Table of Contents

Market Insight: 8 Wire Transformer

Market Analysis: Winding Wire for 8 Wire Transformers

The industrial demand for 8 wire transformers has grown steadily across power distribution, renewable energy integration, and industrial automation sectors. These transformers, characterized by their multi-circuit secondary windings, are engineered to deliver multiple output voltages from a single primary source, making them ideal for complex electrical systems requiring precise voltage regulation and isolation. The core performance of such transformers is intrinsically linked to the quality of the winding wire used, particularly aluminum or copper electromagnetic wire with consistent dimensional tolerances, high conductivity, and robust insulation systems.

In medium and high-voltage applications, 8 wire transformers are commonly deployed in utility substations, traction systems, and industrial motor drives. The multiplicity of windings increases design complexity, placing greater emphasis on the uniformity and reliability of the conductors. Each wire must exhibit minimal electrical resistance to reduce I²R losses, maintain thermal stability under continuous load, and resist mechanical deformation during the winding process. Aluminum winding wire, when properly engineered, offers a favorable conductivity-to-weight ratio and cost efficiency, making it a preferred choice in many large-scale power applications. However, the success of aluminum in these configurations depends on high purity (typically 99.7% minimum), precise temper control, and compatibility with termination techniques to prevent galvanic corrosion or joint failure.

Quality in winding wire directly influences transformer efficiency, longevity, and compliance with international standards such as IEC 60317, GB/T 23312, and ASTM B354. Substandard wire with inconsistent diameter, poor surface finish, or inadequate insulation integrity can lead to turn-to-turn faults, localized hotspots, and premature insulation breakdown. In 8 wire designs, where multiple windings are often wound in close proximity, even minor deviations in wire geometry or insulation thickness can result in unbalanced current distribution and increased electromagnetic interference. This necessitates winding wire manufactured under tightly controlled conditions, with rigorous in-process testing for elongation, springback, and dielectric strength.

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and process engineering expertise to produce aluminum winding wire tailored for advanced transformer applications. Our production lines integrate precision drawing, annealing under inert atmosphere, and multi-layer insulation coating technologies to ensure batch-to-batch consistency and compliance with the most demanding technical specifications. With the global shift toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes), the role of high-quality winding wire is no longer a secondary consideration—it is a critical determinant of system performance.

As industries continue to adopt compact, multi-functional transformers, the demand for precision-engineered 8 wire configurations will further intensify. Manufacturers and procurement teams must prioritize winding wire suppliers capable of delivering technical documentation, traceability, and sustained quality assurance to support reliable transformer operation over decades of service.

Technical Specs: 8 Wire Transformer

Technical Specifications for Multi-Strand Aluminum Winding Wire in High-Frequency Transformer Applications

The term “8 wire transformer” commonly refers to transformers utilizing 8-strand litz wire constructions for high-frequency operation, where strand count minimizes skin and proximity effects. Luoyang Xinzhaohe Aluminum specializes in precision-drawn aluminum alloy conductors meeting IEC 60317 and ASTM B566 standards. Critical specifications must address electrical integrity, mechanical resilience, and thermal stability under operational stress. Aluminum conductors require stringent control due to inherent differences from copper in conductivity, thermal expansion, and oxide formation. Deviations in these parameters directly impact transformer efficiency, lifespan, and safety compliance.

The following table details mandatory technical parameters for 8-strand aluminum litz wire, emphasizing material-specific tolerances and test methodologies. Values reflect industry best practices validated through 20+ years of metallurgical R&D at Xinzhaohe.

