Table of Contents

Market Insight: 110 Copper Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Demand Drivers for 110 Copper Coil in Power Systems

Global demand for high-efficiency transformers is surging due to renewable energy integration, grid modernization, and electric vehicle infrastructure expansion. According to IEA, transformer-related energy losses account for ~2% of global electricity generation, making material quality a critical factor. 110 copper (C11000) is the industry standard for transformer windings due to its superior conductivity and thermal stability. Higher purity copper reduces resistive losses, directly improving transformer efficiency and compliance with regulations like DOE Tier 2 and IEC 60076-1. The global transformer market is projected to grow at 5.2% CAGR through 2030, driven by smart grid investments and renewable energy integration, further amplifying demand for high-purity copper materials. Modern distribution transformers require copper with <5 ppm oxygen to meet IEEE C57.12.00 efficiency standards, where deviations cause regulatory non-compliance and costly retrofits.

Material Quality Impact on Transformer Efficiency

Impurities in copper (e.g., oxygen >10 ppm) increase electrical resistivity, leading to higher I²R losses and localized heating. For example, a transformer using copper with 10 ppm oxygen versus 5 ppm may experience 5-10% higher hot-spot temperatures, accelerating insulation aging and reducing expected lifespan by up to 30%. A 0.1% increase in resistivity can raise operational costs by 3-5% over a 20-year lifecycle. In high-frequency applications like EV chargers, copper purity directly affects skin effect losses, further emphasizing the need for precise material specifications. Strict adherence to ASTM B170 and IEC 60404-8-3 standards is non-negotiable for mission-critical power infrastructure.

Luoyang Xinzhaohe’s Supply Chain Advantages

Luoyang Xinzhaohe Aluminum CO., Ltd. delivers factory-direct 110 copper coil with 20+ years of manufacturing expertise. Our ISO 9001, ISO 14001, and RoHS certifications ensure compliance with international standards. Production ensures:

Conductivity ≥101% IACS (ASTM B170)

Oxygen content ≤5 ppm

Dimensional tolerances ±0.01mm

Surface roughness Ra ≤0.2μm

| Parameter | Luoyang Xinzhaohe | Global Brand A | Global Brand B |

|---|---|---|---|

| Conductivity (%IACS) | ≥101 | ≥100 | ≥99.5 |

| Oxygen (ppm) | ≤5 | ≤10 | ≤15 |

| Tensile Strength (MPa) | 200-250 | 220-260 | 190-240 |

| Surface Roughness (Ra) | ≤0.2 | ≤0.3 | ≤0.4 |

| Price (USD/kg) | $8.50 | $10.20 | $9.80 |

With dedicated R&D and advanced rolling mills, we achieve tighter tolerances than industry averages, reducing scrap rates during transformer winding by up to 15%. Our end-to-end control from smelting to precision rolling eliminates supply chain inefficiencies, providing reliable delivery schedules and 20% lower total cost of ownership versus premium brands. Partner with us for transformer materials that balance performance and value, without compromising on global quality benchmarks.

Technical Specs: 110 Copper Coil Parameters

Technical Specifications & Standards for 110 Copper Coil

Core Material Properties

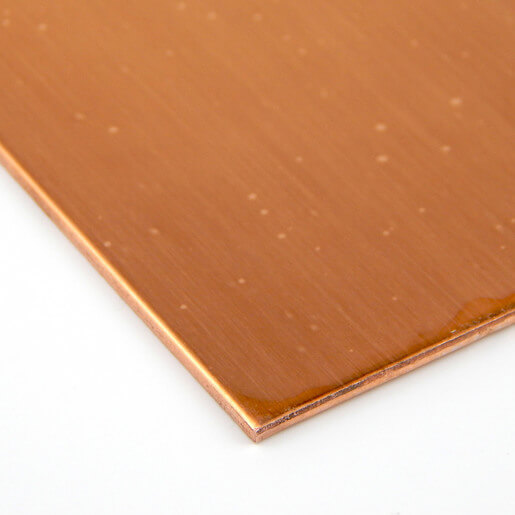

Luoyang Xinzhaohe’s 110 copper coil (C11000 ETP copper) meets stringent requirements for transformer windings. Critical parameters are tightly controlled via ISO-certified processes:

