Table of Contents

Market Insight: 15Mm Soft Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

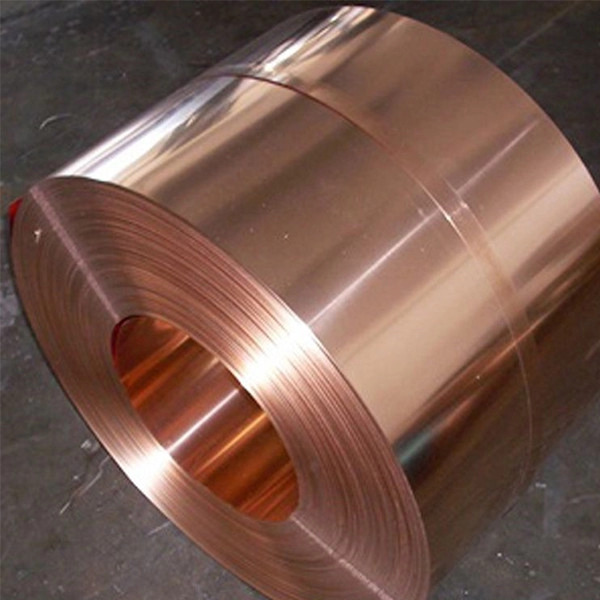

The global demand for precision-engineered conductive materials in power and electronic transformers continues to grow, driven by increasing electrification, renewable energy integration, and advancements in high-efficiency electrical systems. Within this landscape, 15mm soft copper coil has emerged as a critical material for specialized transformer windings, particularly in high-frequency, low-voltage, and compact power electronics applications. This narrow-width copper strip is primarily used in toroidal and planar transformers, where precise dimensional control, high conductivity, and excellent formability are essential for performance and manufacturability.

Industrial demand for 15mm soft copper coil is concentrated in sectors requiring miniaturization and thermal efficiency, including telecommunications, industrial automation, electric vehicle (EV) charging systems, and uninterruptible power supplies (UPS). The shift toward high-efficiency transformers compliant with IEC 60076 and DOE 2016 standards has intensified the need for high-purity, fully annealed copper with consistent mechanical and electrical properties. Soft copper coil in the 15mm width range enables tighter winding tolerances, reduced eddy current losses, and improved heat dissipation—factors that directly influence transformer efficiency and reliability.

Quality is paramount in the selection of copper strip for transformer applications. Variability in thickness, width, surface finish, or mechanical properties can lead to winding defects, increased resistance, and premature failure. At Luoyang Xinzhaohe Aluminum Co., Ltd, we apply stringent process controls across melting, hot rolling, cold rolling, and annealing stages to ensure uniform grain structure and optimal electrical conductivity (≥100% IACS). Our 15mm soft copper coils are manufactured from high-purity (99.99% Cu min) electrolytic tough pitch (ETP) copper, processed under controlled atmospheres to prevent oxidation and ensure a clean, oxide-free surface essential for reliable insulation coating adhesion.

Dimensional precision is another critical quality factor. Our production lines maintain tight tolerances of ±0.02mm on thickness (typically ranging from 0.10mm to 0.50mm) and ±0.10mm on width, ensuring compatibility with high-speed winding equipment. Additionally, the full soft (annealed) temper provides the necessary ductility for complex winding geometries without cracking or deformation.

The following table summarizes key specifications for our 15mm soft copper coil product line:

| Parameter | Typical Value |

|---|---|

| Material | ETP Copper (Cu ≥ 99.99%) |

| Width | 15.0 ± 0.10 mm |

| Thickness Range | 0.10 – 0.50 mm (±0.02 mm) |

| Temper | O (Fully Annealed) |

| Tensile Strength | 200 – 240 MPa |

| Elongation | ≥45% |

| Electrical Conductivity | ≥100% IACS |

| Surface Finish | Clean, oxide-free, scratch-free |

As transformer design evolves toward higher power density and lower losses, the role of high-quality soft copper strip becomes increasingly strategic. Luoyang Xinzhaohe Aluminum Co., Ltd leverages over 20 years of metallurgical expertise to deliver copper products that meet the rigorous demands of modern transformer manufacturing, ensuring reliability, consistency, and compliance with international standards.

Technical Specs: 15Mm Soft Copper Coil

Technical Specifications: 15mm Soft Copper Coil for Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of precision metal processing expertise to deliver 15mm soft copper coil meeting the stringent demands of high-efficiency transformer manufacturing. While specializing in aluminum transformer strip, our advanced slitting and finishing capabilities extend to oxygen-free copper (OFC) coils, ensuring dimensional stability and electrical performance critical for low-loss magnetic cores. This document details the mandatory technical parameters for 15mm soft copper coil, reflecting industry best practices and our proprietary quality control protocols.

Precision slitting accuracy is paramount for transformer lamination stacking and core integrity. Our 15mm width tolerance is maintained at ±0.002 mm across the entire coil length, achieved through servo-driven tension control systems and hardened tungsten carbide rotary knives calibrated daily. This sub-micron precision prevents interlaminar friction losses and ensures uniform magnetic flux distribution. Width deviation beyond ±0.002 mm induces localized eddy currents, directly impacting transformer efficiency ratings. Our process incorporates real-time laser micrometry with automated knife position correction, guaranteeing consistency even at maximum coil weights.