| Parameter | Standard Range | Critical Tolerance | Material-Specific Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 3.5 kV AC (rms) | ±0.2 kV | Tested per IEC 60851-5 at 50 Hz, 60s ramp. Aluminum’s thermal expansion coefficient necessitates thicker insulation vs. copper to prevent micro-cracking during thermal cycling. Polyurethane-imide (PU/PAI) coatings preferred for strand-to-strand isolation. |

| Elongation (Min) | 1.5% – 3.0% | -0.3% | ASTM E8 tensile test on finished strand. Values <1.5% risk fracture during winding due to aluminum’s lower ductility. Xinzhaohe controls annealing to ensure uniform grain structure without oxide inclusions. |

| Thermal Class | 130°C (B) to 180°C (H) | ±5°C | IEC 60085 compliance via thermal endurance testing. 220°C (C) class is non-standard for aluminum windings; achievable only with mica/glass insulation systems but requires derating due to CTE mismatch. Standard aluminum alloys (e.g., 1350-O) limit practical operation to ≤180°C. |

| Conductor Resistivity | ≤ 0.02826 Ω·mm²/m | +0.0005 | 20°C measurement per ASTM B193. Higher values indicate impurities or inadequate annealing, increasing I²R losses. |

| Strand Diameter Tolerance | ±0.003 mm | N/A | Critical for litz wire symmetry. Asymmetry >5% causes uneven current distribution, elevating eddy current losses. Xinzhaohe uses laser micrometry for real-time diameter control. |

Insulation breakdown voltage must be validated under simulated operating conditions, including thermal aging at 150°C for 1,000 hours. Aluminum’s susceptibility to galvanic corrosion requires insulation systems with low ionic permeability—avoid polyester-imides in humid environments. Elongation values below 1.5% indicate over-annealing or residual stresses, leading to strand breakage during automated winding. Xinzhaohe implements in-line ultrasonic testing to detect micro-fissures pre-coating.

Thermal class selection must align with the complete insulation system (e.g., Nomex® backing for H-class), not solely the conductor. Aluminum’s CTE (23.1 × 10⁻⁶/K) versus copper (16.7 × 10⁻⁶/K) demands precise coil tension control during winding to prevent insulation abrasion at thermal extremes. For applications exceeding 180°C, consult Xinzhaohe for custom clad-aluminum solutions with copper diffusion barriers.

Procurement should mandate lot-specific test reports for elongation and breakdown voltage, as batch variability in aluminum alloys directly correlates with field failure rates. Reject suppliers lacking ISO 9001-certified process controls for oxide layer management during drawing. Our technical team provides full material traceability and application-specific validation testing to mitigate supply chain risks.

