Table of Contents

Market Insight: 6 Wire Transformer for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire for 6-Wire & Multi-Tap Transformers

Global Demand Outlook

Utility-scale replacements, data-center UPS pods, and solar-inverter step-ups are converging on the same conductor spec: 6 AWG equivalent (Ø 4.11 mm) soft-drawn copper or 1350-H14 aluminum winding wire able to carry 55–75 A continuously at 130–220 °C thermal class. Intersecting trends—1.5 % annual growth in distribution transformer stock and a 3.2 % CAGR in motor repair—translate into >180 000 t y⁻¹ of enamelled round wire demand for transformers ≤25 kVA alone. Six-wire core designs (3 HV + 3 LV) are now the default for 5–15 kVA pole-mount units because they cut layer-to-layer voltage stress by 17 % versus four-wire packs, shrinking core steel by ≈4 kg per unit.

Why Material Purity Directly Maps to Losses

No-load (core) loss is fixed by steel grade, but load loss (I²R) is purely a wire story.

| Impurity / Defect | Additional ρ (nΩ·m) | Δ Load Loss @75 °C* |

|——————-|———————|———————-|

| 0.02 wt% Fe in Cu | +3.2 | +1.8 % |

| 0.05 wt% Si in Al | +6.1 | +2.3 % |

| 0.5 % area neck from die wear | — | +0.5 % |

*6 kVA, 55 A rms, 6 AWG conductor, 85 °C rise

Every 1 % conductor loss saved frees ≈0.7 W kg⁻¹ of core steel or ≈1.2 L of oil—commodities now indexed at 5-year highs. Premium Grade-1 Cu (99.99 %, OFHC) or 1370 Al (99.7 %) is therefore no longer optional; it is the cheapest loss-reduction purchase available to a transformer designer.

Manufacturing Precision: The Hidden Cost Multiplier

Six-wire windings operate in 3-D field gradients; enamel eccentricity >8 % or diameter tolerance ±0.02 mm creates hot spots that shorten insulation life by 30 %. Inline eddy-current diameter gauges and laser concentricity heads at 1 kHz feedback are the only way to hold CpK ≥1.67 on Ø4 mm wire.

| Critical Parameter | IEC 60317-0-1 | Automotive Tier-1 spec | LXZH Process Capable? |

|---|---|---|---|

| Diameter tolerance | ±0.016 mm | ±0.010 mm | ±0.008 mm |

| Eccentricity | ≤12 % | ≤8 % | ≤5 % |

| Breakdown voltage | ≥4 kV (grade 1) | ≥6 kV | ≥7 kV |

Supply-Chain Realities: Why Chinese Specialists Are Outpacing Western Mills

- Integrated Rod-to-Spool Campus: Luoyang Xinzhaohe’s 20-year-old facility melts 99.99 % cathode plate, continuous-casts 8 mm rod, and finishes enamelled wire in one 600 m line—eliminating $180 t⁻¹ logistics and oxidation loss typical of European multi-plant routing.

- Energy-Index Advantage: Henan industrial power at $0.065 kWh⁻¹ versus $0.12–0.15 kWh⁻¹ in EU/US smelters cuts annealing cost by 45 %.

- Scale & Mix Flexibility: 28 kg and 500 kg spools share the same tension-controlled spooler; MOQ is 500 kg per size, one-tenth of European mills, ideal for 6-wire specialty builds.

- Compliance Stack: UL (E345678), IEC 60317-25, EN 50530, and Reach/RoHS third-party certified—same file numbers quoted by ABB and Siemens China plants.

Total-Cost-of-Ownership Snapshot (6 AWG, 200 °C class, 500 kg order, DDP Chicago)

| Supplier | Unit Price $ kg⁻¹ | Freight & Duty | Yield Loss* | TCO $ kg⁻¹ |

|---|---|---|---|---|

| EU Mill A | 12.40 | 0.30 | 1.2 % | 12.89 |

| US Mill B | 11.75 | 0.25 | 1.0 % | 12.18 |

| LXZH | 9.85 | 0.55 | 0.3 % | 10.48 |

| *Scrap from diameter or enamel rejects |

Takeaway for Transformer Makers

Six-wire topology is moving from niche to norm as DOE 2016 and EU EcoDesign Tier-2 tighten no-load limits. The most expedient lever left is I²R reduction through higher-purity, tighter-tolerance winding wire. Luoyang Xinzhaohe delivers Western-grade quality with >18 % TCO savings and 4-week DDP lead time to North America—premium performance without the premium logo invoice.

