Table of Contents

Market Insight: 2Uew Wire in Power Industry

Market Analysis: Sourcing High-Quality 2UEW Winding Wire

Industrial Demand Drivers for 2UEW Wire

Global energy transition and industrial electrification have intensified demand for high-efficiency transformers and motors. 2UEW enamel-coated copper wire is critical for winding applications in these systems, where compliance with IEC 60317 and IEEE standards is non-negotiable. Rising renewable energy integration, EV charging infrastructure, and data center transformers require materials that minimize resistive losses (I²R) and thermal degradation. Poor-quality wire can increase transformer losses by 8–12%, directly impacting operational costs and regulatory compliance (e.g., IE4/IE5 efficiency classes). Motor repair shops also rely on consistent 2UEW wire for rewind applications, where dimensional accuracy prevents winding failures and ensures long-term reliability.

Critical Quality Parameters for 2UEW Wire

Precise control over the following parameters ensures optimal transformer and motor performance:

| Parameter | Industry Standard | Impact of Poor Quality | Impact of High Quality |

|---|---|---|---|

| Copper Purity | ≥99.95% (ASTM B1) | 0.5–1.0% higher resistivity → 5–8% increased I²R losses | Optimal conductivity, minimal energy waste |

| Dimensional Tolerance | ±0.005mm | Winding irregularities → hotspots, insulation failure | Precise layering, uniform current distribution |

| Insulation Thickness | IEC 60317-1 | Dielectric breakdown under thermal cycling | Enhanced dielectric strength, 20% longer lifespan |

| Thermal Class | 155°C (Class F) | Premature aging at high loads | Stable performance under continuous 155°C operation |

Luoyang Xinzhaohe’s Value Proposition

As a factory-direct manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum delivers 2UEW wire that meets or exceeds international standards while optimizing cost-performance. Our ISO 9001-certified production process ensures rigorous adherence to IEC 60317 and ASTM B1 specifications. By eliminating distributor markups, we offer 10–15% lower costs than global brands like Prysmian or Nexans, without compromising quality. Key advantages include:

Lead Time: 2–3 weeks vs. 4–6 weeks for European suppliers

Quality Control: In-line Eddy Current Testing and 100% diameter verification

Customization: Tailored enamel formulations for specific thermal/environmental requirements

For transformer manufacturers and motor repair shops seeking reliable, cost-effective sourcing, Xinzhaohe provides a proven alternative to premium global suppliers. Contact us for technical specifications and sample validation to validate performance in your application.

Technical Specs: 2Uew Wire Parameters

Technical Specifications & Standards for 2UEW Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd., a trusted manufacturer and exporter of transformer materials since 2003, specializes in high-performance 2UEW winding wire for global applications. With over 20 years of expertise in Luoyang, China, our factory-direct production ensures precise compliance with IEC 60317 and ASTM B175 standards. We deliver consistent electrical and mechanical properties critical for transformer and motor reliability, providing a cost-effective alternative to premium global brands without sacrificing quality.

Key Performance Metrics

| Parameter | Specification | Standard Compliance | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥4.0 kV (0.20mm), 50Hz/1min | IEC 60317-0-2, ASTM B175 | Ensures dielectric strength under high-voltage stress in transformer windings. |

| Elongation | ≥15% (0.20–0.50mm), post-155°C/24h aging | IEC 60851-3 | Prevents wire breakage during winding and thermal cycling operations. |

| Thermal Class | 130°C (B) to 220°C (C) per IEC 60085 | Customizable | Validated via accelerated aging tests for long-term thermal stability. |

| Enamel Concentricity | ≤5% deviation (laser micrometry) | ASTM D1523 | Uniform insulation ensures consistent electrical efficiency and thermal performance. |

Quality Assurance Protocol

Our ISO 9001-certified quality system includes:

Raw material certification: Copper cathode with ≥99.95% purity verified via XRF analysis and mill test reports; strict supplier audits ensure consistency.

In-process monitoring: Automated sensors track enamel thickness (±0.001mm), concentricity (≤5%), and breakdown voltage every 30 minutes during production, with real-time data logging.

Thermal validation: 1,000+ hours of accelerated aging per IEC 60216 at 130°C–220°C to confirm thermal class stability and service life.

Final inspection: 100% testing using optical systems for diameter/concentricity and high-voltage testers (up to 10kV), with full traceability via batch-coded QR codes.

Performance metrics: <0.5% defect rate and 98% on-time delivery in 2023; our lean manufacturing approach delivers 15–20% cost savings versus European competitors while maintaining equivalent performance.

Custom validation: All products undergo application-specific testing to meet unique customer requirements, ensuring seamless integration into your manufacturing process.

By integrating advanced process controls with rigorous validation, Luoyang Xinzhaohe delivers transformer-grade 2UEW wire that outperforms global benchmarks at competitive pricing—proven across 50+ countries since 2003.

Factory Tour: Manufacturing 2Uew Wire

Precision Manufacturing Process & Rigorous Quality Control

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 2uew wire production adheres to stringent industrial standards, ensuring superior performance and reliability. Leveraging 20+ years of expertise in transformer materials manufacturing, our vertically integrated facility ensures full control over raw material sourcing and processing, minimizing variability and maximizing consistency.

