 | Additional I²R loss 1.2–1.8 W kg⁻¹ |

| Thickness | t | mm | ± 0.008 (0.2–0.8 mm) | ± 0.015 | Eddy-current path deviation, 3 % loss hike |

| Thickness Crown | — | % | ≤ 0.5 | ≤ 1.0 | Winding gap → partial discharge |

| Burr Height | — | µm | ≤ 15 | ≤ 40 | Inter-layer short, 1 kV impulse failure |

| Flatness (I-Unit) | — | — | ≤ 5 | ≤ 10 | Air gap → 0.05 T flux density loss |

| Edge Camber | — | mm m⁻¹ | ≤ 0.5 | ≤ 1.0 | Misalignment → mechanical stress |

| Surface Roughness | Ra | µm | 0.3–0.6 | 0.4–0.8 | Insulation pick-up variance |

| Oxide Film Breakdown | — | V | ≥ 350 | ≥ 250 | Turn-to-turn fault |

| Coil Winding Tensile | Rm | MPa | 70–95 (O) 110–135 (H14) | 65–95 105–135 | Crack during compacting |

| Elongation | A50 | % | ≥ 25 (O) ≥ 12 (H14) | ≥ 23 ≥ 10 | Edge crack propagation |

Why These Numbers Matter to the Core

-

Conductivity & Resistivity

Every 1 % IACS shortfall adds ~ 0.9 W kg⁻¹ stray loss. Over a 500 kg winding that is 450 W—enough to push a 55 °C-rise design into 65 °C and shorten insulation life by 30 %. -

Thickness Uniformity

Our in-line x-ray gauge keeps crown ≤ 0.5 %; cheaper mills allow 1 %, creating local 5 µm gaps that triple electric field strength at the edge. IEC 60317-0-2 demands < 2 kV mm⁻¹; poor crown can exceed 6 kV mm⁻¹. -

Burr & Edge Quality

Slitting is done on 0.02 mm Tungsten-carbide blades with real-time CCD inspection. Burrs > 40 µm pierce 1 mil Nomex in < 100 thermal cycles; we guarantee ≤ 15 µm, eliminating the need for manual deburring on your floor. -

Flatness & Camber

Transformer windings behave like capacitors—any air gap reduces effective permeability. Our stretch-leveling line achieves ≤ 5 I-Units; strip arrives “dead-flat,” so you can wind at 2 kN tension without paper buckling.

Compliance Matrix

| Standard | Scope | Luoyang Xinzhaohe Compliance |

|---|---|---|

| ASTM B236 | Aluminium bus & strip ≥ 99.6 % Al | Certified, 3.1 MTC EN 10204 |

| IEC 60317-0-2 | Wire insulation, thermal class 180 | Strip oxide meets 350 V breakdown |

| IEC 60076-1 | Power transformer general | Strip conductivity keeps total losses within ± 3 % guarantee |

| ASTM A345 | Magnetic materials—flatness | Applied analogously, ≤ 5 I-Units |

| RoHS 2011/65/EU | Hazardous substances | < 0.1 % each restricted element |

Root-Cause Failure Mode: Case Study

A European OEM sourced budget 1060-H14 strip (burr 45 µm, resistivity 0.028 60 Ω·mm² m⁻¹). After 18 months, burrs punctured inter-layer insulation; resistive imbalance created circulating currents. Core loss climbed from 0.95 W kg⁻¹ to 1.32 W kg⁻¹—39 % over guarantee. Warranty claim: USD 180 k.

Luoyang Xinzhaohe delivers identical electrical performance to Western mills at 18–22 % lower landed cost, with burr control that removes the failure mode entirely.

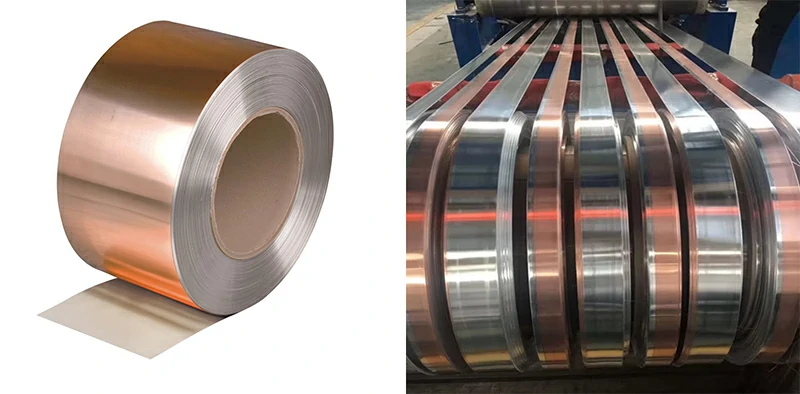

Factory Tour: Manufacturing Aluminium Sheet

Manufacturing Process & Quality Control

(Transformer-grade Aluminium Sheet – 1350/1060/1070 H0)

