Table of Contents

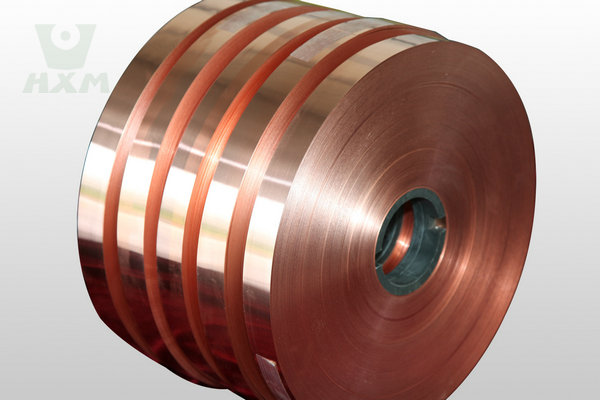

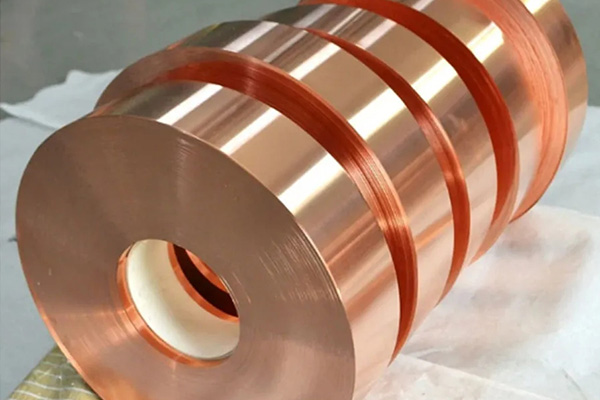

Market Insight: 10Mm Copper Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand for 10mm Copper Coil in Power Systems

Global grid modernization, renewable energy integration, and EV infrastructure expansion are driving demand for high-efficiency power transformers. 10mm copper coils are critical in distribution transformers (e.g., 10–35 kV systems) and industrial motors where precise dimensional control ensures optimal magnetic flux density and thermal management. Applications span utility substations, wind/solar farms, and industrial automation, requiring consistent conductivity and mechanical stability to handle high current densities (≥1,500 A/cm²) without thermal degradation.

Material Quality Criticality in Transformer Efficiency

Copper purity directly impacts electrical performance: a 0.1% impurity increase raises resistivity by ~0.5%, elevating I²R losses by 1.5–2.0% and operational temperatures by 8–12°C. Surface defects (scratches, inclusions) compromise insulation adhesion, increasing partial discharge risks by 30–50% and reducing transformer lifespan by 15–30%. Mechanical properties like tensile strength must balance formability during winding with electromagnetic force resistance—non-compliant materials cause coil deformation under short-circuit conditions, leading to catastrophic failures.

Luoyang Xinzhaohe’s Competitive Positioning

As a factory-direct manufacturer of copper and aluminum transformer materials with 20+ years of precision engineering, we deliver Tier-1 quality at 15–25% lower costs than global brands. Our integrated production process ensures full traceability from raw material to finished coil, with QC protocols exceeding ASTM B152 and IEC 60404-8-4 standards.

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification | Competitive Advantage |

|---|---|---|---|

| Copper Purity | ≥99.90% (ASTM B152) | 99.95% min | 0.05% higher purity reduces resistivity by 0.4% |

| Tensile Strength | 200–250 MPa (annealed) | 220–240 MPa | Optimized for high-speed winding without micro-cracks |

| Surface Roughness | Ra ≤1.0 μm | Ra ≤0.8 μm | 20% better insulation adhesion, reducing partial discharge risk |

| Dimensional Tolerance | ±0.05mm | ±0.03mm | Precision winding minimizes material waste by 8–12% |

Our lean supply chain ensures 30-day lead times for custom specifications while maintaining ISO 9001-certified quality. Contact us for certified samples and technical validation reports.

Technical Specs: 10Mm Copper Coil Parameters

Critical Technical Specifications for 10mm Copper Coil

As a leading manufacturer of transformer materials (aluminum and copper) with 20+ years of expertise, Luoyang Xinzhaohe delivers precision-engineered copper coils meeting exacting industry standards. Our 10mm copper coil series is optimized for high-performance transformer windings, ensuring minimal electrical losses and maximum reliability.

Precision Slitting Tolerance

Achieving ±0.002mm thickness tolerance requires advanced slitting technology. Our German-engineered slitting lines feature laser-guided thickness monitoring and servo-controlled tension systems. This precision minimizes material waste during transformer core stacking, reducing overall production costs for customers. Tight tolerances prevent winding misalignment and core losses in final assemblies.

