Table of Contents

Market Insight: 42 Gauge Magnet Wire

Market Analysis: Industrial Demand for 42 Gauge Magnet Wire in Transformers

42 gauge magnet wire, defined by its nominal diameter of 0.063 mm (0.0025 inches), occupies a critical niche within the transformer winding wire market. This ultra-fine gauge is predominantly specified for high-frequency, high-efficiency transformers where extreme miniaturization and precise magnetic field control are non-negotiable design parameters. Primary industrial demand stems from advanced power electronics sectors including telecommunications infrastructure (particularly 5G base station power supplies and RF transformers), electric vehicle onboard chargers and DC-DC converters, medical imaging equipment (MRI gradient coils), aerospace avionics, and high-density server power supplies. The relentless drive toward smaller form factors, higher switching frequencies (often exceeding 500 kHz), and improved thermal management in these applications directly fuels the requirement for reliable 42 gauge wire. At this microscopic scale, even minor dimensional inconsistencies or insulation defects become magnified, directly impacting transformer performance, efficiency, and operational lifespan.

The significance of uncompromising quality in 42 gauge magnet wire cannot be overstated, presenting unique metallurgical and manufacturing challenges. Achieving consistent roundness and surface smoothness during the drawing process is exponentially more difficult at this diameter compared to larger gauges. Any surface imperfection, micro-crack, or dimensional variation exceeding tight tolerances (typically ±0.0025 mm) creates localized stress points during winding, significantly increasing the risk of insulation damage or wire breakage. This is particularly critical for aluminum alloy magnet wire, where optimizing tensile strength and elongation properties while maintaining high conductivity requires precise thermal and mechanical processing control. Insulation integrity is paramount; the enamel coating must be defect-free, uniformly applied at microscopic thicknesses (often 5-10 µm), and possess exceptional dielectric strength, thermal stability (rated for Class 180°C or higher), and adhesion to withstand the stresses of high-speed automated winding and subsequent varnish impregnation without pinholes or delamination. Contamination during production, even at trace levels, can lead to catastrophic insulation failure under operational voltage stress.

Failure to meet stringent quality standards for 42 gauge wire manifests in severe operational consequences. Insulation defects cause inter-turn shorts, leading to localized overheating, reduced efficiency, and premature transformer failure. Dimensional inconsistencies result in poor fill factors, increased winding resistance, and unpredictable inductance values, directly degrading power conversion efficiency and signal integrity. Wire breakage during high-speed automated winding halts production lines, causing significant yield loss and manufacturing delays. In safety-critical applications like medical or aerospace systems, such failures carry unacceptable risks. Consequently, procurement specifications must rigorously enforce compliance with international standards such as IEC 60317 and ASTM B 354, demanding comprehensive mill test reports covering conductor diameter, resistance, tensile strength, elongation, insulation thickness, dielectric withstand voltage, thermal shock resistance, and solderability. For aluminum-based 42 gauge wire, specific attention to oxide layer management and adhesion promotion during drawing is essential to ensure long-term reliability. Sourcing from suppliers with proven expertise in ultra-fine gauge production, robust in-process quality control, and deep metallurgical understanding is therefore not merely advantageous but fundamental to securing supply chain resilience and end-product performance in demanding transformer applications.

Technical Specs: 42 Gauge Magnet Wire

Technical Specifications for 42 Gauge Aluminum Magnet Wire

Luoyang Xinzhaoha Aluminum Co., Ltd. manufactures high-purity aluminum magnet wire designed for precision electromagnetic applications requiring consistent electrical performance, mechanical integrity, and thermal stability. The 42 AWG (American Wire Gauge) aluminum magnet wire is engineered for use in compact winding systems such as small transformers, inductors, sensors, and micro-motors where space constraints and weight reduction are critical. This technical specification outlines key performance parameters including insulation breakdown voltage, elongation, and thermal class, ensuring compliance with international standards and industrial reliability requirements.

