Table of Contents

Market Insight: 30 Awg Enameled Wire

Market Analysis: Winding Wire – Industrial Demand for 30 AWG Enameled Wire in Transformers

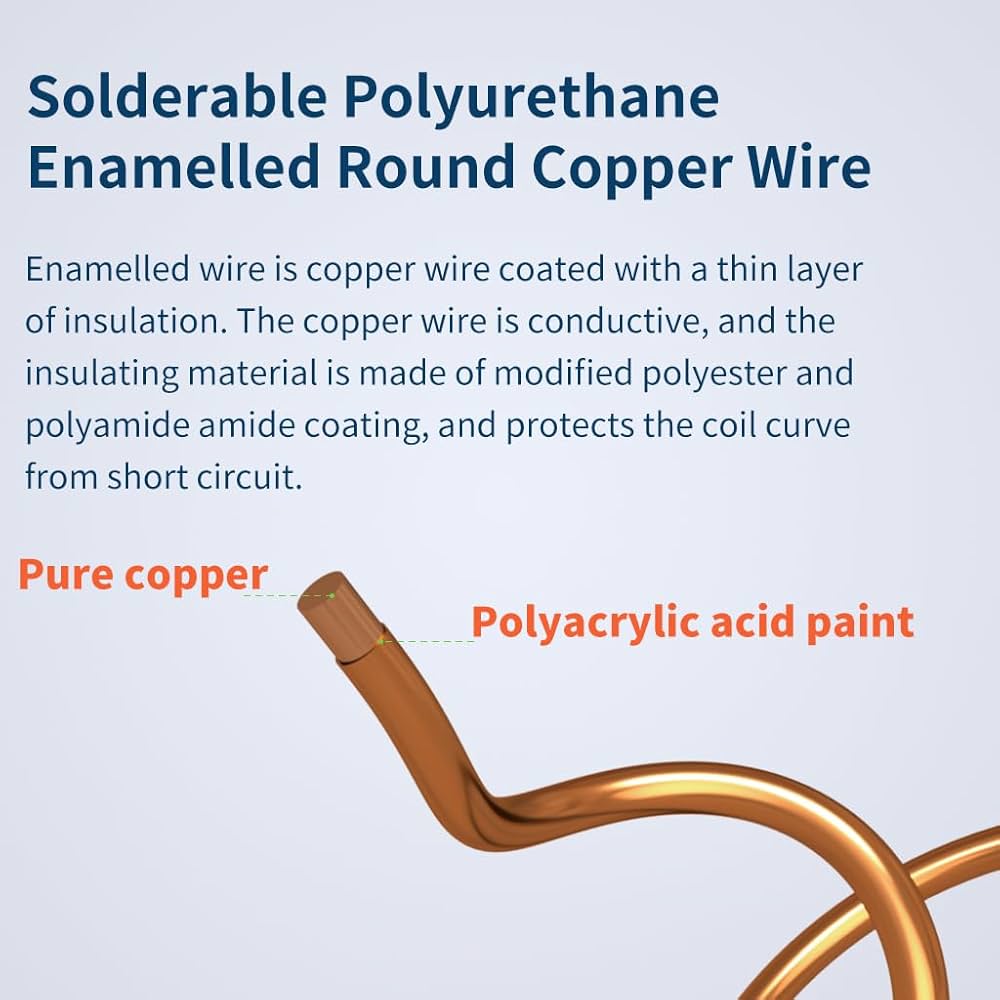

The global demand for 30 AWG enameled aluminum wire continues to grow, driven primarily by its widespread application in small to medium power transformers used in consumer electronics, industrial control systems, telecommunications equipment, and renewable energy inverters. As electronic devices trend toward miniaturization and higher energy efficiency, the role of fine-gauge magnet wire such as 30 AWG becomes increasingly critical in enabling compact, high-performance magnetic components. Transformers in switch-mode power supplies (SMPS), isolation amplifiers, and signal coupling circuits frequently utilize 30 AWG enameled wire due to its optimal balance between current-carrying capacity, winding density, and thermal performance.

In transformer design, the selection of magnet wire directly influences core saturation characteristics, copper losses, and overall thermal management. The 30 AWG size, with a nominal conductor diameter of 0.255 mm, allows for high turn counts within constrained bobbin spaces, which is essential for achieving precise voltage transformation ratios and impedance matching. However, the benefits of fine wire gauges are only fully realized when paired with consistent dimensional tolerances, uniform insulation thickness, and high dielectric strength. Variability in any of these parameters can lead to inter-turn shorts, reduced thermal endurance, or mechanical failure during automated winding processes.

