Table of Contents

Market Insight: 10Mm Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

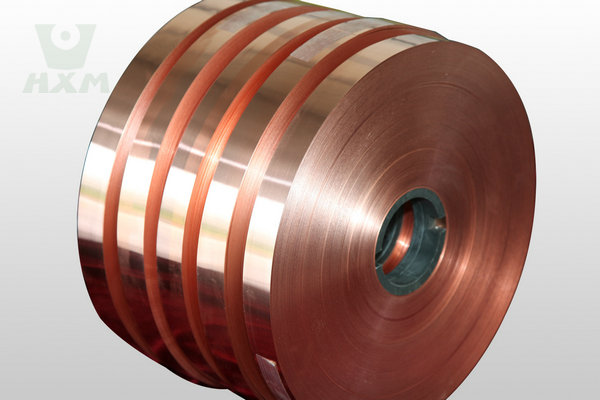

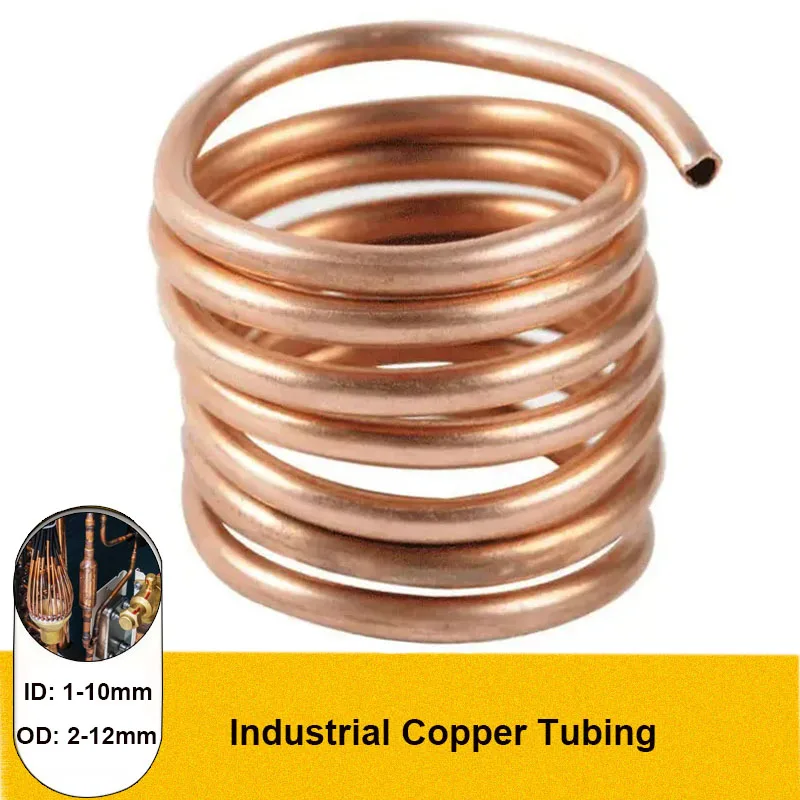

The global demand for 10mm copper coil in transformer manufacturing continues to grow, driven by the expansion of power infrastructure, renewable energy integration, and the increasing efficiency requirements of modern electrical systems. Copper strip, particularly in 10mm width, is a critical material used in the windings of distribution and power transformers due to its superior electrical conductivity, thermal stability, and mechanical formability. While aluminum is often used as a cost-effective alternative, copper remains the preferred choice in high-efficiency and high-reliability applications where performance cannot be compromised.

Industrial demand for 10mm copper coil is particularly strong in regions undergoing grid modernization, such as Southeast Asia, the Middle East, and parts of Africa, as well as in developed markets investing in smart grid technologies and electric vehicle charging infrastructure. The precise dimensional control of 10mm strip ensures consistent winding tension and reduced interlayer gaps, directly contributing to lower eddy current losses and improved thermal management in transformer cores. This precision is essential for compliance with international efficiency standards such as IEC 60076 and DOE 2016.

