Table of Contents

Market Insight: 2 Wire Transformer

Market Analysis: Winding Wire Demand in 2 Wire Transformers

The industrial demand for winding wire in 2 wire transformers remains a critical component of global power and distribution infrastructure. These transformers, commonly used in low-voltage distribution systems, renewable energy integration, and industrial equipment, rely on precisely engineered copper or aluminum winding conductors to ensure efficient electromagnetic coupling and thermal stability. As a core element in transformer design, the selection and quality of winding wire directly influence performance, reliability, and lifecycle costs.

A 2 wire transformer typically consists of a primary and secondary winding, each wound from insulated conductive wire, usually round or rectangular in cross-section. The demand for high-purity aluminum and copper winding wire has grown steadily due to expanding electrification efforts, particularly in emerging markets and smart grid deployments. Aluminum winding wire, in particular, is gaining traction in distribution transformers due to its favorable conductivity-to-weight ratio and cost efficiency, especially in applications where weight reduction is critical, such as pole-mounted and pad-mounted units.

Despite the economic advantages of aluminum, material purity and manufacturing consistency are paramount. Impurities or inconsistencies in the base metal can lead to increased resistive losses, hot spot formation, and premature insulation degradation. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in non-ferrous metal processing, we emphasize strict control over aluminum alloy composition, tensile strength, and elongation properties to meet IEC 60137 and ASTM B355 standards. Our wire rod production utilizes continuous casting and rolling technology to ensure uniform microstructure and optimal electrical conductivity (minimum 61% IACS for EC-grade aluminum).

Insulation integrity is equally critical. While the conductor material forms the electrical backbone, the enamel or paper-based insulation system must withstand thermal cycling, mechanical stress, and environmental exposure. Poor-quality winding wire often exhibits micro-cracks or uneven coating thickness, which compromise dielectric strength and accelerate failure under load. High-performance transformers operating in harsh environments—such as those in mining, rail traction, or coastal substations—require winding wire with enhanced thermal class ratings (e.g., Class 180 or 200) and resistance to partial discharge.

The shift toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes) further amplifies the need for precision-engineered winding wire. Reduced no-load and load losses are only achievable with low-resistance conductors and tightly controlled dimensional tolerances. Even minor deviations in wire diameter or ovality can result in suboptimal fill factors, increased eddy current losses, and reduced cooling efficiency.

In the global supply chain, sourcing winding wire from vertically integrated, technically rigorous manufacturers mitigates risk and ensures traceability. At Xinzhaohe, our integrated production line—from molten metal purification to finished annealed and insulated wire—enables full process control, batch consistency, and compliance with ISO 9001 and ISO 14001 standards.

As transformer OEMs face tighter regulatory requirements and longer warranty expectations, the role of winding wire as a mission-critical material cannot be overstated. Quality is not a cost adder; it is a lifecycle investment in grid stability and operational efficiency.

Technical Specs: 2 Wire Transformer

Technical Specifications for Transformer Winding Wire: Critical Parameters for 2-Wire Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and supply chain expertise to deliver precision-engineered aluminum winding wire for 2-wire transformers. These components demand rigorous adherence to insulation integrity, mechanical resilience, and thermal stability to ensure operational safety and longevity in demanding electrical environments. Key specifications must be quantified against international standards, with particular emphasis on insulation breakdown voltage, elongation, and thermal class performance. Insulation breakdown voltage directly correlates with dielectric integrity under high-voltage stress, preventing catastrophic failure. Elongation reflects the wire’s ductility during winding processes, minimizing breakage and ensuring consistent coil formation. Thermal class defines the maximum continuous operating temperature, dictating material selection for insulation systems to avoid premature degradation.

