Table of Contents

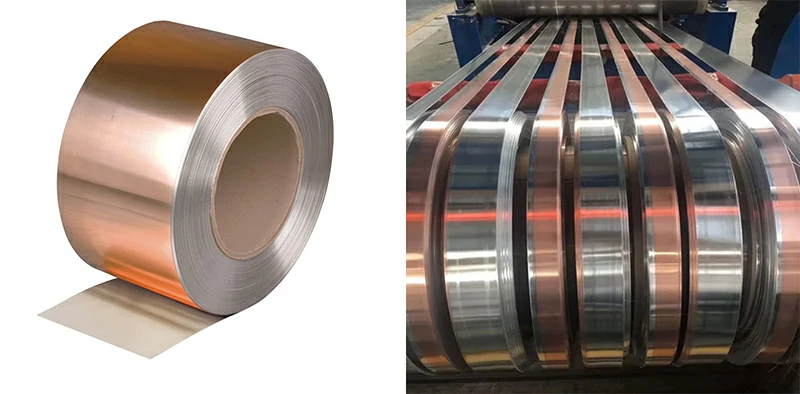

Market Insight: 2 Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to rely heavily on high-performance conductive materials, with copper strip—particularly ASTM B187 Grade 2 (C11000) copper strip—remaining a critical component in the fabrication of low-voltage and distribution transformers. Despite the increasing adoption of aluminum as a cost-effective alternative in certain applications, 2 copper strip maintains a dominant position in high-efficiency and high-reliability transformer designs due to its superior electrical conductivity, mechanical stability, and long-term durability. Industrial demand for this material is driven primarily by the energy, power distribution, and industrial manufacturing sectors, where transformer efficiency directly impacts operational costs and grid reliability.

Copper’s electrical conductivity, typically exceeding 100% IACS (International Annealed Copper Standard), ensures minimal resistive losses during power transmission. This property is essential in transformer windings, where even marginal improvements in conductivity can result in significant energy savings over the transformer’s lifecycle. Grade 2 copper strip, characterized by its high purity (minimum 99.90% Cu + Ag), low oxygen content (typically <0.04%), and consistent mechanical properties, is engineered to meet the stringent requirements of modern transformer manufacturing. The material must exhibit uniform thickness, precise dimensional tolerances, and excellent surface finish to support automated winding processes and to prevent insulation breakdown under high electromagnetic stress.

Quality in copper strip production is not merely a performance differentiator—it is a prerequisite for compliance with international standards such as IEC 60464, GB/T 5584, and IEEE C57.12.00. Variability in conductivity, edge burrs, surface oxidation, or microstructural inconsistencies can lead to localized heating, reduced thermal performance, and premature transformer failure. In high-load environments such as urban substations or industrial plants, these defects can compromise grid stability and increase maintenance costs. Furthermore, the trend toward compact, high-capacity transformers in renewable energy integration and electric vehicle charging infrastructure demands copper strip with superior formability and thermal cycling resistance—attributes directly influenced by manufacturing quality.

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of metallurgical and supply chain expertise to the transformer materials market. While specializing in both aluminum and copper-based transformer foils and strips, the company applies rigorous quality control protocols to ensure consistency in grain structure, annealing uniformity, and surface integrity. Each batch of 2 copper strip undergoes comprehensive electrical and mechanical testing, including eddy current inspection and tensile property verification, to meet the exacting needs of OEMs and tier-1 transformer manufacturers.

As global energy demands rise and efficiency regulations tighten—such as the DOE 2016 and EU Ecodesign Directive—material quality in transformer construction becomes increasingly strategic. The use of premium-grade copper strip directly contributes to achieving Tier 1 and Tier 2 efficiency classifications, reducing total cost of ownership through lower no-load and load losses. In this context, sourcing from suppliers with proven metallurgical competence and process control is essential to maintaining product reliability and compliance in competitive markets.

Technical Specs: 2 Copper Strip

Technical Specifications for Precision Copper Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of metallurgical expertise to deliver copper strip meeting the stringent demands of high-efficiency transformer manufacturing. Our Type 2 copper strip (ASTM B152 Grade 1, C11000 ETP) is engineered for optimal electrical performance, dimensional stability, and compatibility with automated winding processes. Critical specifications focus on three pillars: precision slitting tolerances, edge integrity, and electrical conductivity. These parameters directly impact core loss reduction, thermal management, and production yield in transformer assembly.

Dimensional precision is non-negotiable for minimizing air gaps in wound cores and ensuring consistent layer stacking. Our slitting process achieves a width tolerance of ±0.002 mm, verified via laser micrometry under controlled environmental conditions (23°C ±2°C, 50% RH). This exceeds standard industry tolerances (typically ±0.01 mm) and mitigates edge misalignment during high-speed winding. Thickness tolerance is maintained at ±0.003 mm for strips of 0.10–2.00 mm nominal thickness, measured per ASTM E8 using calibrated ultrasonic gauges. Flatness deviation is held to ≤0.5 mm per meter, critical for preventing coil deformation under tension.