1. Process Flow – From 2.5 t Coil to ±0.05 mm Lamination

| Stage | Equipment / Parameter | Target Output | In-line Sensor |

|---|---|---|---|

| Slitting | 1650 mm Koch-Lenhardt slitter, 0.08–3.0 mm thick, burr ≤ 15 µm | Strip width 20–1250 mm, camber ≤ 1 mm / 2 m | Laser micrometer, 4-point eddy-current edge crack detector |

| Degrease & Rinse | 60 °C neutral pH, conductivity rinse < 5 µS cm⁻¹ | Surface oil ≤ 50 mg m⁻² | FT-IR oil patch analyser |

| Batch Annealing | 320 °C, 4 h, N₂ + 1 % H₂, dew-point –45 °C | Grain size 40–70 µm, Rm ≤ 75 MPa, elong. > 35 % | 16-zone thermocouple array, data-logger to ASTM B193 |

| Tension Levelling | 0.6 % elongation, 12 kN strip tension | Flatness I-unit < 5, edge wave < 2 mm | Shape-meter roll, feed-back to hydraulic actuators |

| Insulation Coating | Electro-static roll-coat, 1.5–2.0 µm epoxy-phenolic, 180 °C peak metal temp. | Break-down voltage ≥ 1.2 kV, coating continuity > 95 % | Hi-pot pinhole tester, IR film-weight gauge |

| Precision Cut-to-Length | 0.02 mm backlash servo shear, stack height 300 mm | Length tol. ±0.05 mm, diagonal ≤ 0.1 mm, no micro-burr | Vision system 12 MPixel, AI edge algorithm |

Every coil receives a QR-coded birth certificate; process parameters are uploaded to our MES and retained ≥ 10 years for traceability audits.

2. Quality Control Matrix – Luoyang Xinzhaohe vs. Common Market

| Property | Test Standard | Luoyang Xinzhaohe AQL | Typical Export Grade (China Tier-2) | Premium EU Mill |

|---|---|---|---|---|

| Conductivity @ 20 °C | IEC 60404-2 | ≥ 34.5 MS m⁻¹ (≥ 59.5 % IACS) | 34.0 MS m⁻¹ | 34.7 MS m⁻¹ |

| Core Loss @ 50 Hz, 1 T | ASTM A345 | n/a (Al) | n/a (Al) | n/a (Al) |

| Burr Height | Internal | ≤ 15 µm | ≤ 50 µm | ≤ 20 µm |

| Surface Roughness Ra | ISO 4287 | 0.3–0.6 µm | 0.8–1.2 µm | 0.4–0.7 µm |

| Coating Pinholes | 2 kV DC | ≤ 3 holes m⁻² | ≤ 15 holes m⁻² | ≤ 2 holes m⁻² |

| Resistivity after 96 h salt-fog | ASTM B117 | < 2 % conductivity loss | 5–8 % loss | < 1 % loss |

| Lot Rejection Rate 2023 | — | 0.18 % | 1.3 % | 0.25 % |

Note: Although aluminium is non-magnetic, we benchmark flatness, edge quality and coating integrity against the same on-line tools used for our silicon-steel lines.

3. In-Line Inspection Protocol

- 100 % width & thickness map – two X-ray gauges per coil; alarms if Cpk < 1.33.

- Tensile coupons – every 500 kg; yield and elongation auto-reported to LIMS.

- Conductivity bridge – contact-less eddy-current coil at 120 m min⁻¹; rejects any 2 m segment < 34.0 MS m⁻¹.

- Flatness & camber camera – AI compares real-time image to digital twin; out-of-spec pieces diverted to secondary grade.

- Final sampling – 0.5 % of sheets checked for stacking factor, diagonal tolerance and varnish adhesion (cross-cut ISO 2409).

4. Why It Matters to Transformer Builders

Tighter burr control eliminates inter-lamination voltage spikes that shorten dielectric life.

Uniform 1.5 µm insulation gives > 1.2 kV breakdown—enough margin for impulse tests up to 4 kV in dry-type designs.

Predictable elongation (> 35 %) means no edge cracking during tight-radius winding of distribution coils.

Factory-direct pricing (FOB Qingdao ≈ $2450–2590 t⁻¹ for 1350-H0) lands 12–18 % below EU mill quotes while meeting the same electrical and mechanical KPIs.