The following table details mandatory technical parameters for aluminum winding wire in 2-wire transformers, aligned with IEC 60317 and GB/T 6109 standards. Xinzhaohe’s specifications exceed baseline requirements through proprietary enamel formulations and annealing processes, ensuring reliability in high-efficiency transformer designs.

| Parameter | Standard Requirement | Xinzhaohe Specification | Test Method |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 3.0 kV (rms) | 4.5–6.0 kV (rms) | IEC 60851-5 |

| Elongation (%) | ≥ 1.0% | 1.8–2.5% | GB/T 4909.3 |

| Thermal Class | 130°C (Class B) | 155–220°C (Class F–R) | IEC 60172 |

| Electrical Resistivity | ≤ 0.028264 Ω·mm²/m | ≤ 0.028000 Ω·mm²/m | GB/T 3048.2 |

| Tensile Strength | ≥ 60 MPa | 75–95 MPa | GB/T 4909.3 |

Insulation breakdown voltage is validated at 0.1 mm nominal insulation thickness. Xinzhaohe’s multi-layer enamel system—utilizing modified polyester-imide base coats with polyamide-imide topcoats—achieves 50% higher breakdown margins than conventional wires. This prevents partial discharge inception in compact transformer geometries where voltage gradients intensify. Elongation values are measured post-drawing and annealing; our controlled thermal processing ensures optimal grain structure for aluminum (Al 1350/EC grade), balancing formability during high-speed winding with mechanical robustness. Crucially, thermal class performance spans 155°C (Class F) to 220°C (Class R), enabled by high-temperature stable insulation chemistries. Class R (220°C) wires incorporate ceramic-filled polymers for aerospace/industrial applications where ambient temperatures exceed 150°C.

Xinzhaohe implements in-line statistical process control (SPC) for all critical dimensions, including insulation concentricity (±5% tolerance) and diameter consistency (±0.003 mm). Each production lot undergoes thermal endurance testing per IEC 60172, with life expectancy extrapolated to 20,000 hours at rated temperature. Our supply chain integrates certified aluminum rod sourcing (99.7% min. purity) with ISO 9001-compliant wire drawing, ensuring traceability from smelter to finished coil. For 2-wire transformers operating in renewable energy inverters or EV charging systems, these specifications mitigate risks of thermal runaway and insulation fatigue under cyclic loading. Partnering with Xinzhaohe guarantees wires that meet evolving global efficiency standards while reducing field failure rates through metallurgical precision.