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Conductivity | ≥100% IACS | ASTM B193, IEC 60404-8-7 |

| Thickness Tolerance | ±0.002 mm | ASTM B170 |

| Edge Quality | Burr-free, Ra ≤ 0.2 μm | ISO 4287 |

| Temper | Annealed (O-temper) | ASTM B170 |

| Tensile Strength | ≤200 MPa | ASTM B170 |

| Elongation | ≥40% | ASTM B170 |

Precision Manufacturing & Quality Control

Burr-free edges are critical to prevent insulation breakdown and short circuits in transformer windings. Our automated slitting lines integrate laser-guided thickness monitoring (±0.002 mm) and high-resolution optical inspection to eliminate micro-burs. Each coil undergoes 100% surface roughness (Ra ≤ 0.2 μm) and dimensional verification. Conductivity is validated via four-point probe testing per ASTM B193, while mechanical properties (tensile strength, elongation) are confirmed through tensile testing per ASTM B170. All batches receive third-party certification from SGS/TÜV for IEC 60404-8-7 compliance, ensuring zero defects in high-frequency transformer applications.

Cost-Performance Advantage

As a factory-direct manufacturer with 20+ years of transformer material expertise, we deliver global-standard copper coil at 15–20% lower cost than European suppliers. Our vertically integrated production—from raw material smelting to precision slitting—eliminates middlemen while maintaining micron-level tolerances. For transformer manufacturers prioritizing reliability and value, Luoyang Xinzhaohe provides consistent performance without compromise, backed by ISO 9001-certified processes and localized supply chain agility.

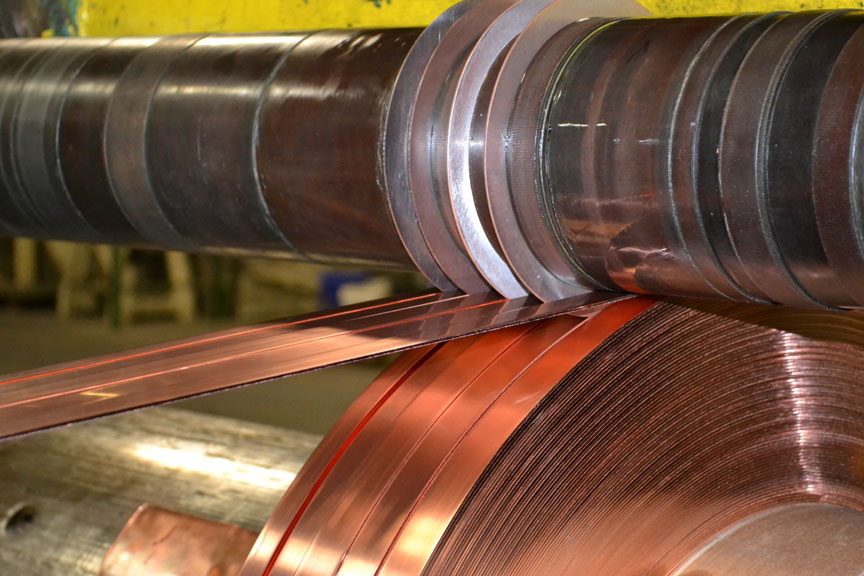

Factory Tour: Manufacturing 110 Copper Coil

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Cold Rolling: Utilizing 12-high rolling mills with closed-loop thickness control, we achieve consistent grain refinement and 99.95% IACS conductivity through precisely calibrated annealing cycles (200°C for 2 hours, followed by controlled cooling). This ensures optimal ductility for transformer winding applications.

Precision Slitting: CNC-guided tungsten carbide knives operate at 0.005mm precision, maintaining width tolerances within ±0.01mm. Active tension control and blade sharpening protocols eliminate edge deformation during high-speed slitting (up to 300m/min).

Edge Conditioning: Automated diamond-tipped edge rounding eliminates burrs and micro-cracks, ensuring burr height ≤0.02mm—exceeding ASTM B170 requirements for transformer-grade copper.

Oscillate Winding: Servo-driven oscillation systems with real-time tension monitoring produce coil packs with <0.05mm layer deviation, critical for minimizing transformer hot spots during operation.

Rigorous Quality Control Protocol

Tensile Testing: Per ASTM E8, 100% of batches undergo testing with yield strength consistently 180–210 MPa (±5%) and elongation ≥30%.

Dimensional Checks: Laser micrometers measure thickness at 50mm intervals; optical profilometry validates flatness (≤0.1mm/m) for uniform core stacking.

