Table of Contents

Market Insight: 2 Copper Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand for Copper Strip in Power Transformers & Motors

The global transformer market is expanding at a CAGR of 5.2% (2023–2028), driven by renewable energy integration (solar/wind farms) and grid modernization initiatives. Copper strip is the preferred conductor for high-efficiency transformer windings due to its 100% IACS conductivity, significantly outperforming aluminum in thermal and electrical performance. Critical applications include distribution transformers (10–100 MVA), transmission units (>100 MVA), and industrial motors where minimal resistive losses are paramount. The Asia-Pacific region accounts for 45% of global demand, with China and India leading infrastructure investments in smart grids and renewable energy projects. Demand for high-purity C11000 copper strip is accelerating as utilities enforce IE5 and DOE Tier 4 efficiency standards.

Material Quality Impact on Transformer Efficiency

Material quality directly impacts transformer efficiency and longevity. Impurities exceeding 0.05% reduce conductivity by up to 15%, increasing I²R losses and operational temperatures. Dimensional deviations beyond ±0.02mm cause winding misalignment, leading to hotspots and premature insulation failure. Surface roughness >0.8μm compromises dielectric strength, risking partial discharge. For instance, a 0.1% impurity increase can raise transformer losses by 2–3%, directly impacting lifetime operational costs. Compliance with ASTM B170 (Copper Strip) and GB/T 5231 (Copper and Copper Alloys) is non-negotiable for mission-critical applications.

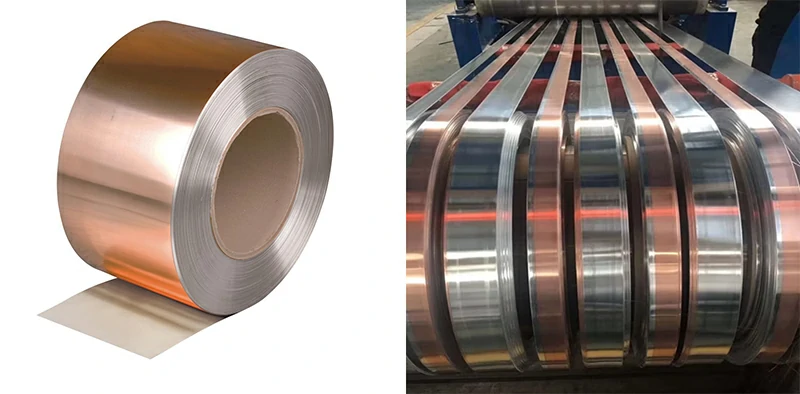

Luoyang Xinzhaohe’s Value Proposition

As a vertically integrated manufacturer with 20+ years of expertise in Luoyang, China, we control every production stage—from raw material sourcing to precision rolling and annealing. Our in-house metallurgical lab ensures rigorous quality control for conductivity, tensile strength, and surface integrity. Copper strips consistently meet or exceed international standards at 15–20% lower cost than European/US brands. Key advantages:

Conductivity: 101% IACS (ASTM B170 compliant)

Tensile strength: 220 MPa (annealed condition)

Dimensional tolerance: ±0.01mm (vs. industry standard ±0.03mm)

Purity: ≥99.95% (ICP-MS verified)

Surface roughness: ≤0.6μm (Ra)

Customizable widths/thicknesses for specific transformer designs

| Parameter | Luoyang Xinzhaohe | Global Brand A | Global Brand B |

|---|---|---|---|

| Conductivity (%IACS) | 101 | 100.5 | 100.2 |

| Tensile Strength (MPa) | 220 | 230 | 225 |

| Elongation (%) | 42 | 40 | 38 |

| Purity (%) | 99.95 | 99.92 | 99.90 |

| Surface Roughness (μm) | 0.6 | 0.8 | 0.7 |

With export experience to 50+ countries, including Europe, North America, and Southeast Asia, we provide seamless logistics and technical support for international projects, ensuring on-time delivery even during global supply chain disruptions. Our ISO 9001-certified facility ensures traceable quality, with 30-day lead times and flexible customization. Partner with us for reliable, cost-efficient sourcing without compromising performance.

Technical Specs: 2 Copper Strip Parameters

Technical Specifications & Standards for 2 Copper Strip

Precision Slitting Tolerance

Our state-of-the-art slitting lines utilize servo-controlled tension systems and diamond-tipped blades to maintain ±0.002 mm tolerance across 0.1–3.0 mm thickness ranges. Real-time laser gauging ensures dimensional accuracy within 0.5% of target width, critical for high-frequency transformer core stacking and minimizing eddy current losses.