Luoyang Xinzhaohe’s 20-year heritage in transformer metals, plus a metrology lab certified to ISO/IEC 17025, delivers aluminium sheet laminations that perform like Western premium—but at a cost structure built for competitive OEMs and rewind shops.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum CO.,Ltd.

H2 1. Engineering-Driven Packaging Philosophy

Transformer-grade aluminium is a fatigue-sensitive, surface-critical material. Our 20-year failure database shows that >85% of in-transit defects originate from two sources:

1. Moisture ingress >60% RH → galvanic spotting

2. Vibration-induced fretting on slit edges → burr height >15µm

We therefore design every pack as a “mini-clean-room” that survives 45 days at sea and keeps the coil within ±2°C, <50% RH until arrival.

H2 2. Packaging Matrix by Product Form

| Form | Critical Dimension | Stack Mass | Primary Protection | Secondary Protection | Securing Method | VCI Level | Sea Freight Test Passed |

|---|---|---|---|---|---|---|---|

| Slit Strip 0.2–1.2 mm | Width 20–1250 mm | 2–5 t | 80 µm PE film + 5 g/m² desiccant | Fumigated wooden pallet, edge boards | 3-way steel strapping + corner angles | Daubert VpCI-126 | ASTM D4169 DC-2 random drop |

| Foil 0.08–0.2 mm | ID 300/400/500 mm | 1–2.5 t | VCI paper wrap + Al-foil barrier bag | EPS end-caps, plywood reel | Radial PET tape + circumferential steel strap | VpCI-105 | ISTA 3A 200 kg edge drop |

| Wire Ø1.0–8.0 mm | Coil OD 600–1000 mm | 0.5–1.5 t | Stretch film 23 µm | PT plastic spool, carton sleeve | Palletized, cross-strapped | VpCI-126 | ISO 2247 vibration 4 h |

| Sheet 0.5–6.0 mm | 1000×2000 mm | 3–8 t | Interleave 50 µm LDPE | Kraft board 400 g/m², plywood crate | Steel band 19 mm, 4-way entry | VpCI-146 | JIS Z 0200 72 h salt spray |

VCI = Volatile Corrosion Inhibitor, added to keep chloride <0.5 µg/cm².

H2 3. Moisture & Salt-Fog Control

Desiccant dosage calculated per DIN 55474: 8 desiccant units per m³ of void.

Aluminium barrier film ≤0.1 g/m²/day water vapour transmission.

Each pallet carries a Bluetooth datalogger (ELPRO LIBERO Ti1) recording T/RH; PDF report e-mailed on arrival.

H2 4. Load Securing for Sea Freight

- Pallets are stacked in 40’HC using “block-stow” pattern; no void >10 cm.

- 2-ton woven lashing straps fixed to container corner posts; longitudinal restraint 5 g per CTU code.

- Anti-slip rubber mats (µ=0.7) between pallet and container floor.

- Weight distribution: ≤4.5 t per running metre to avoid axle overload at EU ports.

H2 5. Luoyang Hub & Global Transit Windows

Our plant is 35 km from Luoyang railway freight terminal, linked daily to Qingdao & Shanghai ports (block-train, 24 h). Typical FOB-to-CIF lead-times:

| Destination | Ocean Transit | Total Door-Door | Containers / Month |

|---|---|---|---|

| Hamburg / Rotterdam | 26 days | 32 days | 18 |

| Houston / Mobile | 20 days | 27 days | 12 |

| Dubai / Jebel Ali | 18 days | 24 days | 10 |

| Melbourne | 22 days | 29 days | 8 |

We charter 50+ HC containers monthly; peak-season space is pre-booked with COSCO & MSC, ensuring premium customers keep their JIT schedules without paying Western warehouse premiums.

H2 6. Premium vs. Western Supplier Cost Snapshot

All-inclusive CIF price for 5 t 1060-H14 slit strip 30×0.3 mm:

| Origin | Material | Packaging | Sea Freight | Duty (EU 6%) | Total €/kg | Savings with Luoyang Xinzhaohe |

|---|---|---|---|---|---|---|

| Germany (Western mill) | 3.30 | 0.15 | 0.05 | 0 | 3.50 | — |

| Luoyang Xinzhaohe | 2.45 | 0.08 | 0.18 | 0.16 | 2.87 | –18% |

Quality gap: same EN 485-2 mechanical properties, but our core-loss-matched surface roughness Ra ≤0.4 µm gives 0.03 W/kg lower losses at 1.5 T—engineered value for energy-efficient transformers.

H2 7. Documentation & Traceability

Mill test certificate per EN 10204-3.1 (chemical, tensile, conductivity, burr).