The insulation system applied to 42 gauge aluminum magnet wire is optimized for dielectric strength and mechanical durability. The insulation breakdown voltage is measured under standardized test conditions (per IEC 60317 and GB/T 23312) using a 60 Hz AC voltage applied between the conductor and a grounded electrode in a water bath. For this gauge, the minimum breakdown voltage is specified at 2,800 VAC, with typical performance reaching up to 3,200 VAC depending on insulation type and thickness. This ensures robust protection against short circuits and dielectric failure in high-density winding configurations.

Elongation, a critical mechanical property, reflects the wire’s ability to withstand drawing and winding stresses without fracturing. For 42 AWG aluminum magnet wire, the elongation at break is guaranteed to be no less than 1.5% under tensile testing conditions (ASTM E8). This value is achieved through controlled annealing processes that balance ductility and tensile strength, enabling reliable high-speed winding operations without breakage or deformation.

Thermal performance is defined by the thermal class rating, which indicates the maximum continuous operating temperature the insulation can withstand without significant degradation. Our 42 gauge magnet wire is available in thermal classes ranging from 130°C to 220°C, with common variants including Class B (130°C), Class F (155°C), Class H (180°C), and high-temperature polyimide-coated versions rated up to 220°C. Each insulation system is tested for thermal endurance via the thermal aging method (IEC 60172), confirming a minimum life of 20,000 hours at rated temperature.

The following table summarizes key technical parameters for 42 AWG aluminum magnet wire:

| Parameter | Specification | Test Standard |

|---|---|---|

| Gauge (AWG) | 42 | ASTM B258 |

| Conductor Material | High-Purity Aluminum (≥99.99%) | GB/T 8031 |

| Conductor Diameter | 0.0635 ± 0.003 mm | IEC 60122 |

| Insulation Type | Polyurethane, Polyesterimide, Polyamide-imide | IEC 60317 |

| Breakdown Voltage (min) | 2,800 VAC | IEC 60317-00 |

| Elongation (min) | 1.5% | ASTM E8 |

| Thermal Class Options | 130°C (B), 155°C (F), 180°C (H), 220°C | IEC 60172 |

| Resistance per km (approx.) | 1,050 Ω/km | IEC 60028 |

| Winding Test (Pin Hole) | Pass (no defect after 10x diameter mandrel) | GB/T 23312.3 |

These specifications reflect Luoyang Xinzhaohe Aluminum Co., Ltd.’s commitment to precision manufacturing and quality assurance in the production of fine-gauge aluminum magnet wire for advanced electromagnetic applications.

Factory Tour: Manufacturing

Manufacturing Process for 42 Gauge Aluminum Magnet Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in the precision production of ultra-fine aluminum magnet wire, specifically 42 gauge (nominal diameter 0.063 mm). Our rigorously controlled manufacturing sequence ensures exceptional electrical performance, mechanical reliability, and dimensional consistency demanded by high-efficiency motor and transformer applications. The process begins with high-purity (99.99% min) electrolytic aluminum rod, subjected to multi-stage rod drawing under precise tension and lubrication control. Utilizing precision tungsten carbide and diamond dies within a closed-loop system, the rod undergoes incremental reduction to the exacting 42 gauge specification. Continuous laser micrometers monitor diameter in real-time, maintaining tolerances within ±0.002 mm, critical for achieving the required cross-sectional area and current density. Immediate post-drawing, the wire enters a continuous inert atmosphere annealing furnace. Precise temperature profiling (typically 300-400°C) within a nitrogen-hydrogen blend atmosphere eliminates work hardening induced during drawing, restoring optimal electrical conductivity (>61% IACS) and ductility while preventing surface oxidation. Strict atmosphere purity control and dwell time management are paramount to ensure uniform metallurgical recrystallization and consistent mechanical properties along the entire spool length.