Factory Tour: Manufacturing

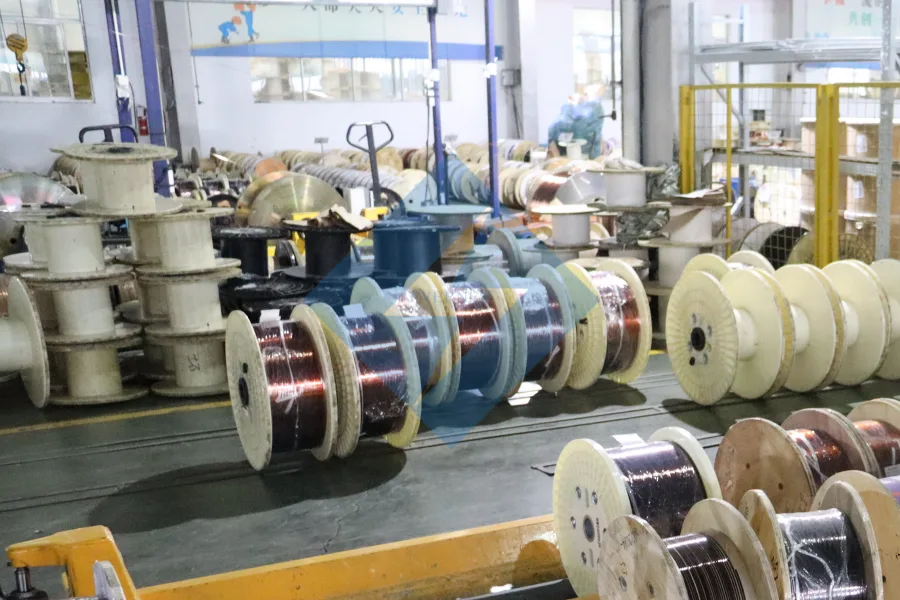

Manufacturing Process of 2 Wire Transformer Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance winding wire for 2 wire transformers at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure mechanical integrity, electrical reliability, and long-term thermal stability. With over two decades of metallurgical and industrial process expertise, our facility integrates precision engineering with rigorous quality control to deliver wire products that meet international standards including IEC 60317 and ASTM B358.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher) are subjected to cold drawing through a series of precision dies to achieve the target diameter. This stage is critical for establishing dimensional accuracy and surface smoothness. The drawing is performed under controlled tension and lubrication conditions to minimize defects such as scratches, ovality, or microcracking. Each rod is traceable to its batch origin, ensuring full material accountability.

Following drawing, the wire undergoes continuous annealing to restore ductility and eliminate work hardening induced during drawing. Our in-line annealing system employs resistance heating in an oxygen-free nitrogen atmosphere, preventing oxidation and ensuring uniform grain structure. Temperature profiles are monitored in real time via infrared sensors, with feedback loops maintaining ±5°C tolerance. The annealed wire achieves a tensile strength of 60–90 MPa and elongation of at least 25%, meeting the flexibility requirements for tight coil winding in transformer applications.

