Table of Contents

Market Insight: 10Mm Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for precision transformer strip and foil, including 10mm copper coil, is intensifying due to accelerating energy infrastructure modernization and renewable energy integration. Utilities and Original Equipment Manufacturers (OEMs) are deploying significantly more distribution and power transformers to support grid expansion, electrification initiatives, and the connection of solar and wind farms. This surge directly increases consumption of high-purity copper strip, particularly in the critical 8mm to 12mm width range where 10mm represents a standard dimension for low-voltage windings in distribution transformers. Market growth is further propelled by efficiency regulations like DOE 2016 and IEC 60076-20, mandating lower no-load and load losses, which necessitate superior conductor materials. Supply chain dynamics remain complex, with copper price volatility and geopolitical factors influencing procurement strategies, yet the fundamental requirement for reliable, high-performance material in critical power infrastructure remains non-negotiable.

The stringent performance demands of modern transformers make the quality of 10mm copper coil paramount. This component is not a generic commodity; it is a precision-engineered electrical conductor where minute deviations directly impact transformer efficiency, lifespan, and safety. Critical quality parameters include absolute minimum oxygen content (typically <10 ppm) to prevent hydrogen embrittlement and ensure long-term stability, electrical conductivity consistently exceeding 100% IACS (International Annealed Copper Standard) to minimize resistive losses, and exceptional dimensional control. For 10mm coil, width tolerance must be held within ±0.05mm, thickness tolerance within ±0.005mm for common gauges (0.20mm-0.50mm), and edge straightness must be flawless to enable high-speed, defect-free winding without creasing or misalignment. Surface integrity is equally vital; any micro-scratches, pits, or residual lubricants become initiation points for partial discharge under operational stress, leading to premature insulation degradation and potential catastrophic failure. Consistent mechanical properties, achieved through precise annealing control, are essential for uniform elongation and tensile strength, ensuring the coil withstands the rigors of the winding process without breakage or deformation.

Failure to meet these exacting quality standards carries severe consequences far exceeding the initial material cost differential. Substandard copper strip introduces significant efficiency penalties through increased I²R losses, directly violating regulatory mandates and increasing the transformer’s lifetime operational cost. More critically, dimensional inaccuracies or surface defects drastically elevate the risk of internal faults, short circuits, and fire hazards during service. Transformer failures result in costly unplanned outages, expensive replacements, potential safety liabilities, and reputational damage for OEMs and utilities. Luoyang Xinzhaohe Aluminum Co., Ltd leverages over 20 years of specialized metallurgical expertise in non-ferrous rolling to deliver 10mm copper coil meeting the most rigorous international specifications. Our integrated quality control, from cathode sourcing through precision cold rolling and final annealing, ensures the dimensional precision, ultra-high purity, surface perfection, and consistent mechanical properties demanded by the transformer industry. Investing in certified, high-integrity copper strip is fundamentally an investment in grid reliability, operational efficiency, and long-term asset security. The true cost of transformer conductor material is measured not at purchase, but over the decades of critical service the transformer provides.

Technical Specs: 10Mm Copper Coil

Technical Specifications for 10mm Copper Coil – Precision Slit Strip for Transformer Applications