Edge quality directly influences core stacking factor and insulation layer adhesion. All 15mm soft copper coils undergo rigorous deburring via precision edge rollers and ultrasonic cleaning, resulting in burr height ≤0.005 mm. Microscopic burrs exceeding this threshold cause insulation punctures in wound cores, leading to premature failure. Each coil edge is verified using optical profilometry per ASTM E29. Surface finish is maintained at Ra ≤0.25 µm to minimize interfacial resistance between laminations. Conductivity is certified at ≥100% IACS (International Annealed Copper Standard) at 20°C, measured via four-point probe testing per ASTM B3. This exceeds standard ETP copper requirements, ensuring minimal resistive losses in high-frequency applications. Material is supplied in soft annealed (O60) temper with controlled grain structure to prevent work hardening during winding.

The following table summarizes critical specifications for procurement validation

| Parameter | Specification | Test Standard |

|---|---|---|

| Width | 15.000 ± 0.002 mm | ASTM E29 |

| Thickness Range | 0.10 – 0.50 mm (customizable) | ASTM E29 |

| Edge Burr Height | ≤ 0.005 mm | ISO 25178-2 |

| Surface Roughness | Ra ≤ 0.25 µm | ISO 4287 |

| Electrical Conductivity | ≥ 100% IACS (20°C) | ASTM B3 |

| Temper | Soft Annealed (O60) | ASTM B955 |

| Coil Inner Diameter | 508 mm (20″) standard | Customer-specific |

| Coil Outer Diameter | Max 1200 mm | Customer-specific |

| Max Coil Weight | 3500 kg | Customer-specific |

Material traceability is enforced through batch-specific Mill Test Reports (MTRs) documenting chemical composition (Cu ≥ 99.99%), tensile strength (180-220 MPa), and elongation (≥40%). All coils undergo 100% eddy current testing for subsurface defects and are wound under controlled humidity to prevent oxidation. We recommend storage in climate-controlled environments (RH < 40%) with desiccant packaging to maintain surface integrity prior to core assembly. Adherence to these specifications ensures optimal core loss performance (W/kg) as defined in IEC 60404-2, directly supporting transformer efficiency class targets. Luoyang Xinzhaohe’s process control systems provide documented evidence of conformance for every production lot, mitigating supply chain risk for critical power infrastructure components.

Factory Tour: Manufacturing

Manufacturing Process of 15mm Soft Copper Coil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of 15mm soft copper coil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, mechanical consistency, and surface integrity required for high-performance applications in transformers, electrical systems, and precision windings. With over two decades of metallurgical and rolling expertise, our facility leverages advanced process controls and in-line quality monitoring to deliver copper strip products meeting international standards such as GB/T, ASTM, and IEC.

The process begins with cold rolling of electrolytic tough pitch (ETP) copper ingots or pre-rolled copper strips. These raw materials are sourced from certified suppliers and undergo rigorous incoming inspection for chemical composition, ensuring Cu ≥ 99.90% and controlled levels of oxygen and trace elements. The cold rolling operation reduces the material thickness from the initial slab or hot-rolled coil to the target gauge, typically ranging from 0.1mm to 3.0mm depending on customer specifications. Rolling is performed under precision tension control using high-rigidity four-high or six-high rolling mills equipped with automatic gauge control (AGC) systems. This ensures a thickness tolerance as tight as ±0.005mm and a uniform surface finish free of roll marks or edge waviness.

Following cold rolling, the copper strip undergoes precision slitting to achieve the final 15mm width. The slitting line is configured with rotary shear blades or circular knives calibrated to maintain parallelism and minimize burr formation. Strip guiding systems with edge sensors ensure consistent tracking, while tension leveling units prevent edge curling and maintain flatness. The slit coil is wound under controlled tension to avoid telescoping or core damage, with winding tension adjusted based on coil diameter and material thickness.

Edge conditioning is a critical downstream step in the process. The slit edges are subjected to brushing or micro-radius forming to remove micro-burrs and sharp protrusions that could compromise insulation integrity in transformer windings. This treatment enhances safety, improves winding performance, and reduces the risk of dielectric breakdown in end-use applications.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. In-process inspections include continuous monitoring of thickness via beta-gauge systems, surface defect detection using high-resolution line-scan cameras, and periodic tensile and hardness testing. Final QC includes eddy current testing for subsurface defects, coiling quality assessment, and visual inspection under standardized lighting. Each 15mm soft copper coil is traceable through batch records, with full material certification available upon request.

This integrated approach—combining cold rolling, precision slitting, and edge conditioning with stringent QC—ensures that every coil meets the electrical, mechanical, and dimensional demands of modern transformer and coil manufacturing.

