Table of Contents

Market Insight: 6 Wire Transformer

Market Analysis: Winding Wire Demand for Transformer Applications

The industrial demand for aluminum winding wire, particularly in configurations relevant to medium and distribution transformers often misreferenced as “6 wire transformer” units, is driven by global energy infrastructure modernization and cost-sensitive design optimization. This terminology typically signifies transformers utilizing multi-strand or specific conductor bundling techniques, where precise wire geometry and material properties are critical. Actual demand centers on aluminum electromagnetic wire meeting stringent dimensional tolerances (e.g., 6.00 mm ±0.03 mm diameter for specific high-current windings) and metallurgical specifications, not a literal six-wire count. Global distribution transformer production, heavily reliant on aluminum windings due to copper cost volatility, fuels consistent demand. Key growth drivers include renewable energy integration requiring step-up transformers, aging grid replacements in developed economies, and rural electrification projects in emerging markets. Asia-Pacific remains the dominant consumption region, with China’s State Grid Corporation driving significant volume through standardized transformer procurement programs.

Quality in aluminum winding wire is non-negotiable for transformer reliability and performance. Substandard wire introduces systemic failure risks during manufacturing and operational life. Inconsistent tensile strength or elongation properties cause wire breaks during high-speed winding, increasing scrap rates and production downtime. Surface imperfections—scratches, pits, or excessive oxide layers—compromise enamel insulation adhesion, creating localized hotspots and accelerating dielectric breakdown under electrical stress. Dimensional inaccuracies, particularly ovality exceeding 0.02 mm, lead to uneven winding tension, poor coil packing density, and increased stray losses. Crucially, inadequate electrical conductivity (below 61.0% IACS for fully annealed AA-1350 or AA-8030 alloys) directly elevates I²R losses, reducing transformer efficiency and increasing lifetime operational costs. Hydrogen embrittlement from improper annealing can cause delayed wire fractures, while inconsistent grain structure affects fatigue resistance during thermal cycling.

The consequences of compromised wire quality extend beyond immediate manufacturing issues. Field failures due to insulation degradation or thermal runaway result in costly unplanned outages, warranty claims, and reputational damage for transformer manufacturers. Grid operators face penalties for non-compliance with efficiency standards like DOE 2016 or IEC 60076-20. Premium aluminum wire ensures process stability, maximizes coil fill factor, minimizes no-load and load losses, and guarantees 30+ year service life under fluctuating loads. Metallurgical control over annealing homogeneity, surface cleanliness, and mechanical property consistency is paramount.

Critical quality parameters directly impacting transformer performance are summarized below:

| Parameter | Standard Requirement | Premium Requirement | Impact of Deviation |

|---|---|---|---|

| Conductivity | ≥61.0% IACS | ≥61.5% IACS | Increased load losses, lower efficiency |

| Diameter Tolerance | ±0.05 mm | ±0.03 mm | Winding instability, stray flux |

| Ovality | ≤0.04 mm | ≤0.02 mm | Poor coil compaction, hotspots |

| Surface Roughness | Ra ≤1.0 µm | Ra ≤0.6 µm | Insulation adhesion failure |

| Tensile Strength | 40-60 MPa | 45-55 MPa (±3 MPa) | Wire breaks during winding |

Luoyang Xinzhaohe Aluminum applies two decades of metallurgical expertise to eliminate these failure modes through rigorous process control from molten metal purification to precision drawing and annealing. Our wire ensures transformer manufacturers achieve target efficiency classes, manufacturing yield, and field reliability—transforming a commodity specification into a strategic asset for grid resilience.

Technical Specs: 6 Wire Transformer

Technical Specifications for 6 Wire Transformers – Winding Wire Parameters

Luoyang Xinzhaoang Aluminum Co., Ltd. provides high-performance aluminum winding wire solutions engineered for reliable operation in 6 wire transformers used in industrial, power distribution, and renewable energy applications. With over two decades of metallurgical expertise, our materials are optimized for dielectric integrity, mechanical ductility, and thermal endurance. The following technical parameters define the critical performance characteristics required for aluminum winding wire in 6 wire transformer configurations, with emphasis on insulation breakdown voltage, elongation, and thermal class compatibility.