Quality in 30 AWG enameled wire is not merely a performance differentiator—it is a reliability imperative. High-quality wire must exhibit excellent thermal class ratings (typically 130°C to 180°C for polyurethane or polyester-imide coatings), superior flexibility, and resistance to solvents and mechanical abrasion. During transformer manufacturing, the wire undergoes significant stress during high-speed winding, including tension, bending, and friction against bobbin edges and adjacent turns. Inferior insulation can crack or delaminate, compromising dielectric integrity and leading to premature field failures.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized production experience in aluminum-based winding wires, we emphasize strict process control in drawing, annealing, and coating application to ensure consistent quality in our 30 AWG enameled wire products. Our manufacturing protocols adhere to IEC 60317 and GB/T 23312 standards, with inline monitoring of diameter, elongation, and breakdown voltage. This precision ensures compatibility with automated winding equipment and enhances the long-term reliability of transformers in demanding environments.

The industrial market increasingly prioritizes supply chain stability and technical accountability. As transformer manufacturers serve sectors where failure is not an option—such as medical devices, automotive electronics, and industrial automation—the provenance and performance consistency of enameled wire are under greater scrutiny. Sourcing from experienced, standards-compliant suppliers mitigates risk and supports robust product design. In this context, the value of high-quality 30 AWG enameled aluminum wire extends beyond material cost, contributing directly to product longevity, efficiency, and compliance with international safety standards.

Technical Specs: 30 Awg Enameled Wire

Technical Specifications: 30 AWG Aluminum Enameled Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical expertise to deliver precision-engineered 30 AWG aluminum enameled wire for demanding electromagnetic applications. Our product adheres strictly to IEC 60317 and NEMA MW 1000 standards, with rigorous in-process controls ensuring consistency in conductor purity (Al 1350-O, 99.5% min), dimensional accuracy, and insulation integrity. The following parameters define our baseline specification for 30 AWG (0.255 mm nominal diameter) aluminum magnet wire, optimized for high-efficiency motors, transformers, and compact inductive components where weight reduction and thermal management are critical.

| Parameter | Value | Test Standard | Notes |

|---|---|---|---|

| Conductor Material | Electrolytic Tough Pitch Aluminum | ASTM B230 | 99.5% min purity, annealed temper |

| Nominal Conductor Diameter | 0.255 mm ± 0.003 mm | IEC 60028 | Measured per ASTM B298 |

| Insulation Type | Dual-layer Polyurethane/Polyesteramide | IEC 60317-13 | Solvent-resistant, solderable |

| Insulation Thickness | 0.035 mm ± 0.005 mm | ASTM D2305 | Uniform concentricity |

| Breakdown Voltage (AC) | ≥ 2500 V RMS | IEC 60851-5 | Tested at 1 kV/s, 25°C, 50 Hz |

| Elongation (Min) | 18% | ASTM D4565 | Measured at 50 mm gauge length |

| Thermal Class | 155°C (F) / 180°C (H) options | IEC 60172 | Thermal endurance per IEC 60172 |

| DC Resistance (20°C) | 0.212 Ω/m ± 3% | IEC 60028 | Calculated per ASTM B230 |

| Solderability | Pass (260°C, 3 sec) | IEC 60851-6 | No insulation delamination |

Insulation breakdown voltage is a non-negotiable parameter for reliability in high-voltage density windings. Our 30 AWG wire consistently achieves ≥ 2500 V AC breakdown, validated through 100% production-line testing per IEC 60851-5. This exceeds the IEC 60317-13 minimum of 1800 V, mitigating risks of inter-turn faults in miniaturized stators or high-frequency inductors. The dual-layer polyurethane/polyesteramide insulation provides superior dielectric strength while maintaining flexibility for tight-pitch winding.

Elongation directly impacts manufacturability and mechanical resilience. Xinzhaohe’s aluminum wire achieves 18–22% elongation (ASTM D4565), ensuring minimal conductor fracture during high-speed winding operations. This exceeds the industry minimum of 12% for 30 AWG, reducing scrap rates in automated coil winding and enhancing vibration resistance in end-use applications. Our proprietary annealing process optimizes grain structure to balance ductility with tensile strength (80–100 MPa).

Thermal class selection is application-dependent. We offer 155°C (Class F) and 180°C (Class H) variants, validated per IEC 60172 thermal endurance testing. Class F wire withstands 155°C continuous operation with a 20,000-hour life expectancy, while Class H sustains 180°C. Both grades utilize thermally stable polyesteramide topcoats to prevent thermal degradation at the conductor-insulation interface. For applications requiring 130°C (Class B) operation, our Class F wire provides a 25°C safety margin.

