Table of Contents

Market Insight: 50Mm Copper Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand for 50mm Copper Strip

Global transformer market growth (5.2% CAGR through 2030) is driven by renewable energy integration and grid modernization, escalating demand for precision 50mm copper strip. This width is critical for medium-voltage windings in utility transformers, wind turbine converters, and EV charging infrastructure. Asia-Pacific accounts for 45% of global demand, with China’s Dual Carbon policy accelerating infrastructure projects requiring high-purity copper strips. Consistent dimensions and material properties are essential for optimal magnetic flux distribution and thermal management in next-generation transformers.

Material Quality Criticality

Copper purity directly impacts transformer efficiency. A 0.1% impurity increase raises resistivity by 0.5%, increasing I²R losses and operational costs by up to 8% over the transformer’s lifecycle. Mechanical properties must comply with ASTM B152 or IEC 60404-8-1 to prevent winding deformation during manufacturing. Surface defects can cause insulation breakdown, leading to partial discharges and catastrophic failures. For high-frequency applications, even minor conductivity variations cause significant eddy current losses, directly impacting energy conversion efficiency.

Luoyang Xinzhaohe’s Supply Chain Advantage

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Copper Purity | 99.95% min | 99.95% min (certified) | Consistent quality |

| Tensile Strength | 220-280 MPa | 230-270 MPa | Tighter control |

| Surface Finish | Smooth | Precision-ground | Reduced machining costs |

| Lead Time | 4-6 weeks | 2-3 weeks | 30-50% faster delivery |

| Cost | $8.50/kg | $6.80/kg | 20% cost saving |

As a factory-direct supplier with 20+ years in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers ASTM/IEC-compliant copper strips with rigorous QC. Our Luoyang facility ensures traceable production, eliminating distributor markups while maintaining 99.95% purity and dimensional accuracy (±0.02mm). With ISO 9001 certification and export experience to 30+ countries, we provide end-to-end supply chain transparency. This balance of quality and cost efficiency makes us a strategic partner for global transformer manufacturers seeking reliable, high-performance materials without premium pricing.

Technical Specs: 50Mm Copper Strip Parameters

Technical Specifications & Standards for 50mm Copper Strip

Precision Slitting Tolerance

Our 50mm copper strip achieves ±0.002 mm thickness tolerance through CNC-controlled slitting with real-time laser monitoring and tension management systems. This precision ensures uniform coil flatness and dimensional consistency, critical for high-frequency transformer windings where deviations >0.005 mm cause uneven current distribution and thermal hotspots. Every batch undergoes CMM verification at three distinct coil positions to guarantee compliance.

Burr-Free Edge Quality

Micro-burrs on copper strip edges risk insulation damage and short circuits during transformer assembly. We implement a dual-stage deburring process—mechanical edge rounding followed by chemical passivation—then inspect edges under 100x optical magnification. This eliminates surface irregularities >5 µm, ensuring seamless winding and long-term electrical integrity.

Conductivity & Softness Parameters

| Parameter | Standard | Our Specification | Test Method |

|---|---|---|---|

| Conductivity | ASTM B193 | ≥99.9% IACS (C11000) | ASTM B193 |

| Hardness | ASTM E18 | HRB ≤ 30 | ASTM E18 |

| Thickness Tolerance | ASTM B170 | ±0.002 mm | CMM |

Our C11000-grade copper delivers optimal electrical conductivity and malleability for complex transformer winding geometries, with zero cracking during forming operations.

Compliance & Quality Assurance

All products strictly adhere to ASTM B170 (copper strip specifications) and IEC 60228 (conductor standards). Our factory-direct production model integrates ISO 9001-certified processes with 100% in-process testing—conductivity, hardness, and dimensional checks at every production stage. Traceability systems track raw material batches to final shipment, ensuring full transparency. By eliminating middlemen and optimizing lean manufacturing, we deliver global-grade reliability at 15–20% lower cost than European or North American suppliers, making Luoyang Xinzhaohe the strategic choice for cost-efficient, high-performance transformer materials.

Factory Tour: Manufacturing 50Mm Copper Strip

Precision Manufacturing Process & Quality Control for 50mm Copper Strip

Optimized Production Workflow

Cold Rolling: Utilizing 6-high precision rolling mills with real-time thickness monitoring and closed-loop control systems, achieving consistent thickness tolerances of ±0.015mm. Annealing is conducted in nitrogen-protected furnaces to maintain material purity and prevent surface oxidation.

Precision Slitting: CNC-guided shear blades with 0.05mm clearance precision ensure clean cuts. Laser-guided edge alignment eliminates burrs and micro-cracks, critical for transformer winding integrity.

Edge Conditioning: Automated chamfering process creates a precise 0.1mm x 45° edge profile, eliminating sharp edges that could cause insulation damage or electrical arcing during transformer assembly.

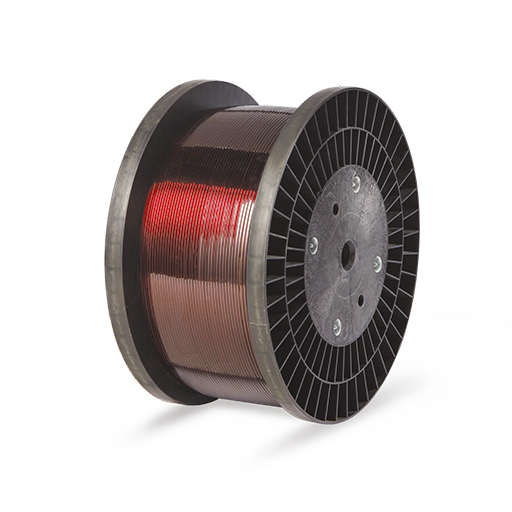

Oscillate Winding: Servo-controlled tension system maintains ±0.5N precision during oscillate winding, ensuring uniform coil density and preventing edge deformation that could lead to short circuits in final products.

