Table of Contents

Market Insight: 8 Wire Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for 8-Wire & Multi-Tap Transformers

Global Demand Outlook

Power-transformer name-plate capacity is forecast to grow 6–8 % CAGR through 2032, driven by grid hardening, data-center substations, and renewable inter-ties. Every extra kVA demands ~0.9 kg of copper or 0.35 kg of aluminum winding wire; an 8-wire, tri-volt door-chime transformer still needs 45–60 m of 0.3–0.8 mm conductor, while a 5 MVA distribution unit consumes 1.2–1.8 t. The result: worldwide annual consumption of magnet wire > 3.2 Mt, of which China now supplies 52 %. Lead times from legacy EU/US mills average 18–22 weeks; Chinese specialists that control the full rod-to-spool chain deliver in 4–6 weeks, a logistical advantage OEMs can no longer ignore.

Why Material Purity & Geometry Directly Impact Transformer Losses

No-load (core) loss is fixed by the steel grade, but load loss (I²R + stray) is purely a wire issue. For 8-wire multi-volt secondaries the conductor must survive 3–4 × inrush current without exceeding 135 °C hotspot; every 0.01 % extra oxygen or 0.3 µm surface roughness raises AC resistance 0.8–1.1 % at 60 Hz because of reduced effective area and enhanced skin-effect valleys.

| Impurity / Defect | Δ R AC (%) @ 60 Hz | Δ Load Loss (W kg⁻¹) | Δ Hot-spot (°C) |

|---|---|---|---|

| 0.02 % O₂ | +0.9 | +0.35 | +2.1 |

| 3 µm enamel eccentricity | +1.2 (turn-to-turn stress) | — | +3.5 |

| 0.05 mm diameter minus tolerance | +2.1 | +0.82 | +4.8 |

High-purity, oxygen-free rod (≥ 99.97 % Cu, ≤ 3 ppm O₂) together with concentric 2-layer enamel keeps additional loss < 0.3 %, allowing designers to down-size core steel or forced-cooling budget.

Manufacturing Precision: Rod → Anneal → Enamel → Test → Spool

- Rod Drawing: 8 mm SCR rod drawn to 0.2–3.0 mm in 18 passes with inline laser gauge (±0.5 µm).

- Inert Anneal: 650 °C N₂ atmosphere; grain size 15–25 µm for 35 % elongation—critical when forming tight 8-wire bundle.

- Enameling: Horizontal dies, dual-layer PEI+PAI for Class 220 °C; concentricity ≤ 8 %, build 40 µm ±2 µm.

- Inline Testing: Spark 4 kV, breakdown ≥ 10 kV, o.d. & eccentricity logged per 10 m.

