Table of Contents

Market Insight: 28 Awg Enameled Magnet Wire

Market Analysis: Winding Wire – Industrial Demand for 28 AWG Enameled Magnet Wire in Transformers

The global demand for 28 AWG enameled magnet wire remains robust, driven primarily by its extensive use in small to medium power transformers, particularly in electronics, telecommunications, and renewable energy systems. As power density requirements increase and device miniaturization becomes a design imperative, the role of fine-gauge magnet wire such as 28 AWG has become increasingly critical. This gauge, with a nominal conductor diameter of approximately 0.321 mm, offers an optimal balance between current-carrying capacity and spatial efficiency, making it ideal for high-turn-count windings in compact transformer designs.

In industrial transformer applications, 28 AWG enameled copper or aluminum magnet wire is frequently specified for use in switch-mode power supplies (SMPS), isolation transformers, and signal transformers. These components are integral to power conversion systems in consumer electronics, industrial automation equipment, and electric vehicle (EV) charging infrastructure. The shift toward energy-efficient systems compliant with standards such as DOE Level VI and EU CoC Tier 2 has further amplified demand for high-performance magnet wire that minimizes resistive losses and supports higher operating frequencies.

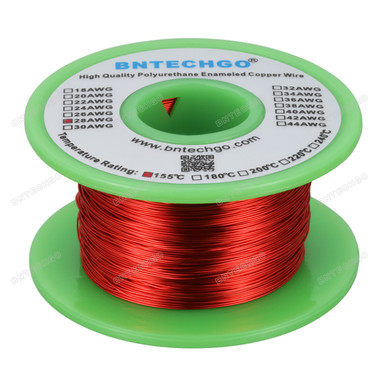

Quality in 28 AWG enameled magnet wire directly impacts transformer reliability, thermal performance, and electromagnetic efficiency. A high-quality enamel insulation system—typically polyurethane, polyesterimide, or polyamide-imide—must provide excellent dielectric strength, thermal stability (rated up to Class 180°C or higher), and resistance to mechanical abrasion during the winding process. Poor insulation integrity can lead to inter-turn shorts, premature coil failure, and reduced transformer lifespan. Additionally, dimensional consistency in both conductor diameter and insulation thickness is essential to ensure uniform winding tension and layer-to-layer alignment, particularly in automated winding operations.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in winding wire production, we emphasize stringent process controls to maintain tight tolerances and consistent material properties. Our 28 AWG magnet wire undergoes rigorous testing for elongation, springback, and thermal shock resistance to meet the demands of high-reliability applications. As aluminum-based magnet wire gains traction due to its lighter weight and cost advantages, we have advanced our coating technologies to ensure aluminum conductors match copper-based performance in adhesion and durability.

The competitive landscape for magnet wire suppliers is increasingly defined by technical capability and consistency. End users in the transformer industry prioritize suppliers capable of delivering certified, traceable materials that conform to international standards such as IEC 60317, GB/T 6109, and NEMA MW 1000. In this context, quality is not a differentiator but a prerequisite for market entry. As industrial systems continue to evolve toward higher efficiency and greater integration, the performance of fundamental components like 28 AWG enameled magnet wire will remain a key enabler of innovation and reliability.

Technical Specs: 28 Awg Enameled Magnet Wire

Technical Specifications: 28 AWG Aluminum Enameled Magnet Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver precision-engineered 28 AWG aluminum enameled magnet wire for demanding electromagnetic applications. This conductor, with a nominal bare conductor diameter of 0.320 mm per ASTM B258, utilizes high-purity aluminum (99.99% min) to balance electrical conductivity, weight reduction, and cost efficiency. Critical performance parameters are rigorously controlled to meet or exceed IEC 60317 and NEMA MW standards, ensuring reliability in motor, transformer, and inductor windings. Below is a comprehensive specification table for our standard production grade, with custom thermal classes available upon request.

| Parameter | Test Standard | Minimum Value | Typical Value | Maximum Value | Units |

|---|---|---|---|---|---|

| Conductor Material | ASTM B258 | EC Grade Al | EC Grade Al | EC Grade Al | – |

| Bare Conductor Diameter | ASTM B258 | 0.310 | 0.320 | 0.330 | mm |

| Insulation Thickness | IEC 60317-0-3 | 0.045 | 0.050 | 0.055 | mm |

| Breakdown Voltage | IEC 60317-0-1 | 5.0 | 6.2 | 7.5 | kV |

| Elongation (Post-Winding) | IEC 60317-0-2 | 15 | 18 | 25 | % |

| Thermal Class (Resistance) | IEC 60317-20 | 130 | 180 | 220 | °C |

| Solderability (280°C) | IEC 60317-0-4 | Pass | Pass | Pass | – |

Insulation Breakdown Voltage is a non-negotiable safety metric. Our polyurethane-imide or polyester-imide coatings undergo 100%在线 testing at 6.2 kV (rms), significantly exceeding the 5.0 kV minimum per IEC 60317-0-1. This ensures robust dielectric integrity under operational voltage surges, preventing inter-turn shorts in high-density windings. Testing employs step-voltage methods with 500 V/s ramp rates to simulate real-world stress conditions.