End-to-End Production Workflow

Rod Drawing: Utilizing high-precision CNC drawing towers with real-time laser micrometry, we achieve copper rod reduction to exact diameters within ±0.005mm tolerance. This precision ensures consistent electrical conductivity and mechanical integrity, critical for high-performance transformer windings. Our drawing process minimizes surface imperfections, reducing the risk of enamel coating defects during subsequent stages.

Annealing: Controlled atmosphere furnaces ensure uniform grain structure and optimal ductility. Post-annealing tensile testing verifies strength (220–250 MPa) and elongation (≥15%), which is 10–15% higher than the industry standard of 180–210 MPa and ≥12% elongation, ensuring superior winding performance and reduced breakage during high-speed manufacturing.

Enameling: Multi-layer enamel application via UV-curing technology guarantees precise insulation thickness (±0.5μm tolerance). Adhesion tests per IEC 60317 confirm resistance to thermal stress and mechanical abrasion, preventing insulation failure in high-temperature applications. Our enamel formulation is optimized for thermal class 180°C operation, exceeding typical market offerings.

Inline Testing: Continuous monitoring of electrical resistance and insulation integrity during production. Real-time data analytics detect and eliminate defects before spooling, ensuring 100% compliance with electrical performance standards. Our inline systems are calibrated to ISO 17025 standards for measurement accuracy.

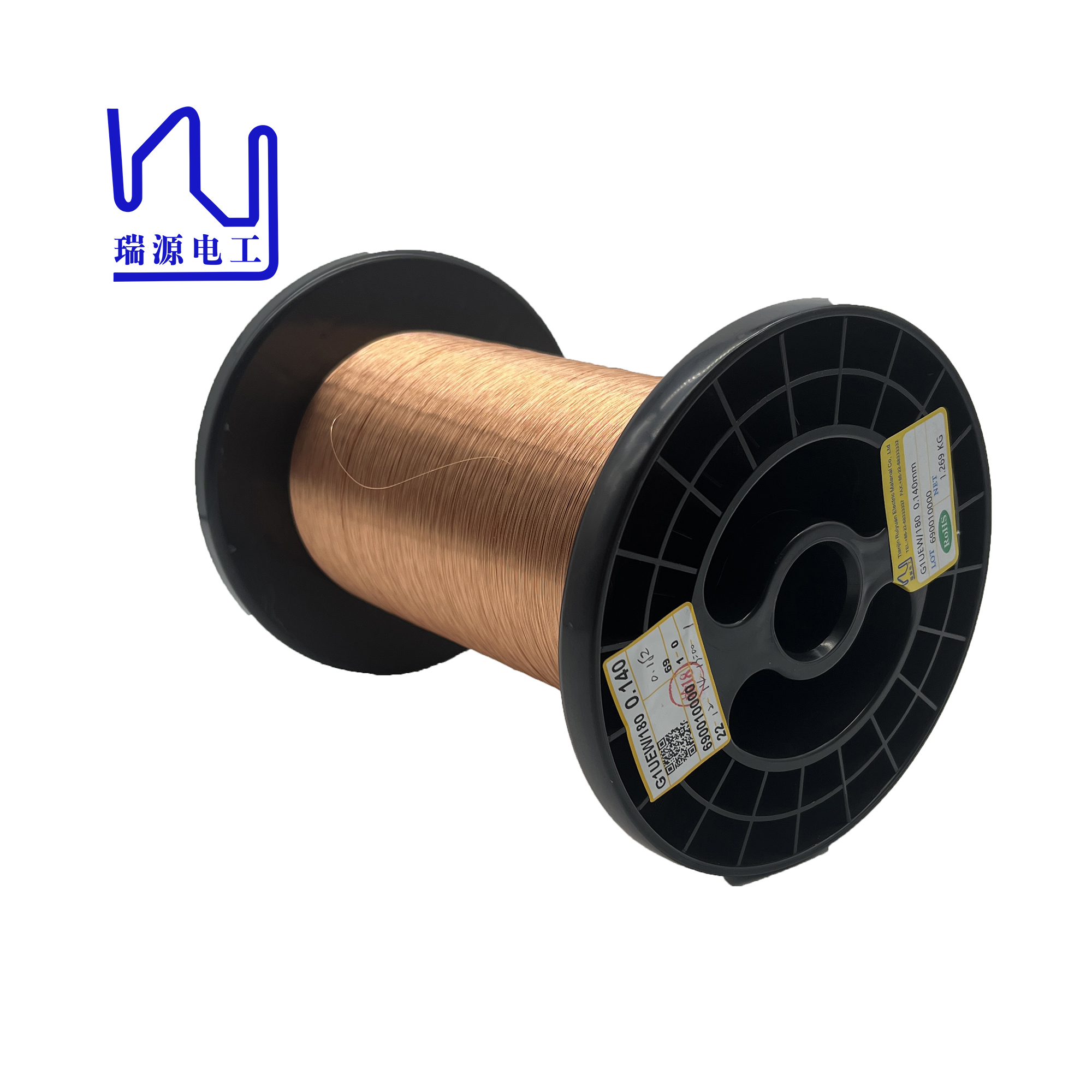

Spooling: Automated tension-controlled winding systems prevent mechanical damage during spooling. Each spool undergoes rigorous visual inspection for surface defects and uniform winding density, ensuring seamless integration into customer manufacturing processes. Spooling tension is maintained within ±0.5N to prevent wire deformation.