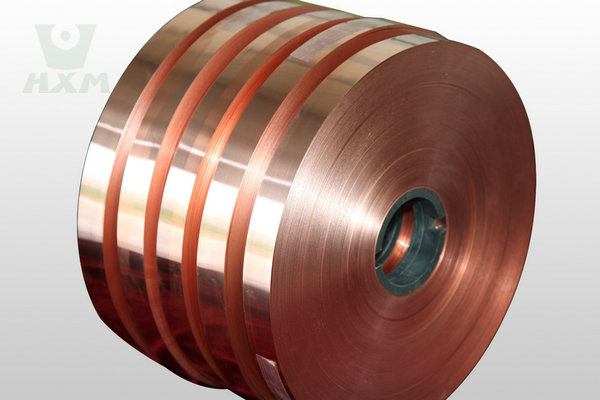

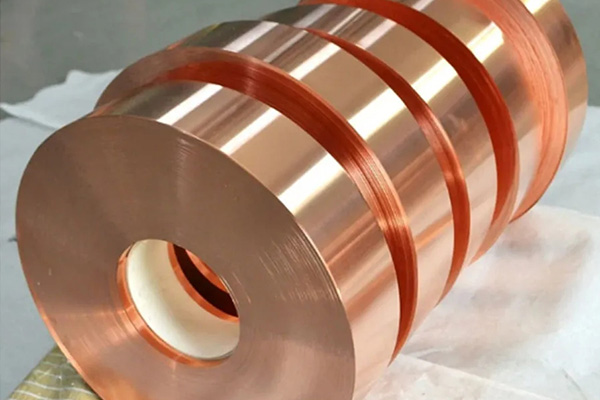

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision 10mm copper coil strips engineered for critical electrical applications, particularly in transformers, inductors, and high-efficiency power distribution systems. Our production process integrates advanced cold rolling, precision slitting, and edge conditioning technologies to ensure dimensional accuracy, superior surface integrity, and optimal electrical performance. Each coil is produced under strict quality control protocols compliant with GB/T 5584.1-2009 and IEC 60317 standards.

The 10mm width dimension is maintained through servo-guided slitting systems with a tolerance of ±0.002 mm, ensuring uniformity across the entire coil length. This level of precision is essential for minimizing winding irregularities and maximizing fill factor in transformer bobbins. Edge quality is rigorously controlled to achieve burr-free profiles, with maximum edge burr height held below 2µm. Burr reduction is accomplished via high-precision rotary shear slitting with optimized blade clearance and post-slit edge brushing, eliminating micro-tears and stress concentrations that could compromise dielectric integrity or cause interlayer shorting.

All 10mm copper coils are fabricated from high-purity, oxygen-free copper (C10100/C10200), delivering a minimum electrical conductivity of 100% IACS at 20°C. This ensures minimal resistive losses and high thermal efficiency in continuous-load operations. The material is fully annealed to achieve a soft temper (O-temper), providing excellent formability and consistent mechanical properties across batches. Tensile strength ranges between 200–240 MPa, with elongation exceeding 40%, supporting tight-radius winding without cracking or edge lifting.

Surface finish is maintained at Ra ≤ 0.4 µm, free from scratches, pits, or oxidation, to support uniform insulation coating adhesion in subsequent magnet wire processing. Coils are supplied in diameters ranging from 300 mm to 600 mm, with inner core sizes of 50.8 mm (2”) or 76.2 mm (3”), depending on customer requirements. Standard lengths per coil range from 350 to 500 meters, with continuous length options available upon request.

All materials undergo 100% eddy current testing and laser micrometer verification during slitting to ensure defect-free output. Traceability is maintained through batch-specific Mill Test Certificates (MTC) that include conductivity, dimensional data, and mechanical properties.

| Parameter | Specification |

|---|---|

| Product Type | Precision Slit Copper Strip |

| Nominal Width | 10 mm |

| Width Tolerance | ±0.002 mm |

| Thickness Range | 0.10 mm – 1.50 mm (customizable) |

| Thickness Tolerance | ±0.005 mm (for 0.5 mm base) |

| Edge Burr Height | ≤ 2 µm (burr-free to optical inspection) |

| Material Grade | C10100 / C10200 (Oxygen-Free Copper) |

| Temper | O-temper (Fully Annealed) |

| Electrical Conductivity | ≥ 100% IACS (at 20°C) |

| Surface Roughness (Ra) | ≤ 0.4 µm |

| Tensile Strength | 200–240 MPa |

| Elongation | ≥ 40% |

| Coil ID | 50.8 mm or 76.2 mm |

| Coil OD | Up to 600 mm |

| Standard Length | 350–500 meters |

| Packaging | Anti-corrosion paper, sealed plastic, wooden reel |

Factory Tour: Manufacturing

Manufacturing Process for 10mm Copper Coil: Precision Engineering for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages over two decades of metallurgical expertise in non-ferrous strip production to deliver high-integrity 10mm copper coil meeting stringent transformer industry demands. Our process rigorously controls material properties and dimensional precision from raw material to finished coil, ensuring optimal performance in demanding electromagnetic applications. The core sequence involves Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating integrated quality verification.