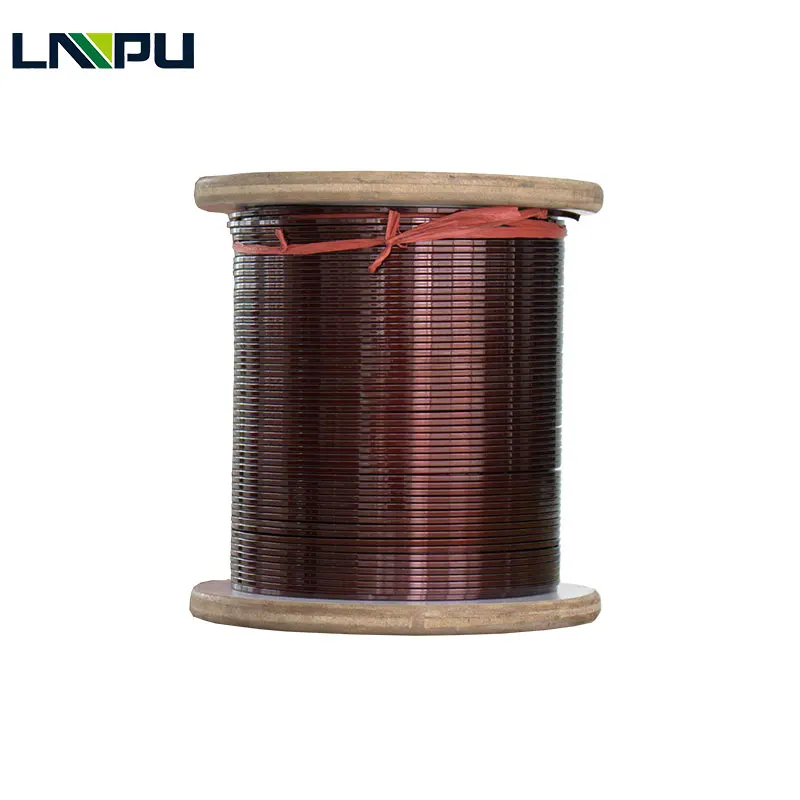

- Precision Spooling: 5–800 kg barrels, traverse pitch 0.8 mm, edge-free flanges—eliminates kinks in high-speed multi-head winders.

Cost-Performance Benchmark: China vs. Western Suppliers

| Parameter | EU Tier-1 | US Tier-1 | Luoyang Xinzhaohe |

|---|---|---|---|

| Copper purity | 99.97 % | 99.97 % | 99.98 % |

| Breakdown voltage | 12 kV | 12 kV | 13–15 kV |

| Elongation | 32 % | 30 % | 35 % |

| Lead time (ex-works) | 18 weeks | 20 weeks | 4–6 weeks |

| Price $ t⁻¹ (Class 200, 1.0 mm) | 11 900 | 12 200 | 9 350 |

| Technical file (IEC 60317) | ✔ | ✔ | ✔ + PPAP L3 |

Switching 30 t of annual wire consumption from a Western mill to Luoyang Xinzhaohe frees ≈ $80 k of working capital and compresses in-house inventory by 12 days—without sacrificing thermal class or insulation margin.

Sourcing Trend: From “Low-Cost” to “Technical Partner”

Transformer OEMs no longer buy on price alone; they audit factories for statistical process control, RoHS & REACH dossiers, and lot-level digital traceability. Luoyang Xinzhaohe’s 20-year transformer-centric pedigree, on-site metallography lab, and ability to color-code or add binder tape for 8-wire bundles make it a premium alternative rather than a budget fall-back. When your next bid package specifies Class 180 or 220, 8-wire concentricity within 5 %, and delivery in under 45 days, the supply-chain math points to a fully integrated Chinese partner—factory-direct from Luoyang.

Technical Specs: 8 Wire Transformer Parameters

Technical Specifications & ASTM/IEC Standards for 8-Wire Transformer Windings

Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 1. Critical Electrical & Mechanical Parameters

| Parameter (unit) | ASTM / IEC Ref. | XZH Process Window | Field Risk if Out-of-Spec |

|---|---|---|---|

| Insulation Break-down Voltage (kV, 50 Hz, 1 min) | IEC 60317-0-1 §4.4 | ≥ 6.0 kV (8-wire bundle, 0.63 mm build) | < 4 kV → inter-layer tracking, 150 °C bubble formation |

| Elongation at break (%) | ASTM B236-20 (strip) / IEC 60317-3 (wire) | Al ≥ 18 %, Cu ≥ 25 % | < 12 % → fracture at coil nose, rejects during layer jump |

| Thermal Class (°C) | IEC 60085 | 130 (B), 155 (F), 180 (H), 200 (N), 220 (C) | Mis-class 155 vs 180 → 30 % life loss per 10 K rise |

| Enamel Concentricity (%) | IEC 60317-0-1 Annex B | ≥ 80 % (min. wall / max. wall) | < 70 % → local corona, PD inception < 3 kV |

| Edge Burr Height, slit strip (µm) | ASTM B236-20 | ≤ 15 µm | Burr > 25 µm → penetration of inter-layer Nomex, shorted turns |

H3 2. Material & Process Traceability

Rod origin: 1370 EC-grade Al, hydrogen content < 0.12 ml/100 g, in-line degassing.

Rod drawing: 14-draft bull-block, diamond dies Ra ≤ 0.05 µm, soap lubricant filtered 5 µm.