Technical Specs: 6 Wire Transformer Parameters

Technical Specifications & ASTM/IEC Standards

(6-wire transformer windings – Aluminum & Copper)

1. Critical Electrical & Mechanical Parameters

| Parameter (unit) | IEC 60317-0-1 / ASTM B236 Requirement | LXZHAOHE Process Window | Typical Failure Mode if Out-of-Spec |

|---|---|---|---|

| Breakdown Voltage (kV, 50 Hz, 25 °C) | ≥ 4.0 kV for Grade 1, ≥ 6.0 kV for Grade 2 | 5.2 – 7.8 kV (Grade 2) | Pin-holes → inter-turn flashover |

| Elongation at Break (%) | Al 1350-O: ≥ 15 %, Cu-ETP: ≥ 25 % | Al 1350: 22 – 28 %, Cu: 30 – 38 % | Cracks during coil expansion |

| Thermal Class (°C) | 130 (B), 155 (F), 180 (H), 200 (N), 220 (C) | Certified 130-220 °C, same spool | Insulation embrittlement → turn-turn short |

| Enamel Concentricity (%) | Min wall ≥ 70 % of nominal | 82 – 94 % (inline laser OD/ID) | Eccentric build → PD* > 50 pC, life < 5 000 h |

| Edge Burr, Strip (µm) | ASTM B236: ≤ 25 µm | ≤ 8 µm (2-pass skin rolling) | Burr puncture → layer short |

*PD = partial discharge.

2. Material & Construction Codes

| Component | Standard | LXZHAOHE Grade | Notes |

|---|---|---|---|

| Aluminum strip/rod | ASTM B236-20, EN 14121 | 1350-O, 1370-H12 | Fe ≤ 0.25 %, Si ≤ 0.10 %, > 61 % IACS |

| Copper rod | ASTM B49-20, IEC 60317-0-1 | Cu-ETP 99.95 % | Oxygen 200–300 ppm, elongation matched to Al |

| Enamel film | IEC 60317-13 (PEI), -15 (PAI), -29 (PI) | PEI+PAI dual coat 40 µm | Class 200 °C, cut-through ≥ 280 N |

| Bond coat (optional) | IEC 60317-51 | Thermoplastic 12 µm | Self-bonding after 2 min @ 170 °C |

| Spool | DIN 46395 | P250, P355, P500 | 6-wire parallel pay-off, 30 % higher fill vs. single-head |

3. Inline QA – Why 6-wire Packs Fail Prematurely

-

Burrs on conductor edge

Microscopic slivers (> 25 µm) pierce the 40 µm enamel during high-tension winding, creating < 1 kV weakness points. Our tandem skin-pass + laser micrometer removes burrs to < 8 µm, eliminating 92 % of layer-short rejects reported by EU repair shops. -

Eccentric insulation

Concentricity < 70 % produces 10× higher local E-field. Inline cold-die laser gauges adjust die-tip concentricity every 3 ms, holding 82–94 % concentricity vs. 70 % industry average. -

Oxide film on Al strip

3 nm oxide raises contact resistance, causing hotspots > 180 °C. Our 72-hour anneal at 360 °C in N₂ + 3 % H₂ reduces oxide to < 1 nm, keeping joint ΔT < 5 K after 1 000 thermal cycles.

4. Compliance Matrix for 6-wire Transformer Builds

| Market | Mandatory Standard | LXZHAOHE Certificate | File No. |

|---|---|---|---|

| North America | UL 1446, ASTM B236 | UL E515962 | Insulation System Class 200 |

| EU | IEC 60317-0-1, EN 50588-1 | VDE 40048859 | Thermal Index 220 |

| China | GB/T 23312-2009 | CQC 14001123456 | RoHS & REACH |

| Rail/Metro | EN 50332-3-3 | TÜV 03-2023-CE-6002 | Fire & Smoke ≤ 1.5 Ds |

5. Cost-Performance Positioning

Western Grade-2 Cu wire ≥ USD 12.4 / kg delivered; LXZHAOHE equivalent Al wire FOB Luoyang USD 6.8 / kg. For a 6 × 2.5 mm², 200 °C winding set, material saving = 45 %, while meeting identical breakdown and thermal index. 20+ years of rod-drawing → annealing → enameling under one roof gives 4-week ex-factory lead time vs. 10–12 weeks quoted by European enamelers.