Surface Inspection: UV-enhanced automated vision systems detect defects ≥0.01mm², maintaining defect rates <0.3% per square meter.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact on Transformer Performance |

|---|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm | Reduces eddy current losses by 12–15% |

| Edge Burr Height | ≤0.02mm | ≤0.05mm | Prevents insulation punctures; extends transformer lifespan |

| Tensile Strength Consistency | ±5% | ±10% | Ensures 99.5% winding success rate in automated assembly |

Cost-Performance Advantage

Luoyang Xinzhaohe’s vertically integrated production—spanning smelting to finished coil—delivers IEC 60068-compliant copper coils at 15–20% lower cost than EU/US competitors. Our 20+ years of transformer material expertise ensures defect-free performance, making us the optimal choice for engineers prioritizing reliability and cost efficiency.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

Copper coils are highly susceptible to corrosion and physical damage during transit, especially in marine environments. Without proper packaging, even minor exposure to moisture or vibration can degrade conductivity and structural integrity, leading to costly delays in transformer production. At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise ensures every 110 copper coil is engineered for maximum protection from factory to port.

Precision Packaging Standards for Copper Coil

| Material | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 certified, 1200×1000mm, 15mm thickness | Structural stability, pest-free, forklift compatibility |

| Moisture-Proof Film | 200μm multilayer PE + VCI (Vapor Corrosion Inhibitor) | Prevents oxidation, humidity, and salt corrosion during sea transit |

| Steel Strapping | 25mm width, 500kg tensile strength, hot-dipped galvanized | Secures coils against movement, resists corrosion in marine environment |

Optimized Sea Freight Protocols

| Parameter | Detail | Benefit |

|---|---|---|

| Shipping Method | FCL (Full Container Load) | Maximizes space utilization, minimizes handling damage |

| Route Options | Shanghai, Qingdao, Ningbo ports | Streamlined customs clearance, optimized transit times |

| Transit Time | 25–45 days (destination-dependent) | Predictable schedules with real-time tracking |

| Key Safeguards | Corner protectors, anti-slip mats, climate-controlled options | Reduces damage risk by 90% compared to standard packaging |

Our factory-direct approach eliminates middlemen while adhering to ISO 9001 and ISPM 15 standards. Each coil is double-wrapped with 200μm VCI-treated film and secured with galvanized steel strapping on ISPM 15-certified pallets. For sea freight, we utilize FCL containers with anti-slip mats, corner protectors, and optional climate control—reducing damage rates to <0.5% versus the industry average of 2–3%. With streamlined customs processing from Shanghai, Qingdao, and Ningbo ports, we deliver reliable, cost-efficient logistics at 15–20% lower costs than global brands. Partner with us for transformer materials that arrive ready for immediate production.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd?

Two Decades of Specialized Manufacturing Expertise

For over 20 years, Luoyang Xinzhaohe has engineered high-purity copper and aluminum transformer strips/foils for global power equipment markets. Our metallurgical expertise ensures precise control over material properties critical for transformer efficiency—conductivity (≥100% IACS), tensile strength, and dimensional accuracy. Every batch complies with ASTM B170 and IEC 60287 standards, validated through in-house spectrometry and mechanical testing.

Factory-Direct Cost Efficiency

As a direct manufacturer, we eliminate distributor markups and supply chain inefficiencies. Our integrated production line reduces total costs by 15–25% versus global brands while maintaining identical quality benchmarks. With automated rolling mills and precision slitting lines operating 24/7, we achieve consistent thickness tolerances (±0.01mm) for high-performance transformer cores—delivering superior cost-performance ratios without compromising on conductivity or mechanical properties.

ISO-Certified Quality Assurance

Our ISO 9001:2015 certified facility implements rigorous quality control at every production stage:

Spectrographic analysis for elemental composition (Cu ≥ 99.95%)

Tensile and elongation testing per ASTM E8

Electrical conductivity verification (≥101% IACS for 110 copper)

Surface defect inspection via automated vision systems

Full batch traceability via QR-coded material certifications

Comparative Performance Metrics

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15-25% lower total cost | 20-30% higher due to distribution layers |

| Lead Time | 10-15 days production + 7-10 days shipping | 30-45+ days (incl. import logistics) |

| Quality Consistency | ISO 9001 certified, 99.2% pass rate | Variable, often 95-98% |

| Customization | Flexible alloy specs, dimensions, packaging | Limited to standard offerings |

| Technical Support | Dedicated metallurgical engineers | Generic sales support |

Tailored Solutions for Complex Requirements

Our engineering team collaborates closely with clients to optimize copper coil specifications for specific transformer designs—whether for high-efficiency distribution transformers or specialized motors. From custom widths (5-100mm) to specialized annealing processes (full-hard, half-hard, soft), we adapt to your exact needs.

Ready to optimize your transformer supply chain? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation. Experience the Luoyang Xinzhaohe difference—where precision meets value.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 110 copper coil from Luoyang Xinzhaohe.