Insulation breakdown voltage is a primary determinant of electrical safety and long-term reliability in transformer windings. For 6 wire transformer applications, the enamel insulation system must withstand high transient voltages and continuous operating stress without dielectric failure. Our recommended winding wire systems achieve a minimum breakdown voltage of 4,500 V AC (rms) under standard test conditions (IEC 60317-0-7), ensuring robust inter-turn insulation and resistance to partial discharge. This performance level supports medium-voltage transformer designs and enhances operational safety in grid-tied and industrial environments.

Elongation at break is a key mechanical property that influences winding processability and resistance to cracking during coil formation. Aluminum conductors, while lightweight and cost-effective, require precise control of tensile properties to avoid fracture during tight-radius winding. For 6 wire configurations involving multi-strand cabling and helical winding techniques, the aluminum alloy core must exhibit a minimum elongation of 18% (ASTM E8). This ensures compatibility with high-speed winding equipment and reduces the risk of conductor breakage under repeated flexing and tension.

Thermal class rating directly impacts the transformer’s overload capacity and service life. Our winding wire solutions support thermal classes ranging from 130°C to 220°C, aligning with global insulation system standards (IEC 60085). The enamel insulation is formulated with polyamide-imide (PAI) or modified polyester-imide (PEI) chemistries to deliver superior thermal stability, chemical resistance, and adhesion to aluminum substrates. Thermal class 220 (220°C) systems are recommended for high-efficiency transformers operating in elevated ambient temperatures or subject to frequent thermal cycling.

The following table summarizes the critical technical parameters for aluminum winding wire in 6 wire transformer applications:

| Parameter | Test Standard | Minimum Requirement | Typical Value | Notes |

|---|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-7 | 4,500 V AC | 5,000–6,000 V AC | Measured at 1.5x nominal wire diameter |

| Elongation at Break | ASTM E8 | 18% | 20–24% | On aluminum conductor (1350-O temper) |

| Thermal Class | IEC 60085 | 130°C to 220°C | 180°C / 200°C | Based on insulation system rating |

| Conductor Resistivity | ASTM B230 | ≤ 28.264 nΩ·m | 27.5–28.0 nΩ·m | At 20°C, annealed aluminum |

| Adhesion Strength | IEC 60851-5 | Pass | No flaking | After winding and heat shock test |

These specifications ensure compatibility with automated winding processes, long-term thermal aging resistance, and compliance with international safety and performance benchmarks. Luoyang Xinzhaohe Aluminum Co., Ltd. tailors material formulations to meet customer-specific transformer designs, ensuring optimal balance between electrical, mechanical, and thermal performance.