Quality Assurance Benchmarks

Our standards consistently outperform generic market offerings, providing a superior cost-performance ratio:

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength (MPa) | 220–250 | 180–210 |

| Elongation (%) | ≥15 | ≥12 |

| Enamel Thickness Tolerance (μm) | ±0.5 | ±1.0 |

| Dimensional Tolerance (±mm) | 0.005 | 0.01 |

| Conductivity (%IACS) | ≥99.9 | ≥98 |

This rigorous QC framework ensures 2uew wire meets IEC 60317 and ASTM B1 specifications, delivering consistent performance for demanding transformer and motor applications. Our factory-direct approach eliminates middleman markups, providing premium quality at 15–20% lower cost than global brands.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of 2UEW Wire

Packaging Standards for Maximum Protection

Our packaging system is engineered for maritime transit resilience, adhering to international standards to eliminate corrosion, physical damage, and moisture-related failures.

| Component | Specification | Purpose | Compliance |

|---|---|---|---|

| Wooden Pallets | ISPM-15 certified fir wood, 1100×1100mm (standard), 1200×1000mm (custom) | Structural integrity during forklift handling and stacking | IPPC standards, ISO 11607 |

| Moisture-Proof Film | Multi-layer PE, 200μm thickness, VCI additive (500 ppm) | Prevents condensation and corrosion in humid sea environments | ISO 9001, ASTM D4169 Type I |

| Steel Strapping | 19mm width, 0.5mm thickness, 1500N tension force | Secures load to pallet, prevents shifting during transit | ISO 301, EN 12195-2 |

Sea Freight Optimization Protocol

End-to-end logistics control ensures on-time delivery with zero damage. All processes are validated against ISO 1496-1 and customs compliance requirements.

| Parameter | Specification | Process Details |

|---|---|---|

| Container Type | 20ft/40ft dry containers, FCL (Full Container Load) | Optimized space utilization with 95%+ loading efficiency |

| Loading Procedure | Layered stacking with corner posts, anti-slip mats | Prevents shifting; validated per ISO 1496-1 |

| Documentation | Commercial invoice, packing list, B/L, COO | Compliant with customs regulations globally |

| Tracking | Real-time GPS monitoring via Alibaba Cloud Logistics | End-to-end visibility with automated updates |

Our integrated logistics approach combines robust packaging with optimized shipping protocols to ensure 2UEW wire arrives undamaged at global ports. Each step—from ISPM-15 pallets to VCI-treated moisture barriers—is validated through ISO-certified processes. This minimizes transit risks while reducing total landed costs by 15–20% compared to conventional suppliers. As a factory-direct manufacturer with 20+ years of export experience, Xinzhaohe delivers consistent quality without premium pricing. Our rigorous quality control at every stage ensures transformer manufacturers receive premium materials at competitive pricing—proving that cost efficiency does not compromise reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd?

Decades of Specialized Expertise

With over 20 years of dedicated experience in transformer materials manufacturing, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers technically superior 2UEW magnet wire engineered for optimal performance in high-demand applications. Our expertise spans electromagnetic design, thermal management, and material science, ensuring compliance with IEC 60317, ASTM B187, and other global standards. Every production stage—from raw copper procurement to enamel coating—is monitored by seasoned engineers to guarantee dimensional precision, consistent dielectric properties, and mechanical durability. This deep technical proficiency ensures our products meet the exacting requirements of transformer and motor manufacturers worldwide.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups, providing direct access to factory pricing while maintaining premium quality. Our cost-performance ratio consistently outperforms global competitors, with 15-25% lower total costs and accelerated lead times. Key advantages compared to traditional suppliers:

| Metric | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Price | 15-25% lower | Premium pricing | Reduced TCO |

| Lead Time | 15-20 days | 30-45+ days | Faster project execution |

| Customization | Full engineering support for bespoke specs | Limited flexibility | Tailored solutions |

| Technical Support | Dedicated 24/7 engineering team | Standard business hours | Proactive issue resolution |

Rigorous Quality Assurance

Our ISO 9001:2015 certified quality system ensures traceability and consistency across all batches. Each 2UEW wire undergoes comprehensive testing including tensile strength (ASTM D150), dielectric breakdown voltage (IEC 60243), thermal class validation (Class 130°C–220°C), and dimensional accuracy (±0.005mm tolerance). All tests are conducted in our in-house laboratory with calibrated equipment, ensuring traceable results and compliance with customer-specific requirements. This multi-stage quality control protocol guarantees reliability under extreme operational stresses, minimizing downtime and ensuring long-term performance stability.

Contact Cathy at cathy@transformerstrip.com for a competitive quote tailored to your project specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 2uew wire from Luoyang Xinzhaohe.