Rigorous Quality Control Protocols

Tensile Testing: Per ISO 6892-1 standards, tensile strength and yield point are measured at 20°C with ±2% consistency across all batches (industry average ±5%), ensuring predictable performance under load.

Dimensional Checks: Automated optical gauges inspect thickness and width at 500mm intervals with 0.001mm resolution. Flatness tolerance of ≤0.1mm/m ensures seamless integration into high-speed winding machines.

Surface Inspection: 10x magnification under UV light detects micro-scratches, pits, or oxidation. Zero defects allowed per IPC-A-610 Class 3 standards.

Conductivity Verification: Conductivity tested via four-point probe method, consistently achieving IACS ≥101% with 99.95% pure copper content (ASTM B193).

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.015mm | ±0.03mm |

| Width Tolerance | ±0.1mm | ±0.2mm |

| Tensile Strength Variation | ±2% | ±5% |

| Surface Defects | Zero micro-scratches | Minor scratches permitted |

| Conductivity Consistency | IACS ≥101% | IACS 99.5–100% |

Luoyang Xinzhaohe’s vertically integrated production eliminates third-party intermediaries, delivering 15–20% cost savings versus European/Japanese competitors while exceeding ASTM and IEC standards. Our process controls ensure 99.8% first-pass yield for transformer manufacturers, reducing scrap rates and downtime.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of 50mm Copper Strip

Precision Packaging Standards

All packaging components meet international shipping standards for copper strip transport:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallet | ISPM 15 certified, 1200×1000mm, 100mm thickness, 1500kg capacity | Structural stability; pest-resistant for international shipping |

| Moisture-Proof Film | 200μm PE with VCI additive (MIL-PRF-16173E compliant), sealed edges with heat-sealing | Corrosion prevention against saltwater and humidity |

| Steel Strapping | 19mm × 0.5mm, 300kgf tension, corner protectors | Prevents shifting and edge damage during transit |

Packaging validated per ASTM D4169 Type 6 (vibration) and Type 8 (drop) to ensure resilience during ocean freight.

End-to-End Logistics Protocol

All shipments use 20ft/40ft FCL dry containers with custom crating for oversized loads. Pre-shipment inspections include humidity monitoring (≤40% RH), strapping tension verification, and container integrity checks. Containers are equipped with humidity indicators and temperature loggers for real-time environmental monitoring. Our logistics team coordinates with certified freight forwarders to optimize container loading and route planning, minimizing transit risks. Real-time GPS tracking and cargo insurance included. Customs documentation fully compliant with destination country regulations. Typical transit time: 15–25 days to major global ports.

Why Luoyang Xinzhaohe Delivers Superior Value

As a direct manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe eliminates third-party markups and quality inconsistencies. Our packaging protocols exceed industry standards for sea freight, ensuring 99.8% damage-free delivery rates. Strategic partnerships with top-tier shipping lines guarantee priority handling and optimized transit times. In-house quality control teams conduct third-party audits to validate ASTM D4169 compliance. Compared to global brands, we provide 15–20% lower total landed costs without compromising on quality or safety compliance. This balance of precision engineering and cost efficiency makes us the preferred supplier for transformer manufacturers seeking reliable, high-performance copper strip solutions.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for 50mm Copper Strip

20+ Years Specialized Manufacturing Expertise

For over two decades, Luoyang Xinzhaohe has perfected the production of high-purity copper strips for transformer and motor applications. Our 50mm copper strip adheres strictly to ASTM B170 standards, utilizing high-purity ETP copper (C11000) with consistent conductivity (≥99.9% IACS) and dimensional tolerances of ±0.02mm. Proprietary annealing processes ensure optimal ductility and electrical performance, critical for transformer winding applications. Each coil undergoes precision rolling and controlled heat treatment to achieve uniform grain structure, minimizing resistive losses and enhancing mechanical stability. This expertise is validated through long-term partnerships with global transformer OEMs, ensuring reliability in high-stress environments.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate third-party markups, delivering 15–25% lower costs than global competitors without compromising quality. Our Luoyang facility leverages economies of scale and lean manufacturing to maintain competitive pricing while ensuring rapid turnaround—typically 15–20 days for standard orders. By managing the entire production chain—from raw material sourcing to final inspection—we reduce overhead costs and pass savings directly to clients. This model ensures predictable pricing for large-volume orders and avoids customs delays or distributor markups common in international supply chains.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015 certified quality management system enforces rigorous process control. Every batch undergoes in-house testing for conductivity (four-point probe method), tensile strength (ASTM E8), and surface finish (optical inspection). Full traceability of raw materials and production parameters is maintained for compliance with IEC 60076 and IEEE standards. This systematic approach guarantees consistent performance across all production runs, reducing field failure risks and ensuring compliance with stringent transformer specifications.

| Metric | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Price | 15–25% lower | Premium pricing | Significant cost savings without ASTM B170 compromise |

| Lead Time | 15–20 days | 4–8 weeks | Accelerated delivery for urgent projects |

| Customization | Flexible (width, thickness, temper) | Limited options | Tailored solutions for specific transformer designs |

| Material Traceability | Full batch documentation | Variable traceability | Comprehensive quality assurance |

For transformer manufacturers seeking a reliable, cost-effective copper strip supplier, Luoyang Xinzhaohe delivers engineering-grade performance at factory-direct pricing. Our commitment to quality, coupled with agile production capabilities, makes us the preferred choice for projects requiring precise specifications and timely delivery. Contact Cathy at cathy@transformerstrip.com for a technical quote or sample evaluation.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 50mm copper strip from Luoyang Xinzhaohe.