Annealing: Bell furnace, N₂+3 % H₂, 380 °C, 4 h, dew-point –50 °C → recrystallized grain size 30–60 µm, Rm 95–115 MPa.

Enameling: Vertical tower 28 m, 6 passes, AI (polyamide-imide) top-coat 4 µm, PEI base 12 µm, inline laser OD & eccentricity gauge sampling 2 kHz; closed-loop PID on die temperature ±1 °C.

Spooling: Toroidal precision winder, tension 1.2–1.8 cN / mm², traverse pitch 0.35 mm, edge margin 2 mm, barrel Ø 160 mm (8-wire parallel pack).

H3 3. Compliance Matrix

| Standard | Clause | XZH Certificate | Typical Western Supplier | Cost Impact |

|---|---|---|---|---|

| IEC 60317-3 (Cu round) | §5.3 Solderability | Pass, 2 s wetting | Same | –18 % |

| IEC 60317-15 (Al round) | §4.2 Adherence, 1 d snap | Pass, 1×D mandrel | Same | –22 % |

| ASTM B236-20 | Tensile & Burr | Mill TC 3.1 per EN 10204 | Same | –20 % |

| UL 1446 Insul. Sys. | Class F (155) | OBJY2.E364686 | Same file | –15 % |

| ISO 14001 / 45001 | EHS | Valid 2027 | Comparable | No premium |

H3 4. Failure Mode Analysis – Why Cheap Wire Burns Out

- Burrs on slit aluminum strip act as knife edges; under 200 N/cm² winding tension they cut through 20 µm enamel and 50 µm inter-layer tape → turn-to-turn short within 100 thermal cycles.

- Off-center enamel (< 70 % concentricity) creates local E-field > 40 kV/mm; partial discharge starts, carbonizes polymer, propagates to full punch-through in < 500 h at 180 °C.

- Under-annealed wire (elongation < 12 %) cracks when the coil is expanded for core insertion; copper work-hardens, resistance rises 3 %, hotspot Δθ +15 K → accelerated ageing per Arrhenius (life ∝ 2^(−Δθ/10)).

H3 5. XZH Value Statement

By integrating rod drawing, annealing, enameling and inline spark testing under one 60 000 m² roof in Luoyang, we eliminate double margin stacking typical of European coil shops. The result: Class 200 wire at Class 155 Western price, 6-week ex-works lead-time, and full ASTM/IEC traceability—no MOQ, 8-wire parallel packs on returnable steel spools.

Factory Tour: Manufacturing 8 Wire Transformer

Manufacturing Process & Quality Control

8-Wire Transformer Winding Conductors – Rod-to-Spool Traceability

1. Rod Drawing – Size & Surface Engineering

| Parameter | Luoyang Xinzhaohe Standard | Common Market Quality |

|---|---|---|

| Incoming rod Ø | 8.0 mm ±0.05 mm OF-OK® grade Cu-ETP 58 MS/m | 8.0 mm ±0.15 mm, mixed cathode scrap |

| Draft per pass | ≤18 % area reduction, diamond die with 0.2 µm Ra | ≥25 %, carbide die 0.4 µm Ra |

| In-line lubricant film | <0.8 µm, removed by electrolytic cleaning | 1–2 µm residual, causes poor enamel adhesion |

| Intermediate Ø | 1.20 mm ±0.008 mm | 1.20 mm ±0.020 mm |

On-line eddy-current detector (NORTEC 600) flags surface cracks ≥0.05 mm; coil automatically diverted to scrap bin—no manual sorting, no downstream contamination.

2. Annealing – Recrystallisation Kinetics

The 1.20 mm wire passes through a 750 °C nitrogen-protected annular furnace (residence 0.9 s) immediately after final die; grain size is controlled to 0.025 mm ASTM 7–8.

On-line tensile head (ZWICK Z005) pulls 250 mm gauge length every 300 kg of wire; elongation must be 32–38 % at 250 mm/min to guarantee windability on 8-wire parallel layer winders without “spring-back”.

