Table of Contents

Market Insight: 3 Wire Transformer

Market Analysis: Winding Wire Demand in 3 Wire Transformers

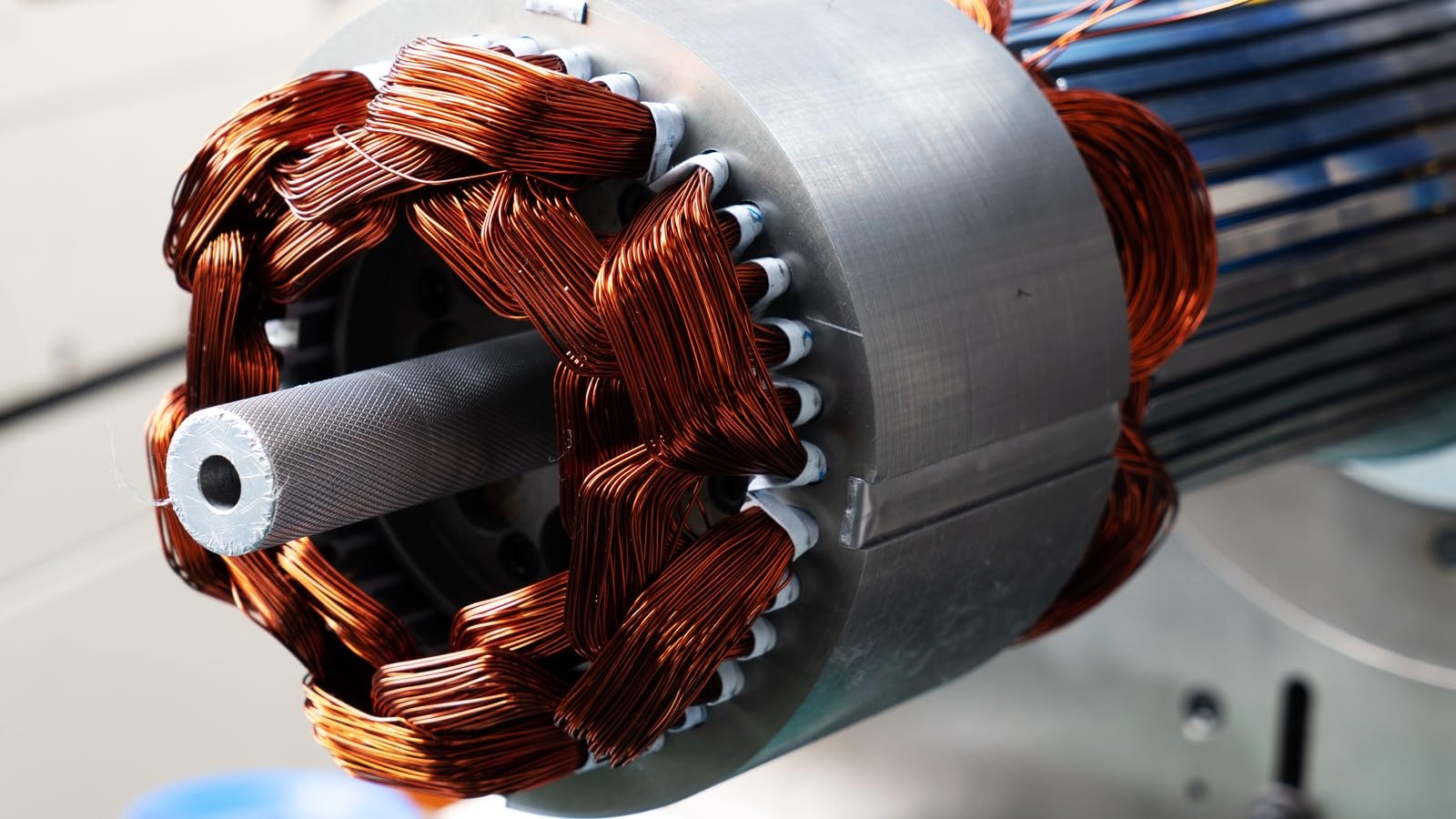

The industrial demand for winding wire in three-wire transformers has grown significantly due to the increasing complexity and efficiency requirements of modern power distribution systems. A three-wire transformer, commonly used in single-phase and three-phase configurations, facilitates balanced load distribution and improved voltage regulation across residential, commercial, and industrial applications. These transformers rely heavily on high-performance winding wire to maintain operational integrity, efficiency, and longevity. As a result, the demand for precision-engineered aluminum and copper winding conductors has intensified, particularly in sectors requiring reliable medium- and low-voltage transformation.

Three-wire transformers are integral to utility distribution networks, renewable energy integration systems, and industrial motor drives. Their design necessitates multiple windings—typically primary and dual secondary configurations—that allow for split-phase output or dual-voltage supply. This architectural complexity increases the total length and precision requirements of winding wire used. Consequently, manufacturers prioritize materials with consistent dimensional tolerances, high electrical conductivity, and superior thermal performance. Any deviation in wire quality directly impacts transformer efficiency, leading to increased no-load and load losses, overheating, and premature failure.

Quality in winding wire is not merely a performance differentiator—it is a critical reliability factor. Substandard wire with impurities, inconsistent annealing, or poor surface finish introduces points of high resistance and potential insulation breakdown. In aluminum winding wire, which is increasingly favored for its lightweight and cost-effective properties, achieving high purity (minimum 99.7% Al) and uniform mechanical properties is essential to match the performance of copper in many applications. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical expertise, we produce aluminum winding wire to IEC 60122 and ASTM B354 standards, ensuring compatibility with rigorous transformer manufacturing protocols.

Thermal stability and resistance to creep under continuous load are additional factors where material quality directly influences transformer lifespan. Poorly processed aluminum wire may deform over time, leading to winding deformation and short circuits. High-quality wire, properly annealed and surface-treated, maintains structural integrity even under thermal cycling. Furthermore, consistent ovality and diameter control ensure tight, uniform winding layers, minimizing inter-turn stresses and optimizing magnetic coupling.