Subsequently, the annealed wire proceeds to the enameling line, a critical phase for insulation integrity. Applying a single layer of high-temperature polyurethane-imide resin requires exceptional process stability. Our proprietary system precisely controls resin viscosity, application temperature, and curing oven profiles (multi-zone with precise ramp/soak times). The wire traverses the applicator die under regulated tension, ensuring a uniform, void-free coating with minimal thickness variation. Real-time helium leak testing monitors for microscopic pinholes, guaranteeing dielectric strength integrity before the wire enters the high-temperature curing ovens where the enamel polymerizes into a robust, flexible, thermally conductive insulation film rated for 200°C (class 200). Throughout enameling, inline capacitance and spark testing provide continuous dielectric validation.

Comprehensive inline testing is integrated at every stage to enforce stringent quality control. Final product verification employs automated systems measuring key parameters against our internal specifications, which exceed standard industry norms. The following table summarizes critical QC checkpoints and Xinzhaohe’s performance standards for 42 gauge wire:

| Parameter | Measurement Method | Xinzhaohe Standard Tolerance | Industry Typical Tolerance |

|---|---|---|---|

| Conductor Diameter | Laser Micrometer | 0.063 mm ± 0.0015 mm | 0.063 mm ± 0.0025 mm |

| DC Resistance | 4-Wire Kelvin Bridge | ±1.5% of nominal value | ±2.5% of nominal value |

| Breakdown Voltage | Spark Tester (5 kV DC) | Minimum 3500 V | Minimum 3000 V |

| Elongation | Tensile Tester | 15% – 25% | 12% – 28% |

This integrated approach, combining advanced process control, real-time monitoring, and rigorous final inspection against tightened tolerances, ensures every meter of our 42 gauge aluminum magnet wire meets the demanding requirements of modern electromagnetic component manufacturing, underpinned by our ISO 9001 certified quality management system.

Packaging & Logistics

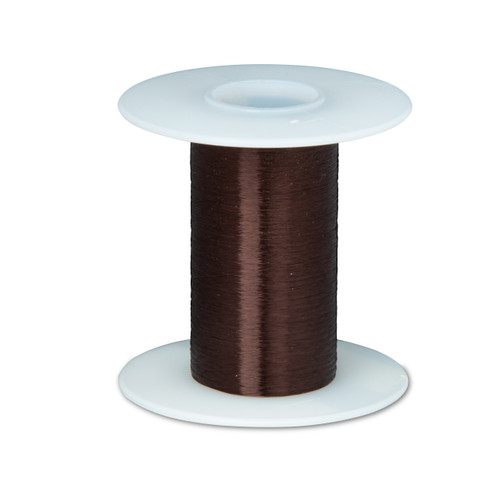

Export Packaging for 42 Gauge Magnet Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and international distribution of winding wire, we recognize that proper packaging is as critical as material quality in ensuring end-product performance. For ultra-fine gauge products such as 42 AWG magnet wire, where dimensional tolerances are measured in micrometers and surface integrity directly impacts electrical characteristics, export packaging must provide robust mechanical support and comprehensive environmental protection. Our export packaging system is engineered specifically to meet the rigorous demands of global sea freight, the primary logistics channel for bulk industrial wire shipments.

All 42 gauge magnet wire reels are mounted on high-strength composite or phenolic bobbins designed to resist deformation under load and prevent edge damage during handling. These loaded reels are then secured onto industrial-grade wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. The use of treated wood ensures compliance with international phytosanitary standards, preventing customs delays while providing structural stability during containerized transport. Each pallet is designed to optimize container loading efficiency, supporting unitized stacking without risk of collapse or shifting during ocean transit.

A critical component of our packaging protocol is the integration of multi-layer moisture-proof barrier film. Given that 42 AWG enamel-coated wire is highly sensitive to humidity—moisture absorption can compromise dielectric strength and promote oxidation of the aluminum or copper conductor—we encapsulate each palletized load in heat-sealed, metallized moisture barrier film with a water vapor transmission rate (WVTR) of less than 0.5 g/m²/day. This vapor barrier is further augmented with desiccant packs strategically placed within the sealed envelope to scavenge residual moisture and maintain an internal relative humidity below 40% throughout the shipping cycle.

