Table of Contents

Market Insight: 1060 Aluminum Foil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Industrial demand for 1060 aluminum foil within the transformer sector remains robust and strategically critical, driven by fundamental electrical engineering requirements and global energy infrastructure trends. The 1060 alloy, defined by its minimum 99.60% aluminum content per ASTM B209 and ISO 6361 standards, delivers the optimal balance of high electrical conductivity (approximately 55-59% IACS), excellent formability for tight winding radii, and cost-effectiveness compared to copper alternatives. This specific alloy composition is non-negotiable for critical transformer components like winding conductors and electrostatic shields, where predictable electromagnetic performance under sustained high-voltage stress is paramount. Global expansion of power transmission and distribution networks, coupled with the integration of renewable energy sources requiring grid-stabilizing transformers, sustains consistent demand. Stringent international efficiency regulations, such as IEC 60076 and DOE Level 2016 standards, further amplify the need for materials enabling minimal core and winding losses, directly favoring the consistent properties of high-purity 1060 foil.

Quality consistency in 1060 aluminum foil is not merely preferable; it is an absolute prerequisite for transformer reliability and longevity. Minute deviations from specification introduce significant operational risks. Impurities exceeding the strict 0.05% Fe and 0.03% Si limits inherent to the 1060 designation act as conductive pathways or nucleation sites, drastically increasing the probability of partial discharge inception under operational voltage stress. Partial discharges, even at micro-amp levels, progressively erode solid insulation (typically cellulose-based paper or pressboard) through chemical degradation and physical pitting. This initiates a cascading failure mechanism ultimately leading to catastrophic transformer failure, unplanned grid outages, and substantial financial losses far exceeding the initial foil cost. Surface defects such as scratches, rolls marks, or embedded particles become focal points for intense electric field concentration, similarly triggering premature discharge activity. Dimensional precision is equally critical; thickness tolerances tighter than ±0.002mm are essential to ensure uniform current distribution across parallel conductors and maintain precise winding geometry. Inconsistent thickness directly impacts magnetic flux distribution, increasing eddy current losses and localized heating, thereby reducing efficiency and accelerating insulation aging.

Luoyang Xinzhaohe Aluminum leverages over two decades of specialized production expertise to mitigate these risks. Our manufacturing process employs rigorous melt purification, precision cold rolling under controlled atmospheres, and comprehensive in-line quality monitoring adhering strictly to IEC 60204 and customer-specific technical requirements. Critical quality parameters are non-negotiable:

| Parameter | Critical Tolerance | Impact of Deviation |

|---|---|---|

| Thickness | ±0.002mm | Uneven current density, increased losses |

| Surface Roughness | Ra ≤ 0.3μm | Partial discharge initiation |

| Tensile Strength | 40-60 MPa | Winding integrity during processing |

| Elongation | ≥ 2% | Formability for tight radii |

| Fe+Si Content | ≤ 0.08% | Conductivity loss, discharge risk |

The transformer industry operates on a zero-failure paradigm for core materials. Sourcing 1060 aluminum foil demands a supplier with demonstrable metallurgical control and unwavering commitment to these exacting specifications. Compromised foil quality directly translates to compromised transformer integrity, making certified material consistency the cornerstone of reliable power infrastructure.

Technical Specs: 1060 Aluminum Foil

Technical Specifications for 1060 Aluminum Foil – Transformer Strip/Foil Application

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-purity 1060 aluminum foil engineered specifically for precision transformer strip and foil applications. With over 20 years of metallurgical expertise, our manufacturing process ensures strict adherence to dimensional tolerances, electrical performance, and edge quality required in high-reliability electrical systems. The 1060 alloy, composed of 99.60% minimum aluminum, offers excellent conductivity, formability, and thermal stability, making it ideal for use in transformer windings, busbars, and electromagnetic shielding components.