Cold rolling initiates the transformation of high-conductivity electrolytic tough pitch (ETP) copper castings into the precise strip form. Annealed copper slabs undergo multiple rolling passes within a tandem mill under precisely controlled reduction ratios and interstand tensions. This critical phase determines the final mechanical properties and surface integrity. Temperature and lubrication are meticulously managed to prevent work hardening inconsistencies and surface defects. In-process gauges continuously monitor strip thickness deviation, ensuring tolerance bands remain within ±0.005mm prior to slitting. Final annealing in a protective atmosphere furnace achieves the target temper (typically H00, H01, or H02 per ASTM B28-19) while eliminating residual stresses, optimizing electrical conductivity (>100% IACS) and ductility for subsequent winding.

Precision slitting follows, where the master coil is longitudinally divided into the exact 10.00mm nominal width required. This operation utilizes high-precision rotary shear slitters with computer-controlled knife positioning and tension management systems. Critical parameters include knife sharpness, optimal overlap and clearance settings specific to the copper alloy and temper, and precise web guiding. Any deviation induces camber, edge waviness, or width variation exceeding ±0.05mm, rendering the coil unsuitable for automated transformer winding lines. Real-time laser micrometers verify width consistency across the entire coil length during slitting.

Edge conditioning is paramount for transformer foil reliability. Slit edges inherently contain micro-burrs and work-hardened zones that can damage insulation during winding or create localized heating points in operation. Xinzhaohe employs a dedicated edge conditioning line utilizing precision brushing and/or controlled abrasive techniques. This process removes burrs, rounds the edge profile to a specified radius (typically 0.02-0.05mm), and eliminates surface contaminants. The result is a smooth, consistent edge free of nicks, tears, or residual stress concentrations, essential for preventing dielectric breakdown and ensuring long-term transformer integrity.

Quality control is embedded throughout the process, not merely a final check. Key verification points include:

| Process Stage | Critical QC Parameter | Measurement Method | Acceptance Criteria |

|---|---|---|---|

| Cold Rolling | Thickness Profile | Laser Micrometer Array | ±0.005mm across width |

| Surface Roughness (Ra) | Profilometer | ≤0.4 µm | |

| Precision Slitting | Width Tolerance | Laser Micrometer | 10.00 ±0.05mm |

| Camber | Straight Edge Gauge | ≤1.0mm per 1000mm length | |

| Edge Conditioning | Burr Presence | Optical Microscopy (200x) | None detectable |

| Edge Radius | Contour Measuring Instrument | 0.02-0.05mm | |

| Final Coil | Conductivity | Eddy Current Tester | ≥100% IACS (ASTM E1004) |

| Tensile Strength / Elongation | Universal Testing Machine | Per Specified Temper (ASTM E8) |

This integrated manufacturing and quality framework guarantees that every 10mm copper coil shipped by Xinzhaohe possesses the dimensional accuracy, edge perfection, and metallurgical consistency demanded by high-efficiency transformer manufacturers, directly contributing to enhanced product reliability and manufacturing yield downstream.

Packaging & Logistics

Export Packaging for 10mm Copper Coil – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global supply of transformer strip and foil—both aluminum and copper—we maintain rigorous standards in export packaging to ensure product integrity throughout international logistics, particularly during sea freight. The transportation of 10mm copper coil presents unique challenges due to its high density, susceptibility to oxidation, and sensitivity to mechanical deformation. Our packaging methodology is engineered to mitigate these risks through a multi-layered protective system centered on wooden pallets and moisture-proof barrier films.

Each 10mm copper coil is first wound under controlled tension and inspected for surface defects prior to packaging. The coil is then mounted onto a custom-fabricated wooden pallet, constructed from high-strength coniferous timber that meets ISPM-15 international phytosanitary standards for wood packaging material. These pallets are designed to support the full weight distribution of the coil—typically ranging from 1,500 to 3,000 kg—while maintaining structural rigidity during lifting, stacking, and long-duration marine transit. Reinforced base blocks and cross-bracing ensure resistance to dynamic loads encountered during vessel movement and port handling.