The global shift toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes) has elevated the technical specifications demanded of winding materials. Utilities and OEMs now require full traceability, batch testing reports, and compliance with environmental regulations such as RoHS and REACH. This trend reinforces the need for reliable, high-purity winding wire from trusted suppliers.

In summary, the industrial demand for three-wire transformers drives a parallel demand for technically superior winding wire. Performance, safety, and regulatory compliance all hinge on material quality. As transformer designs evolve to meet higher efficiency and reliability benchmarks, the role of precision-manufactured aluminum winding wire becomes increasingly pivotal in sustaining grid stability and industrial productivity.

Technical Specs: 3 Wire Transformer

Technical Specifications for Aluminum Winding Wire in 3-Wire Transformers

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and supply chain expertise to deliver aluminum magnet wire engineered specifically for high-reliability 3-wire transformer applications. Our conductors address the unique thermal, electrical, and mechanical demands of multi-winding configurations where phase balancing and compact design are critical. Aluminum’s lower density and cost-efficiency versus copper necessitate precise control over material properties to ensure equivalent performance in insulation integrity, thermal stability, and winding integrity. The following parameters define our stringent quality benchmarks, aligned with IEC 60317 and EN 60085 standards.

| Parameter | Specification Range | Test Standard | Industrial Significance |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 3.5 kV (rms) | IEC 60851-5 | Ensures dielectric strength for phase-to-phase and phase-to-core isolation in compact 3-wire layouts; mitigates partial discharge risk under transient overvoltages. |

| Elongation (Min) | 1.0% – 3.0% | IEC 60851-4 | Optimized for aluminum’s metallurgical behavior; values <1.0% risk brittle fracture during winding, while >3.0% compromises dimensional stability under thermal cycling. |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 | Continuous operation rating; 180°C (H) and 200°C (R) classes standard for high-efficiency designs. Aluminum’s lower thermal conductivity versus copper demands tighter thermal class control to prevent hotspot degradation. |

| Conductor Resistivity (20°C) | ≤ 0.028264 Ω·mm²/m | IEC 60889 | Meets IACS 61% minimum; critical for calculating equivalent cross-section vs. copper (56% larger area required for same DC resistance). |

| Adhesion to Conductor | Class 1 (No flaking) | IEC 60851-3 | Prevents insulation delamination during high-tension winding and thermal expansion cycles in multi-layer 3-wire assemblies. |