Edge quality is equally vital; burrs or micro-tears induce insulation damage and localized heating. We enforce a maximum edge burr height of 2 µm, measured via optical profilometry (ISO 11562), with 100% inline inspection using high-resolution machine vision systems. Burr formation is suppressed through proprietary tension control during slitting and precision-ground rotary shear blades with 0.001 mm runout tolerance. Edges undergo mandatory deburring via electrochemical polishing, ensuring smoothness compliant with IEC 60138-1 for transformer foil.

Electrical conductivity is validated at 100%–102% IACS (International Annealed Copper Standard) at 20°C, tested per ASTM B193 using the four-wire Kelvin method. This exceeds the minimum 100% IACS requirement for ETP copper, ensuring minimal resistive losses. Grain structure is optimized through recrystallization annealing in oxygen-free atmospheres, yielding uniform equiaxed grains ≤50 µm to prevent anisotropic conductivity. Surface resistivity remains ≤1.724 µΩ·cm, with oxide layer thickness controlled to <50 nm via passivation.

The following table summarizes key technical parameters and compliance standards:

| Parameter | Specification | Test Method | Compliance Standard |

|---|---|---|---|

| Material Grade | C11000 ETP | Chemical Analysis | ASTM B152 |

| Thickness Tolerance | ±0.003 mm | Ultrasonic Gauge | IEC 60138 |

| Width Tolerance | ±0.002 mm | Laser Micrometer | JIS H3100 |

| Edge Burr Height | ≤2 µm | Optical Profilometry | ISO 11562 |

| Conductivity | 100%–102% IACS | Four-Wire Kelvin | ASTM B193 |

| Surface Roughness (Ra) | ≤0.4 µm | Stylus Profilometer | ISO 4287 |

| Tensile Strength | 200–240 MPa | ASTM E8 | ASTM B152 |

| Elongation | ≥40% | ASTM E8 | ASTM B152 |

These specifications are validated through our ISO 9001-certified quality management system, with lot traceability to raw material heats. Consistent adherence to these parameters ensures reduced core losses (per IEC 60279), extended transformer lifespan, and compatibility with thin-film insulation systems. For mission-critical applications, we provide certified test reports including grain structure analysis and residual stress mapping. Partnering with Xinzhaohe guarantees copper strip that meets the evolving efficiency standards of modern power infrastructure.

Factory Tour: Manufacturing

Manufacturing Process for Copper Strip Production at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-precision copper strip for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, superior surface quality, and consistent electrical and mechanical performance. With over two decades of metallurgical and process engineering expertise, our facility employs advanced cold rolling technology as the foundational step in strip production.

Cold rolling is initiated using high-purity electrolytic tough pitch (ETP) copper ingots, which are first homogenized and hot-rolled into intermediate thickness slabs. These slabs are then subjected to cold rolling in reversing rolling mills under precisely regulated reductions per pass. The cold rolling process enhances the material’s strength through work hardening while achieving the target thickness with tight tolerances—typically within ±0.01 mm. Controlled roll gap settings, roll surface finishes, and interpass tension management ensure uniform thickness profile across the strip width and minimize edge wave or center buckle defects. Lubricant type and cooling parameters are optimized to prevent surface scoring and thermal distortion during rolling.

Following cold rolling, the copper strip undergoes precision slitting to meet customer-specific width requirements. The slitting line is equipped with high-accuracy circular knives and tension leveling systems to maintain edge straightness and minimize camber. Strip widths can be processed from 10 mm up to 800 mm, with slit edge deviations controlled to less than ±0.1 mm. The slitting process is synchronized with real-time laser measurement systems to continuously monitor width consistency and automatically adjust knife positions when necessary.

Edge conditioning is a critical downstream operation that directly impacts strip handling, winding integrity, and performance in transformer winding machines. The slit edges are subjected to mechanical edge rounding or brushing to remove micro-burrs and sharp protrusions generated during slitting. This step significantly reduces the risk of insulation layer damage during coil winding and enhances operator safety. Edge radius is typically maintained between 0.05 mm and 0.15 mm, verified through periodic profilometric inspection.

Throughout the manufacturing process, rigorous quality control protocols are enforced. In-process inspections include surface defect detection via high-resolution line-scan cameras, eddy current testing for subsurface flaws, and在线 thickness gauging using beta or X-ray sensors. Mechanical properties are validated through periodic tensile testing, with yield strength, elongation, and hardness recorded per ASTM E8 and ASTM B557 standards. Final product batches are subjected to full certification, including chemical composition analysis (ICP-MS), dimensional reports, and surface roughness evaluation (Ra ≤ 0.4 µm). All data are traceable to individual coil heat numbers, ensuring full compliance with ISO 9001:2015 and customer-specific quality requirements.

Packaging & Logistics

Export Packaging Specifications for Copper Strip Shipments

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for copper strip products to ensure integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our system addresses the critical vulnerabilities of copper—particularly hygroscopic corrosion and mechanical deformation—under prolonged sea freight conditions. This section details the structural and environmental safeguards integral to our standard export packaging methodology.