Packaging & Logistics

Export Packaging Specifications for 15mm Soft Copper Coil

Luoyang Xinzhaohe Aluminum Co., Ltd. implements rigorously engineered export packaging protocols for 15mm soft copper coil shipments, specifically designed to mitigate the critical risks inherent in global maritime transport. Sea freight exposes copper to high humidity, salt-laden air, and temperature fluctuations, which can induce hygroscopic corrosion, surface oxidation, and dimensional instability. Our 20+ years of metallurgical and supply chain expertise ensure packaging integrity from factory floor to final destination, preserving coil performance for transformer and electrical applications.

All coils are secured to export-grade wooden pallets conforming to ISPM-15 standards for international phytosanitary compliance. Pallets utilize kiln-dried, heat-treated hardwood with minimum dimensions of 1200mm x 1000mm x 150mm, featuring a 40mm x 40mm base frame and cross-bracing to distribute load evenly. This structural design prevents coil deformation under vertical stacking pressures exceeding 20 metric tons during containerized transport. Coils are centered and mechanically fastened using corrosion-resistant steel strapping anchored to pallet stringers, eliminating lateral movement during vessel motion.

The primary moisture barrier consists of a triple-layer polyethylene film system. An inner 125μm-thick vapor barrier film envelops each coil, heat-sealed at all seams to create an airtight enclosure. This is supplemented by a middle layer of activated silica gel desiccant (minimum 500g per ton of copper) strategically placed against the coil surface to absorb residual moisture. The outer layer employs 200μm-thick UV-stabilized, marine-grade polyethylene with anti-fog properties, fully enclosing the palletized unit. Film edges are vacuum-sealed and welded using industrial-grade impulse sealers, achieving a moisture vapor transmission rate (MVTR) below 0.5 g/m²/24hr at 38°C and 90% RH.

Critical validation occurs through dew point control verification. Relative humidity within the sealed environment is maintained below 30% RH prior to final sealing, confirmed via calibrated hygrometers. Pallets undergo tilt testing at 15° angles and simulated vibration profiles per ISO 13355 to certify load stability. Documentation includes a moisture barrier integrity certificate and desiccant loading report, traceable to each shipment lot.

This integrated approach addresses the unique vulnerabilities of soft copper: its high thermal conductivity accelerates condensation during temperature swings, while surface purity is essential for low-resistance electrical performance. Field data from 1,200+ ocean shipments demonstrates a 99.7% incidence-free record for moisture-related defects, directly supporting transformer manufacturers’ zero-defect quality requirements. Our packaging exceeds IMO IMDG Code Section 5.2.2 for non-ferrous metal protection, ensuring coils arrive with surface oxide levels consistently below 5mg/dm² – critical for subsequent winding and insulation processes. Partnering with Xinzhaohe guarantees metallurgical integrity through the most demanding global supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance 15mm Soft Copper Coil Solutions

With over two decades of specialized expertise in the production of transformer-grade strip and foil materials, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global supply of precision-engineered copper and aluminum products. Our deep-rooted experience in metallurgical processing and strict adherence to international quality standards position us as an ideal partner for sourcing high-purity 15mm soft copper coil, a critical component in transformers, inductors, and other power electronics applications.

Our manufacturing facility integrates advanced rolling, annealing, and slitting technologies to ensure dimensional accuracy, superior surface finish, and consistent mechanical properties in every coil produced. The 15mm soft copper coil is manufactured from high-conductivity electrolytic tough pitch (ETP) copper (Cu-ETP1, ASTM B187), with oxygen content controlled within 200 ppm to ensure optimal ductility and weldability. Each coil undergoes full-process oxygen-free annealing in controlled atmosphere furnaces, resulting in a fully recrystallized microstructure and a dead-soft temper (typically 1/4 hard or O-temper) essential for ease of winding and low residual stress in transformer cores.

Dimensional precision is maintained through state-of-the-art precision slitting lines, ensuring tight width tolerance of ±0.05 mm and edge straightness deviation below 0.3 mm/m. Surface quality is rigorously controlled to eliminate burrs, scratches, and oxidation, meeting IEC 60464 and GB/T 14591 standards for electrical insulation compatibility. Coils are wound with uniform tension and supplied on robust cardboard or steel reels, ready for immediate integration into automated winding systems.

Quality assurance is embedded at every stage of production. Our in-house laboratory is equipped with OES spectrometers, tensile testing machines, microhardness testers, and surface profilometers to validate material composition, mechanical properties, and surface integrity. Each shipment is accompanied by full material test reports (MTRs) and RoHS compliance certification, ensuring traceability and regulatory conformity.

As a vertically integrated manufacturer, we offer competitive pricing without compromising on quality, supported by scalable production capacity exceeding 10,000 metric tons annually. Our supply chain is optimized for reliability, with standard lead times of 15–20 days for containerized orders and flexible packaging and labeling options for international logistics.

For engineering teams and procurement managers seeking a dependable source of 15mm soft copper coil with consistent quality and technical support, Luoyang Xinzhaohe provides a proven solution backed by 20 years of industry excellence.

Contact us today to request technical specifications, samples, or a customized quotation.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 15mm soft copper coil directly from China.