All specifications are empirically validated through Xinzhaohe’s ISO/IEC 17025-accredited laboratory. We emphasize that aluminum’s 61% IACS conductivity versus copper necessitates precise cross-sectional area control to meet resistance targets. Our process control parameters—conductor diameter tolerance ±1.2%, insulation concentricity ≤15%—ensure electrical performance parity with copper equivalents in weight-sensitive designs. Custom thermal classes (130–220°C) and insulation chemistries are available upon technical review.

Factory Tour: Manufacturing

Manufacturing Process of 30 AWG Enameled Aluminum Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of 30 AWG enameled aluminum winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of specialization in aluminum winding wire, our facility integrates advanced process controls and in-line quality verification to meet international standards including IEC 60317 and GB/T 23312.

The process begins with rod drawing, where high-purity aluminum rod (99.99% minimum conductivity) is subjected to a series of cold-drawing operations through precision tungsten carbide or diamond dies. The rod is progressively reduced from its initial diameter of 9.5 mm down to the target 30 AWG size, which corresponds to a finished conductor diameter of 0.255 mm. This stage is conducted under controlled tension and lubrication conditions to maintain surface smoothness and avoid microcracking. Each drawing pass is monitored for dimensional consistency using laser micrometers, ensuring tolerance adherence within ±0.003 mm.

Following drawing, the aluminum wire undergoes a continuous annealing process in a nitrogen-purged furnace. This softens the work-hardened structure induced during drawing, restoring optimal electrical conductivity and ductility. The annealing temperature is precisely regulated between 350°C and 400°C, with residence time calibrated to achieve a final temper of soft (O-temper) as required for winding applications. Oxygen levels within the furnace are maintained below 50 ppm to prevent surface oxidation, which could compromise enamel adhesion.

The annealed wire then proceeds to the enameling stage, where it is coated with one or more layers of thermosetting polymer insulation—typically polyesterimide (PEI), polyamide-imide (PAI), or a dual-layer system for enhanced thermal class performance (up to 200°C). The wire passes through a precision applicator die, followed by a multi-zone curing oven in which the enamel is polymerized under controlled temperature gradients. Film build is maintained at 0.020–0.030 mm per layer, with total diameter held within ±0.005 mm. Multiple passes may be employed for heavy build or multi-layer insulation systems.

Throughout the process, inline testing systems continuously monitor critical parameters. These include high-voltage dielectric testing (typically 2,500–3,000 V AC) to verify insulation integrity, diameter scanning via laser gauges, and tension control to prevent elongation. Final quality control includes off-line verification of elongation (minimum 15%), wrap test for adhesion, thermal shock resistance at 150°C, and resistance measurement to confirm conductivity (≥53% IACS for 30 AWG).

All process data is logged and traceable by production batch, ensuring full compliance with ISO 9001 quality management protocols. This integrated approach enables Luoyang Xinzhaohe to deliver consistent, high-performance 30 AWG enameled aluminum wire suitable for demanding applications in transformers, motors, and electronic components.

Packaging & Logistics

Export Packaging Specifications for 30 AWG Aluminum Enameled Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. implements rigorously engineered export packaging protocols specifically designed to preserve the critical surface integrity and electrical properties of 30 AWG aluminum enameled wire during global maritime transport. Our two-decade specialization in aluminum magnet wire production informs a system prioritizing structural resilience against mechanical stress and absolute barrier protection against atmospheric moisture ingress, the primary degradation vector for thin-gauge enameled conductors in ocean freight environments.

Wooden Pallet Specifications

All export shipments utilize heat-treated, ISPM 15 compliant wooden pallets constructed from kiln-dried hardwood. Standard dimensions are 1100mm x 1100mm x 150mm, engineered to support static loads exceeding 1500 kg per pallet. Pallets feature reinforced stringers and deck boards secured with galvanized steel钉, preventing deformation under container stacking pressures. Wire spools (typically 5kg or 10kg reels) are vertically stacked in stable, interlocked configurations, secured to the pallet base via steel strapping rated for 500 kg tensile strength. This configuration eliminates inter-spool movement during vessel roll, pitch, and heavy weather conditions, preventing reel damage and wire surface abrasion.