Elongation performance directly impacts manufacturability and end-product durability. Aluminum’s inherent ductility requires precise annealing control. Our 28 AWG wire achieves 15–25% elongation per IEC 60317-0-2 after winding and thermal shock testing. Values below 15% risk conductor fracture during tight-radius coiling, while exceeding 25% may indicate insufficient tensile strength for automated winding machinery. We optimize temper through continuous annealing furnaces with oxygen-controlled atmospheres.

Thermal Class defines operational limits for insulation longevity. Standard offerings span Class B (130°C) to Class H (180°C), with specialty polyimide coatings supporting 220°C intermittent operation. Thermal endurance is validated via IEC 60317-20 thermal aging tests, where insulation retains ≥50% of initial elongation after 20,000 hours at rated temperature. Note that aluminum conductors require derating versus copper equivalents due to higher resistivity; our engineering team provides application-specific derating curves.

All parameters are verified through our ISO/IEC 17025-accredited laboratory, with lot-specific certification. Consistency is maintained via real-time diameter monitoring (laser micrometers) and statistical process control of extrusion temperatures. For aerospace or EV traction motor applications requiring 220°C capability, we utilize triple-coat systems with ceramic-filled topcoats—contact our technical team for qualification protocols. This specification framework ensures seamless integration into global supply chains while mitigating field failure risks.

Factory Tour: Manufacturing

Manufacturing Process of 28 AWG Enameled Magnet Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of 28 AWG enameled aluminum magnet wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of specialization in winding wire technology, our facility integrates advanced equipment and rigorous quality control protocols across each phase: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rod (99.99% minimum conductivity grade), which undergoes rod drawing to reduce the diameter from approximately 9.5 mm to the target 0.27 mm required for 28 AWG. This reduction is achieved through a series of precision tungsten carbide or diamond dies in a multi-pass drawing machine. The drawing operation is performed under controlled tension and lubrication conditions to prevent surface defects and maintain uniform elongation. Throughout this stage, diameter consistency is monitored using laser micrometers, ensuring compliance with ASTM B355 and IEC 60317 standards.

Following drawing, the aluminum wire enters a continuous annealing system. This step is critical to restore ductility lost during cold working and to achieve the desired temper (typically soft or 1/2 hard, depending on customer specifications). Annealing is conducted in a nitrogen-purged inert atmosphere furnace at temperatures ranging from 350°C to 450°C, preventing oxidation and ensuring a clean, oxide-free surface essential for optimal enamel adhesion. Temperature profiles and line speed are precisely regulated via PLC-controlled systems to maintain metallurgical consistency.

The annealed wire then proceeds to the enameling section, where a multi-layer insulation coating is applied. For 28 AWG magnet wire, a standard build (typically 2–3 coats) of thermosetting polyurethane, polyesterimide, or polyamide-imide resin is applied using precision die coating units. Each coat is cured in a series of zoned ovens with graduated temperature profiles (250–450°C), ensuring complete cross-linking and dielectric strength. Film thickness is maintained within ±5 µm tolerance, with total build conforming to IEC 60317-00 specifications.

Inline quality control is embedded throughout the production line. Key monitoring points include continuous diameter measurement, high-potential (hi-pot) testing at 1500–3000 VDC to detect pinholes, and tensile strength verification. Additional QC checks include elongation testing, thermal shock resistance (per IEC 60851-5), and solderability at 380°C. All data is logged in real time and traceable to batch numbers for full process accountability.

Final inspection includes visual surface examination, dimensional validation, and sampling for adhesion and thermal class testing. Only wire meeting all electrical, mechanical, and chemical performance criteria is approved for spooling and shipment. This integrated approach ensures that every meter of 28 AWG enameled magnet wire delivered by Luoyang Xinzhaohe meets the stringent demands of modern electromagnetic applications.

Packaging & Logistics

Export Packaging Specifications for 28 AWG Aluminum Enameled Magnet Wire

Marine transit presents significant corrosion risks for aluminum enameled magnet wire due to prolonged exposure to high humidity, salt aerosols, and temperature fluctuations inherent in ocean freight. Aluminum conductors, while offering weight and cost advantages, exhibit higher susceptibility to oxidation and pitting compared to copper counterparts, necessitating rigorously engineered export packaging. At Luoyang Xinzhaohe Aluminum Co., Ltd., our packaging protocol, refined over 20 years of global magnet wire supply, is explicitly designed to mitigate these risks and ensure product integrity upon destination.