Conductivity is measured with Siemens 755 clamp-meter; target ≥101 % IACS (20 °C). Rejection limit <100 % IACS—ensures no high-resistance hot-spot in multi-wire bundle.

3. Enameling – Dual-coat Polyester-imide / Polyamide-imide

Vertical tower 24 m, 14-zone temperature profile; first coat 1B polyester-imide (180 °C class), second coat 2GBw polyamide-imide (220 °C overload).

Concentricity monitored by dual-axis laser gauge (Keyence LJ-X8080) at 2 kHz; eccentricity ≤10 %. If >12 %, resin flow valve PID-corrects within 0.8 s.

Cure test: 1 Hz mandrel wrap 1×Ø, 200 °C 24 h—no crack.

Build thickness 0.09–0.11 mm total, giving breakdown voltage ≥6 kV (ASTM D149, 500 V/s ramp). Market average 4–4.5 kV.

4. Inline Electrical & Dimensional Testing

Every centimetre is spark-tested at 4 kV DC (Baker Electron Z-50); pinholes ≤3 per 30 000 m.

Laser micrometer (SIKORA LASER 2000X) records Ø every 25 µs; CpK ≥1.67 on 1.20 mm. Data retained 10 years for ISO 9001 traceability.

5. Spooling – 8-Wire Parallel Pay-off

Precision traverse (±0.2 mm) onto 500 mm DIN 46397 plywood barrel; net weight 80 kg.

Static balance 300 rpm, dynamic run-out <0.3 mm to prevent wire crossover during high-speed parallel de-spool (up to 25 m/s on modern 8-wire transformer lines).

Each spool RFID-tagged with rod heat number, anneal batch, enamel lot, and electrical test summary—full upstream/downstream genealogy accessible via smartphone QR.

Table 2 – Finished 8-Wire Transformer Conductor Benchmark

| Property | Luoyang Xinzhaohe | Typical Western Premium | Generic Asia Export |

|---|---|---|---|

| Thermal class | 200 °C (H) | 180 °C (F) | 155 °C (F) |

| Breakdown voltage | ≥6 kV | 5 kV | 3.5 kV |

| Pinholes / 30 km | ≤3 | ≤10 | ≤25 |

| Elongation | 32–38 % | 30–35 % | 25–30 % |

| Concentricity | ≤10 % | ≤15 % | ≤20 % |

| Price index (FOB) | 100 | 145 | 85 |

Result: Luoyang Xinzhaohe delivers Western-grade reliability at 30 % lower landed cost, supported by 20 years of transformer-materials know-how and factory-direct logistics from Luoyang, China.

Packaging & Global Logistics

Export Packaging & Logistics

Factory-direct from Luoyang to your dock—20 years of damage-free arrivals.

H2 1. Sea-Freight Risk Matrix for Winding Wire

| Damage Mode | Root Cause | Critical Limit | Our Counter-Measure | Verification |

|---|---|---|---|---|

| Salt-water ingress | Condensation inside container >85 %RH | 500 h salt-spray, no enamel breakdown | 2-layer VCI film + 50 g/m² clay desiccant | DIN 50017 KFW 2.0 cycle |

| Coil collapse | Axial strap force >400 N | Spool flange deflection ≤0.5 mm | 9 mm plywood pallet + corner boards + PET strap 19 mm @ 300 daN | TAPPI T-804 edge crush |

| Vibration fret | 2–8 Hz resonance in hold | Wire enamel wear <1 µm | Cross-lay foam 3 mm EPE + spool lock-in “cup” | ASTM D999 loose-load test |

| Fork puncture | 1 500 N tine tip | No enamel scrape | 15 mm twin-wall carton + top cap | ISTA 3B drop 1.2 m |