Moisture-Proof Barrier System

The core defense against hygroscopic degradation and electrochemical corrosion employs a multi-layer moisture barrier. Primary reels are first individually sealed within 0.15mm thick, metallized polyethylene vapor corrosion inhibitor (VCI) film. This inner wrap actively suppresses oxidation at the aluminum-enameled surface. Sealed reels are then palletized and enveloped in a secondary, hermetically sealed layer of 0.20mm co-extruded moisture barrier film (MBF), achieving a water vapor transmission rate (WVTR) below 0.5 g/m²/24hr at 38°C and 90% RH. Critical to performance is the inclusion of calibrated desiccant units (minimum 100g silica gel per m³ pallet volume) within the sealed MBF chamber, actively scavenging residual moisture and maintaining internal relative humidity below 40% throughout typical 30-60 day ocean voyages. All film seams are thermally welded, not taped, ensuring continuous barrier integrity.

Sea Freight Integrity Assurance

Ocean transport subjects cargo to extreme humidity cycles (20% to 95% RH), temperature fluctuations, and potential salt-laden air intrusion within ISO containers. Standard plastic stretch wrap provides insufficient protection; our dual-film VCI/MBF system is validated per ASTM E1749 to maintain reel core moisture content below 0.1% during simulated transoceanic conditions. This prevents enamel blistering, inter-turn short circuits, and aluminum substrate pitting – failures frequently traced to inadequate export packaging. Pallets are further secured within containers using dunnage and lashing points compliant with CTU Code standards, minimizing shift-induced impact damage. Each shipment includes a humidity indicator card within the MBF chamber, providing visual verification of environmental control upon client receipt.

This integrated packaging methodology, refined through 20+ years of global aluminum wire shipments, directly mitigates the dominant failure modes encountered in maritime logistics. It ensures the 30 AWG product arrives with pristine enamel insulation, consistent dimensional tolerances, and uncompromised electrical performance, eliminating costly field rejections and downstream production delays for our international partners. Compliance with IEC 60317-0-7 environmental testing protocols underpins our packaging validation process.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd – Your Trusted Source for High-Performance 30 AWG Enameled Wire

With over two decades of specialized expertise in the production of winding wires, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a leading manufacturer in the electromagnetic wire industry. Our dedication to material science, process optimization, and consistent quality control has positioned us as a preferred supplier for global OEMs, transformer manufacturers, and electronics integrators requiring precision-engineered 30 AWG enameled aluminum and copper wire. As demand for compact, energy-efficient electrical components grows, our 30 AWG enameled wire solutions deliver the reliability, thermal performance, and electrical integrity essential for advanced winding applications.

Our manufacturing facility integrates fully automated drawing, annealing, and enameling lines, ensuring precise dimensional control and uniform insulation build. For 30 AWG wire, this translates to tight tolerances in conductor diameter (0.255 mm ±0.005 mm) and consistent dielectric strength exceeding 3,000 V AC, meeting or surpassing IEC 60317 and GB/T 6109 standards. We utilize high-purity aluminum (99.99% Al) and electrolytic tough pitch copper (ETP, Cu ≥ 99.90%), sourced through audited supply chains, to ensure optimal conductivity and mechanical performance. Each batch undergoes rigorous in-process and final inspection, including elongation, springback, thermal shock, and scrape resistance testing, to guarantee compliance with application-specific requirements.

Luoyang Xinzhaohe operates a 28,000 m² production complex equipped with advanced enamel coating systems capable of applying single, double, or triple layers of polyurethane (PU), polyester (PE), or polyester-imide (PEI) insulation. For 30 AWG applications, this flexibility allows customization based on thermal class needs—ranging from 130°C (Class B) to 200°C (Class H)—enabling performance in demanding environments such as switch-mode power supplies, small transformers, inductors, and automotive sensors. Our vertical integration model, from rod to finished coil, ensures full traceability and reduces lead times, providing clients with stable supply and reduced procurement risk.

Quality assurance is embedded in every stage of production. Our ISO 9001:2015-certified quality management system is supported by state-of-the-art laboratories equipped for chemical analysis, thermal aging, and electrical performance validation. Third-party certifications from SGS and TÜV confirm compliance with RoHS and REACH directives, ensuring global market access.

For sourcing managers and engineering teams seeking a technically capable, responsive, and scalable partner for 30 AWG enameled wire, Luoyang Xinzhaohe offers proven performance, competitive pricing, and long-term supply security. We support custom spooling configurations, private labeling, and technical collaboration for new product introduction.

Contact us today to discuss your specifications and receive sample reels for evaluation.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 30 awg enameled wire directly from China.