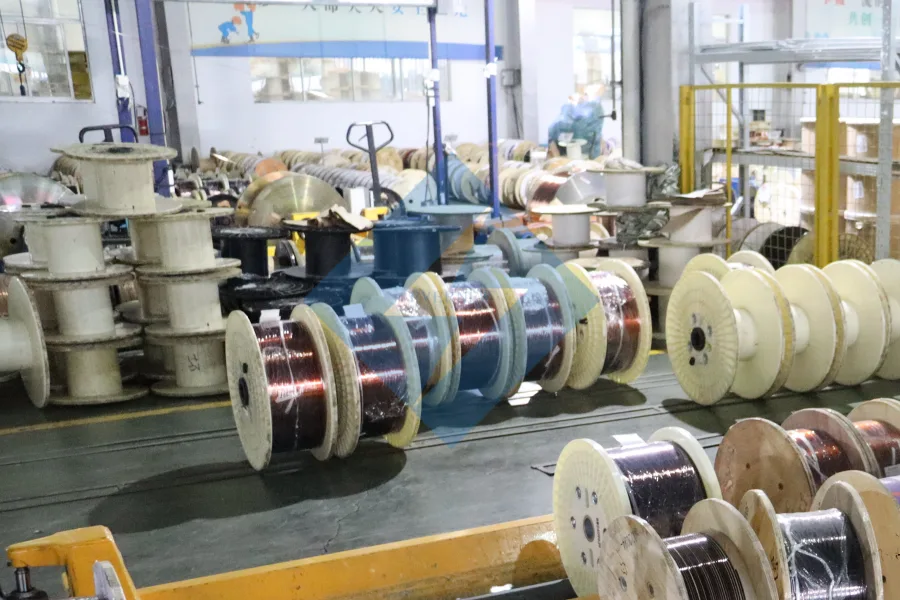

Factory Tour: Manufacturing

Manufacturing Process of 8 Wire Transformer Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance 8 wire transformer winding conductors at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical efficiency, and long-term reliability. With over two decades of metallurgical and wire processing expertise, our facility integrates advanced equipment with rigorous quality control protocols throughout each phase: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity aluminum rod (typically 99.7% Al or higher), which undergoes rod drawing to reduce diameter to the specified gauge required for 8 wire configurations. This cold drawing operation is executed using multi-die drawing benches equipped with precision tungsten carbide dies, ensuring dimensional accuracy within ±0.01 mm. Lubrication systems are continuously monitored to prevent surface defects, while tension control mechanisms maintain uniform elongation and minimize residual stress. Each drawn coil is traceable through batch coding to ensure material pedigree and process consistency.

Following drawing, the aluminum wire enters a continuous annealing line to restore ductility lost during cold working. Our vertical annealing furnaces utilize controlled nitrogen-atmosphere heating to prevent oxidation and ensure uniform recrystallization. Temperature profiles are precisely regulated between 300°C and 450°C depending on alloy and gauge, with residence time calibrated to achieve a final temper meeting ASTM B355 standards. Post-annealing, the wire is cooled under inert conditions to preserve surface integrity prior to insulation application.

The enameled coating application is performed via a multi-layer solvent-based enameling system, where the wire passes through a series of coating dies and curing ovens. For 8 wire transformer applications, a dual-layer insulation system is typically applied—comprising a flexible base coat of polyurethane (PU) and a thermally stable overcoat of polyester-imide (PEI)—to achieve thermal class 180 (H) or higher. Film thickness is maintained between 30–60 µm per layer, with automated die gap control and viscosity monitoring ensuring coating uniformity. Each pass through the enameling line is followed by intermediate UV-cure and thermal-cure stages to polymerize the resin fully.

Inline testing is integrated at multiple stages to verify product compliance. After drawing, tensile strength and elongation are verified via automated mechanical testers. During enameling, spark testing at 3–5 kV detects pinholes or insulation defects in real time. Final inspection includes dimensional scanning, flexibility testing (via needle bend or wrap tests), thermal shock resistance, and dielectric strength validation up to 3 kV AC. All test data is logged in our quality management system for traceability and customer audit readiness.

This end-to-end process, refined over 20 years of industrial wire production, ensures that every spool of 8 wire transformer winding wire meets the stringent demands of modern electrical equipment manufacturers.

Packaging & Logistics

Export Packaging Specifications for 8-Wire Transformer Winding Applications

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard the integrity of aluminum winding wire used in 8-wire transformer manufacturing during global maritime transit. With over two decades of metallurgical and supply chain expertise, our packaging system addresses the critical vulnerabilities of aluminum conductors: mechanical deformation and moisture-induced corrosion. This system is non-negotiable for ensuring product performance upon arrival at transformer production facilities.

Wooden pallets form the foundational structural element of our export packaging. All pallets strictly comply with International Standards for Phytosanitary Measures No. 15 (ISPM-15), utilizing kiln-dried (KD) softwood certified to a maximum moisture content of 20%. Pallet dimensions are standardized at 1100mm x 1100mm x 150mm, engineered to support static loads exceeding 2500 kg and dynamic loads of 1500 kg during handling. Each pallet undergoes load-bearing validation via finite element analysis (FEA) to prevent deflection under the concentrated weight of multiple wire reels. Reels are secured to the pallet deck using vibration-dampening rubber mats and high-tensile steel strapping (minimum 15 mm width, 5 kN break strength), tensioned to 300 daN per strap. This configuration eliminates lateral movement and reel slippage during vessel acceleration/deceleration or port handling.