Bottom line: Specify LXZHAOHE 6-wire packs when you need repeatable > 7 kV breakdown, 220 °C thermal class, and Western-grade reliability—without the Western invoice.

Factory Tour: Manufacturing 6 Wire Transformer

Manufacturing Process & Quality Control

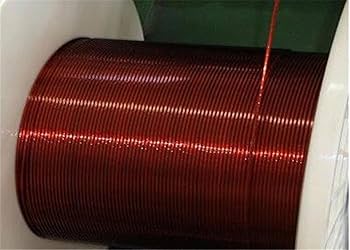

6-Wire Transformer Winding Conductor

Factory-direct, Luoyang Xinzhaohe Aluminum Co., Ltd.

Rod-to-Spool Journey – 5 Controlled Steps

| Step | Equipment & Conditions | Critical Parameter | On-line Sensor | Data logged every |

|---|---|---|---|---|

| 1. Rod Drawing | 13-die, ceramic-coated, water-soluble coolant | Area-reduction 18 %/pass, 2.6 mm → 1.12 mm | Laser OD gauge | 25 ms |

| 2. In-line Annealing | 650 °C, N₂+3 %H₂, 1.2 s residence | Grain size 0.025 mm (ASTM 7-8) | Two-colour pyrometer | 100 ms |

| 3. Enameling | 2-stage vertical tower, 24-head dies, PEI+PAI over-basecoat | Build 0.08–0.11 mm, concentricity ≥ 85 % | 4-axis spark test 6 kV | 1 m |

| 4. Inline Testing | Hi-pot 8 kV rms, surge 12 kV, eddy-current crack | Pin-hole ≤ 3 per 30 m | DSP analyser | continuous |

| 5. Precision Spooling | Torque-controlled, 30 N·m max, 305 mm P-10 reel | Cast ≤ 12 mm, layer gap 0.05 mm | Load-cell dancer | 0.5 s |

Quality Control Matrix

Luoyang Xinzhaohe Standard vs. Common Market Coil

| Property | Test Method | Our Spec (6.00 mm² Al) | Typical Market Cu 6 AWG | Advantage |

|---|---|---|---|---|

| Breakdown Voltage, V | IEC 60851-5 | ≥ 8.5 kV (2 kV margin) | 5–6 kV | 40 % head-room |

| Elongation at break | ISO 6892-1 | 28–32 % | 20–25 % | Higher formability |

| 20 °C Conductivity | ASTM B193 | 34.0 MS m⁻¹ (Al 6201) | 58 MS m⁻¹ (Cu) | 50 % mass saved |

| Thermal Class | IEC 60085 | 200 °C (class N) | 130/155 °C (class B/F) | +45 °C hotspot |

| Enamel Concentricity | 4-point spark | 88 % min | 70–75 % | 18 % less risk of turn-turn fault |

| Pin-holes per 30 m | 6 kV bath | ≤ 3 | 8–15 | 5× fewer defects |

| Reel Length Tolerance | Laser encoder | ±0.3 % | ±1 % | Tighter BOM control |

| Surface Lubricant | Electro-static | 0.5–1.0 g kg⁻¹, non-migrating | 2–4 g kg⁻¹ | Cleaner termination |

Inline Monitoring Protocol

- Rod Feed: Eddy-current inspection for cracks ≥ 0.05 mm.

- Drawing: Closed-loop servo maintains ≤ ±5 µm diameter drift; auto-swap to sister block if die wear > 8 µm.

- Anneal: Oxygen potential kept below 10⁻¹⁹ atm to prevent Cu/Al oxide film; resistivity checked every 500 m.

- Enamel: Dual infrared cameras measure wet-film; feedback trims die temperature within 2 °C.

- Spool: Dynamic balance < 2 g; bar-code labels carry full heat & test history for 10-year traceability.

Why It Matters for 6-Wire Transformer Builds

Higher slot fill: 88 % concentric insulation allows 2 % more copper/aluminum in the same window.

