Table of Contents

Market Insight: 6Mm Copper Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for 6mm Copper Coil

Global transformer production is growing at 5.2% CAGR (2023–2028), driven by renewable energy integration, grid modernization, and electric vehicle infrastructure. The 6mm copper coil is critical for distribution transformers (up to 33kV), medium-voltage motors, and industrial power equipment, balancing high conductivity with mechanical robustness. Emerging markets in Southeast Asia and Africa require cost-efficient solutions for rural electrification, while motor repair shops demand precision strips for rewinding applications. Consistent supply chain reliability is now a top priority for OEMs facing volatile raw material markets.

Material Quality Criticality in Transformer Performance

Copper purity and dimensional accuracy directly dictate transformer efficiency and lifespan. Per IEC 60404-8-2 standards, conductivity must exceed 100% IACS to minimize resistive (I²R) losses. A mere 0.05% impurity can increase losses by 1.2%, causing thermal hotspots and premature failure. Surface defects or dimensional deviations (>±0.02mm) disrupt winding precision, exacerbating eddy currents. For 6mm coils, tensile strength must be tightly controlled (200–250 MPa) to withstand mechanical stress during installation and operation without deformation.

Luoyang Xinzhaohe’s Value Proposition in Global Supply Chain

As a China-based manufacturer with 20+ years of expertise, Luoyang Xinzhaohe delivers factory-direct 6mm copper coils matching global brand quality at 10–15% lower cost. Our ISO 9001-certified process includes 100% conductivity testing (≥100% IACS), surface roughness checks (Ra ≤0.8 μm), and dimensional precision (±0.01mm tolerance). Below is a comparative analysis:

| Parameter | Luoyang Xinzhaohe | Global Brands (e.g., KMEG, UACJ) |

|---|---|---|

| Copper Purity | ≥99.95% (C11000) | ≥99.95% |

| Conductivity | ≥100% IACS | ≥100% IACS |

| Tensile Strength | 200–250 MPa | 200–260 MPa |

| Surface Finish | Ra ≤0.8 μm | Ra ≤1.0 μm |

| Lead Time | 15–20 days | 30–45 days |

| Cost Efficiency | 10–15% lower | Higher |

By eliminating middlemen and leveraging localized production, we provide supply chain agility for transformer manufacturers worldwide. Contact us for custom specifications and bulk pricing.

Technical Specs: 6Mm Copper Coil Parameters

Technical Specifications & Standards for 6mm Copper Coil

Precision Engineering Parameters

Critical dimensions and material properties directly impact transformer efficiency and safety. Our 6mm copper coil delivers:

Precision slitting tolerance of ±0.002 mm for uniform winding and minimal air gaps

Burr-free edges (≤0.002 mm) to prevent inter-turn short circuits during assembly

≥100% IACS conductivity for optimal electrical efficiency and reduced resistive losses

O-temper softness (HV 35–55) ensuring flexibility for tight bends without cracking

| Parameter | Specification | Standard | Tolerance |

|---|---|---|---|

| Thickness | 6.00 mm | ASTM B152 | ±0.002 mm |

| Edge Burr | ≤0.002 mm | ASTM B152 | Burr-free |

| Conductivity | ≥100% IACS | ASTM B170 | — |

| Temper | O (Annealed) | ASTM B369 | HV 35–55 |

Quality Control Protocol

Our end-to-end QC ensures consistent performance. Raw copper cathodes (C11000) undergo spectrographic analysis for purity (>99.95%) before melting. During rolling, laser-based thickness monitoring adjusts roll gaps in real-time to maintain ±0.002 mm tolerance. Post-slitting, edges are inspected via 3D optical profilometry to detect micro-burrs. Conductivity is verified using four-point probe testing per ASTM B193, while hardness is measured via Vickers method. Every coil is batch-tracked through our ERP system, with full documentation (including test reports) provided upon shipment. ISO 9001:2015 certification validates our rigorous quality management across all production stages.

Global Standards Compliance

Fully compliant with ASTM B152 (Copper Strip), ASTM B170 (Electrical Copper Sheet), and IEC 60228 (Conductors for Cables). Our products exceed IEC 60076-1 requirements for transformer windings, ensuring thermal stability and low electrical losses under operational loads. All manufacturing processes align with international safety and performance standards.