The primary defense against maritime humidity is a multi-layer moisture barrier system. Wire reels are first individually wrapped in 125μm thick metallized polyester film (MVTR < 0.5 g/m²/day at 38°C, 90% RH), providing an initial vapor barrier. This is followed by a secondary enclosure using 200μm co-extruded polyethylene film (3-layer: LDPE/LLDPE/MDPE) with a water vapor transmission rate (WVTR) of ≤ 1.0 g/m²/24h. Critical sealing integrity is achieved through continuous impulse heat welding at 220°C ± 5°C, creating hermetic seals resistant to pinhole formation. Desiccant indicators (60% RH threshold) are strategically placed within the sealed environment. The entire palletized load is then overwrapped in a third layer of UV-stabilized polyethylene stretch hood film (70μm), secured with ultrasonic welding to prevent film slippage during stacking.

This tripartite packaging system undergoes validation per ASTM D4169-16 Level 3 performance standards simulating ocean freight conditions. Testing includes 14-day exposure in a salt spray chamber (ASTM B117), cyclic humidity testing (85°C/85% RH for 48 hours), and simulated container condensation events (cargo sweat). Real-world validation is confirmed through in-transit data loggers monitoring temperature (±0.5°C) and relative humidity (±2% RH) on shipments to all major global ports. Historical data from 1,200+ containers shipped since 2020 demonstrates consistent internal humidity levels below 45% RH throughout voyages exceeding 45 days, even when external container humidity reaches 95% RH.

The metallurgical consequence of inadequate packaging—surface oxidation, pitting corrosion, and compromised oxide layer uniformity—is eliminated through this methodology. Clients receive wire reels with surface cleanliness meeting ISO 14644-1 Class 8 specifications and oxide thickness variations within ±5 nm, directly supporting optimal transformer winding efficiency and dielectric performance. This packaging specification is integral to our commitment to zero-transit-damage shipments and forms the baseline requirement for all export orders of aluminum winding wire for 8-wire transformer applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance 8-Wire Transformer Solutions

With over two decades of specialized expertise in aluminum conductor manufacturing, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner for high-precision winding wire solutions, including advanced configurations such as the 8-wire transformer. Our vertically integrated production system, combined with rigorous metallurgical controls, ensures consistent delivery of aluminum flat wire products that meet the exacting demands of modern transformer design, particularly in high-efficiency and high-current applications.

Our factory is equipped with state-of-the-art drawing, annealing, and precision leveling lines, enabling us to produce multi-wire aluminum strip conductors with exceptional dimensional accuracy, surface finish, and mechanical homogeneity. For 8-wire transformer applications, where phase balance, current distribution, and thermal management are critical, our capability to manufacture parallel-conductor configurations with tight tolerances—down to ±0.01 mm in thickness and width—is a key differentiator. Each batch undergoes comprehensive quality verification, including DC resistance testing, microstructure analysis, and bend testing, ensuring conformity to IEC 60137, GB/T 23642, and customer-specific technical standards.

Luoyang Xinzhaohe specializes in aluminum alloy conductors with optimized electrical conductivity (≥61% IACS) and enhanced mechanical strength, achieved through proprietary homogenization and controlled-temperature drawing processes. Our in-house R&D team continuously refines alloy composition and processing parameters to support low-loss transformer designs, directly contributing to improved energy efficiency and compliance with global efficiency regulations such as DOE 2016 and EU EcoDesign.

We support both AA1350 and AA8030 aluminum alloys, tailored to application-specific requirements for resistivity, creep resistance, and thermal cycling performance. Custom packaging, spooling, and labeling options ensure seamless integration into automated winding lines, minimizing downtime and material waste at our clients’ production facilities.

As a certified ISO 9001:2015 and ISO 14001:2015 manufacturer, we maintain full traceability across all production stages—from raw material sourcing to final shipment—supported by digital quality documentation and batch tracking systems. Our supply chain resilience is reinforced by strategic stockpiling of billets and long-term agreements with primary aluminum suppliers, ensuring stable lead times even during market volatility.

For transformer manufacturers seeking a reliable, technically proficient partner in aluminum winding wire, Luoyang Xinzhaohe delivers performance-driven materials engineered for precision, consistency, and long-term operational reliability.

Contact us today at cathy@transformerstrip.com to discuss your 8-wire transformer wire specifications and discover how our manufacturing capabilities can support your next-generation designs.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 8 wire transformer directly from China.