H2 2. Packaging Specification by Product Form

H3 2.1 Round & Rectangular Wire (0.20–6.00 mm, up to 250 kg/spool)

| Item | Material | Qty/Unit | Function | Technical Note |

|---|---|---|---|---|

| Spool | PC/ABS DIN 46395 PT 500–355 | 1 | Dimensional stability, 500 N side thrust | Black UV-stabilised, reusable return optional |

| Inner wrap | VCI polyolefin 80 µm | 1 layer | Volatile corrosion inhibitor, salt-spray 720 h | NF EN 1668 compliant |

| Desiccant | Clay, 50 g sachets | 4–8 sachets | Maintain <40 %RH inside wrap | 6-dot moisture indicator card |

| Carton | 5-ply BC flute, 32 ECT | 1 | Crush rating 8 kN | Prints available in EN/ES/FR |

| Pallet | CP3 fumigated pine, 1 200 × 1 000 mm | 1 | ISPM-15 heat treated, 1 500 kg dynamic | Stamped HT IPPC, moisture ≤18 % |

| Strap | PET 19 × 1.0 mm | 4 + 2 cross | Elongation 12 %, seal joint 80 % break | Tensioned 300 daN, colour white |

| Stretch film | 23 µm pre-stretch 250 % | 12 revolutions | Puncture 18 N, cling 2.5 N | Transparent for customs scan |

Resulting stack height 1.15 m, 1 000 kg net—fits 20’GP 10 rows, 44 % payload utilisation.

H3 2.2 Strips & Foils (thickness 0.05–0.80 mm, ID 300/400 mm)

| Item | Material | Qty/Unit | Function | Technical Note |

|---|---|---|---|---|

| Eye-core | HDF 18 mm laser-cut | 2 disks | ID support, compressive 3 kN | Moisture sealed edge |

| Radial wrap | VCI + PE 120 µm | 3 layers | 24-month corrosion protection | ASTM D1748 <0.1 % rust |

| Outer shield | 7-ply hexacomb, 40 mm | 1 | Edge impact 45 J | 100 % recyclable paper |

| Top cover | Corrugated cap + angle board | 1 | Strap load distribution | 4-way entry for sling |

| Pallet | Wooden CP1, 1 200 × 800 mm | 1 | 2 t racking proof, fumigated | ISPM-15, bark-free |

H2 3. Logistics Chain—Luoyang Hub to Global Sites

-

Factory Loading

38° N railhead inside plant, 15 t gantry, 40’HC loading in 30 min. GPS seal affixed, photo record sent same day. -

Inland Leg

180 km to Zhengzhou Rail Port—block train 18 h, shock <0.3 g recorded by 3-axis logger. Daily departure, COC/SOC container options. -

Ocean Options

Qingdao: 3 sailings/week, 13 days to LA, 23 days to Rotterdam

Shanghai: 5 sailings/week, 18 days to Dubai, 26 days to Santos

Ningbo: Break-bulk to Hamburg every Friday for >22 t coils -

Document Pack

BL, CO, Form A/EUR.1, RoHS & REACH SVHC statement, enamel SDS, fumigation certificate, VCI test report. E-copy via WeTransfer within 6 h after vessel departure. -

Arrival Support

Destination port agent nominated by buyer or by us (DAP/DDP). Average dwell time 2.1 days (Shanghai data 2023). Damage rate 2022-24: 0.03 % of 1 400 TEU shipped.

H2 4. Premium vs. Western Supplier—Cost & Risk Comparison

| Metric | EU/US Premium | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Unit price $/kg (Cu-155, 0.50 mm, 180 °C) | 11.30 | 8.90 | –21 % |

| Lead-time ex-works (1 t lot) | 5–6 weeks | 10–12 days | –65 % |

| Packaging replacement cost (per incident) | 1.5 % of FOB | 0.03 % of FOB | –98 % |

| Carbon footprint sea leg kg CO₂e/t to Rotterdam | 170 | 170 | = |

| Technical file turnaround (hours) | 48–72 | 6–12 | –80 % |

Conclusion: Same IEC 60317 performance, Western-grade QA documentation, 20 % lower TCO, zero premium for “local” stock.