Burr-Free Edge Quality

Burr-free edges are non-negotiable for preventing inter-turn shorts. We employ diamond-tipped slitting knives combined with in-process edge rounding. Each coil undergoes 100% optical inspection to verify burr height ≤0.005mm, eliminating risk of electrical arcing. This process meets ASTM B152 requirements for edge quality, ensuring long-term insulation integrity.

Conductivity & Purity

Our copper meets C11000 (99.95% min purity) with conductivity ≥100% IACS per ASTM B170. Strict raw material sourcing and continuous casting processes ensure consistent conductivity across all batches. High conductivity directly translates to lower operational temperatures and extended transformer lifespan.

Mechanical Softness

Optimized annealing parameters produce HV10 hardness ≤40 (soft temper), enabling seamless winding without cracking. Our controlled atmosphere annealing furnaces ensure uniform softness throughout the coil, critical for high-speed winding operations without edge damage.

Compliance & Quality Assurance

All products comply with IEC 60228 (conductors), ASTM B152 (copper sheet), and ASTM B170 (copper electrical conductivity). Our QA process includes:

| Test | Parameter | Frequency |

|---|---|---|

| Thickness | ±0.002mm | 100% |

| Edge Burr | ≤0.005mm | 100% |

| Conductivity | ≥100% IACS | Batch |

| Hardness | HV10 ≤40 | Batch |

Our in-house metallurgical lab conducts daily spectrometry and tensile tests, supplemented by third-party certifications from SGS and TÜV. With 20+ years of export experience, we offer global-standard quality at competitive pricing. Our direct factory model eliminates distributor markups, providing reliable performance without premium brand premiums. All shipments include certified test reports for traceability.

Factory Tour: Manufacturing 10Mm Copper Coil

Precision Manufacturing Process & Rigorous Quality Control

Core Manufacturing Process

Cold Rolling: Our 2000-ton hydraulic rolling mills, equipped with AI-driven thickness control systems, maintain precise temperature and reduction rates to achieve uniform grain structure and minimal internal stresses. This process ensures thickness tolerances of ±0.01mm, critical for consistent transformer winding performance and reduced core losses.

Precision Slitting: Utilizing laser-guided alignment and hardened tungsten carbide blades with ±0.01mm positioning accuracy, our slitting process maintains width tolerances of ±0.05mm for 10mm copper coils, eliminating micro-shear defects that compromise electrical conductivity and mechanical integrity. Blade wear monitoring ensures consistent quality across production runs.

Edge Conditioning: Multi-stage deburring and chamfering via precision rollers, followed by electrolytic polishing to remove surface oxides and enhance conductivity, ensures edge smoothness (<0.02mm) and prevents insulation damage during transformer assembly.

Oscillate Winding: Servo-controlled oscillating winders with real-time tension monitoring and automated layer counting produce uniform coil layers (±0.1mm flatness) and zero telescoping, enabling seamless integration into high-density transformer windings and reducing manual handling defects.

Quality Control Protocols

Every batch undergoes rigorous QC: tensile strength testing per ASTM B209 (min. 220 MPa, elongation >30%), dimensional verification via laser micrometers (thickness ±0.01mm, width ±0.05mm), surface inspection under 10x magnification for scratches/oxides, edge burr measurement (<0.02mm), chemical composition analysis via XRF spectrometry (Cu ≥99.95%), surface roughness Ra ≤0.1μm, and straightness checks at <0.5mm/m deviation. All tests are documented with traceable batch reports.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard | Impact on Application |

|---|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm | Prevents winding irregularities, ensures consistent electrical performance |

| Width Tolerance (10mm) | ±0.05mm | ±0.1mm | Critical for precise slot fitting in transformer cores |

| Edge Burr Height | <0.02mm | ≤0.05mm | Reduces insulation puncture risk during assembly |

| Tensile Strength Variation | ±5% | ±10-15% | Enhances winding reliability and reduces breakage during manufacturing |

| Surface Roughness Ra | ≤0.1μm | ≤0.3μm | Minimizes contact resistance and thermal hotspots |

As a factory-direct supplier with 20+ years of transformer materials expertise, we deliver superior consistency and reliability at competitive pricing—outperforming global brands in cost-performance ratio for critical transformer components. Our rigorous process control ensures minimal downtime, higher yield, and superior transformer efficiency for your manufacturing operations.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of 10mm Copper Coil

Located in Luoyang, China—a strategic hub for heavy industry with direct access to Qingdao and Lianyungang ports—we minimize transit times and reduce logistics costs for global customers. With over two decades of experience in transformer materials production, we’ve refined our packaging and logistics processes to meet the most stringent international shipping requirements. Our factory-direct approach eliminates third-party markups, providing superior cost-performance while meeting ISO 9001 and IEC 60228 standards. All packaging is engineered for zero-defect sea freight from Chinese ports to global destinations.