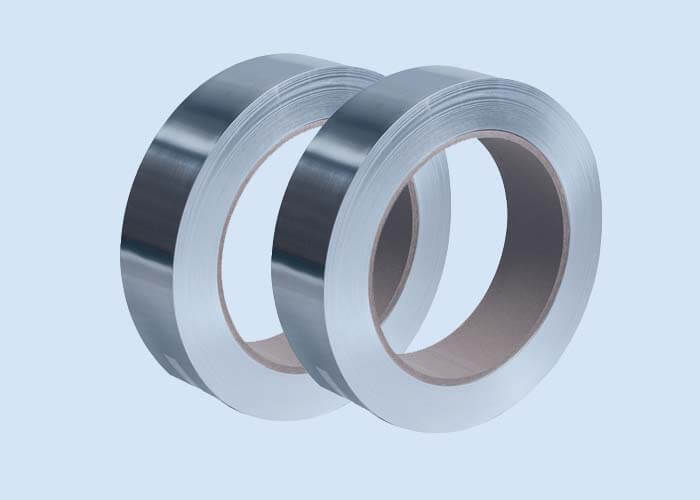

A critical aspect of our 1060 aluminum foil production is precision slitting, which is maintained within a tolerance of ±0.002 mm. This level of dimensional control is achieved through advanced tension leveling and laser-guided slitting technology, ensuring uniform strip width and consistent coil geometry. Such precision minimizes material waste during automated winding processes and enhances the interlayer alignment in transformer cores, directly contributing to improved electrical efficiency and reduced hot-spot formation.

Edge quality is equally paramount in transformer applications. Our foil undergoes a proprietary deburring process that eliminates micro-tears, jagged edges, and particulate generation during slitting. Burr-free edges prevent dielectric puncture in insulation layers and reduce the risk of short circuits in tightly wound coils. All coils are inspected using high-resolution edge profiling systems to verify compliance with internal edge smoothness standards, which are aligned with IEC 60404-8-7 for soft magnetic materials.

Electrical conductivity is a defining performance metric for transformer conductors. Our 1060 aluminum foil achieves a minimum conductivity of 59% IACS (International Annealed Copper Standard) at 20°C, as verified by four-point probe resistivity testing. This high conductivity ensures low ohmic losses and superior energy transfer efficiency in power distribution systems. The material is supplied in O (annealed) temper, which maximizes ductility and electrical performance while maintaining adequate tensile strength for handling and processing.

All production batches are subject to rigorous quality control, including chemical composition verification via optical emission spectroscopy (OES), mechanical testing per ASTM E8, and surface defect inspection under controlled lighting conditions. Traceability is maintained through batch-specific mill test certificates, ensuring full compliance with ISO 9001 and customer-specific requirements.

The following table outlines the key technical parameters for our 1060 aluminum foil product line:

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Designation | 1060 (Al 99.60% min) | GB/T 3190, ASTM B209 |

| Temper | O (Fully Annealed) | ASTM B66 |

| Thickness Range | 0.10 mm – 3.0 mm | Custom upon request |

| Width Tolerance (Slitting) | ±0.002 mm | ISO 2174 |

| Edge Condition | Burr-free, smooth, no micro-cracks | Visual & Microscopic |

| Electrical Conductivity | ≥59% IACS | ASTM E1004 |

| Tensile Strength | 65 – 95 MPa | ASTM E8 |

| Elongation (min) | 35% | ASTM E8 |

| Surface Finish | Clean, oxide-controlled, no oil residue | Visual, FTIR for residue |

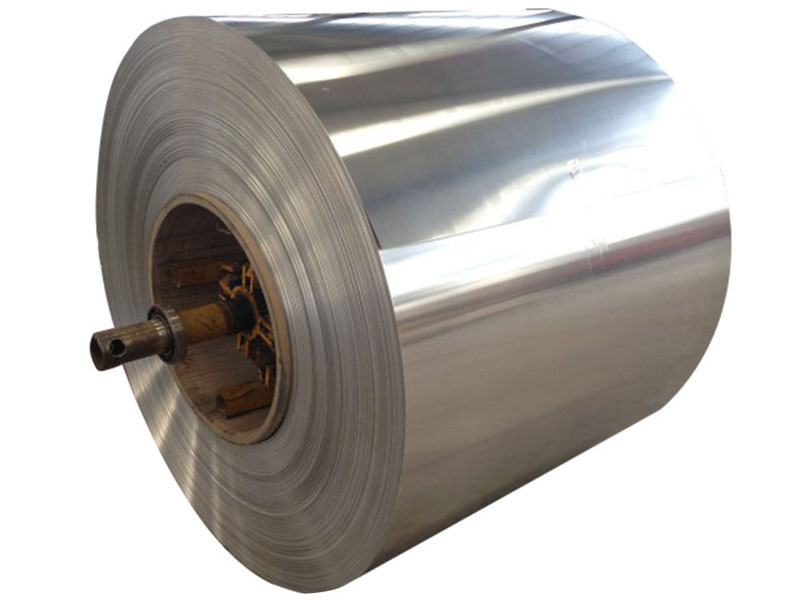

| Coil ID | 200 mm, 305 mm, 508 mm (customizable) | Customer Specification |

| Packaging | Waterproof, anti-corrosion, wooden core | Export-standard |

This specification sheet reflects Luoyang Xinzhaohe Aluminum’s commitment to delivering technically superior aluminum foil products tailored for the global transformer industry.