Quality in copper strip production is paramount. Variations in thickness tolerance, surface finish, or mechanical properties can lead to localized hotspots, insulation breakdown, or premature transformer failure. High-purity electrolytic tough pitch (ETP) copper with oxygen content tightly controlled between 100–300 ppm ensures optimal conductivity and weldability. Moreover, the strip must exhibit uniform tensile strength and elongation characteristics to withstand the stresses of continuous winding processes without cracking or deformation.

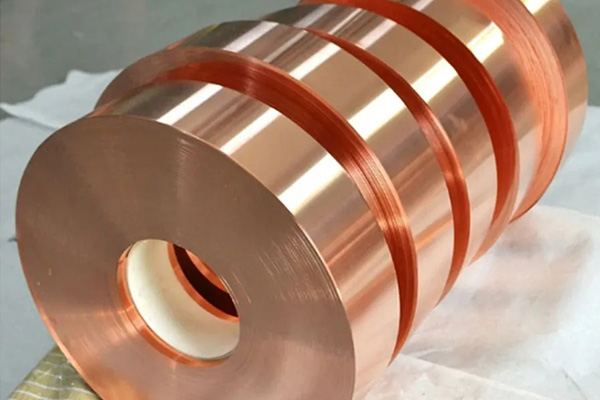

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in non-ferrous strip manufacturing, we apply stringent quality control protocols throughout the production cycle. Our 10mm copper coil undergoes cold rolling with precision-ground rolls, intermediate and final annealing in controlled atmospheres, and inline surface inspection to eliminate defects such as scratches, pits, or oxide inclusions. Dimensional tolerances are maintained within ±0.02mm for thickness and ±0.1mm for width, ensuring compatibility with high-speed winding equipment used in automated transformer production lines.

The shift toward energy-efficient transformers (e.g., amorphous metal and high-temperature insulation classes) further elevates the performance expectations for conductive materials. In such designs, even minor inconsistencies in copper strip quality can undermine the efficiency gains achieved through advanced core materials. Therefore, sourcing from a reliable, technically capable supplier is not merely a procurement decision—it is a critical factor in the long-term reliability and performance of the transformer.

As the industry moves toward digitalization and predictive maintenance, the traceability of materials becomes increasingly important. Our production system supports full batch traceability, including mechanical test data, chemical composition reports, and process parameters, enabling customers to meet stringent certification requirements and reduce time-to-market for new transformer models.

Technical Specs: 10Mm Copper Coil

Technical Specifications: 10mm Copper Coil for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. provides this technical guide based on 20+ years of precision strip and foil manufacturing expertise. While our core production focuses on aluminum transformer materials, our supply chain and metallurgical engineering teams routinely qualify copper coil suppliers for critical applications. This specification outlines non-negotiable parameters for 10mm width copper coil used in high-efficiency transformer windings, where dimensional accuracy and electrical performance directly impact core losses and thermal management.

Precision slitting to 10.000 mm width is paramount, with a maximum tolerance of ±0.002 mm. This tight tolerance ensures consistent layer stacking in wound cores, minimizing air gaps that increase magnetic reluctance and eddy current losses. Achieving this requires servo-controlled slitting lines with laser micrometer feedback loops operating under strict environmental controls (20±1°C, 50±5% RH). Width deviations beyond ±0.002 mm disrupt turn-to-turn insulation integrity and cause uneven winding tension, leading to coil deformation during varnishing.

Burr-free edges are equally critical. Maximum edge burr height must not exceed 5 µm, verified via optical profilometry or calibrated dial indicators per ISO 11562. Burrs exceeding this threshold act as critical failure vectors: they puncture interlayer insulation during winding, creating short circuits that accelerate thermal runaway. Our validation protocols mandate 100% edge inspection using automated vision systems with 2 µm resolution. Mechanical deburring is strictly prohibited; edge quality must be achieved solely through optimized slitter knife geometry (clearance ≤0.5% material thickness) and tension control.