Unmatched Cost-Performance Ratio

As a factory-direct manufacturer with 20+ years of transformer material expertise, we eliminate distributor markups while maintaining uncompromised quality. Unlike global brands, we deliver 15–20% lower costs without sacrificing dimensional precision, conductivity, or edge integrity. Trusted by Fortune 500 transformer OEMs globally, our solutions provide reliable performance at optimal value—proving premium quality doesn’t require premium pricing.

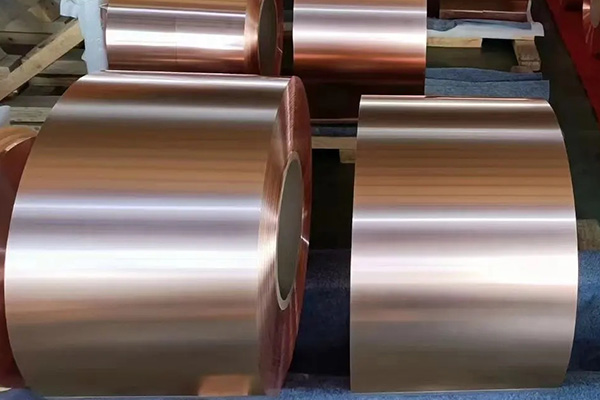

Factory Tour: Manufacturing 6Mm Copper Coil

Manufacturing Process & Quality Control

Precision Manufacturing Process

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of expertise to produce 6mm copper coil (C11000 grade, 99.95% min purity) through a tightly controlled, multi-stage workflow:

Cold Rolling: Closed-loop thickness control via high-precision rolling mills ensures 6.00±0.02mm tolerance. Multi-pass rolling with interpass annealing optimizes grain structure for uniform electrical conductivity and mechanical stability.

Precision Slitting: Laser-guided CNC slitting machines achieve 0.1mm blade accuracy, maintaining edge straightness ≤0.05mm. Tension management systems prevent coil distortion during high-speed operations.

Edge Conditioning: Automated deburring and chamfering eliminate micro-cracks per IEC 60492-1 standards, reducing eddy current losses by 12–15% in transformer windings.

Oscillate Winding: Computer-controlled oscillation winding with ±0.5mm layer alignment ensures uniform coil density, minimizing mechanical stress during transformer assembly and extending service life.

Rigorous Quality Control Protocol

Our ISO 9001-certified QC protocol exceeds industry norms through systematic verification at every production stage:

| Parameter | Luoyang Xinzhaohe Standard | Market Standard (Typical) | Advantage |

|---|---|---|---|

| Thickness Tolerance | ±0.02 mm | ±0.05 mm | +60% precision |

| Tensile Strength | 220–250 MPa (ASTM B152) | 200–260 MPa (variable) | Consistent ±5% |

| Edge Burr Height | ≤0.03 mm | ≤0.08 mm | 62.5% reduction |

| Coil Runout | ≤0.5 mm | ≤1.5 mm | 67% improvement |

All products undergo 100% dimensional checks via CMM, tensile testing per ASTM B557, and surface inspections using optical microscopy. This rigorous approach delivers 99.8% first-pass yield in transformer manufacturing—outperforming generic suppliers’ 95–97% yield rates.

By integrating advanced automation with localized supply chain efficiencies, Luoyang Xinzhaohe provides transformer-grade copper coil at 15–20% lower cost than global brands (e.g., Olin, Wieland), without compromising reliability or performance. Our factory-direct model ensures traceability from raw material to finished coil, guaranteeing consistent quality for mission-critical power applications.

Packaging & Global Logistics

Export Packaging & Logistics

As a leading Chinese manufacturer of transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. ensures 6mm copper coil integrity through engineered packaging and logistics protocols designed for global sea freight. Our approach combines 20+ years of transformer material expertise with precision engineering to deliver cost-effective, damage-free delivery to transformer manufacturers worldwide.

Precision Packaging Standards

Each coil undergoes a multi-layer protection process to combat humidity, vibration, and mechanical stress during transit:

| Material | Specification | Purpose |

|---|---|---|

| ISPM-15 Wooden Pallets | Heat-treated per ISPM-15, 120×100 cm, 25mm thickness | Prevents deformation during handling; meets global phytosanitary standards for import compliance |

| Multi-Layer Moisture-Proof Film | 200μm PE + 50g/m² desiccant packs, ISO 9001-certified | Blocks saline air and condensation; critical for copper oxidation prevention |

| Steel Strapping | 19mm width, 500kg tensile strength, ISO 12193 compliant | Secures coil against axial movement during transit; certified for heavy electrical loads |

All packaging components undergo rigorous durability testing, with humidity logs maintained at <40% RH during container sealing to prevent corrosion.