Factory Tour: Manufacturing

Manufacturing Process for 1060 Aluminum Transformer Foil

Luoyang Xinzhaohe Aluminum CO.,Ltd employs a rigorously controlled sequence for producing 1060 aluminum foil used in transformer windings, ensuring compliance with ASTM B209 and IEC 60137 standards. The process begins with cold rolling of high-purity (99.60% min) 1060 aluminum ingot cast strip. Initial hot-rolled coils undergo intermediate annealing before entering the 4-high or 6-high cold rolling mill. Precise roll gap calibration and tension control reduce thickness from 2.5–3.0 mm to the final gauge range of 0.08–0.30 mm. Critical parameters include maintaining rolling speed below 800 m/min to minimize thermal expansion, controlling interstand tension within ±1.5% of setpoint, and utilizing oil-air lubrication systems to achieve surface roughness (Ra) ≤ 0.4 μm. Thickness tolerance is held to ±0.0025 mm across the strip width, verified via continuous X-ray gauging with real-time feedback to the mill’s automatic gauge control (AGC) system.

Precision slitting follows cold rolling to achieve the exact width required for transformer coil winding. Foil coils are processed through servo-driven slitting lines equipped with tungsten carbide circular knives and tension leveling units. Width tolerances are maintained at ±0.10 mm for standard grades and ±0.05 mm for premium electrical applications. The slitting stage incorporates laser-based edge tracking to prevent camber deviation exceeding 1.0 mm per meter of travel. Simultaneously, an inline surface inspection system utilizing high-resolution line-scan cameras detects micro-defects such as pinholes, scratches, or inclusions larger than 50 μm, triggering automatic rejection of non-conforming sections.

Edge conditioning is a non-negotiable step for transformer foil to eliminate micro-burrs that could compromise dielectric integrity. The slit edges undergo controlled mechanical brushing with calibrated nylon-abrasive filaments at 1500–1800 RPM, followed by vacuum-assisted debris removal. This process reduces edge protrusions to ≤5 μm height, verified through profilometric analysis. Final tension leveling at 0.3–0.5% elongation ensures flatness deviation remains below 0.5 mm per 1000 mm strip length, critical for uniform winding tension during transformer assembly.

Quality control is embedded at every phase, not as discrete checkpoints but as an integrated process. The table below summarizes key QC parameters:

| Stage | Parameter | Measurement Method | Acceptance Standard |

|---|---|---|---|

| Cold Rolling | Thickness Profile | X-ray Gauge (Online) | ±0.0025 mm (0.08–0.30 mm) |

| Surface Roughness | Contact Profilometer | Ra ≤ 0.4 μm | |

| Precision Slitting | Width Tolerance | Laser Micrometer | ±0.05 mm (Premium Grade) |

| Edge Defects | Automated Optical Inspection | Zero burrs >5 μm | |

| Edge Conditioning | Burr Height | Scanning Electron Microscopy | ≤5 μm |

| Flatness | Tension Leveling Sensor Array | ≤0.5 mm/1000 mm |

All coils undergo final certification testing, including DC electrical resistivity (≤0.028264 Ω·mm²/m at 20°C), tensile strength (45–65 MPa), and elongation (≥1.0%). Hydrogen content is verified below 0.10 ml/100g via vacuum fusion analysis to prevent porosity. This end-to-end metallurgical control, refined over 20+ years of transformer foil production, guarantees the dimensional stability and surface integrity demanded by high-voltage transformer manufacturers.

Packaging & Logistics

Export Packaging for 1060 Aluminum Foil – Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global distribution of transformer-grade aluminum and copper strips, we recognize that proper export packaging is critical to maintaining product integrity during extended international transit. For our 1060 aluminum foil—widely utilized in transformer windings, capacitor electrodes, and other precision electrical applications—packaging is engineered to withstand the rigors of sea freight while preserving dimensional stability, surface quality, and metallurgical performance.

All 1060 aluminum foil coils are wound with strict tension control and surface protection protocols prior to packaging. The primary packaging layer consists of high-density, moisture-proof polyethylene film, sealed using heat-welded seams to form a hermetic barrier. This vapor-resistant encapsulation is essential in preventing oxidation, moisture ingress, and surface contamination—common risks during ocean transport through tropical and high-humidity climates. The film is further reinforced at coil edges with protective corner guards made from rigid plastic or fiberboard to mitigate mechanical damage during handling.