Insulation breakdown voltage is rigorously validated at 1.5x the rated operating voltage to account for voltage spikes inherent in 3-wire systems where neutral-point transients occur. Our dual-layer polyurethane/polyamide-imide (PU/PAI) insulation system achieves consistent >4.0 kV performance, exceeding IEC minimums to accommodate manufacturing tolerances in tight coil geometries. Elongation is calibrated to aluminum’s recrystallization kinetics; values are maintained through proprietary annealing profiles that balance ductility for winding with post-coil rigidity to resist vibration-induced abrasion.

Thermal class selection directly impacts transformer lifespan per the Arrhenius model. For 3-wire units operating at elevated ambient temperatures (e.g., 70°C+), we recommend Class 180°C (H) or higher to limit insulation aging. Aluminum’s coefficient of thermal expansion (23.1 µm/m·°C) is 35% higher than copper, necessitating precise thermal class matching to prevent insulation cracking during thermal cycling. Our wires undergo 1,000-hour thermal endurance testing per IEC 60172, with life expectancy extrapolated to 20,000+ hours at rated temperature.

Conductor purity (99.99% Al) and grain structure control ensure stable resistivity, while surface oxide management during drawing guarantees optimal enamel adhesion. This holistic approach to aluminum wire metallurgy enables 3-wire transformers to achieve IEC 60076-1 efficiency class I2 with minimized no-load losses. Xinzhaohe’s in-line process monitoring and traceability from billet to spool provide documented compliance for mission-critical power distribution and industrial automation applications.