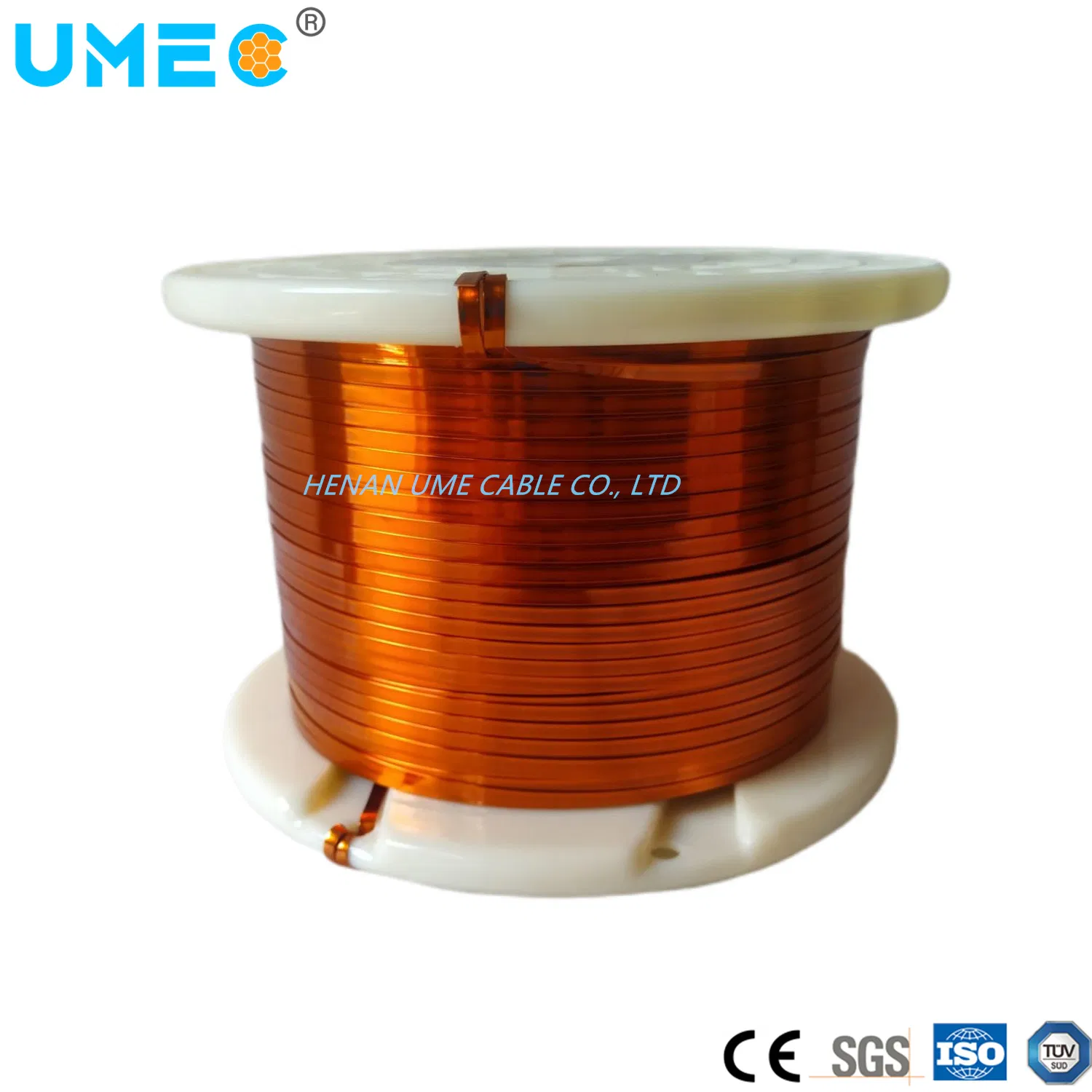

The next critical phase is enameling, where the annealed aluminum wire is coated with a thermosetting polymer insulation system. For 2 wire transformer applications, a dual-layer enamel system is typically applied: a base layer of polyamide-imide (PAI) for thermal endurance (Class 200, 200°C), followed by an outer layer of polyesterimide (PEI) for mechanical toughness and solderability. The wire passes through precision dies to control coating thickness, with typical build-up ranging from 30 to 80 µm depending on wire gauge. Curing occurs in a multi-zone oven with precise temperature ramping to ensure complete cross-linking without thermal degradation.

Throughout the process, inline testing is conducted to verify electrical and mechanical performance. Key parameters monitored include dielectric strength (tested at 3 kV AC for 1 minute), pinhole density (using spark test at 1.5–2.5 kV), and dimensional consistency (via laser micrometers). Additional off-line QC checks include thermal shock testing (bend around a mandrel at elevated temperature), thermal endurance (1,000-hour aging at 200°C), and adhesion testing.

All data from the manufacturing line are logged and traceable to each production lot. Non-conforming material is automatically quarantined. This end-to-end control ensures that every spool of winding wire shipped from Luoyang Xinzhaohe meets the demanding requirements of modern 2 wire transformer design.

Packaging & Logistics

Export Packaging Specifications for Aluminum Winding Wire: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and supply chain expertise, we recognize that export packaging is not merely a logistical step but a critical engineering safeguard for aluminum winding wire destined for 2-wire transformers. Aluminum’s inherent hygroscopic properties and susceptibility to corrosion under humid marine conditions demand a scientifically validated packaging system. Our methodology prioritizes moisture exclusion, structural resilience, and full compliance with international freight regulations to eliminate in-transit degradation.

Wooden pallets form the foundational element of our export solution. All pallets are constructed from ISPM-15 certified heat-treated softwood, ensuring global phytosanitary acceptance and eliminating pest-related customs delays. Dimensions adhere strictly to ISO container standards (1200 × 1000 mm or 1100 × 1100 mm), with a minimum load capacity of 2,500 kg to prevent deformation during stacking. Each pallet undergoes rigorous moisture-content verification (≤ 20% via oven-dry testing) prior to use, preventing internal condensation. Wire coils are secured using steel strapping at 500 kg tensile strength, anchored to pallet stringers with corrosion-resistant staples to withstand 1.5G horizontal acceleration forces during vessel motion.