Coils are then mounted onto robust wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to meet international phytosanitary standards, ensuring unrestricted customs clearance across global markets. The structural integrity of the pallet supports the full weight of the coil—typically ranging from 500 kg to 2,500 kg—while distributing load evenly to prevent deformation during stacking. Each coil is securely fastened to the pallet using galvanized steel strapping, tensioned to industrial specifications, minimizing axial and radial movement throughout transit.

For additional protection, outer wrapping includes a secondary layer of weather-resistant plastic sheeting, sealed and taped to the pallet base. This multi-layered approach ensures resilience against condensation, salt spray, and temperature fluctuations inherent in maritime logistics. All packaging components are tested for compatibility with containerized shipping, including resistance to vibration, compression, and prolonged storage in non-climate-controlled environments.

Our packaging methodology is validated through internal quality audits and real-world shipping performance data collected across key export corridors, including Southeast Asia, the Middle East, and South America. This evidence-based approach enables us to guarantee that 1060 aluminum foil arrives at the destination facility in the same condition as it left our production line in Luoyang.

Customs documentation includes detailed packing lists specifying coil dimensions, weights, and protective measures taken, facilitating smooth port inspections and expedited clearance. For clients with specific logistics requirements—such as double moisture barriers, steel pallets, or vacuum sealing—we offer tailored packaging solutions without compromising on compliance or cost-efficiency.

In the transformer materials supply chain, where even minor surface defects can compromise electrical performance, our export packaging standards reflect our commitment to technical excellence and customer reliability.

Sourcing from Luoyang Xinzhaohe

Metallurgical Excellence and Manufacturing Capabilities

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of specialized expertise in transformer-grade aluminum foil production to deliver uncompromising material integrity for critical power applications. Our 1060 aluminum foil (Al 99.60% min per GB/T 3190) undergoes rigorous metallurgical process control from molten metal purification through continuous casting, ensuring consistent hydrogen content below 0.10 ml/100g and inclusion levels under 15 ppm. This foundational purity directly translates to superior electrical conductivity (≥55% IACS) and thermal stability in transformer windings. Our proprietary homogenization and cold-rolling protocols eliminate microstructural anisotropy, guaranteeing uniform tensile strength (50–70 MPa) and elongation (0.5–1.5%) across every coil.

Precision Engineering for Transformer Demands

We operate fully integrated production lines designed exclusively for high-tolerance foil manufacturing. Key technical capabilities include:

| Parameter | Standard Capability | Premium Option |

|---|---|---|

| Thickness Range | 0.006–0.5 mm | 0.006–0.2 mm |

| Thickness Tolerance | ±3% | ±1.5% (for ≤0.1 mm) |

| Width Tolerance | ±0.5 mm | ±0.2 mm |

| Surface Roughness (Ra) | ≤0.35 μm | ≤0.20 μm |

| Coil ID/OD | 76/508–1220 mm | Custom configurations |

Our 4.3-meter wide twin-roll caster enables defect-free large-width production, while 20-high precision rolling mills maintain micron-level thickness consistency. All foil undergoes 100%在线 eddy current testing for subsurface flaws and laser profilometry for surface topography validation. This results in foil with zero edge cracks, consistent lubricity for high-speed winding, and no interlayer adhesion issues during transformer assembly.

Supply Chain Resilience and Technical Partnership

With an annual capacity exceeding 30,000 metric tons and strategic inventory of 1060 alloy billets, we ensure uninterrupted supply for global transformer OEMs. Our supply chain integrates real-time metallurgical data tracking from casting to shipment, providing full traceability via batch-specific MTRs (Material Test Reports) including OES chemical analysis, mechanical property curves, and surface defect maps. We maintain JIT delivery performance at 99.2% on-time-in-full (OTIF) through dedicated logistics partnerships and regional warehousing in Shanghai and Rotterdam. All facilities are ISO 9001 and IATF 16949 certified, with in-house labs accredited to ISO/IEC 17025 for rapid non-conformance resolution.

Partner with Luoyang Xinzhaohe to eliminate material-related transformer failures through scientifically validated aluminum solutions. Request our technical dossier including ASTM B479 compliance documentation and case studies on reducing winding scrap rates by 22% for 500 kV transformers. Contact Cathy Zhang, Technical Sourcing Manager, at cathy@transformerstrip.com to schedule a metallurgical audit of your current foil supply chain. Specify your required thickness tolerance class and annual volume for a customized capability assessment within 48 hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 1060 aluminum foil directly from China.