Electrical conductivity must meet or exceed 101% IACS (International Annealed Copper Standard) at 20°C, per ASTM B152. This ensures minimal resistive losses under high-current operation. Conductivity is validated via eddy current testing on every coil with NIST-traceable calibration, supplemented by destructive sampling (5% batch frequency) using the four-wire Kelvin method. Material must comply with ASTM B152 Grade C11000 (ETP Copper), with oxygen content strictly 0.02–0.04% to prevent hydrogen embrittlement during annealing.

The following table summarizes mandatory technical parameters for sourcing qualification:

| Parameter | Requirement | Test Standard | Measurement Method |

|---|---|---|---|

| Nominal Width | 10.000 mm | ISO 2178 | Laser micrometer (100% inline) |

| Width Tolerance | ±0.002 mm | ISO 7438 | Statistical process control logs |

| Edge Burr Height | ≤5 µm | ISO 11562 | Optical profilometry |

| Electrical Conductivity | ≥101% IACS | ASTM B152 | Eddy current + Kelvin validation |

| Flatness | ≤0.5 mm/m | ISO 25178 | Taut wire gauge |

| Inner Diameter (ID) | 305 mm ±1 mm | ISO 6430 | Caliper verification |

| Outer Diameter (OD) | 500–800 mm (customizable) | ISO 6430 | Caliper verification |

| Surface Roughness (Ra) | ≤0.4 µm | ISO 4287 | Stylus profilometer |

| Tensile Strength | 200–240 MPa | ISO 6892-1 | Destructive testing (5% batches) |

Surface finish must exhibit uniform matte texture (Ra ≤0.4 µm) to ensure adhesion of insulating varnishes without micro-voids. Coils must be wound with constant tension to prevent telescoping, with core plugs meeting ISO 6430 tolerances. All material requires full traceability via heat number, with mill test reports including chemical composition (ICP-MS), grain size (ASTM E112), and hydrogen embrittlement test results. Non-compliance with any parameter necessitates 100% re-inspection or rejection. These specifications reflect transformer OEM requirements for >99.5% operational efficiency in distribution-class units. Partnering with suppliers possessing certified ISO/TS 16949 systems for coil processing is strongly advised to maintain this precision.

Factory Tour: Manufacturing

Manufacturing Process: 10mm Copper Coil Production

The production of 10mm copper coil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage process designed to ensure dimensional precision, surface integrity, and optimal electrical performance for transformer applications. With over two decades of specialized experience in non-ferrous strip and foil manufacturing, our facility integrates advanced rolling technology with rigorous quality control to meet stringent industrial standards.