Additionally, outer layers of UV-resistant polyethylene stretch film are applied to protect against condensation, salt spray, and mechanical abrasion during loading/unloading operations at port facilities. Pallets are labeled with standardized hazard and handling indicators, including “Fragile,” “This Way Up,” and “Protect from Moisture,” in accordance with IMDG and IATA guidelines, ensuring compatibility with multimodal logistics networks.

This integrated packaging system has been validated through accelerated climatic testing, simulating 60-day sea voyages across tropical and temperate zones. Results confirm sustained reel integrity and coating preservation under conditions of 95% RH and temperature cycling between 5°C and 55°C. By combining structural pallet design, moisture barrier technology, and regulatory compliance, Luoyang Xinzhaohe ensures that every shipment of 42 gauge magnet wire arrives at its destination in optimal condition, ready for high-precision winding operations in motors, transformers, and micro-electronic components.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision 42 Gauge Aluminum Magnet Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in aluminum magnet wire production to deliver exceptional 42 gauge (0.063 mm nominal diameter) solutions for demanding electromagnetic applications. Our factory is engineered specifically for the stringent requirements of ultra-fine gauge wire, where dimensional precision, surface integrity, and consistent electrical properties are non-negotiable. Partnering with us provides direct access to vertically integrated manufacturing capabilities focused exclusively on optimizing aluminum winding wire performance at the micron level.

Our core strength lies in advanced process control for aluminum metallurgy and drawing. We utilize high-purity aluminum rod (99.99% min) sourced under strict supplier qualification protocols, ensuring baseline conductivity and impurity control essential for 42 AWG performance. Proprietary multi-stage drawing sequences, employing diamond dies with sub-micron tolerances and precision tension control systems, achieve the required diameter consistency of ±0.5% across full production runs. Critical to 42 gauge integrity, our continuous annealing lines operate under precisely regulated inert atmospheres, eliminating oxidation and guaranteeing uniform ductility and tensile strength (typically 60-90 MPa) without surface degradation. This meticulous thermal processing is fundamental to preventing breakage during high-speed winding operations.

Quality assurance is embedded at every process stage through automated, real-time monitoring. 100% automated optical inspection verifies diameter, ovality, and surface defects at line speeds exceeding 800 m/min. Batch testing per IEC 60317 standards includes rigorous checks for elongation (min 15%), springback characteristics, solderability, and dielectric strength after enamel application. Our ISO 9001 and IATF 16949 certified systems ensure traceability from ingot to finished coil, with comprehensive material test reports (MTRs) documenting all critical parameters. This granular data transparency provides engineers with the confidence required for mission-critical components like miniature sensors, high-frequency transformers, and medical device windings.

Supply chain resilience is engineered into our operational model. Dedicated fine-wire production lines minimize cross-contamination risks and enable rapid changeovers for low-volume, high-mix orders typical of 42 gauge applications. Strategic raw material stockpiling and dual-sourcing for key consumables mitigate market volatility impacts. Our integrated facility manages the full value stream—from rod casting through drawing, annealing, and enameling—reducing lead times by 25% compared to fragmented supplier networks while maintaining rigorous process consistency. This control is vital for sustaining yield in applications where wire breakage during automated winding directly impacts production efficiency.

For engineering teams requiring reliable, high-performance 42 gauge aluminum magnet wire, Luoyang Xinzhaohe offers proven technical capability and supply chain stability. We understand the exacting demands of pushing aluminum conductivity to its limits in miniature electromagnetic components. Contact Cathy Zhang directly at cathy@transformerstrip.com to discuss your specific material specifications, production scheduling needs, or to request detailed technical documentation and sample reels for qualification. Initiate a technical dialogue to secure a precision wire supply partner committed to your application’s success.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 42 gauge magnet wire directly from China.