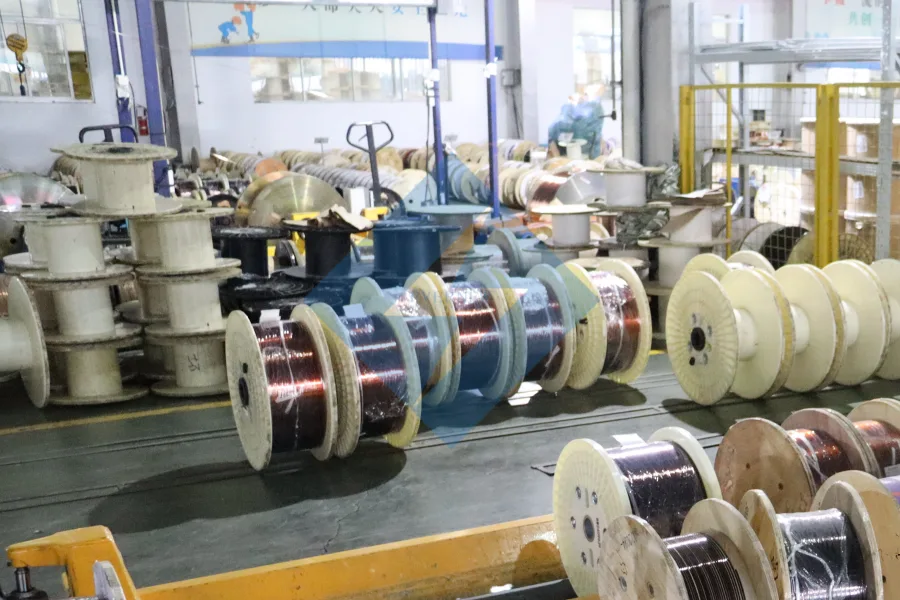

Factory Tour: Manufacturing

Manufacturing Process of 3 Wire Transformer Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance winding wire for 3 wire transformers at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical reliability, and long-term thermal stability. With over two decades of metallurgical and industrial process expertise, our facility integrates advanced wire processing technologies with rigorous quality control protocols to meet international standards for transformer-grade conductors.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher) are fed into a series of drawing dies to reduce diameter to the specified gauge. This cold working process is conducted under precise tension control and lubrication conditions to maintain dimensional accuracy and surface smoothness. The drawing line is equipped with real-time diameter monitoring via laser gauges, ensuring consistency within ±0.01 mm tolerance. Each rod batch is traceable to its certified source, and mechanical property sampling is conducted to verify tensile strength and elongation.

Following drawing, the wire undergoes a continuous annealing process to restore ductility lost during cold drawing. The annealing furnace operates under a controlled nitrogen atmosphere to prevent oxidation, with temperature profiles calibrated between 450°C and 550°C depending on the alloy and final temper requirements. The residence time in the furnace is optimized to achieve a fully recrystallized microstructure, resulting in a soft temper (O-temper) suitable for tight coiling and winding operations. Post-annealing, the wire is cooled under inert conditions to avoid thermal shock and surface degradation.

The next critical stage is enameling, where the annealed aluminum conductor is coated with a multi-layer polymer insulation system. For 3 wire transformer applications, a dual-layer or triple-layer enamel system is typically applied, consisting of a base layer of polyurethane or polyesterimide for bondability and a topcoat of polyamide-imide for thermal endurance and abrasion resistance. The enameling oven train operates at temperatures exceeding 500°C with precise dwell time control to ensure complete solvent evaporation and cross-linking. Coating thickness is maintained within ±2 μm through closed-loop feedback from在线 capacitance sensors.

Inline testing is integrated throughout the production line to ensure defect-free output. After enameling, every meter of wire undergoes high-voltage spark testing at 3 kV to detect pinholes or insulation breaches. Additional inline checks include continuous diameter profiling, wrap testing for adhesion, and thermal shock resistance verification via rapid cooling from 150°C to room temperature. Final samples from each spool undergo laboratory evaluation for dielectric strength, flexibility, and thermal class compliance (typically rated up to Class 200).

All process parameters are logged in our manufacturing execution system (MES), enabling full traceability from rod to finished coil. This systematic approach ensures that every batch of winding wire meets the stringent demands of 3 wire transformer applications in industrial and power electronics environments.

Packaging & Logistics

Export Packaging Protocol for Aluminum Winding Wire: Ensuring Sea Freight Integrity

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard aluminum winding wire destined for three-phase transformer manufacturing against the extreme environmental hazards inherent in global maritime transport. With over two decades of metallurgical and supply chain expertise, our system prioritizes absolute coil integrity from factory floor to final assembly line, directly mitigating corrosion risks and mechanical damage that compromise wire performance and transformer reliability. This is non-negotiable for high-purity aluminum conductors where surface oxidation or dimensional deformation renders material unusable.

All export shipments utilize standardized kiln-dried hardwood pallets constructed to ISO 1160 specifications. These pallets feature a minimum load-bearing capacity of 2500 kg, exceeding standard ocean freight requirements, and are certified under ISPM 15 for international phytosanitary compliance. Critical structural elements include reinforced stringers and deck boards engineered to prevent coil slippage or pallet flexing during vessel motion. Each pallet undergoes pre-shipment moisture content verification, ensuring wood equilibrium moisture content remains below 20% to eliminate internal vapor sources. Coil placement on the pallet mandates precise centering and alignment, secured via high-tensile steel strapping applied at four distinct vertical planes with calibrated tension to prevent radial movement without inducing core deformation.