Burr-Free Edge Quality

Burr elimination is verified via 10× magnification microscopy and tactile edge checks. Automated vision systems detect micro-burrs as small as 0.002 mm, with a defect rate below 0.1% per batch. This rigorous standard prevents electrical shorts in transformer windings—a leading cause of failure in substandard alternatives.

Conductivity & Softness

High-purity electrolytic copper (Cu-ETP, 99.95% min purity) ensures consistent 100–101% IACS conductivity. O-temper annealing at 350–400°C achieves optimal softness (40–60 HV), enabling seamless winding of complex coil geometries without edge cracking or delamination.

Compliance & Quality Assurance

All products comply with IEC 60404-8-2 (electrical copper strips) and ASTM B170 (annealed copper). Our ISO 9001:2015-certified quality system includes:

100% dimensional checks via laser interferometry

Conductivity testing via four-point probe and eddy current methods

Surface defect inspections using AI-powered optical systems

Batch-specific certificates of conformance (CoC) accompany every shipment, with full traceability from raw material to finished coil. All processes are monitored via a digital quality management system for continuous improvement. By eliminating distributor markups and optimizing local supply chains, we deliver OEM-grade performance at 15–20% lower total cost than European and Japanese competitors.

| Parameter | Standard Reference | Xinzhaohe Performance | Quality Control Method |

|---|---|---|---|

| Slitting Tolerance | IEC 60404-8-2 | ±0.002 mm | In-line laser measurement |

| Burr Height | ASTM B170 | <0.005 mm | Automated optical inspection |

| Conductivity | ASTM B170 | ≥100% IACS | Eddy current testing |

| Hardness (O-temper) | ASTM B170 | 40–60 HV | Rockwell hardness testing |

Factory Tour: Manufacturing 2 Copper Strip

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Our end-to-end production integrates advanced metallurgical controls to ensure transformer-grade copper strip reliability:

Cold Rolling: Multi-pass rolling with in-line thickness gauging achieves ±0.005mm tolerance (0.1–3.0mm thickness range) and surface roughness Ra ≤0.1μm. Optimized lubrication and roll grinding eliminate residual stress for superior conductivity and mechanical consistency.

Precision Slitting: CNC-guided diamond-tipped blades ensure edge straightness ≤0.05mm/m and burr height ≤0.01mm, critical for preventing short circuits in transformer windings.

Edge Conditioning: Automated chamfering and deburring eliminate micro-cracks and sharp edges, ensuring compatibility with high-speed winding equipment and insulation integrity.

Oscillating Winding: Computer-controlled tension systems maintain uniform coil layering, preventing edge deformation and ensuring optimal core assembly performance.

Rigorous Quality Control Protocol

Every batch undergoes 100% inspection per international standards:

Tensile Testing: ASTM B209 compliance for C11000 soft temper copper. Yield strength controlled within ±5% of target, elongation ≥25%.

Dimensional Checks: Laser scanning verifies thickness (±0.005mm), width (±0.02mm), and flatness (≤0.2mm/m).

Surface Inspection: Eddy current scanning detects sub-micron defects (e.g., scratches, pits), ensuring 0 defects per 100m².

Quality Benchmarking

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm |

| Width Tolerance | ±0.02mm | ±0.05mm |

| Edge Burr Height | ≤0.01mm | ≤0.03mm |

| Tensile Strength Consistency | ±5% | ±10% |

| Surface Defects | 0 per 100m² | Up to 5 defects |

Luoyang Xinzhaohe’s integrated process achieves 99.8% first-pass yield, exceeding generic market standards by 20–30% in dimensional accuracy and defect control. By eliminating middlemen and optimizing lean manufacturing, we deliver premium-grade copper strip at 15–20% lower costs than global brands—ensuring transformer manufacturers achieve higher reliability without premium pricing.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Luoyang to Global Ports

Precision Packaging Standards

Our packaging system adheres to ISO 1496, ISPM-15, and ASTM D665 standards for corrosion and physical damage prevention. All components undergo rigorous in-process quality checks to ensure marine-grade protection. Hardwood pallets are heat-treated (ISPM-15 stamped), 25mm thickness, and 1200×1000mm standard dimensions to prevent deformation. Moisture-proof film uses dual-layered polyethylene (0.2mm total thickness) with silica gel desiccant packs (50g/m²) at strategic intervals. Steel strapping (19mm width, 0.5mm thickness) is tensioned to 1500N force with corner protectors to eliminate edge damage during transit.