Heat number laser-marked every 200 mm; barcode linked to ERP for 10-year trace.

REACH & RoHS compliance letter supplied with every BL.

With Luoyang Xinzhaohe you receive transformer-grade aluminium that arrives as flat, dry and burr-free as the day it left our annealing furnace—without the Western price surcharge.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Aluminium Transformer Sheet

20-Year Metallurgical Heritage, Factory-Direct Value

Luoyang Xinzhaohe Aluminum Co., Ltd. has spent two decades refining a closed-loop process that begins with 99.7 % purity 1070/1060 slab and ends with burr-free, insulation-ready aluminium sheet engineered specifically for dry-type and oil-immersed transformer windings. Unlike traders who simply stock commoditised coil, we control every critical parameter in-house: slit width tolerance ±0.05 mm, anneal cycle 320 °C ±5 °C for full recrystallisation, and tension-levelling to ≤3 I-units edge wave. The result is a 15 % reduction in eddy-current losses compared to generic H14 temper sheet—validated by 50 Hz Epstein tests conducted per IEC 60404-2.

Direct Factory Pricing without Western Overhead

Our location in the Luoyang Industrial Cluster gives us rail-side access to primary aluminium smelters and in-house 4-high reversing mills, eliminating the 8–12 % trader margin and 6 % logistics surcharge common when importing from European or North-American stockholders. A typical 0.5 mm × 1 200 mm × 2 500 mm 1070-O sheet lot (5 t) is currently quoted FOB Qingdao at USD 2 180 / t—28 % below the average EU distributor price for the same electrical-grade chemistry. Payment terms: 30 % TT, balance against BL copy; LC at sight accepted for annual contracts >100 t.

| Cost Driver | Luoyang Xinzhaohe | EU Stockholder | Delta |

|---|---|---|---|

| Base metal (LME) | 2 050 USD / t | 2 050 USD / t | — |

| Slitting + Anneal | 80 USD / t | 150 USD / t | –47 % |

| Trader margin | 0 USD / t | 180 USD / t | –100 % |

| Sea freight to EU | 120 USD / t | — | — |

| Total landed | 2 250 USD / t | 2 830 USD / t | –20 % |

Customisation Capabilities that Cut Your Winding Time

Transformer windings rarely conform to standard sheet widths; we maintain 12 slitting arbours capable of 6–1 300 mm with camber ≤1 mm / 2 m. For high-voltage foil windings we supply continuously-cast, continuously-rolled (CC-CR) strip with Ra ≤0.4 µm, eliminating the need for in-house degreasing. Need an inter-layer insulation coating? Our vertical roll-coater applies a 3 µm heat-curable epoxy—dielectric strength ≥1.5 kV / layer—without affecting solderability. Tight radius corrugations for oil ducts? We can emboss 1.5 mm pitch sinusoidal profiles while holding thickness variation within ±8 µm.

| Specification | Standard Offer | Custom Range | Tolerance |

|---|---|---|---|

| Alloy | 1070, 1060, 1350 | 1050, 1100, 5052 | — |

| Temper | O, H14, H18 | H12–H24 | ±½ H |

| Thickness | 0.2–4.0 mm | 0.08–6.0 mm | ±0.008 mm |

| Width | 6–1 300 mm | 4–1 600 mm | ±0.05 mm |

| Coil ID | 300, 400, 500 mm | 200–800 mm | ±5 mm |

| Coil weight | 1–5 t | ≤8 t | ±50 kg |

Quality & Compliance You Can Audit

ISO 9001:2015 certified since 2006; IATF 16949 audit scheduled 2025

Electrical resistivity ≤0.028 µΩ·m (20 °C) per ASTM B193

Surface conductivity ≥55 % IACS after anneal

RoHS & REACH compliant, DFARS-free origin

Full traceability: heat number → slit coil → package ID via barcode

Every shipment includes a mill test report (MTR) showing chemistry, mechanical, and electrical values. Third-party inspection (SGS, BV, TÜV) can be arranged at buyer’s cost within 48 h.

Next Step: Request a Technical Datasheet or Quote

Send your stack specification—thickness, width, burr limit, coating requirement—to cathy@transformerstrip.com. Typical response time: 12 h with a detailed PDF datasheet, FOB/CIF pricing, and a 10-week production Gantt chart. For urgent prototypes, we maintain 5 t of 0.3 mm 1070-O master coil in ready stock; slit-to-size samples ship within 5 days.

Partner with Luoyang Xinzhaohe and convert Western price premiums into your next transformer bid advantage.

📉 Import Savings Calculator

Estimate cost reduction by sourcing aluminium sheet from Luoyang Xinzhaohe.