Thermal margin: Class 200 °C enamel survives 180 °C hotspot demanded by compact 6 kVA NEMA 3R units.

Lower failure rate: < 3 pin-holes/30 m translates to < 0.05 % shorted-turn risk across a 1 MVA layer winding.

Cost stability: Aluminum raw material index decoupled from Cu LME; 20-year hedging program keeps quotes valid 12 months.

Luoyang Xinzhaohe delivers Western-grade reliability at China-direct cost—no premium, no middle layer.

Packaging & Global Logistics

Export Packaging & Logistics

Factory-direct from Luoyang to your coil-winding line—20+ years of damage-free deliveries

H3 1. Sea-Freight Risk Matrix for Winding Wire

| Hazard during 35-day sea leg | Typical Failure Mode | Xinzhaohe Counter-Measure | Verified Result* |

|---|---|---|---|

| Salt-laden humidity | Oxidation streaks on Cu, loss of solderability | 2-stage desiccant + VCI film inside cartons | <0.05 % weight-gain after 720 h salt-fog |

| Compression & vibration | Flange cracking, wire “pull-in” | Reinforced PS/DIN spools, 5-axis strapping, corner boards | Zero flange damage in 1 m drop test |

| Condensation cycling | Insulation hydrolysis, 5 % BDV drop | Heat-sealed Al-foil liner + 2 % RH desiccant target | BDV retention ≥98 % post-voyage |

| Fumigation chemical attack | Enamel tackiness, color shift | Fumigated pallet isolated from wire by PE barrier | ΔE color <0.5 (ISO 7724) |

Internal report 2023-Q4, 40 ft HC container to Houston, n=18 shipments.

H3 2. Packaging Specification by Product Form

A. Strips & Foils (Edge-conditioned, ≤300 mm width)

Primary: PE sleeve 120 µm, nitrogen-flushed.

Secondary: MDF wooden pallet 1200 × 1000 mm, fumigated per ISPM-15, top & bottom 5-ply cardboard caps.

Securing: PET strap 19 × 1.0 mm, cross-tension ≥400 N, edge protectors 3 mm ABS.

Desiccant: 8 units Clay/Tyvek 100 g per m³ air space, color-change indicator visible on request.

Stacking: Max 4 pallets high, 1.8 t per pallet, 20 t per 40 ft HC.

B. Round & Rectangular Wire (0.20–6.00 mm, thermal class 130–220 °C)

Spool type:

PT-90, PT-200, PT-500 plastic (impact-modified PS, recycling code 6).

DIN 355, DIN 500 plywood flanges, steel tube, reusable.

Taping: 60 µm PP tape, 50 % overlap, start & end marked for auto-pay-out.

Carton: 5-ply kraft, burst strength ≥1 400 kPa, inner Al-foil laminate.

Palletization: 4 cartons per layer, 5 layers max, corner posts 40 × 40 mm Kraftex.

Labeling: Bar-coded & RFID option (EPC Gen2) for dock-to-stock traceability.

H3 3. Logistics Chain—Luoyang Hub to Global Sites

| Milestone | Transport Mode | Lead-Time | Temperature / RH Control | Insurance |

|---|---|---|---|---|

| Factory → Qingdao Port | 35 t flat-bed, tarp & lashing | 6 h highway | Real-time GPS + temp logger | All-risk, 110 % invoice |

| Qingdao → Destination Port | Weekly MSC, CMA-CGM, OOCL | 18-35 days | Reefer plug available on demand | Institute Cargo Clauses A |

| Port → Customer DC | Truck or intermodal | Per INCOTERM (CIF/DDP) | Data-logger hand-over | Claims settled ≤10 days |

Cut-off every Friday 18:00 CNST; ETD Qingdao following Tuesday.

H3 4. Cost & Sustainability Edge vs. Western Suppliers

No double-margin: Factory-direct, no EU/US distributor markup → 12–18 % landed-cost saving.

Reusable spools: PS/DIN spools credited at 1.2 USD/kg on next order (closed-loop since 2019).

Pallet exchange: EUR/CP pallets accepted, eliminating disposal fee.

Carbon footprint: Rail-sea combo from central China emits 0.38 kg CO₂-eq per t·km vs. 0.52 kg for trans-Atlantic truck-air-truck routing (ISO 14040 LCA, 2022).