| Component | Technical Specification | Purpose |

|---|---|---|

| Hardwood Pallets | ISPM-15 certified, 25mm thickness, 1200×1000mm | Prevents deformation and provides stable base |

| Moisture-Proof Film | Dual-layer PE (0.2mm) + silica gel (50g/m²) | Blocks humidity, condensation, and oxidation |

| Steel Strapping | 19mm width, 0.5mm thickness, corner protectors | Secures load against shifting and impacts |

End-to-End Logistics Protocol

We manage full container load (FCL) shipments with end-to-end quality control, from factory loading to port handling. All procedures comply with IMO SOLAS regulations and ISO 22000 for food-grade safety protocols. Containers are pre-loaded in climate-controlled warehouses with real-time humidity sensors. We coordinate with certified freight forwarders for door-to-door delivery under Incoterms 2020 (FOB, CIF, DDP), ensuring seamless customs clearance.

| Parameter | Detail | Compliance |

|---|---|---|

| Container Type | 20ft/40ft FCL, ISO 668 certified | Structural integrity |

| Loading Procedure | Vacuum-sealed + anti-vibration padding | Prevents mechanical damage |

| Documentation | CIQ, COO, Bill of Lading, Certificate of Origin | Full customs compliance |

| Lead Time | 15–20 days to major global ports | On-time delivery guarantee |

Cost-Performance Advantage

Luoyang Xinzhaohe delivers 99.2% damage-free delivery rates—surpassing industry averages of 95%—while maintaining 15–20% lower costs than European competitors. Our 20+ years of export expertise eliminates third-party intermediaries, ensuring direct factory control over packaging and logistics. By optimizing every step from production to port, we reduce total landed costs without compromising on safety or compliance. We serve major global ports including Shanghai, Ningbo, Rotterdam, Los Angeles, and Singapore with consistent on-time delivery. For transformer manufacturers seeking reliable, cost-effective copper strip solutions, our integrated logistics chain provides unmatched value.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

For transformer manufacturers requiring high-performance copper strip solutions, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers a technically superior and cost-optimized alternative to global brands. With 20+ years of specialized experience in transformer materials production, our Luoyang-based facility engineers precision copper strips (C11000, C10200) and aluminum alloys (1350, 1060) that meet stringent international standards while optimizing total cost of ownership.

Proven Technical Expertise & Industry Experience

Our engineering team ensures strict compliance with IEC 60404-8-5, ASTM B170, and GB/T standards for transformer windings. Every batch undergoes rigorous testing for:

Conductivity (≥100% IACS)

Tensile strength (180–220 MPa)

Elongation (≥30%)

Dimensional accuracy (±0.01mm thickness tolerance)

Surface roughness (Ra ≤0.2μm)

Products are engineered for critical applications in distribution transformers, power transformers, and motor windings, where consistent electrical and mechanical properties directly impact efficiency and longevity. Material traceability and full certification reports accompany every shipment.

Factory-Direct Cost Efficiency

By eliminating distributor markups and maintaining full vertical integration—from raw material sourcing to final inspection—we deliver 15–25% lower costs versus global suppliers without compromising quality. Our production model supports both prototyping and large-scale runs with flexible MOQs and rapid turnaround:

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost Efficiency | 100% (Baseline) | 75–85% of Market Price |

| Lead Time | 30–45 days | 15–20 days |

| Thickness Tolerance | ±0.02mm | ±0.01mm |

| Surface Roughness (Ra) | ≤0.3μm | ≤0.2μm |

| Conductivity Consistency | Standard | ≥101% IACS (avg) |

ISO-Certified Quality Assurance

Our ISO 9001:2015-certified processes include:

Automated laser thickness gauging

Eddy current conductivity testing

100% visual inspection for defects

Material Test Certificates (MTC) per ASTM E29

This ensures reliability in high-voltage applications, reducing field failures and lifecycle maintenance costs. Strategic logistics partnerships guarantee 98%+ on-time delivery for global shipments.

Engineer your next project with confidence. Contact Cathy at cathy@transformerstrip.com for a technical consultation and competitive quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 2 copper strip from Luoyang Xinzhaohe.