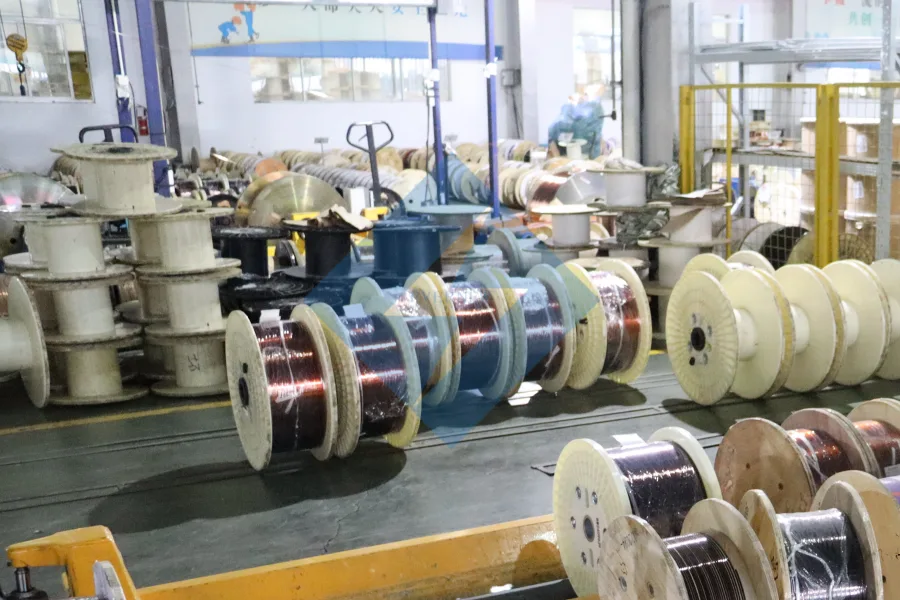

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd employs a rigorously controlled production sequence for aluminum winding wire used in transformer applications, ensuring compliance with IEC 60228 and ASTM B230 standards. The process begins with high-purity aluminum rod (99.7% min Al, 0.1% max Fe+Si) sourced from certified smelters. Rod Drawing reduces the rod diameter to precise wire gauges through multi-die reduction sequences. Critical parameters include die geometry optimization, lubricant viscosity control (50–100 cSt), and tension monitoring to prevent surface defects. In-line diameter verification via laser micrometers (±0.002 mm accuracy) occurs at 10 m intervals, with automatic rejection of out-of-tolerance segments.

Annealing follows drawing to restore ductility and achieve target mechanical properties. Wires pass through a continuous inert-atmosphere furnace (N₂/O₂ < 50 ppm) at 300–350°C, with residence time calibrated to grain structure requirements. Temperature uniformity is maintained within ±5°C across the furnace zone, validated hourly via thermocouple arrays. Key annealing parameters are dynamically adjusted based on wire speed (15–40 m/min) and gauge to ensure consistent elongation (25–30%) and tensile strength (60–75 MPa).

Enameling applies a triple-layer insulation system using modified polyester-imide resin. The wire traverses precision applicators under controlled pressure (0.3–0.5 MPa) and viscosity (30–40 seconds in Ford Cup #4). Curing occurs in staged ovens: pre-bake (180°C), main cure (280°C), and cooling (80°C), with dwell times optimized for film integrity. Adhesion is verified through 180° bend tests over mandrels matching wire diameter, while dielectric strength is confirmed at 3.5 kV/µm via spark testing.

Inline testing integrates real-time quality assurance. Each spool undergoes 100% electrical resistance validation (20°C, ±0.5% tolerance per IACS), dimensional inspection (outer diameter ±0.01 mm), and surface defect scanning via high-resolution cameras. Final QC includes salt-water dielectric testing (60 seconds at 2.5 kV AC), thermal endurance assessment per IEC 60172 (200 hours at 200°C), and elongation checks post-forming. Non-conforming batches are quarantined for root-cause analysis, with corrective actions documented in our ERP system.

This integrated approach—combining metallurgical precision with closed-loop process control—ensures winding wire meets the stringent demands of transformer manufacturers, minimizing field failures through proactive defect prevention.

Typical Annealing Parameters by Wire Gauge

| Wire Diameter (mm) | Furnace Temperature (°C) | Line Speed (m/min) | Target Elongation (%) |

|——————–|————————–|——————-|————————|

| 1.0–1.5 | 320 ± 5 | 25–30 | 28–30 |

| 1.6–2.0 | 330 ± 5 | 20–25 | 26–28 |

| 2.1–2.5 | 340 ± 5 | 15–20 | 25–27 |

Packaging & Logistics

Export Packaging for Aluminum Winding Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production of high-purity aluminum winding wire, we recognize that consistent product performance begins with reliable packaging. This is particularly critical in the export of materials such as 6 wire transformer conductors, where exposure to environmental stressors during sea freight can compromise both material integrity and downstream processing efficiency. Our export packaging system is engineered to mitigate these risks, ensuring that every coil arrives at its destination in optimal condition.

All aluminum winding wire destined for international markets is mounted on robust wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to support the mechanical load of tightly wound coils, which can range from several hundred kilograms to multiple metric tons depending on configuration and wire gauge. The structural rigidity of the pallet prevents deformation during lifting, stacking, and long-haul transport, particularly under the dynamic conditions of containerized maritime shipping. Reinforced base boards and integrated load-bearing stringers distribute weight evenly, minimizing the risk of coil collapse or edge damage.