Immediately following palletization, the coil undergoes a full enclosure process using industrial-grade moisture-proof laminated film. This multi-ply film consists of an aluminum foil core sandwiched between layers of polyethylene, providing a vapor transmission rate of less than 0.1 g/m²·day at 38°C and 90% relative humidity. The film is hermetically sealed using heat-welded seams, creating a fully enclosed microenvironment that prevents exposure to salt-laden air, condensation, and humidity fluctuations inherent in maritime shipping routes. Additionally, desiccant packs are strategically placed within the sealed cavity to absorb any residual moisture and maintain internal dew points below -20°C.

To further enhance mechanical protection, edge protectors made from galvanized steel are affixed to the outer diameter of the coil, preventing impact damage during loading and unloading. The entire packaged unit is then strapped with steel or PET reinforcement bands, tensioned to ISO 22928 specifications, ensuring the coil remains axially fixed and vibration-resistant throughout transit.

This integrated packaging system has been validated across numerous export shipments to North America, Southeast Asia, and the Middle East, consistently delivering 10mm copper coils with zero incidence of corrosion, edge damage, or dimensional distortion. Our compliance with IEC 60404-10 and ISO 9001:2015 standards underscores our commitment to material preservation and supply chain reliability.

For technical inquiries regarding custom packaging configurations or extended sea voyage protocols, our engineering team provides client-specific validation reports, including humidity logging data and finite element analysis of pallet load stability.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Copper Coil Manufacturing for Critical Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 22 years of specialized metallurgical expertise to deliver mission-critical 10mm copper coil for transformer and electrical infrastructure applications. As an ISO 9001 and IATF 16949 certified manufacturer, we operate integrated production facilities in Henan Province, China, dedicated exclusively to high-purity aluminum and copper strip/foil. Our focus on transformer-grade materials ensures your 10mm copper coil meets the stringent demands of modern power systems, where dimensional stability, electrical conductivity, and surface integrity directly impact transformer efficiency and lifespan.

Technical Manufacturing Capabilities

Our 10mm copper coil production utilizes continuous casting-rolling technology followed by precision cold rolling on Sendzimir mills, achieving tolerances of ±0.02mm in thickness and ±0.10mm in width. We exclusively process oxygen-free electronic grade copper (OFHC, ASTM B152 Grade C11000) with minimum 101% IACS conductivity. Critical process controls include:

Laser micrometer-based real-time dimensional monitoring

Controlled atmosphere annealing to prevent oxide inclusion

Surface defect detection via high-resolution optical scanning (defect sensitivity ≤5µm)

Tensile strength and elongation validation per ASTM E8

The following specifications represent our standard production capability for 10mm copper coil:

| Parameter | Standard Specification | Testing Method |

|---|---|---|

| Thickness Tolerance | ±0.02 mm | ISO 11890-2 |

| Width Tolerance | ±0.10 mm | ASTM B946 |

| Conductivity | ≥101% IACS | ASTM B193 |

| Surface Roughness | Ra ≤0.45 µm | ISO 4287 |

| Coil ID/OD | 508mm / ≤1200mm | Customizable per OEM |

Quality Assurance and Supply Chain Reliability

Every 10mm copper coil undergoes 100% eddy current testing and batch-level mechanical/chemical validation in our in-house laboratory, accredited to CNAS (ISO/IEC 17025). Traceability is maintained from cathode to finished coil via blockchain-enabled lot tracking, ensuring full compliance with REACH and RoHS directives. Our supply chain infrastructure includes dedicated 5,000-ton bonded warehousing and JIT delivery coordination with major global logistics partners, reducing lead times by 30% versus industry averages. We maintain strategic raw material reserves covering 45 days of production, mitigating copper price volatility and supply disruptions for clients.

Engineering Collaboration for Optimal Performance

We partner with transformer OEMs during material specification phases to optimize coil performance parameters—such as temper (H00/H01/H02), edge conditioning, and interlayer insulation compatibility—for specific core designs. Our metallurgical team provides DFM support to resolve lamination burring, winding tension issues, or thermal expansion mismatches through material property adjustments.

Secure your transformer production with copper coil engineered for zero field failures. Contact Cathy Wang directly to discuss technical specifications, request mill test reports, or initiate a qualification batch:

cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd | Est. 2002 | IATF 16949:2016 Certified

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 10mm copper coil directly from China.