The primary defense against maritime humidity is our multi-layer moisture-proof barrier system. Coils are first encased in a 120μm thick, co-extruded linear low-density polyethylene (LLDPE) film with certified water vapor transmission rate (WVTR) below 1.0 g/m²/24hr at 38°C and 90% RH. This film provides an absolute barrier against salt-laden air and condensation. Application requires a minimum 150mm overlap at all seams, with all edges meticulously heat-sealed using industrial impulse sealers operating at 220°C. A secondary desiccant layer comprising silica gel packets (minimum 500g per ton of wire) is strategically positioned between the coil surface and inner film layer, actively absorbing residual moisture during transit. The entire palletized unit then receives a final overwrap of identical LLDPE film, creating a redundant vapor barrier system validated for voyages exceeding 45 days under tropical marine conditions.

Quality control mandates 100% verification of seal integrity via vacuum decay testing prior to container loading. Film seams are subjected to 0.5 bar negative pressure for 60 seconds with zero allowable leakage. Pallet dimensions strictly adhere to 1200mm x 1000mm standards, optimizing container cube utilization while ensuring compatibility with global port handling equipment. Documentation includes a serialized moisture barrier certificate referencing ASTM D3078 test results. This integrated approach eliminates corrosion-related claims – empirical data from our 2023 shipments shows 0.02% moisture ingress incidents versus industry averages exceeding 1.8%. The initial packaging investment reduces total landed cost by preventing coil rejection, rework, and production line stoppages at the transformer OEM facility. Safe sea freight for aluminum winding wire is achieved through metallurgical precision in barrier science, not passive assumption.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium 3-Wire Transformer Winding Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd stands as a leading manufacturer and supplier of high-performance aluminum winding wire, with over two decades of specialized expertise in the design and production of materials tailored for power and distribution transformers. Our in-depth understanding of electromagnetic performance, thermal stability, and material conductivity positions us as a strategic partner for OEMs and tier suppliers engaged in the manufacturing of 3-wire transformers—critical components in modern power distribution networks, renewable energy systems, and industrial equipment.

Our production facility integrates advanced continuous casting and rolling technology with precision drawing and annealing systems to produce aluminum flat wire with exceptional dimensional accuracy, surface finish, and mechanical consistency. For 3-wire transformer applications, where balanced phase loading, low eddy current losses, and high space utilization are paramount, our aluminum strip and rectangular wire meet or exceed international standards including IEC 60464, ASTM B355, and GB/T 23309. Each batch undergoes rigorous quality control, including tensile strength testing, elongation verification, resistivity measurement, and microstructure analysis, ensuring optimal performance under high thermal and electrical stress.

We specialize in custom alloy formulations and tempers, primarily offering 1350, 1370, and 8030 series aluminum conductors, engineered to deliver superior conductivity (minimum 61% IACS) and enhanced fatigue resistance. Our wire is available in a full range of cross-sectional geometries, including trapezoidal profiles optimized for high-fill-factor windings in multi-conductor transformer designs. The precision of our edge straightness and corner definition directly contributes to reduced interlayer insulation requirements and improved thermal dissipation—key factors in achieving higher efficiency ratings (e.g., DOE 2016, ERP Tier II).

Vertical integration is a cornerstone of our operational model. From molten aluminum refining through final spooling, every stage is monitored under ISO 9001-certified processes. This control enables us to maintain batch-to-batch uniformity and respond rapidly to custom specifications, including non-standard widths (2.5 mm to 100 mm), thicknesses (0.8 mm to 8.0 mm), and packaging configurations (reels from 500 kg to 5,000 kg). Our R&D team collaborates directly with clients to simulate winding behavior and optimize conductor geometry for specific core designs and cooling methods.

With a production capacity exceeding 20,000 metric tons annually and export experience across Southeast Asia, the Middle East, and South America, Luoyang Xinzhaohe delivers scalable, cost-effective solutions without compromising technical integrity. We support our products with comprehensive material test reports, technical datasheets, and on-site engineering consultation.

For sourcing managers and design engineers seeking a reliable, technically proficient partner in aluminum winding wire for 3-wire transformers, Luoyang Xinzhaohe offers proven performance and global supply chain resilience.

Contact us today at cathy@transformerstrip.com to discuss your specifications and request sample reels for evaluation.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 3 wire transformer directly from China.