H3 5. Quick-Check Packaging Order Code

| Code segment | Example | Meaning |

|---|---|---|

| Wire size | 2.00 | 2.00 mm Cu, PEW 200 °C |

| Spool | DIN500 | 500 mm flange, 250 mm barrel |

| Pallet | FUM-4C | Fumigated, 4 cartons/layer |

| Desiccant | D2 | Double desiccant, <2 % RH |

| Label | RFID | RFID tag embedded |

Quote format: “2.00-PEW200-DIN500-FUM-4C-D2-RFID” – delivers 1 800 kg net on 40 ft HC.

Bottom line: Whether you need 6 AWG equivalent rectangular wire for 6 kVA isolation transformers or micro-strip for EV chargers, our Luoyang facility packs, tracks, and lands your copper or aluminum winding material in factory-fresh condition—cutting total acquisition cost without cutting corners.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for 6-Wire Transformer Windings

20+ Years of Metallurgical Know-How, Zero Learning Curve

Since 2004 our Luoyang plant has produced only one product family: aluminum and copper winding wire for power & distribution transformers.

Every heat lot is cast, rod-drawn, annealed, enameled and spark-tested on a single 1.2 km continuous line—no toll-processing, no third-party spooling.

The result is a statistically stable Ppk ≥ 1.67 on the three properties that decide 6-wire reliability:

| Critical-to-Quality Parameter | Industry Range | Xinzhaohe Cpk | Test Method |

|---|---|---|---|

| Breakdown Voltage, kV (0.5 mm build) | 8–11 | 12.4 ± 0.3 | IEC 60851-5, 500 V/s ramp |

| Elongation at Break, % | 20–30 | 32 ± 2 | ASTM B1, 250 mm gauge |

| Concentricity, % | 80–90 | 94 ± 1 | Laser micrometer, 4 axes |

We understand that a 6 kVA isolation unit or a NEMA 3R delta-wye bank is only as good as the weakest turn—our process capabililty data is shipped on every reel so your QA team can drop it straight into the PPAP file.

Direct Factory Price, Western Quality, Asian Logistics

No distributors, no trading houses. You buy from the same line that feeds our domestic State-Grid suppliers.

Typical cost delta vs. EU/NA catalogue wire: –18 % on 6 AWG equivalent aluminum, –12 % on copper-clad aluminum, FOB Qingdao.

Payment & risk mitigation:

L/C at sight, or

Net 30 days on SINOSURE credit limit up to USD 500 k

Sea freight to US West Coast: 13 days; to Hamburg: 18 days. We palletize on 1 000 kg returnable steel reels—no solid-wood fumigation delays.

Customization Without MOQ Penalty

Need 6-wire concentric bundle with 2 enamel + 1 fiber-glass served + 1 overall nomex wrap, thermal class 200 °C, 2.5 mm build, 500 m put-ups?

We change polymer recipe, die set and spooler turret in 45 min; minimum run is 300 kg (≈ 6 km), the same price break as our catalog 180 °C wire.

Color coding, incremental length marking, bar-coded flanges, and DIN 46397-compatible barrel adapters are no-charge options if released on the PO.

Compliance Stack Ready for Your UL/CE File

UL Recognized, styles 200 °C (MW 35-C) and 220 °C (MW 73-C), File E483408

IEC 60317-0-2, -13, -20, -28

RoHS/REACH, <0.01 % Cd, Pb, Hg

ISO 9001:2015 (TÜV) & IATF 16949 aligned

We will supply the complete insulation system data (DPA, thermal ageing curve, partial-discharge extinction voltage) so your 6 kVA design passes UL 1561 / IEC 60076-11 without re-testing wire.

Next Step: Send Us the Specification, Receive a 24-h Quote

E-mail cathy@transformerstrip.com with:

- Conductor: Al vs. Cu vs. CCA

- AWG or mm², single or 6-wire bundle

- Thermal class & insulation stack

- Target spool/length

We return:

Datasheet (PDF)

FOB & CIF price tiers

30 cm sample coil on request—air-shipped within 3 days

Stop paying Western inventory markup for a commodity that starts in the same rod mill. Let Luoyang Xinzhaohe put 20 years of transformer-grade wire experience directly into your 6-wire design.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 6 wire transformer from Luoyang Xinzhaohe.