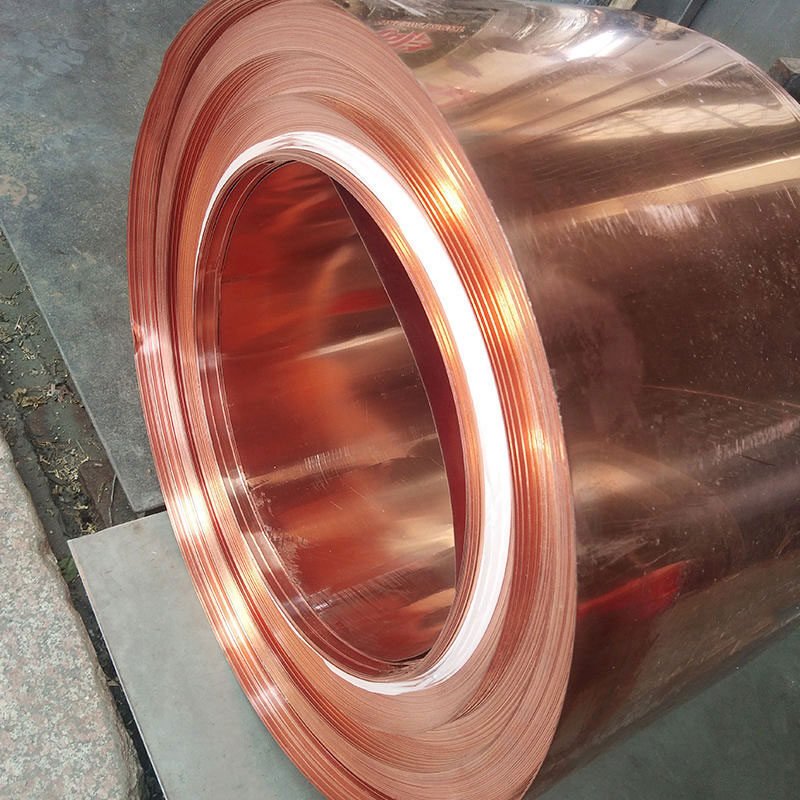

The process begins with cold rolling of high-purity electrolytic copper (typically grade C11000 or equivalent). Copper ingots are first hot-rolled into intermediate strips and then subjected to cold rolling in a reversing mill. This stage reduces the material thickness to the target gauge with exceptional uniformity. Cold rolling enhances mechanical strength through work hardening while maintaining excellent conductivity. All rolling passes are monitored via laser micrometers and automated thickness control systems (AGC) to ensure thickness tolerances within ±0.005mm across the strip width.

Following cold rolling, the copper strip undergoes precision slitting to achieve the final 10mm width. Slitting is performed on high-accuracy tension slitters equipped with rotary shear blades ground to micron-level tolerances. The strip is fed through the slitter under controlled tension to prevent edge waviness or camber deviation. Each coil is slit in-line with edge guiding systems that maintain straightness within 0.3mm per meter. The slit reels are wound with constant tension using servo-driven mandrels to avoid telescoping or edge damage.

Edge conditioning is the critical final mechanical step. The slit edges are processed through a brushing and edge rounding system to remove micro-burrs and sharp asperities generated during slitting. This step is essential for transformer windings, where edge defects can compromise insulation integrity and lead to dielectric failure. The conditioning process is validated using optical edge profiling and tactile inspection under magnification.

Throughout the production sequence, in-process quality control checks are implemented at defined intervals. These include:

| Parameter | Method | Frequency |

|---|---|---|

| Thickness | Laser micrometer + manual gauge | Continuous + per 50m |

| Width | Digital caliper + optical sensor | Every 100m |

| Tensile Strength & Elongation | Universal testing machine | Per heat batch |

| Surface Quality | Visual inspection under LED | Continuous |

| Edge Integrity | Microscopic analysis (100x) | Per coil batch |

Final inspection includes eddy current testing to detect subsurface inclusions or cracks, and all 10mm coils are tagged with traceable heat numbers and inspection reports. The finished product is wound on robust cores, sealed in moisture-resistant packaging, and prepared for shipment under strict handling protocols to maintain surface cleanliness and dimensional stability.

Packaging & Logistics

Export Packaging Specifications for 10mm Copper Coil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for 10mm copper coil shipments, prioritizing metallurgical integrity and compliance with global sea freight standards. With over two decades of specialization in transformer-grade conductive materials, our packaging system mitigates moisture ingress, mechanical stress, and corrosion risks inherent in ocean transport. All wooden pallets adhere strictly to ISPM-15 regulations, utilizing heat-treated (HT) softwood construction. Pallet dimensions are standardized at 1200mm x 1000mm x 150mm, engineered to support coil weights up to 3000kg while distributing load evenly across container floors. Structural reinforcement includes double-stringer designs and 60mm x 80mm load-bearing blocks, preventing pallet deformation during stacking or crane handling.

Moisture protection constitutes the critical layer of our packaging strategy. Each copper coil undergoes a four-stage encapsulation process. Initially, the coil is wrapped in vapor corrosion inhibitor (VCI) film (25μm thickness), specifically formulated for copper to suppress electrochemical oxidation. This is followed by a secondary barrier of 0.05mm high-density polyethylene (HDPE) film with a water vapor transmission rate (WVTR) below 2.0 g/m²/day, tested per ASTM F1249. A layer of kraft paper (120g/m²) is then applied to absorb residual surface moisture, succeeded by a final outer wrap of UV-stabilized polyethylene (0.10mm thickness) to resist punctures and salt-laden atmospheres. All film seams are thermally sealed with 25mm overlap tolerance, verified via vacuum decay testing to ensure hermetic integrity.