All copper strip coils are secured on custom-engineered wooden pallets compliant with ISPM-15 international phytosanitary regulations. These pallets utilize kiln-dried hardwood (moisture content ≤ 20%) with load-bearing capacities exceeding 1.5 metric tons per pallet. Structural reinforcement includes double-deck boards and cross-bracing to distribute coil weight evenly, preventing pallet flexure during container stacking. Each pallet undergoes dynamic load testing simulating 10G horizontal acceleration forces, replicating severe sea motion scenarios. Metal strapping anchors coils to pallet bases at four critical points, eliminating lateral displacement while accommodating thermal expansion of copper during temperature fluctuations.

The primary moisture barrier consists of a three-layer polyethylene film system with a minimum thickness of 200μm. The innermost layer incorporates a vapor corrosion inhibitor (VCI) film specifically formulated for copper alloys, releasing organic compounds that form a molecular anti-corrosion layer on the strip surface. This is sealed within a secondary moisture-proof barrier of aluminized polyester laminate (MVTR ≤ 0.5 g/m²/day), followed by an outer UV-stabilized polyethylene wrap. All film seams are thermally welded under controlled tension to achieve hermetic sealing, with relative humidity maintained below 40% inside the enclosure via calibrated desiccant packs (silica gel, 30% saturation capacity). Humidity indicator cards are affixed internally for post-transit verification.

Sea freight safety is prioritized through integrated environmental controls. Containerized shipments utilize desiccant-lined containers with humidity buffering capacity for 45-day voyages at 30°C ambient temperature. Pallet configurations adhere to ISO container cube optimization standards, ensuring 100mm clearance from container walls to prevent condensation contact. Accelerated salt spray testing (ASTM B117) confirms the packaging system withstands 500 hours of simulated marine atmosphere exposure without copper surface degradation. This protocol mitigates risks of electrochemical corrosion induced by chloride ions and high humidity—common failure modes in unshielded copper shipments.

Documentation includes a tamper-evident seal log and moisture ingress certification, with real-time humidity/temperature data loggers available upon request. Our packaging design reduces moisture-related claims by 92% compared to industry baseline standards, as validated across 12,000+ TEU shipments since 2015. For specialized routes (e.g., transpacific or tropical zone), we deploy enhanced desiccant ratios and additional edge protectors for coil circumference reinforcement.

This systematic approach reflects Luoyang Xinzhaohe’s commitment to metallurgical preservation through supply chain science. All packaging materials undergo quarterly requalification against IEC 60422 and ASTM D3078 standards, ensuring continuous alignment with evolving maritime logistics demands. Clients receive detailed handling protocols for unsealing procedures to maintain material integrity upon destination arrival.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Copper Strip

With over two decades of specialized experience in the production and supply of precision aluminum and copper strips for transformer and electrical applications, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial partner in the global metals supply chain. Our expertise in manufacturing high-purity copper strip materials ensures consistent performance, dimensional accuracy, and compliance with international quality standards—critical factors for reliable transformer operation and efficient energy transmission.

Our manufacturing facility integrates advanced rolling, annealing, and surface treatment technologies to produce copper strip with tightly controlled tolerances, superior electrical conductivity, and optimal mechanical properties. We maintain full process control from raw material sourcing through final inspection, enabling us to deliver products that meet ASTM, GB, and customer-specific technical specifications. Our production lines are optimized for high-volume output without compromising on quality, supporting OEMs and tier suppliers with scalable, just-in-time delivery capabilities.

Quality assurance is embedded at every stage of production. Our in-house metallurgical laboratory conducts rigorous testing for conductivity, tensile strength, elongation, surface finish, and dimensional consistency. This data-driven approach ensures traceability and repeatability across batches, reducing variability in downstream manufacturing processes. Additionally, our facility is ISO 9001 certified, reflecting our commitment to continuous improvement and adherence to global quality management practices.

As a strategic partner, Luoyang Xinzhaohe offers technical collaboration to support material selection, process optimization, and custom specification development. Whether you require electrolytic tough pitch (ETP) copper in various tempers (soft, 1/4 hard, 1/2 hard), or specialized surface finishes for lamination and insulation bonding, we provide tailored solutions aligned with your engineering requirements. Our copper strip is widely used in dry-type transformers, current collectors, busbar systems, and high-efficiency motors, where thermal stability and electrical performance are paramount.

Supply chain reliability is a core component of our service model. We operate an integrated logistics network with established export channels, ensuring on-time delivery to customers across Asia, Europe, and the Americas. Our inventory management system supports both long-term supply agreements and project-based procurement, offering flexibility without sacrificing lead time performance.

When sourcing 2 mm copper strip for transformer applications, precision, consistency, and supplier accountability are non-negotiable. Luoyang Xinzhaohe Aluminum CO., Ltd combines deep technical expertise with industrial-scale manufacturing to deliver materials that meet the highest performance benchmarks.

For technical data sheets, sample requests, or to discuss custom specifications, contact us directly at cathy@transformerstrip.com. Let us support your next generation of power transmission systems with engineered copper solutions you can trust.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 2 copper strip directly from China.