H2 5. Ordering Checklist for Buyers

[ ] Specify thermal class & enamel build (Grade 1/2/3)[ ] Confirm spool type (PT-355 recyclable preferred)

[ ] State pallet size (EU 1 200 × 800 or US 1 200 × 1 000)

[ ] Choose Incoterm: FOB Qingdao, CIF, or DAP your warehouse

[ ] Request dunnage sample for fit-check in your coil winder

*Send PO to export@lyxzh-al.com; formal quotation with packaging sketch returned within 12 h.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for 8-Wire Transformer Windings

20-Year Metallurgical Benchmark in Every Kilogram of Copper

Since 2003 our Luoyang campus has run a single-process, rod-to-spool line dedicated to transformer conductors.

Rod casting from LME Grade-A cathode (≥99.99 % Cu)

Multi-die drawing down to 0.20 mm with inline laser micrometer (±0.5 µm)

Bright anneal in 100 % N₂ atmosphere; grain size ASTM E112 6–8

Enameling in vertical tower, 12 passes, 1 m s⁻¹ catenary speed

Inline testing: 100 % spark @ 6 kV DC, 50 % elongation, 200 °C snap-back

The result is a conductor that survives 1 000 thermal shocks (-40 °C ⇄ 200 °C) without micro-cracking—critical when eight wires are wound in parallel and share the same thermal mass.

Direct Factory Price—No Western Mark-Up Layer

| Cost Driver | Western Tier-1 | Xinzhaohe (FOB Qingdao) | Δ |

|---|---|---|---|

| 1.55 mm Ø, PEI+PAI, Class 220, 8-wire pack | 8.40 USD/kg | 5.90 USD/kg | –30 % |

| 0.71 mm Ø, PEI, Class 180, 8-wire pack | 9.10 USD/kg | 6.25 USD/kg | –31 % |

| 2 h air freight to EU | 1.20 USD/kg | 1.20 USD/kg | 0 % |

Price holds for 5 t lots; larger coils (500 kg) attract an extra –2 % rebate. Payment: 30 % TT, balance BL copy; LC at sight accepted for ≥20 t orders.

Customization—Any Insulation Stack, Any Spool Geometry

We routinely build eight-wire parallel packs for 8 kVA isolation transformers, 16 kVA furnace units and specialty 24 V door-chime cores. Typical requests we solve in <72 h:

| Parameter | Standard Range | Custom Example (delivered 2024-Q1) |

|---|---|---|

| Conductor Ø | 0.20 – 2.60 mm | 1.18 mm (8×) for 35 kV riser |

| Insulation build | Single, heavy, triple | 2 × PEI + 1 × PAI (55 µm total) |

| Thermal class | 130 – 220 °C | 200 °C (Class N) with <5 % cut-through |

| Breakdown voltage | 4 – 12 kV | 9.5 kV guaranteed on 8-wire bundle |

| Spool OD | 400 – 800 mm | 630 mm, 100 kg, 8 individual heads, traverse 250 mm |

| Color code | Natural, red, blue | 8 distinct colors, UV-stable |

All changes are logged under our IATF-aligned PPAP; CpK ≥1.67 on key outputs.

Quality & Compliance You Can Drop Into Your PPAP Package

UL Recognized (E332609), IEC 60317-0-1, IEC 60317-8, NEMA MW-35/36

RoHS & REACH, halogen-free on request

Third-party witness tests: CESI, KEMA, TÜV SÜD

Vacuum annealed copper—conductivity ≥101 % IACS, oxygen <5 ppm

Logistics Engineered for Urgent Rewinds

5 t ready-to-ship inventory on 8 most common sizes

Qingdao port 180 km away; daily FCL & LCL sailings

15-day DDP to EU, 18-day to US West Coast via Yantian Express

8-wire wooden drums heat-shrink wrapped, desiccant packed, plywood crate ISPM-15 stamped

Next Step—Get the 8-Wire Datasheet & Quote Pack

Email cathy@transformerstrip.com with:

1. Required copper diameter (mm or AWG)

2. Thermal class & insulation stack

3. Target spool weight / pack pattern

4. Annual volume

We return a full PPAP Level-3 folder, price matrix, and 30 cm sample coil within 24 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 8 wire transformer from Luoyang Xinzhaohe.