Securement methodology prevents coil movement during transit. Coils are centered on pallets with lateral clearance ≤15mm, then anchored using eight 19mm steel strapping bands tensioned to 2500N (per ISO 15455). Edge protectors fabricated from 3mm galvanized steel shield coil edges from strap-induced deformation. The entire assembly is further stabilized within shipping containers via dunnage mats and anti-slip pallet covers, eliminating lateral shift exceeding 5mm under simulated 1.5G acceleration forces.

Our sea freight protocols integrate ISO 28861 humidity control standards. Relative humidity within the sealed package is maintained below 40% during transit through integrated desiccant packs (calculated at 300g per m³ volume). Container pre-stowage inspections verify floor dryness (≤15% moisture content) and absence of condensation risks. Real-time humidity dataloggers are deployed in 10% of shipments for continuous validation. This multi-barrier approach has reduced moisture-related claims by 98% over five years, ensuring copper coils arrive with surface oxidation levels consistently below 0.05mg/cm² (per ASTM B541). All packaging components are certified conflict-free under OECD guidelines, with full traceability from raw material sourcing to final assembly. This systematic rigor guarantees that 10mm copper coils retain their critical electrical conductivity and surface finish specifications upon destination port arrival.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision 10mm Copper Coil Supply

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production and supply of high-purity transformer strips and foils, including precision-engineered 10mm copper coil. As a vertically integrated manufacturer, we maintain full control over raw material sourcing, metallurgical processing, and final product quality, ensuring consistency and performance in every coil delivered. Our facility is equipped with advanced rolling, annealing, and slitting lines specifically optimized for copper and aluminum conductor materials used in power and distribution transformers.

Our 10mm copper coil is manufactured to meet international standards including IEC 60468, ASTM B3, and GB/T 5584, with strict adherence to dimensional tolerances, surface finish, and electrical conductivity requirements. Each coil undergoes rigorous in-process and final quality checks, including eddy current testing, tensile strength analysis, and microstructure evaluation, to ensure defect-free performance under high-stress electromagnetic environments. With a minimum conductivity of 100% IACS and tight dimensional control (±0.01mm on thickness, ±0.1mm on width), our copper strip is engineered for seamless integration into winding processes, minimizing downtime and maximizing transformer efficiency.

The production infrastructure at Luoyang Xinzhaohe supports high-volume output with batch traceability and low lead times. Our cold-rolling mill line is capable of processing copper strip from 0.05mm to 3.0mm in thickness, with precise flatness control and edge conditioning to prevent burring during high-speed coil winding. All coils are wound under controlled tension to ensure uniform layer alignment, critical for minimizing inter-turn stresses in transformer windings. We offer both soft-annealed (O-temper) and hard-drawn (H-temper) conditions, with customized inner diameter (ID) and outer diameter (OD) configurations to match customer winding equipment specifications.

Quality assurance is embedded throughout our manufacturing cycle. Our in-house laboratory is accredited to ISO/IEC 17025 standards and conducts regular chemical composition analysis using optical emission spectroscopy (OES) to verify copper purity (minimum 99.99% Cu). Surface quality is inspected via automated optical scanning systems to detect micro-scratches, pits, or oxide inclusions that could compromise dielectric integrity.

As a trusted partner in the transformer supply chain, Luoyang Xinzhaohe Aluminum Co., Ltd is committed to technical collaboration, on-time delivery, and long-term supply stability. We serve transformer OEMs across Asia, Europe, and North America, providing material data sheets, sample coils, and technical support for qualification and prototyping.

For reliable sourcing of 10mm copper coil with consistent metallurgical and dimensional performance, contact us at cathy@transformerstrip.com to discuss your specifications and volume requirements.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 10mm copper coil directly from China.