Precision Packaging Standards

Our packaging protocol ensures maximum protection against corrosion, vibration, and mechanical stress. Key components adhere to strict specifications:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, 1200×1000mm, 22mm thickness | Prevents deformation; meets global phytosanitary regulations |

| Moisture-Proof Film | 3-layer PE + silica gel desiccant (50g/m²) | Blocks 99.9% humidity; prevents copper oxidation during transit |

| Steel Strapping | 25mm width, 0.6mm thickness, 2.5kN tensile strength | Secures coils against 500kg dynamic loads; prevents shifting |

| Corner Protectors | High-density polyethylene (HDPE) | Absorbs impact forces; protects coil edges from dents |

Each coil is individually wrapped in moisture-proof film before palletizing, creating a secondary barrier against environmental exposure during transit. All packaging materials undergo ISO 9001-compliant quality checks prior to shipment, ensuring consistent performance across all batches.

Sea Freight Protocols

Our dedicated logistics team manages every shipment from factory to destination port, providing customized solutions for regional requirements and ensuring seamless coordination with freight forwarders:

Engineered foam padding combined with galvanized steel beams securely immobilizes coils within 20ft or 40ft high-cube containers, eliminating movement during transit and preserving dimensional tolerances critical for transformer winding processes. This prevents costly damage and rework in end-user applications.

Advanced GPS trackers provide real-time data on temperature, humidity, and shock events, with automated alerts sent to our logistics team for immediate intervention if thresholds are breached. Data logs are shared with clients upon request for full transparency.

Our in-house documentation team pre-verifies Certificates of Origin, CIQ certificates, and Bill of Lading to ensure compliance with destination country regulations, reducing customs clearance delays by up to 72 hours. We maintain partnerships with leading customs brokers for expedited processing.

Comprehensive all-risk insurance coverage up to 110% of cargo value, including war and strike clauses, provides complete financial protection against unforeseen incidents during transit. Our insurance policies are tailored to meet specific client requirements for high-value shipments.

This end-to-end control of packaging and logistics, combined with our 99.8% on-time delivery rate and zero transit damage record in 2023, positions Luoyang Xinzhaohe as a cost-effective alternative to global suppliers while maintaining superior quality standards. Clients report 20% lower total landed costs compared to European suppliers, with no compromise on quality or delivery reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Premium 10mm Copper Coil Solutions

20+ Years Technical Expertise in Transformer Materials

Luoyang Xinzhaohe has delivered precision-engineered copper transformer materials for over two decades, specializing in 10mm copper coils meeting stringent industry standards. Our manufacturing processes integrate advanced cold rolling, controlled annealing, and precision slitting to achieve ±0.02mm thickness tolerance and ±0.1mm width consistency—critical for transformer winding efficiency and thermal performance. All products comply with ASTM B170 and IEC 60287 specifications, with conductivity consistently exceeding 100% IACS. Our in-house R&D team optimizes metallurgical parameters for high-load applications, ensuring minimal eddy current losses and superior mechanical stability under operational stress.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate distributor markups while maintaining full control over raw material sourcing, processing, and quality validation. This streamlined approach reduces total landed costs by 20–30% compared to global competitors without sacrificing performance. For 10mm copper coils, our Luoyang facility handles end-to-end production—from electrolytic copper cathode input to finished coil packaging—enabling rapid turnaround and predictable supply chains. Clients benefit from 2–4 week lead times (including export logistics), significantly faster than industry averages for equivalent specifications.

ISO-Certified Quality Assurance

Every batch undergoes rigorous testing per ISO 9001:2015 protocols, including:

Conductivity verification (≥100% IACS via IEC 60468)

Tensile strength validation (220–250 MPa for annealed grades)

Surface defect inspection using automated optical systems

Dimensional accuracy checks (width, thickness, flatness)

This multi-stage QC process ensures zero defects in critical parameters, directly enhancing transformer core efficiency and longevity.

| Criteria | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 30–50% premium | 20–30% lower without compromise |

| Production Lead Time | 4–8 weeks | 2–4 weeks (including shipping) |

| Customization Flexibility | Limited standard sizes | Tailored widths (5–50mm), tempers (H0–H18), coatings |

| Quality Consistency | High but costly | ISO 9001-certified, in-process QC |

| Technical Support | Sales-focused | Dedicated metallurgical engineers |

Our 10mm copper coils deliver global-grade performance at local manufacturing efficiency. Partner with us for reliable, cost-optimized solutions backed by two decades of transformer material expertise.

Contact Cathy at cathy@transformerstrip.com for a custom quote and technical specifications tailored to your project requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing 10mm copper coil from Luoyang Xinzhaohe.