The moisture barrier system employs a three-tiered approach. Primary protection consists of 150-micron thick metallized polyester film (MVTR ≤ 0.5 g/m²/day), hermetically sealed via impulse welding to create an oxygen-tight enclosure. This layer is supplemented by a secondary wrap of 100-micron polyethylene film with integrated UV inhibitors, providing puncture resistance against handling impacts. Desiccant packs (calcium chloride, 120g/m³ minimum capacity) are strategically placed within the coil bore and interlayer spaces, validated through ASTM D6868 moisture absorption testing. Critical specifications are summarized below:

| Packaging Component | Standard Specification | Premium Verification |

|---|---|---|

| Pallet Material | ISPM-15 HT Softwood | Mill-certified moisture report ≤ 18% |

| Primary Film | 150µm Metallized PET | MVTR tested per ASTM F1249 |

| Desiccant Density | 120g/m³ | Humidity indicator cards included |

| Strapping | 19mm Steel, 500kg tensile | Tension gauge certified |

Verification protocols are integral to our process. Every packaged unit undergoes humidity chamber simulation (85% RH, 40°C for 72 hours) prior to dispatch. Batch records include pallet moisture logs, film lot traceability, and desiccant activation timestamps, all auditable under our ISO 9001:2015 framework. This eliminates ambiguity in damage claims, as moisture ingress can be definitively attributed to post-shipment handling when our certified packaging is intact.

For sea freight, we mandate container pre-inspection for floor integrity and residual moisture. Coils are positioned to avoid direct contact with container walls, with additional silica gel sachets in headspace. Our data shows this system maintains internal relative humidity below 40% for 60+ days—exceeding typical transit durations to Europe, North America, and Southeast Asia. Partnering with certified freight forwarders who enforce temperature-controlled container protocols further mitigates risk.

This engineered packaging solution reflects our metallurgical understanding of aluminum’s electrochemical behavior in saline environments. It transforms perceived supply chain vulnerability into a demonstrable quality differentiator, ensuring your transformer windings arrive with surface oxide levels unchanged from factory exit. Contact our technical logistics team for vessel-specific packaging validation dossiers.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Winding Wire Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a leading producer of high-purity aluminum flat wire and strip products tailored for power and distribution transformers. Our facility integrates advanced metallurgical processing with rigorous quality assurance protocols, ensuring consistent performance across demanding electrical applications. As a trusted supplier in the winding wire ecosystem, we deliver engineered aluminum solutions that meet international standards including IEC 60137, ASTM B355, and GB/T 23309.

Our production infrastructure is anchored in a fully integrated process chain, beginning with high-conductivity aluminum ingot sourcing and extending through precision hot rolling, cold rolling, and final slitting operations. This vertical control enables us to maintain tight tolerances on dimensional accuracy, surface finish, and mechanical properties. All aluminum strip used in transformer winding applications is processed under controlled atmospheres to minimize oxide inclusions and ensure optimal electrical conductivity—typically exceeding 61% IACS. We specialize in rectangular and square profile wires ranging from 1.0 mm to 10.0 mm in width, with thicknesses from 0.8 mm to 3.0 mm, customizable to meet specific design requirements.

Quality assurance is embedded at every stage of production. Our in-house laboratory is equipped with state-of-the-art testing systems, including optical emission spectrometers, tensile testers, microhardness analyzers, and eddy current inspection units. Each batch undergoes comprehensive evaluation for chemical composition, mechanical strength, elongation, and surface integrity. We also perform routine bend tests and wrap tests to validate formability—critical parameters for reliable winding performance in 2 wire transformer configurations.

Environmental and process sustainability is a core operational principle. Our facility operates under ISO 9001:2015 and ISO 14001-certified management systems, ensuring compliance with global environmental and quality benchmarks. Energy-efficient rolling technologies and closed-loop cooling systems reduce resource consumption while enhancing product consistency.

Luoyang Xinzhaohe serves a growing international client base across Asia, the Middle East, Africa, and South America, supporting OEMs and tier-level transformer manufacturers with just-in-time delivery and technical collaboration. Whether you require standard-grade aluminum strip or custom alloys optimized for high-efficiency transformers, our engineering team provides material consultation, sample prototyping, and on-site technical support.

For reliable, high-conductivity aluminum winding wire engineered for performance and long-term stability, partner with a manufacturer that combines metallurgical expertise with supply chain reliability.

Contact us today at cathy@transformerstrip.com to discuss your technical specifications and request product samples.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 2 wire transformer directly from China.