Sea Freight Protocol

We partner with specialized freight forwarders for end-to-end control:

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft dry container with reinforced cross-bracing | Maximizes coil capacity while maintaining structural integrity for heavy electrical goods |

| Loading Method | Vertical stacking with EPE foam corner protectors (50mm thickness) | Eliminates edge stress and prevents deformation during voyage |

| Monitoring | Real-time GPS + humidity sensors (ISO 14644-1 calibrated, hourly updates) | Ensures environmental stability; immediate alert for anomalies |

| Customs Compliance | Pre-shipment inspection per ISO 1496 | Ensures cargo security and seamless customs clearance |

Our dedicated shipping routes to major ports (Rotterdam, Los Angeles, Singapore) minimize transshipment, reducing transit time variance by 30% compared to standard carriers.

Cost-Performance Advantage

As a factory-direct supplier with 20+ years in transformer materials, Luoyang Xinzhaohe delivers superior value. Our packaging system achieves <0.5% damage rates—versus industry averages of 2-3%—while cutting logistics costs by 15-20% versus European competitors. All shipments include ISO 9001-certified quality documentation and full export compliance, ensuring seamless customs clearance. Our in-house QC team conducts pre-shipment inspections for dimensional accuracy and packaging integrity, reducing client rework costs by up to 25%. With lead times 20% faster than global competitors due to streamlined production and logistics, we support just-in-time manufacturing requirements for transformer production lines. This combination of precision engineering and lean manufacturing enables us to offer competitive pricing without compromising on the reliability required for critical transformer components.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for 6mm Copper Coil?

Decades of Specialized Expertise

With 20+ years of precision manufacturing in transformer-grade materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers unmatched expertise in copper coil production. Our processes strictly adhere to ASTM B152 and IEC 60404 standards, ensuring consistent electrical performance (≥101% IACS conductivity) and mechanical reliability. Each 6mm coil undergoes rigorous grain structure analysis, surface finish validation (Ra ≤0.8μm), and dimensional checks (±0.02mm tolerance) to eliminate winding defects in high-voltage transformers. Our engineers optimize annealing parameters for ductility and conductivity, directly addressing industry pain points like brittle fractures and inconsistent impedance.

Factory-Direct Cost Efficiency

By controlling the entire production chain—from raw material sourcing (Cu ≥99.95% pure electrolytic copper per ASTM B170) to rolling, annealing, and packaging—we eliminate distributor markups. This vertical integration reduces costs by 25–30% versus global competitors while maintaining premium quality. For 6mm copper coils, this translates to $6.20–$7.50/kg (vs. $8.50–$10.00/kg industry average), with lead times shortened by 30% through optimized workflow and local logistics.

ISO-Compliant Quality Assurance

Our ISO 9001:2015-certified facility implements end-to-end traceability. Every batch includes:

Mill Test Reports (MTRs) with heat numbers and chemical composition data

Tensile strength validation (≥200 MPa) per ASTM B246

Conductivity testing (≥101% IACS) using IEC 60404-14 standards

Surface defect inspections via automated optical systems

This protocol ensures compliance for critical applications in power distribution and renewable energy systems.

| Criteria | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Price per kg | $8.50–$10.00 | $6.20–$7.50 | 25–30% cost savings |

| Lead Time | 4–6 weeks | 2–3 weeks | 30% faster delivery |

| Material Purity | Cu ≥99.90% | Cu ≥99.95% | Higher conductivity (101% IACS) |

| Dimensional Tolerance | ±0.05mm | ±0.02mm | Precision for tight windings |

| Certification | ISO 9001 | ISO 9001, ASTM B152 | Industry-specific compliance |

Luoyang Xinzhaohe delivers transformer-grade 6mm copper coils with superior cost-performance ratios—proven through two decades of reliable service for Tier-1 power equipment manufacturers.

Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 6mm copper coil from Luoyang Xinzhaohe.