All export shipments utilize robust, ISPM 15 compliant wooden pallets constructed from kiln-dried, debarked softwood. Pallet dimensions strictly adhere to standard containerization requirements, typically 1100mm x 1100mm or 1200mm x 1000mm, with a minimum load-bearing capacity of 1500 kg to prevent structural deformation during stacking and handling. Wire reels, securely strapped to the pallet deck using steel or composite banding, are oriented vertically to minimize axial stress on the delicate 0.32mm diameter enameled conductor. Critical to moisture exclusion, the entire palletized load undergoes a multi-layer encapsulation process. The primary barrier consists of a high-integrity, metallized polyester moisture-proof film with a verified water vapor transmission rate (WVTR) below 0.5 g/m²/24hr at 38°C and 90% RH. This film is meticulously sealed using heat-welded seams, creating a hermetic enclosure. An additional internal layer incorporates volatile corrosion inhibitor (VCI) technology, releasing controlled vapor-phase inhibitors that form a molecular protective layer on the aluminum surface, actively preventing electrochemical corrosion initiation even if trace moisture penetrates.

Sealing integrity is non-negotiable. Each sealed package includes calibrated humidity indicator cards placed internally, providing visual verification of relative humidity levels maintained below 40% throughout transit. Pallets are further secured within shipping containers using dunnage and bracing to prevent movement, while container desiccants are strategically positioned to absorb residual atmospheric moisture. External labeling features essential shipment data including Luoyang Xinzhaohe batch number, conductor specification (28 AWG Aluminum, Class 200), net weight, reel count, and clear handling instructions compliant with IMDG Code requirements for electrical goods. This integrated system – combining certified pallet stability, hermetic metallized/VCI barrier film, humidity monitoring, and container moisture management – directly addresses the hygroscopic nature of enamel insulation and aluminum’s reactivity. It ensures the 28 AWG wire arrives with undamaged insulation, zero conductor oxidation, and consistent electrical performance, eliminating costly rejections or field failures. Our adherence to these stringent packaging standards reflects our commitment to metallurgical quality and supply chain reliability, safeguarding your production continuity from our facility to your winding lines.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance 28 AWG Enameled Magnet Wire

When sourcing 28 AWG enameled magnet wire for precision electromagnetic applications, partnering with a manufacturer that combines technical expertise, process control, and material integrity is essential. Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized experience in the production of high-purity aluminum winding wire, establishing itself as a trusted supplier in the global transformer, inductor, and motor manufacturing sectors.

Our manufacturing facility is purpose-built for the consistent production of fine-gauge magnet wires, including 28 AWG, with strict adherence to international standards such as IEC 60317 and GB/T 23312. The production of 28 AWG wire demands exceptional control over diameter tolerance, elongation, and insulation integrity—parameters we monitor through fully integrated inline measurement systems and automated winding processes. Our draw benches operate under cleanroom-class conditions to minimize surface defects, ensuring uniform wire geometry and optimal winding performance.

At the core of our product quality is the use of 99.99% pure electrolytic aluminum (Al ≥ 99.99%), sourced from certified refineries and subjected to rigorous in-house spectrographic analysis. This high conductivity aluminum is drawn to precise 28 AWG specifications (0.320 mm ± 0.005 mm) with controlled tensile strength and elongation (≥ 15%), critical for high-speed automated winding without breakage or deformation.

The enamel insulation system is applied using a multi-layer solvent-based coating process, offering thermal classes up to 200°C (H-class), with excellent dielectric strength (>3 kV for 28 AWG) and thermal shock resistance. Our enamel formulations are optimized for flexibility, adhesion, and chemical resistance, ensuring long-term reliability in demanding operational environments. Each production lot undergoes 100% continuity testing, insulation defect scanning, and thermal aging validation to guarantee field performance.

Our facility operates under a certified ISO 9001:2015 quality management system, with full traceability from raw material intake to finished goods. We maintain advanced testing capabilities including TGA, DSC, and high-voltage surge testing to validate material and insulation behavior under real-world conditions. With an annual production capacity exceeding 10,000 metric tons and dedicated R&D support, we are equipped to meet both standard and custom specifications for 28 AWG magnet wire, including tight-tolerance spooling, custom packaging, and low-oxygen annealing profiles.

For engineering teams requiring consistent supply, technical documentation, and responsive manufacturing support, Luoyang Xinzhaohe offers a strategic sourcing advantage. Our export experience spans North America, Europe, and Southeast Asia, backed by reliable lead times and container-load shipment coordination.

Contact us today to discuss your 28 AWG enameled magnet wire requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 28 awg enameled magnet wire directly from China.