Immediately following spooling and inspection, each coil is hermetically wrapped in multi-layer moisture-proof film. This film consists of a composite laminate incorporating aluminum foil and high-density polyethylene, providing a vapor transmission rate of less than 0.5 g/m²·24hr at 38°C and 90% relative humidity. This barrier is essential in preventing moisture ingress during extended ocean voyages, where temperature fluctuations and high ambient humidity can lead to condensation within shipping containers. Moisture exposure poses a severe risk to aluminum conductors, potentially initiating surface oxidation that affects both electrical conductivity and winding compatibility in transformer manufacturing.

The wrapped coils are further secured using UV-resistant polyester strapping, tensioned to industry-standard specifications to maintain clamping force without damaging the underlying film or coil edges. Each package is labeled with durable, weather-resistant identification tags indicating batch number, alloy specification, temper, net weight, and handling instructions compliant with IMDG and IATA maritime regulations.

Our packaging protocol has been validated through accelerated climate chamber testing and real-world shipment monitoring across key trade lanes, including trans-Pacific and Europe-Asia routes. This systematic approach ensures that our aluminum winding wire maintains dimensional stability, surface cleanliness, and electrical performance upon arrival, regardless of transit duration.

For transformer manufacturers relying on precise wire feed behavior and consistent annealing response, our export packaging is not merely a transport solution—it is an extension of our quality assurance framework. Luoyang Xinzhaohe Aluminum Co., Ltd remains committed to delivering materials that meet the exacting demands of global power infrastructure supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Aluminum Winding Wire for Critical Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial-scale production to deliver aluminum transformer winding wire meeting the most stringent global transformer manufacturing standards. Our core strength lies in the precise control of material properties essential for high-efficiency, low-loss 6-wire transformer designs, where dimensional consistency and electrical performance are non-negotiable. We operate fully integrated production lines dedicated exclusively to electrical conductor alloys, ensuring absolute traceability from molten metal to finished strip.

Our advanced continuous casting and cold rolling facility utilizes proprietary process control systems to achieve industry-leading dimensional tolerances critical for automated winding processes. The precision annealing lines maintain exact thermal profiles and protective atmospheres, optimizing electrical conductivity while ensuring uniform mechanical properties across every coil. This metallurgical precision directly translates to reduced eddy current losses, minimized winding bulging, and enhanced thermal stability in the final transformer assembly. The table below summarizes key performance parameters consistently achieved in our production:

| Parameter | Luoyang Xinzhaohe Specification | Typical Industry Standard |

|---|---|---|

| Thickness Tolerance | ±0.005 mm (on 1.0-3.0 mm base) | ±0.015 mm |

| Width Tolerance | ±0.10 mm | ±0.25 mm |

| Electrical Conductivity | ≥61.0% IACS (Al-1350) | ≥60.0% IACS |

| Tensile Strength | 80-100 MPa (O-temper) | 70-110 MPa |

| Elongation | ≥25% | ≥20% |

Quality assurance is embedded at every process stage through in-line laser micrometry, real-time conductivity monitoring, and rigorous laboratory testing per IEC 60138 and GB/T 3190 standards. Our ISO 9001 and IATF 16949 certified systems ensure batch-to-batch repeatability, with comprehensive material test reports including OES chemical analysis, microstructure verification, and surface defect mapping provided with every shipment. This eliminates costly production line stoppages due to wire inconsistency.

Supply chain resilience is engineered into our operational model. Strategic partnerships with primary aluminum producers secure high-purity feedstock, while our 50,000-ton annual capacity and dedicated logistics coordination guarantee on-time delivery for JIT manufacturing schedules. We maintain buffer stock of critical dimensions and offer custom annealing profiles to match specific winding machine requirements, reducing customer inventory risk without compromising lead times. Our technical team provides direct metallurgical support for wire integration challenges, from spool design optimization to troubleshooting winding tension issues.

For transformer manufacturers demanding zero-defect aluminum winding wire that meets the exacting demands of modern 6-wire transformer architectures, Luoyang Xinzhaohe delivers proven performance backed by two decades of metallurgical expertise. Contact our technical sales team to request dimensional capability studies or discuss your specific conductivity and surface finish requirements. Initiate a qualification process with a trusted partner who understands the physics of electromagnetic conversion at the material level. Email Cathy directly at cathy@transformerstrip.com to schedule a technical consultation and receive our latest production capability dossier.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 6 wire transformer directly from China.